Understanding the key elements of marine propulsion systems is essential for maintaining optimal performance and ensuring longevity. Each section of the engine system plays a vital role in delivering power, efficiency, and reliability on the water. By familiarizing oneself with the detailed layout, owners and technicians can more easily identify and replace key elements when necessary.

In this guide, we will delve into the essential components that contribute to the overall functionality of a well-designed marine engine. From the inner workings of the fuel delivery system to the cooling mechanisms, each part has its specific role. Knowing how these elements interconnect ensures that any potential issues are addressed promptly, avoiding more significant problems in the future.

Whether you are performing regular maintenance or need to troubleshoot an issue, understanding the configuration of your marine engine is critical. This comprehensive overview will help clarify the position and function of the most important sections, enabling more efficient diagnostics and repairs.

Understanding the Volvo Penta 5.0 GL Engine Components

The intricate design of this marine power unit is composed of numerous elements that work in harmony to deliver reliable performance. Each component plays a vital role in ensuring smooth operation, from the combustion process to the cooling and exhaust systems. To gain a better understanding of how these elements interact, it’s important to explore the key sections that make up the engine.

- Fuel System: Responsible for delivering the right amount of fuel for combustion, this part ensures optimal engine efficiency and power output.

- Cooling System: Critical for maintaining proper temperature levels, this system prevents overheating and ensures durability over time.

- Exhaust System: Designed to expel gases from the combustion process, it ensures the engine runs clean and efficiently.

- Ignition System: This mechanism initiates the combustion process by providing the necessary spark, contributing to reliable engine startup and operation.

- Lubrication System: Essential for reducing friction, it ensures all

Common Maintenance Parts for the 5.0 GL

Regular upkeep is essential to ensure the reliable performance of your engine. There are a few key components that often require attention during routine maintenance. By addressing these specific elements, you can keep the system running smoothly and avoid unexpected breakdowns.

Essential Filters and Fluids

- Oil filter – Helps maintain clean engine oil by removing impurities.

- Fuel filter – Ensures the fuel remains free of contaminants, preserving engine efficiency.

- Air filter – Protects the engine by preventing debris from entering the combustion chamber.

- Transmission fluid – Keeps the gearbox well-lubricated and functional over time.

Ignition and Electrical Components

Ensuring that the ignition system functions optimally is key to smooth engine performance. Various electrical parts require regular inspection and replacement.

- Spark plugs – Ignite the air-fuel mixture in the cylinders for combustion.

- Ignition wires – Deliver electricity from the ignition coil to the spark plugs.

- Batteries – Provide the necessary power to start the engine.

How to Identify Key Engine Sections

Understanding the major components of a marine engine is essential for effective maintenance and troubleshooting. Each section plays a vital role in the overall performance and longevity of the power system. Whether you are inspecting for routine upkeep or addressing specific issues, being able to recognize and differentiate between the primary areas is crucial.

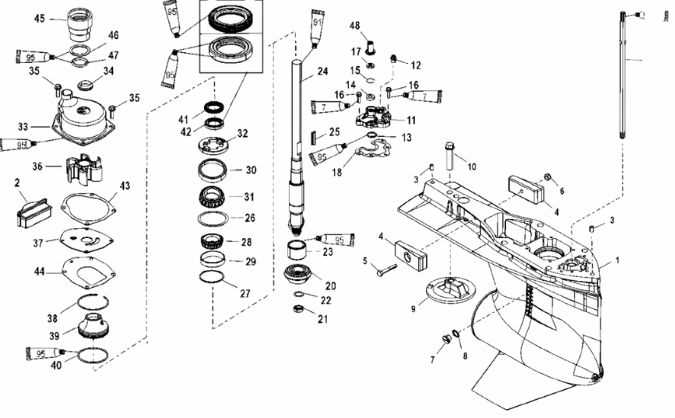

Start by familiarizing yourself with the top portion, which typically houses the systems responsible for combustion and energy conversion. Moving further, the central section involves critical operational mechanics, including the regulation of fluid and air flow. Finally, the lower segment generally contains the elements that support stability and connectivity to the vessel, ensuring smooth operation during use.

Essential Tools for Engine Repair

When working on engine maintenance or restoration, having the right set of tools is crucial for ensuring accuracy, safety, and efficiency. A well-equipped toolkit enables you to perform tasks such as disassembling components, replacing parts, and conducting thorough inspections without unnecessary delays. It’s important to have a variety of both hand and power tools to handle the complexity of different systems within the engine.

Common hand tools such as wrenches, sockets, and screwdrivers are indispensable for basic repairs, while precision instruments like torque wrenches help ensure that everything is tightened correctly to prevent future issues. Additionally, specialized tools like pullers and compression testers may be required for more specific engine-related tasks. Each tool serves its unique purpose, helping you tackle different types of mechanical challenges with confidence.

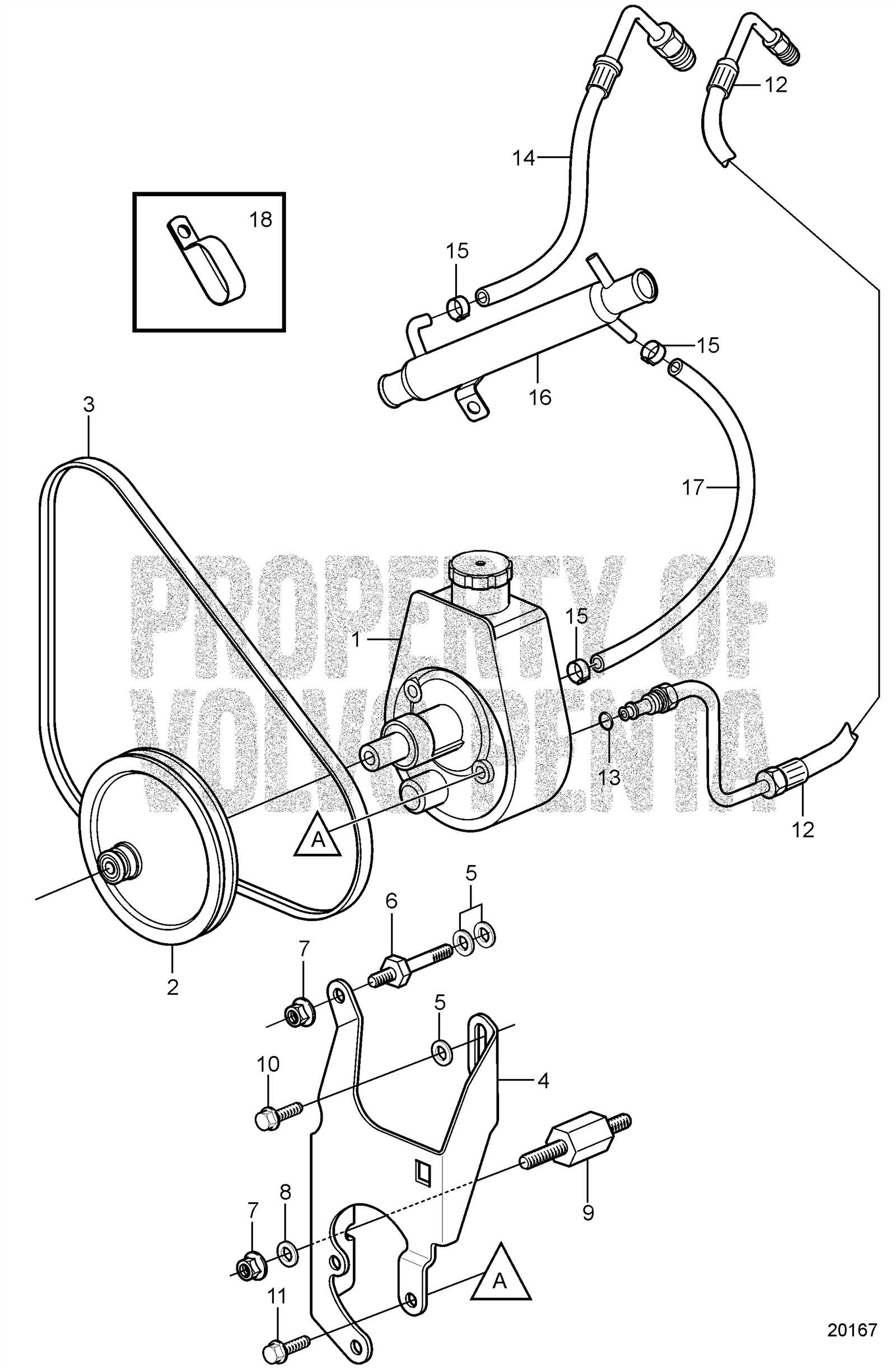

Cooling System Components Overview

The cooling system is designed to regulate engine temperature, ensuring optimal performance and preventing overheating. It operates by circulating coolant through various components, allowing heat to dissipate efficiently while maintaining a stable environment for the engine’s functionality.

Water Pump: This vital element is responsible for moving coolant throughout the system, ensuring a constant flow to prevent temperature spikes. Its efficient operation is crucial for maintaining the correct engine temperature.

Thermostat: The thermostat controls the flow of coolant based on the engine’s temperature. When the engine reaches a certain level of heat, it opens to allow coolant to circulate, preventing the engine from overheating.

Heat Exchanger: The heat exchanger allows heat to transfer between fluids without mixing them. It helps maintain a balanced temperature by cooling the engine’s fluids efficiently.

Hoses and Connectors: These are responsible for transferring coolant between various parts of the system. Their integrity is crucial to prevent leaks and maintain consistent flow.

Fuel System Parts Breakdown

The fuel delivery mechanism is crucial for the efficient operation of marine engines. It ensures that the necessary energy source reaches the combustion chamber effectively. Understanding the components involved in this system is essential for maintenance and troubleshooting.

Key Components

- Fuel Tank: Stores the fuel, providing a reservoir for the entire system.

- Fuel Pump: Responsible for transporting the fuel from the tank to the engine.

- Fuel Filter: Removes impurities and contaminants from the fuel before it reaches the engine.

- Fuel Lines: Hoses that carry the fuel from the tank to the engine.

- Injectors: Spray the fuel into the combustion chamber, ensuring proper atomization for combustion.

Maintenance Tips

- Regularly inspect and replace the fuel filter to prevent clogs.

- Check fuel lines for leaks or wear to maintain system integrity.

- Ensure the fuel pump is functioning correctly to avoid engine stalling.

- Monitor fuel quality to avoid issues with injector performance.

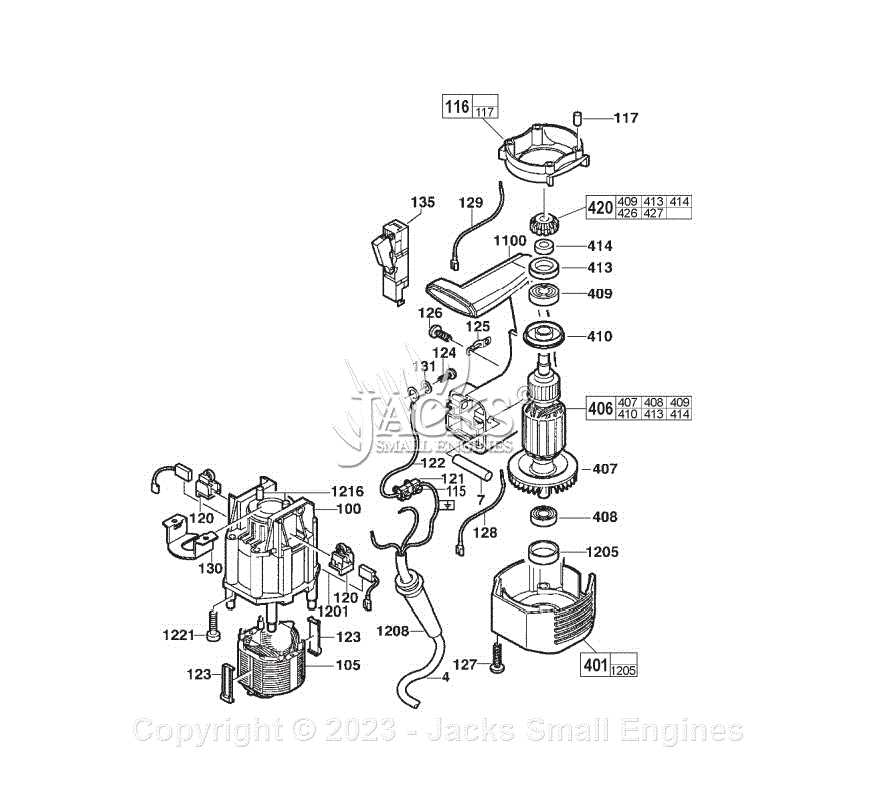

Electrical System Parts Guide

This section provides a comprehensive overview of the essential components that constitute the electrical network within marine engines. Understanding these elements is crucial for maintaining optimal performance and ensuring reliability during operation.

Power Source: The core of the electrical system, responsible for supplying energy to all electrical devices. It is vital to ensure that the power source is functioning correctly to avoid failures in other components.

Wiring Harness: A collection of wires and connectors that facilitate the distribution of electricity throughout the system. Proper management of the wiring harness is essential to prevent short circuits and maintain efficient connectivity.

Control Module: This unit acts as the brain of the electrical system, managing various functions such as ignition and fuel delivery. Regular checks and updates to the control module can enhance performance and reduce the risk of malfunctions.

Sensors: These devices monitor various parameters, providing critical data to the control module. Ensuring that sensors are clean and functioning accurately is essential for optimal engine performance.

Fuse Box: A protective enclosure housing fuses that safeguard the electrical system from overloads. Regular inspection of the fuse box can help identify potential issues before they escalate.

Starter Motor: This component initiates the engine’s operation by turning it over. A reliable starter motor is crucial for quick and efficient engine starts.

By familiarizing yourself with these key components, you can ensure the longevity and reliability of your electrical system, leading to improved performance and safety on the water.

Lubrication System and Related Components

The lubrication system plays a vital role in ensuring the smooth operation of an engine by minimizing friction between moving parts. This system is designed to deliver a continuous flow of oil, providing essential protection against wear and overheating. Understanding the components and functionality of this system is crucial for maintaining engine performance and longevity.

Key Components of the Lubrication System

At the heart of the lubrication system is the oil pump, responsible for circulating oil throughout the engine. This component draws oil from the sump and pushes it through various channels to reach critical areas. Filters are also essential, as they remove contaminants from the oil, ensuring that only clean fluid circulates. Additionally, oil passages and galleries are strategically located to optimize oil flow and coverage.

Importance of Regular Maintenance

Regular maintenance of the lubrication system is crucial for preventing potential failures. Changing the oil and filters at recommended intervals helps maintain the system’s efficiency and extends the life of the engine. Furthermore, periodic inspections can identify leaks or blockages in the oil passages, which can significantly affect performance. Keeping the lubrication system in good condition not only enhances engine reliability but also contributes to overall operational efficiency.

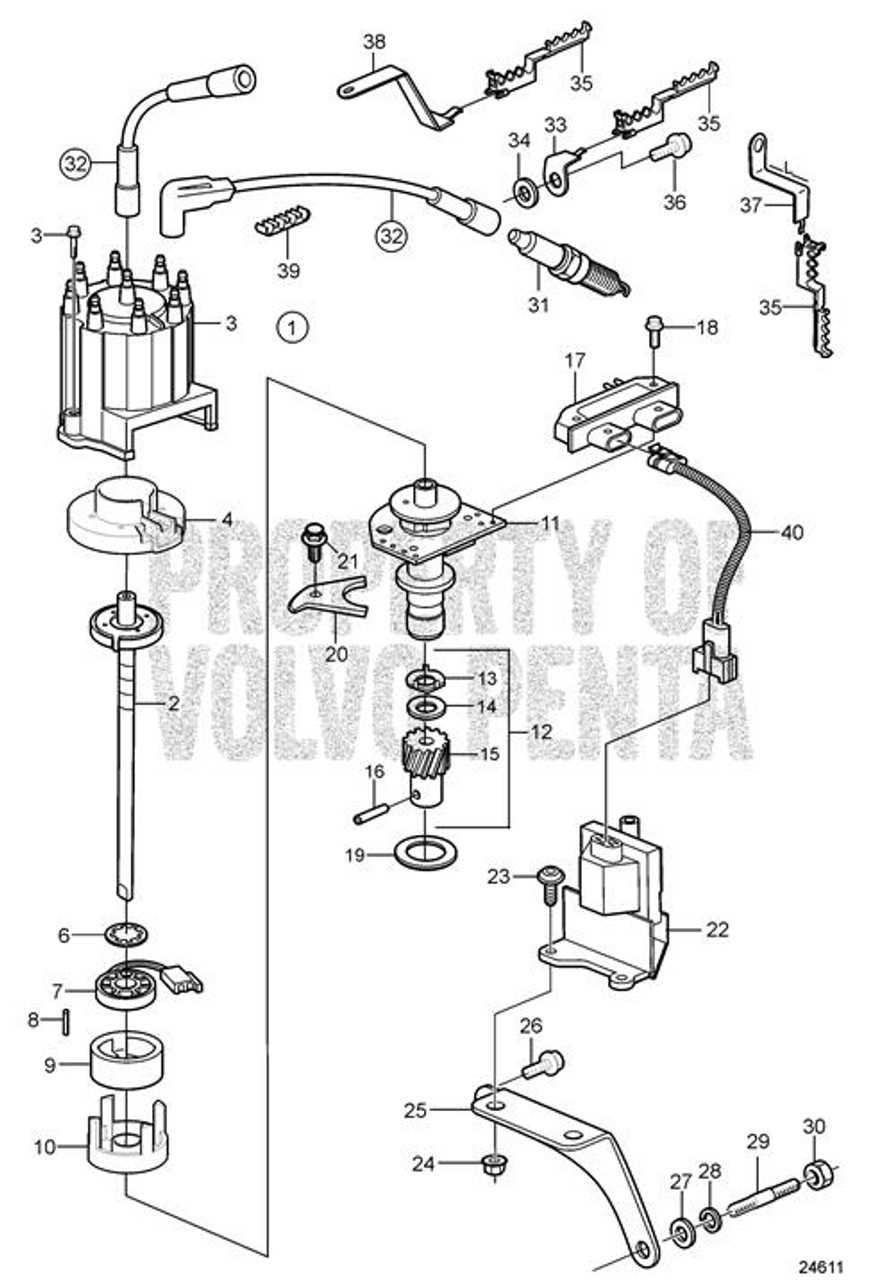

Examining the Ignition System of Volvo Penta

The ignition mechanism in marine engines plays a crucial role in ensuring reliable performance and smooth operation. This section delves into the key components and functions of the ignition setup, highlighting its significance in maintaining optimal engine efficiency and preventing potential issues.

Key Components

- Ignition Coil: This device transforms the battery’s low voltage into a high voltage needed to create a spark at the spark plug.

- Distributor: It directs the high-voltage electricity from the ignition coil to the correct cylinder at the right time.

- Spark Plugs: These components ignite the air-fuel mixture within the engine’s combustion chamber, initiating the power cycle.

- Ignition Module: This electronic component controls the timing and delivery of the ignition spark, optimizing performance.

Functionality and Importance

The ignition system functions by coordinating the timing of sparks to each cylinder, ensuring that the combustion process is efficient. Proper synchronization of these elements is essential for:

- Maximizing fuel efficiency.

- Minimizing emissions and environmental impact.

- Enhancing engine responsiveness and performance.

Regular maintenance and timely inspection of the ignition components can prevent failures, prolonging the engine’s lifespan and improving overall reliability.

Key Sensors and Connectors in the 5.0 GL

This section explores essential monitoring devices and electrical interfaces crucial for optimal performance and functionality in marine engines. Understanding these components is vital for maintenance and troubleshooting, ensuring the system operates smoothly and efficiently.

Overview of Sensors

Monitoring devices play a significant role in providing real-time data about engine conditions. They help in regulating various parameters to ensure safe operation and prevent potential issues.

Sensor Type Function Temperature Sensor Monitors the coolant temperature to prevent overheating. Pressure Sensor Tracks oil pressure levels for optimal lubrication. Throttle Position Sensor Regulates engine power by measuring throttle input. Connectors and Their Importance

Electrical interfaces are critical for connecting various components, enabling seamless communication and power distribution throughout the engine system. Reliable connectors ensure that signals are transmitted accurately, supporting the overall functionality of the engine.

Connector Type Application Multifunction Connector Links multiple sensors to the engine control unit. Waterproof Connector Ensures secure connections in wet environments. Power Connector Distributes electrical power to various components. Exhaust System Components and Function

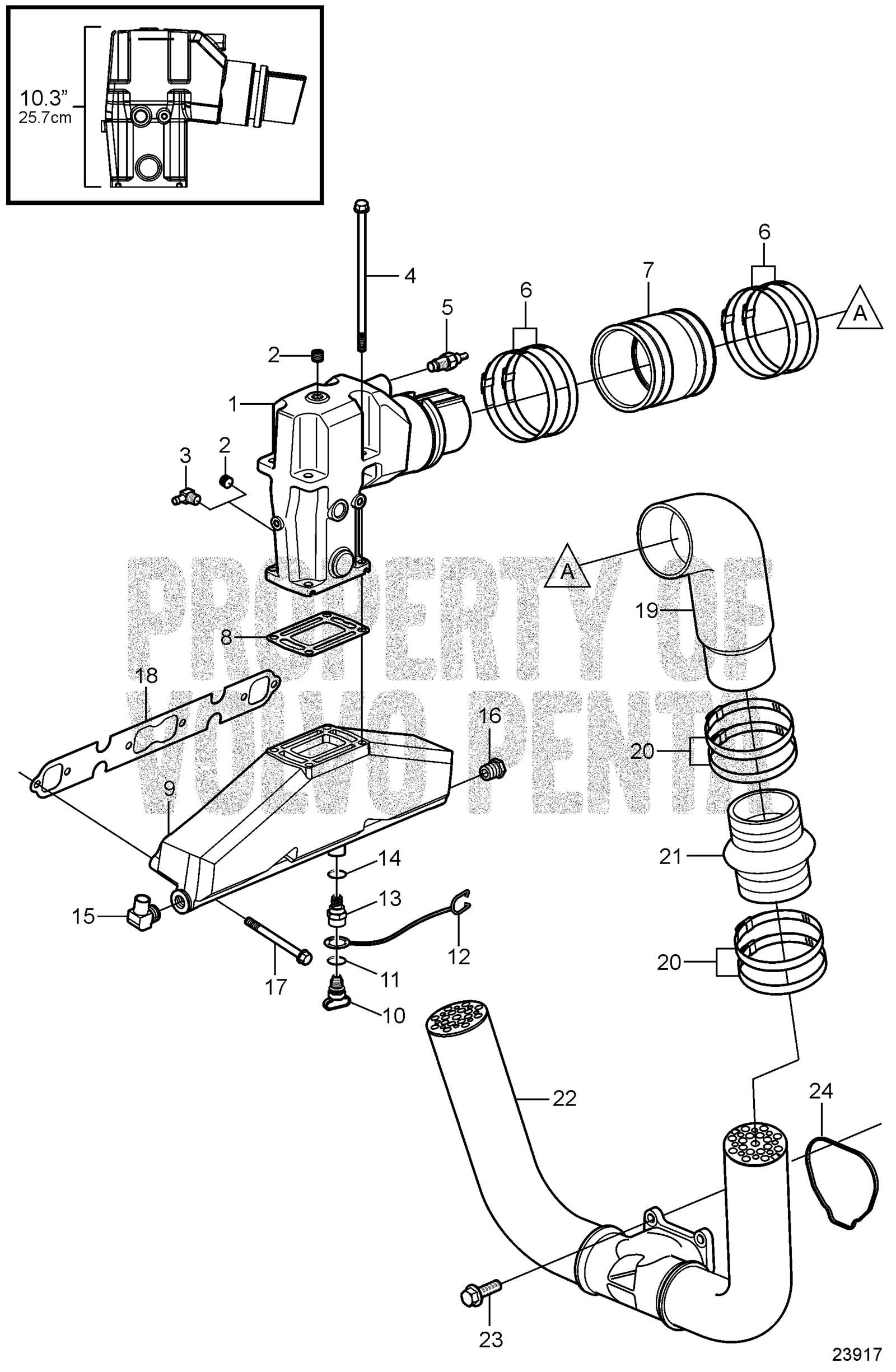

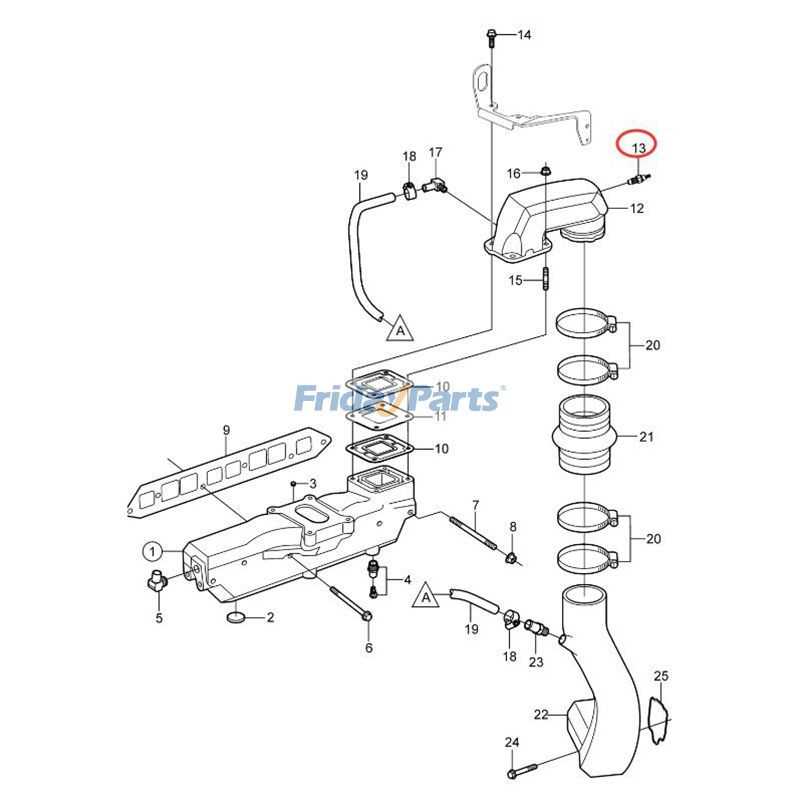

The exhaust system is a crucial element in any marine engine, designed to manage and expel combustion gases safely and efficiently. Its various components work in harmony to ensure optimal performance and reduce harmful emissions. Understanding these parts and their functions is essential for maintaining engine health and longevity.

Main Components

- Exhaust Manifold: This part collects gases from the engine cylinders and directs them to the exhaust pipes. It is typically made of cast iron or stainless steel for durability.

- Exhaust Risers: These components elevate the exhaust gases from the engine to the outlet, preventing water from entering the engine.

- Silencer: Also known as a muffler, it reduces noise produced by the exhaust gases while maintaining optimal flow.

- Exhaust Pipes: These pipes transport gases from the risers to the discharge outlet, often incorporating bends and joints to fit the vessel’s layout.

- Water Injection System: This feature cools the exhaust gases before they exit, helping to prevent damage and improving efficiency.

Functionality Overview

Each component serves a specific purpose within the exhaust system:

- The exhaust manifold gathers gases from multiple cylinders.

- Risers elevate these gases, ensuring they do not mix with seawater.

- The silencer minimizes noise, creating a quieter boating experience.

- Pipes facilitate the safe exit of gases, preventing back pressure that could harm engine performance.

- The water injection system cools the exhaust, promoting optimal operating temperatures.

In summary, the exhaust system plays a vital role in the effective operation of marine engines, and understanding its components can help in maintaining and troubleshooting engine issues.

Troubleshooting Common Issues with Engine Parts

Addressing challenges with engine components is crucial for maintaining optimal performance and longevity. Many issues can arise due to wear and tear, improper installation, or environmental factors. Understanding these common problems can help in diagnosing and rectifying them efficiently.

Common Symptoms and Their Causes

- Overheating:

- Insufficient coolant levels

- Faulty thermostat

- Clogged radiator

- Unusual Noises:

- Worn bearings

- Loose components

- Exhaust leaks

- Poor Performance:

- Clogged fuel filters

- Defective spark plugs

- Vacuum leaks

Steps to Diagnose and Fix Issues

- Check fluid levels and quality.

- Inspect for visible leaks around seals and gaskets.

- Listen for unusual sounds during operation.

- Perform a visual inspection of belts and hoses for signs of wear.

- Utilize diagnostic tools to check error codes if available.

By following these guidelines, one can effectively troubleshoot and resolve common challenges associated with engine components, ensuring reliable functionality and extending the life of the machinery.