The intricate mechanics of marine propulsion systems are crucial for the optimal performance of watercraft. Navigating through the components that facilitate these systems can significantly enhance your comprehension and maintenance skills. This section delves into the various elements involved, offering a detailed exploration that serves both enthusiasts and professionals alike.

Each component plays a vital role in ensuring smooth operation and durability on the water. By dissecting these assemblies, one can gain insights into their functions and interrelations, which is essential for effective troubleshooting and repair. Understanding the layout and specifications of these mechanisms empowers boat owners to make informed decisions regarding their vessels.

Moreover, familiarizing oneself with these structures can lead to improved performance and longevity of the equipment. This knowledge not only enhances user experience but also fosters a deeper appreciation for the engineering marvels that drive maritime exploration and leisure. Let’s embark on this journey to uncover the essentials of propulsion systems and their intricate configurations.

Understanding Volvo Penta DPS Outdrive

This section explores the intricacies of marine propulsion systems, highlighting their components and functionality. A well-designed drive unit is crucial for optimal performance and efficiency on the water.

Key Components

At the core of this system are several essential elements that work in unison. Each component plays a significant role in ensuring smooth operation and durability. Understanding these parts helps in maintenance and troubleshooting.

Benefits of Efficient Design

Efficient propulsion mechanisms enhance vessel maneuverability and fuel consumption. Investing in quality systems ultimately leads to better performance and longevity, allowing boaters to enjoy their time on the water without concern.

Key Components of DPS System

The dynamic propulsion system incorporates several essential elements that work in harmony to ensure optimal performance and control. Understanding these components is vital for maintenance and efficiency.

- Drive Unit: The main mechanism responsible for propulsion, translating engine power into motion.

- Transom Assembly: Connects the drive unit to the hull, providing structural integrity and alignment.

- Control System: Facilitates user input for steering and throttle, enhancing maneuverability.

- Propellers: Critical for generating thrust, their design affects speed and handling.

- Cooling System: Maintains optimal operating temperatures, preventing overheating during use.

Each component plays a crucial role, and regular inspection can prevent costly repairs and enhance the overall experience.

Importance of Outdrive Maintenance

Regular upkeep of marine propulsion systems is essential for optimal performance and longevity. Proper care ensures smooth operation and prevents costly repairs, enhancing the overall experience on the water. Neglecting maintenance can lead to reduced efficiency, safety issues, and eventual breakdowns, underscoring the need for diligence in care practices.

Key reasons to prioritize maintenance include:

| Reason | Description |

|---|---|

| Performance | Well-maintained systems provide better fuel efficiency and handling, improving the overall boating experience. |

| Safety | Regular checks can identify potential issues that may compromise safety, reducing the risk of accidents. |

| Longevity | Consistent care extends the lifespan of components, delaying the need for replacements. |

| Cost-Effectiveness | Preventive maintenance is often less expensive than extensive repairs caused by neglect. |

Investing time in routine inspections and maintenance can yield significant benefits, ensuring reliability and enhancing enjoyment on the water. By staying proactive, boat owners can safeguard their investments and enjoy peace of mind during their voyages.

Common Issues with DPS Outdrives

When operating marine propulsion systems, users may encounter a range of challenges that can impact performance and reliability. Understanding these common concerns is essential for ensuring smooth operation and prolonging the lifespan of the equipment. This section highlights typical problems and their potential solutions, providing valuable insights for maintenance and troubleshooting.

Hydraulic System Failures

One of the most frequent issues relates to the hydraulic system, which is crucial for the effective functioning of the drive. Leaks can develop due to wear and tear, resulting in insufficient pressure. Regular inspections and timely replacement of seals and hoses can mitigate these risks, ensuring optimal performance.

Corrosion and Wear

Another prevalent challenge is corrosion, especially in saltwater environments. Protective coatings may degrade over time, exposing metal components to damaging elements. Regular cleaning and maintenance, along with the application of anti-corrosive treatments, are vital to combat this issue and enhance the longevity of the unit.

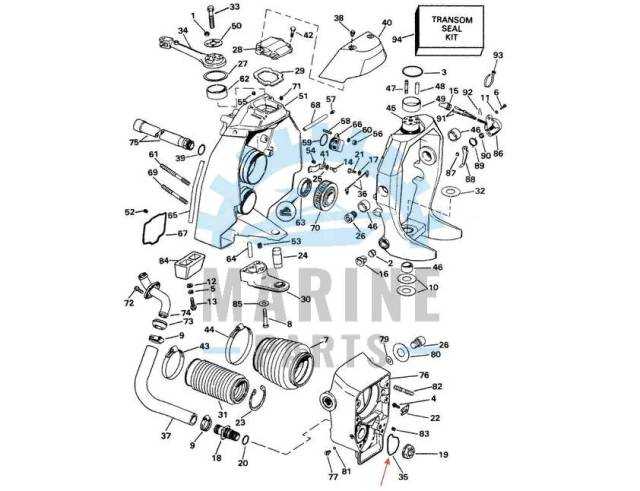

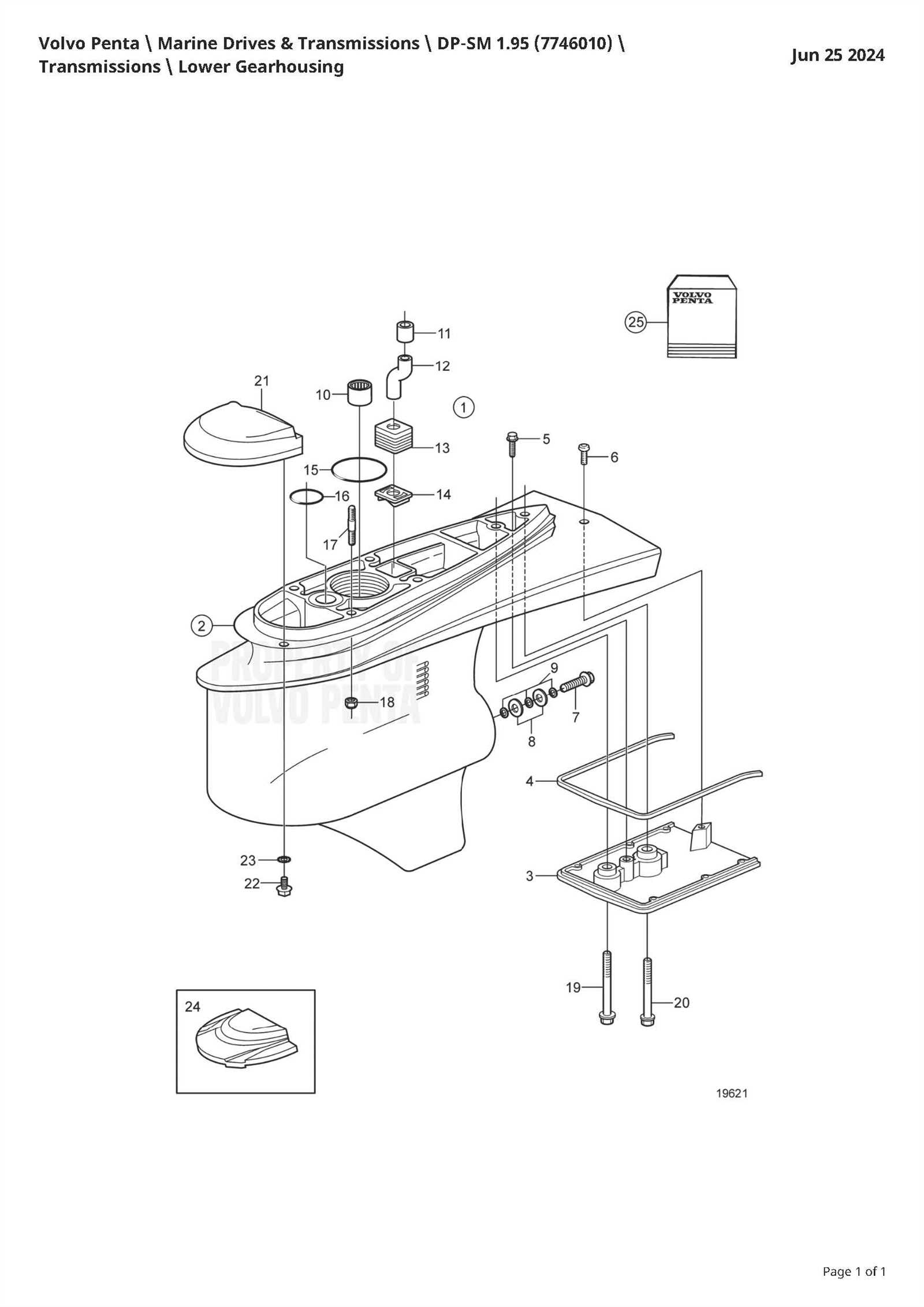

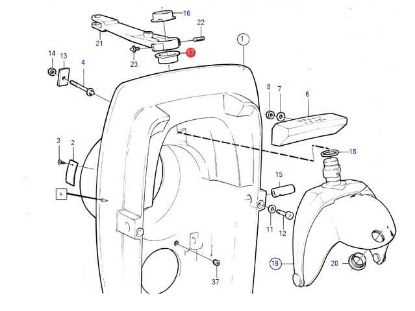

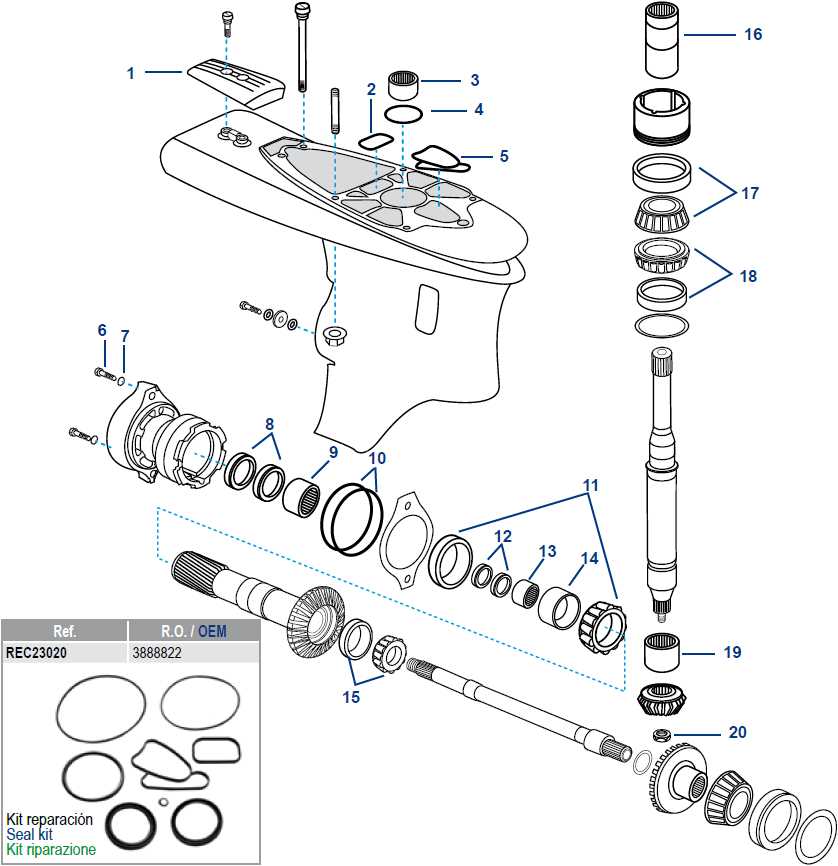

Identifying Parts in the Diagram

Understanding the components of a mechanical system is essential for effective maintenance and repair. A well-structured illustration can greatly aid in recognizing each element’s function and interrelation within the assembly. By familiarizing yourself with the visual representation, you can enhance your troubleshooting skills and optimize performance.

Key Components to Recognize

To effectively navigate the illustration, focus on these fundamental elements:

- Drive Unit: The primary component responsible for propulsion.

- Trim Tabs: Adjusts the angle of the unit for improved handling.

- Gear Housing: Encases the gears and provides protection.

- Shaft: Connects the drive unit to the propulsion mechanism.

- Seal and Gasket: Prevents leaks and maintains integrity.

Understanding Functionality

Each of these components plays a crucial role in the overall operation:

- Ensuring the drive unit operates efficiently.

- Facilitating smooth maneuverability through trim adjustments.

- Protecting sensitive gear mechanisms from environmental damage.

- Transmitting power effectively between units.

- Maintaining a sealed environment to prevent fluid loss.

By mastering the identification of these components, you will be better equipped to carry out necessary repairs and maintenance, ultimately leading to enhanced system reliability.

Tools Needed for Outdrive Repair

When undertaking the task of repairing a marine propulsion system, having the right equipment is crucial for efficiency and effectiveness. This section outlines essential implements that facilitate the process, ensuring you can address issues effectively and with confidence.

Essential Hand Tools

Basic hand tools are the foundation of any repair endeavor. A sturdy set of wrenches, pliers, and screwdrivers is imperative. Additionally, a torque wrench is necessary to ensure all connections are tightened to the proper specifications, preventing future complications.

Specialized Equipment

Incorporating specialized devices can significantly enhance your repair capabilities. A lift or hoist will assist in maneuvering heavy components safely. Furthermore, a multimeter can help diagnose electrical issues, while a caliper allows for precise measurements of critical parts.

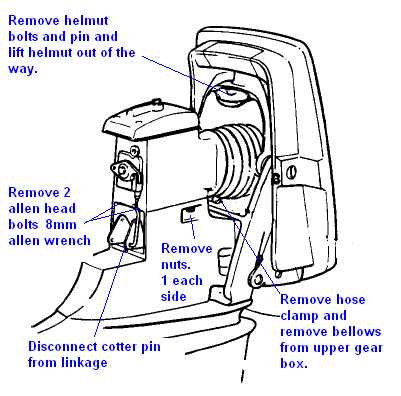

Step-by-Step Repair Process

This section outlines the essential procedures for effectively restoring a marine propulsion system. Each stage is crucial for ensuring optimal functionality and longevity of the components involved.

| Step | Description |

|---|---|

| 1 | Gather necessary tools and safety equipment to ensure a secure working environment. |

| 2 | Carefully remove the external casing, taking note of the configuration for reassembly. |

| 3 | Inspect internal components for wear and damage, documenting any issues encountered. |

| 4 | Replace worn or damaged parts with new, compatible pieces to maintain performance. |

| 5 | Reassemble the unit, ensuring all components are securely fitted and aligned. |

| 6 | Conduct a thorough test to verify functionality and check for any leaks or irregularities. |

Upgrading Your DPS Outdrive

Enhancing your marine propulsion system can significantly improve performance and efficiency. Whether you’re looking to boost speed or increase handling, there are various strategies to elevate your setup. This guide will explore key upgrades that can transform your experience on the water.

Choosing the Right Components

Selecting compatible elements is crucial for achieving optimal results. Focus on high-quality alternatives that enhance durability and functionality. Researching innovative solutions can provide insights into the latest technologies available in the market.

Installation and Maintenance Tips

Proper installation is vital for ensuring longevity and performance. Follow manufacturer guidelines closely and consider consulting with professionals if needed. Regular maintenance checks will help keep your enhancements in peak condition, allowing you to enjoy uninterrupted adventures on the waves.

Safety Tips for Outdrive Handling

When working with marine propulsion systems, safety is paramount. Proper handling techniques can prevent accidents and ensure the longevity of your equipment. Understanding the risks involved and following specific guidelines can help create a secure environment for both the operator and the machinery.

1. Wear Protective Gear: Always don appropriate safety equipment, such as gloves and goggles, to shield yourself from potential hazards. This protects against sharp edges and harmful substances.

2. Secure the Area: Before beginning any maintenance, ensure that the work area is clear of obstacles and that tools are organized. A tidy workspace minimizes the risk of tripping or losing items.

3. Follow Manufacturer Guidelines: Adhere strictly to the manufacturer’s instructions for handling and maintenance. These guidelines are designed to maximize safety and performance.

4. Use Proper Tools: Ensure that you are using the right tools for the job. Improvised tools can lead to accidents or damage to the components.

5. Inspect Before Use: Always perform a thorough inspection of the equipment before starting any work. Check for wear, leaks, or damage that could pose a risk during handling.

6. Work with a Partner: Whenever possible, work alongside another person. Having an extra set of hands can help manage heavier components and provide immediate assistance in case of an emergency.

7. Maintain a Clear Focus: Stay focused on the task at hand and avoid distractions. This ensures that you remain aware of your surroundings and any potential hazards.

By implementing these safety tips, you can create a safer working environment and protect both yourself and your equipment during handling and maintenance activities.

Choosing Quality Replacement Parts

When it comes to maintaining and repairing marine equipment, selecting high-quality components is essential for ensuring longevity and optimal performance. Quality replacements can significantly impact functionality and safety, making it crucial to choose wisely.

- Material Quality: Opt for components made from durable materials that resist corrosion and wear.

- Compatibility: Ensure the replacements match your specific model for a perfect fit.

- Brand Reputation: Consider trusted brands known for their reliability and performance.

- Warranty: Look for products that come with a warranty, reflecting confidence in their quality.

Investing time in selecting the right items can prevent future issues and enhance the overall efficiency of your equipment.

Differences Between DPS and Other Models

Understanding the distinctions between various marine propulsion systems is crucial for making informed choices. Each system offers unique features that cater to specific boating needs and conditions. This section delves into the key contrasts that set one model apart from the rest.

Performance and Maneuverability

The primary differences often lie in performance and handling characteristics. Some systems are designed for optimal speed and stability, while others prioritize agility and ease of maneuvering. For instance, certain configurations allow for tighter turns and better responsiveness, which is essential in crowded marinas.

Technology and Efficiency

Another significant aspect is the integration of advanced technologies. Some systems boast enhanced fuel efficiency and lower emissions, appealing to environmentally conscious users. Others may include sophisticated monitoring tools that provide real-time data, ensuring that operators maintain peak performance and safety.

Customer Experiences with Volvo Penta

Users of marine propulsion systems often share their insights and stories, reflecting a diverse range of experiences. These accounts highlight the reliability, performance, and customer service aspects of the brand, offering potential buyers valuable perspectives.

Many boat enthusiasts appreciate the following features:

- Performance: Users frequently commend the smooth handling and efficiency during operation.

- Durability: A significant number of customers report that their systems withstand harsh marine environments, proving to be long-lasting.

- Fuel Efficiency: Many find that these systems provide excellent fuel economy, which is crucial for long trips.

Customer service experiences also play a vital role:

- Support Availability: Several users note the helpfulness and responsiveness of the support team when issues arise.

- Accessibility of Parts: Many find it easy to obtain replacement components, enhancing maintenance experiences.

- Community Engagement: Enthusiasts often mention the active community, which provides advice and shares tips for optimization.

Overall, testimonials reveal a strong satisfaction rate among users, contributing to the brand’s reputation within the maritime sector.

Frequently Asked Questions About DPS

This section addresses common inquiries related to propulsion systems and their components. Understanding these systems can enhance performance and maintenance efficiency.

- What is the primary function of the propulsion system?

It provides thrust and steering capabilities for marine vessels, ensuring smooth navigation.

- How often should I inspect the components?

Regular checks are recommended, ideally every season or after extensive use, to prevent potential issues.

- What are the signs of wear and tear?

Look for unusual noises, vibrations, or leaks, which may indicate that parts need attention.

- Can I perform maintenance myself?

Basic maintenance can be done by owners, but complex repairs should be handled by professionals.

- Where can I find replacement components?

Authorized dealers and specialized marine supply stores typically offer genuine replacements.