Exploring the intricacies of marine propulsion systems is essential for boat enthusiasts and professionals alike. These systems play a critical role in ensuring smooth navigation and optimal performance on the water. A comprehensive understanding of the various components involved can significantly enhance maintenance efforts and prolong the lifespan of your vessel.

In this section, we will delve into the intricate layout and functionality of key elements that contribute to the overall efficiency of marine drives. By familiarizing yourself with each component’s role, you can better appreciate how they work together to create a seamless driving experience. Whether you are troubleshooting issues or planning upgrades, having a clear visual representation can aid in your understanding.

From gearing mechanisms to propulsion units, recognizing the significance of each part will empower you to make informed decisions regarding repairs and replacements. This guide aims to provide clarity and insight into the essential building blocks of your marine drive, ensuring you are well-equipped to tackle any challenges that may arise.

Understanding Volvo Penta 290 Outdrive

This section delves into the intricacies of a specific marine propulsion system, emphasizing its components and functionality. A comprehensive grasp of this mechanism is essential for effective maintenance and optimal performance. Whether you are a seasoned mariner or a newcomer to the field, familiarizing yourself with the elements involved can significantly enhance your boating experience.

Key Components

The effectiveness of a marine propulsion system relies on various integral parts that work harmoniously. Each component plays a crucial role in ensuring smooth operation, and understanding these elements can aid in troubleshooting and repairs.

| Component | Description |

|---|---|

| Gearbox | Facilitates speed and torque adjustments for the propeller. |

| Propeller | Translates engine power into thrust, propelling the vessel forward. |

| Stern Drive | Connects the engine to the propeller, allowing for directional control. |

| Trim Tab | Helps in maintaining stability and optimizing the vessel’s performance. |

Maintenance Tips

Regular upkeep of your marine propulsion unit is vital for longevity and efficiency. Simple practices, such as routine inspections and prompt repairs, can prevent major issues. Staying informed about the components and their functions will empower you to handle maintenance tasks effectively.

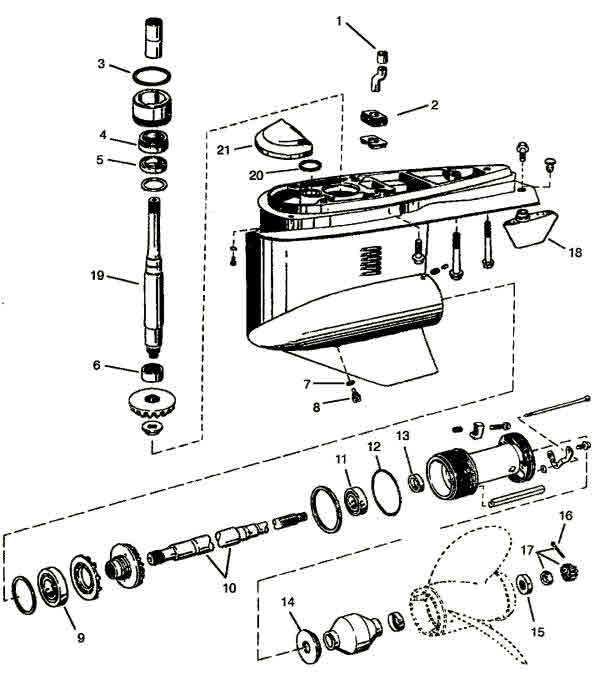

Key Components of the Outdrive System

The propulsion mechanism of a marine vessel relies on several critical elements working in harmony. Understanding these fundamental components can enhance performance and maintenance practices.

- Transom Assembly: This structure supports the drive unit and connects it to the hull.

- Gear Case: Houses the gears that transfer engine power to the propeller.

- Propeller: Converts rotational energy into thrust, propelling the boat forward.

- Stern Drive: Facilitates the angle adjustment for better maneuverability.

- Shift Mechanism: Enables gear shifting for forward, neutral, and reverse operations.

Familiarity with these key components ultimately leads to better maintenance and improved vessel performance.

Importance of Proper Maintenance

Enhanced Performance

Routine care helps to keep machinery operating at peak efficiency. When all components are functioning correctly, the overall performance of the vessel is improved. Regular inspections can identify minor issues before they escalate, allowing for timely interventions that preserve both speed and fuel efficiency.

Safety and Reliability

Neglecting maintenance can compromise the safety of the vessel and its occupants. Routine checks on critical systems help to detect potential hazards, ensuring that all equipment meets safety standards. This proactive approach fosters a reliable boating experience, giving peace of mind to both the operator and passengers.

Common Issues and Troubleshooting Tips

When operating marine propulsion systems, users may encounter various challenges that can hinder performance. Understanding these common issues and applying effective troubleshooting techniques can ensure smooth operation and prolong the life of the equipment.

Frequent Problems

Several recurring issues may arise during use. These can range from mechanical failures to performance inefficiencies. Recognizing symptoms early can aid in prompt resolution.

| Issue | Symptoms | Troubleshooting Tips |

|---|---|---|

| Overheating | Unusual temperature readings | Check coolant levels and inspect the water intake. |

| Vibration | Excessive shaking during operation | Inspect propeller for damage and ensure proper alignment. |

| Difficulty Shifting | Hard to engage gears | Examine cables and linkages for wear or obstruction. |

Maintenance Suggestions

Regular upkeep is vital for preventing issues. Implementing a routine maintenance schedule can greatly enhance reliability and performance.

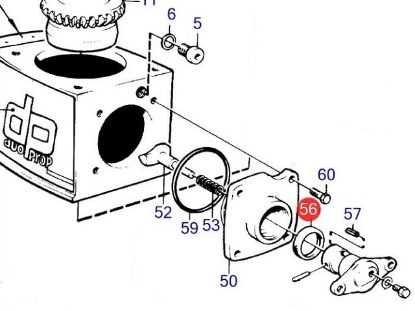

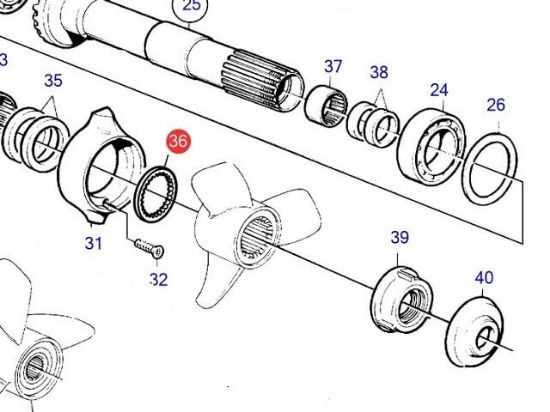

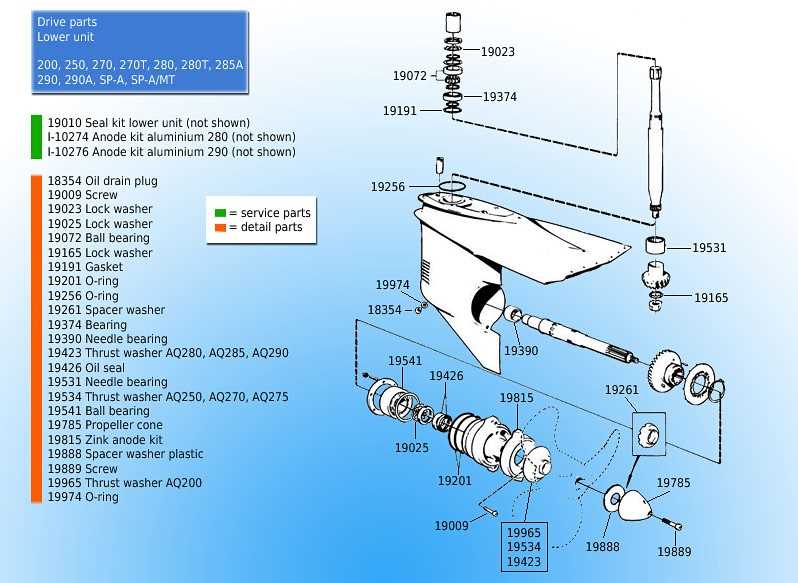

How to Read Parts Diagrams

Understanding technical illustrations is crucial for effective maintenance and repair of mechanical systems. These visual representations break down complex assemblies into manageable components, enabling users to identify and locate specific items quickly. Familiarity with this format can significantly enhance your ability to troubleshoot and perform necessary tasks efficiently.

To start, focus on the layout of the illustration. Components are often organized systematically, with each part assigned a unique reference number or letter. This labeling helps correlate the visual representation with a corresponding list or catalog, where detailed descriptions and specifications can be found.

Next, pay attention to the symbols used. Different shapes and lines can indicate various types of parts or connections, such as electrical or mechanical links. Understanding these symbols will facilitate quicker comprehension of the overall system and its functionality.

Finally, make note of any annotations or notes provided. These additional explanations can offer insights into assembly procedures, maintenance tips, or compatibility considerations. By leveraging this information, you can ensure that your work is both precise and effective.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and repair tasks. A well-equipped workspace not only enhances efficiency but also ensures safety and accuracy during the process.

- Wrenches: Adjustable and socket wrenches are vital for loosening and tightening components.

- Screwdrivers: A set of various sizes and types will help tackle different screws encountered.

- Pliers: These are essential for gripping and bending materials as needed.

- Torque Wrench: Ensures bolts are tightened to the manufacturer’s specifications, preventing damage.

- Multimeter: Useful for diagnosing electrical issues and ensuring proper function.

Investing in quality tools will lead to better repair outcomes and longevity of your equipment.

Step-by-Step Repair Guide

This section provides a comprehensive guide to repairing marine propulsion systems, ensuring optimal performance and longevity. By following the outlined steps, you can effectively diagnose and fix common issues, enhancing the reliability of your equipment.

Preparation

- Gather necessary tools: wrenches, screwdrivers, and a torque wrench.

- Obtain a repair manual specific to your model for reference.

- Ensure a clean and organized workspace to facilitate the repair process.

Repair Steps

- Begin by inspecting the unit for visible damage or wear.

- Remove the outer casing carefully to access internal components.

- Check the seals and gaskets for signs of leakage; replace if necessary.

- Examine the propeller and shaft for any signs of corrosion or damage.

- Reassemble the unit, ensuring all parts are securely fastened.

- Test the system for functionality before returning it to service.

Aftermarket vs. OEM Parts Comparison

When it comes to maintenance and repair, the choice between original components and alternatives can significantly impact performance and reliability. Understanding the differences between these options is crucial for making informed decisions that align with both budget and quality requirements.

Quality and Reliability

Original components are designed to meet specific standards set by manufacturers, ensuring optimal functionality. In contrast, alternatives may vary in quality, with some matching or even exceeding the original specifications, while others might fall short.

Cost Considerations

Typically, alternatives tend to be more budget-friendly, making them an attractive option for many. However, it’s essential to consider the long-term implications of using less expensive components, as they may require more frequent replacements.

| Aspect | OEM Components | Aftermarket Options |

|---|---|---|

| Quality | High, manufacturer-approved | Varies widely |

| Price | Generally higher | More affordable |

| Warranty | Often comes with warranty | Varies by manufacturer |

| Availability | Limited to specific dealers | Widely available |

Tips for Finding Replacement Parts

Locating suitable components for marine machinery can be a challenging yet rewarding task. Whether you’re maintaining an older model or upgrading to newer technology, understanding the best strategies for sourcing replacements is essential. Here are some effective methods to help streamline the process and ensure you find the right items for your needs.

Utilize Online Resources

The internet offers a wealth of information and tools for identifying components. Start by exploring dedicated websites that specialize in marine equipment. Many of these platforms provide extensive catalogs, user manuals, and even community forums where enthusiasts share insights and recommendations. Additionally, online retailers often feature detailed descriptions and compatibility filters that simplify your search.

Consult with Experts

Reaching out to professionals can significantly enhance your search for replacements. Mechanics and technicians who specialize in marine machinery possess invaluable knowledge and can guide you towards reputable suppliers. Don’t hesitate to ask for advice on specific models or alternatives that might be more readily available. Building a relationship with local experts can also lead to tips on maintenance and care, ensuring the longevity of your equipment.

Service Intervals and Recommendations

Regular maintenance is crucial for the longevity and optimal performance of marine propulsion systems. Adhering to specified service intervals not only enhances efficiency but also minimizes the risk of unexpected failures. It is important for operators to familiarize themselves with the recommended schedules for inspections, fluid changes, and component replacements to ensure smooth operation throughout the season.

Maintenance Schedule

Typically, it is advised to conduct a thorough inspection at least once per season. Key tasks include checking the condition of fluids, inspecting seals and gaskets, and ensuring that all moving parts are adequately lubricated. Additionally, replacing worn-out components and filters at regular intervals will help maintain peak performance. For heavy usage, more frequent checks are suggested to address wear and tear.

Best Practices

Implementing a systematic approach to maintenance can significantly extend the lifespan of the system. Keeping a detailed log of all service activities, using quality replacement parts, and following manufacturer guidelines are essential practices. Moreover, operators should pay attention to any unusual sounds or vibrations during operation, as these can indicate underlying issues that require immediate attention.

Benefits of Professional Servicing

Regular maintenance performed by qualified technicians ensures optimal performance and longevity of marine equipment. Engaging experts for servicing not only enhances safety but also minimizes the risk of unexpected failures during critical moments on the water. Professional care allows for thorough inspections and precise adjustments that DIY efforts might overlook.

Expertise and Experience

Trained professionals possess the necessary knowledge and hands-on experience to identify potential issues early. Their familiarity with specific systems and components enables them to provide tailored solutions, ensuring that every aspect of the machinery operates at its best. This expertise significantly reduces the likelihood of costly repairs down the line.

Quality Assurance

Utilizing high-quality tools and genuine components, professionals guarantee that all replacements and repairs meet rigorous industry standards. This commitment to quality not only improves performance but also instills confidence in the reliability of the equipment. By opting for professional servicing, owners can enjoy peace of mind knowing that their machinery is in capable hands.