In the realm of outdoor maintenance, efficient tools are essential for achieving optimal results. A thorough comprehension of the various elements that contribute to the functionality of these devices can enhance their performance and longevity. This section aims to explore the intricate details of a specific model’s configuration.

Identifying and understanding the individual components is crucial for anyone looking to maintain or repair such machines. Each segment plays a vital role in ensuring smooth operation and effectiveness. By familiarizing oneself with these features, users can make informed decisions regarding upkeep and troubleshooting.

Moreover, this knowledge empowers users to engage in better preventive measures, ultimately extending the lifespan of their equipment. Knowing how different elements interact and contribute to overall efficiency can lead to more effective usage and a greater appreciation for the technology behind these essential tools.

Aaladin Pressure Washer Parts Overview

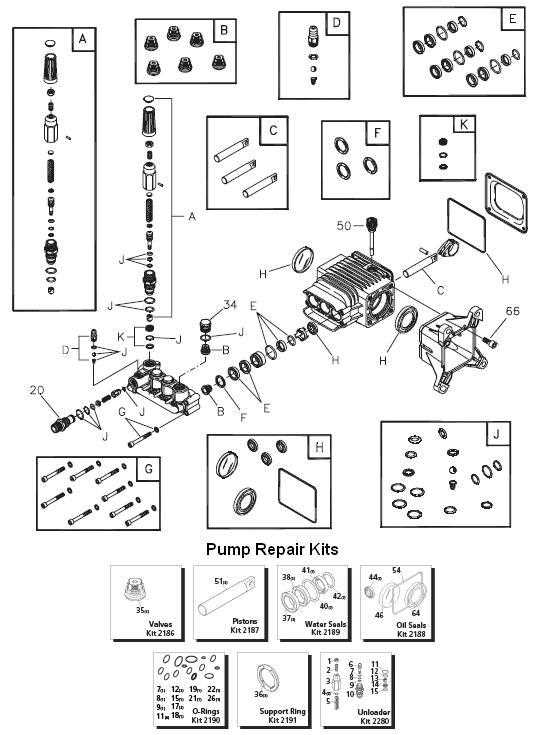

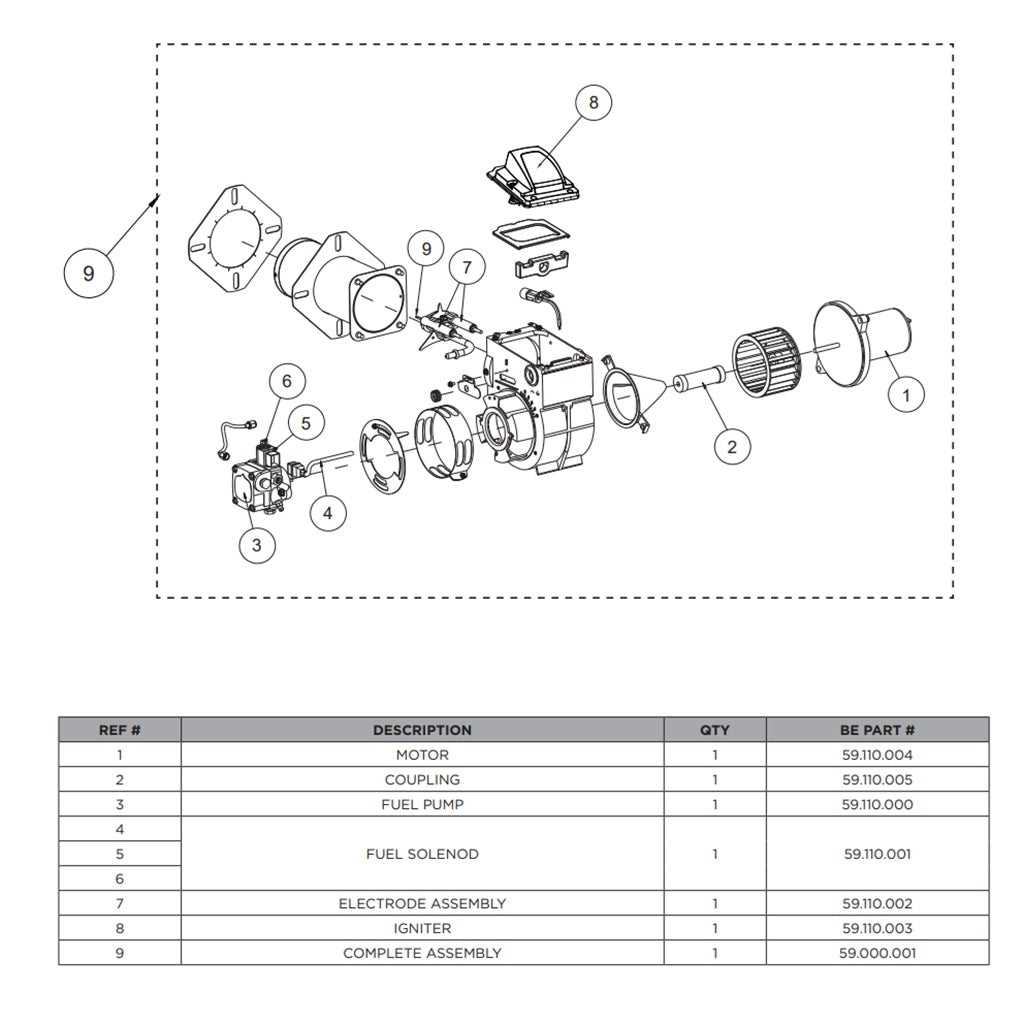

This section provides a comprehensive examination of essential components used in high-performance cleaning machines. Understanding these elements is crucial for efficient operation and maintenance.

- Motor: The powerhouse that drives the system, ensuring effective operation.

- Pump: Responsible for generating the necessary water flow and pressure, vital for cleaning tasks.

- Hose: Facilitates the delivery of water from the unit to the cleaning area.

- Nozzle: Alters the spray pattern, allowing for various cleaning applications.

- Filter: Keeps debris from entering the system, protecting internal mechanisms.

- Frame: Provides structural support and houses various components securely.

Understanding these vital components enhances the user experience and prolongs the lifespan of the equipment. Regular inspection and maintenance are essential for optimal functionality.

Understanding Pressure Washer Functionality

In this section, we will explore the essential mechanisms that drive high-performance cleaning devices, enabling them to effectively remove dirt and grime from various surfaces. Grasping the core principles behind these machines will enhance your ability to maintain and troubleshoot them.

Key Components and Their Roles

- Motor: Powers the entire system and is crucial for generating the necessary force.

- Pump: Converts the motor’s energy into hydraulic power, elevating the water pressure.

- Hose: Delivers the pressurized liquid from the unit to the nozzle.

- Nozzle: Determines the spray pattern and pressure, affecting cleaning efficiency.

How It Works

- Water is drawn into the machine from a source.

- The motor activates the pump, increasing the water pressure.

- Pressurized liquid travels through the hose to the nozzle.

- The nozzle sprays the fluid at high velocity, dislodging contaminants.

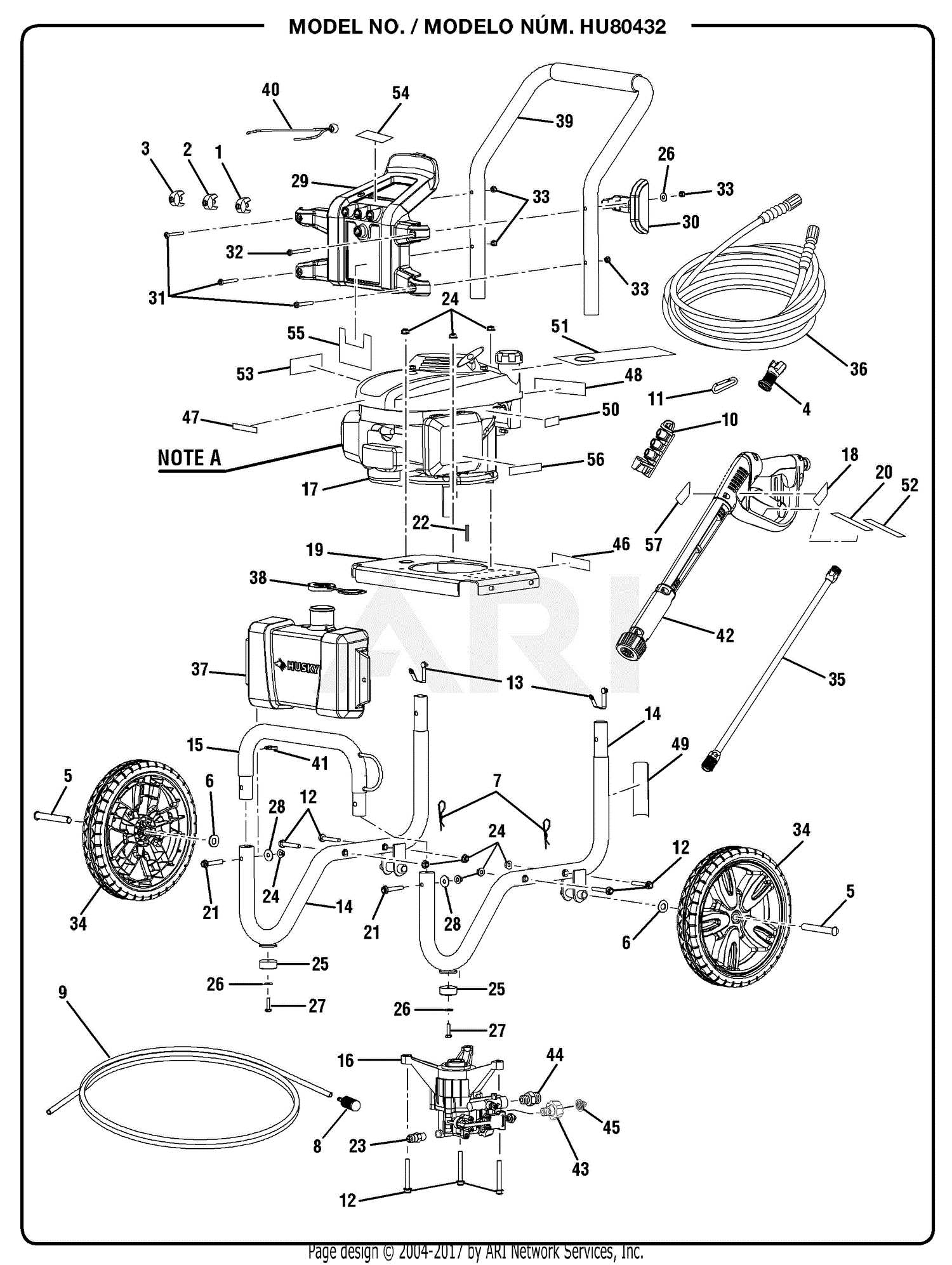

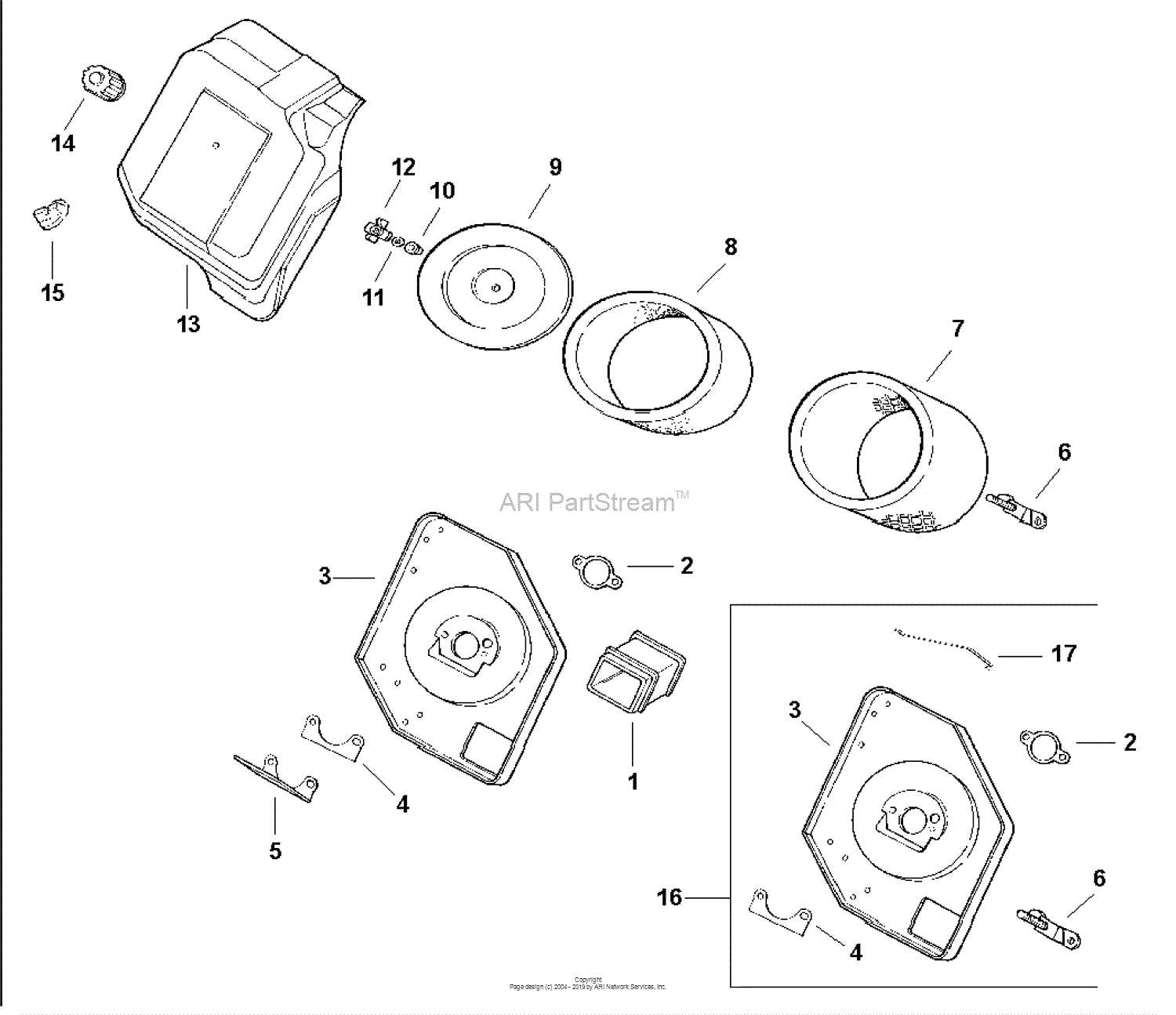

Key Components of Aaladin Models

This section explores the essential elements found in various models, highlighting their significance in the overall functionality and performance. Understanding these components is crucial for effective maintenance and optimal operation.

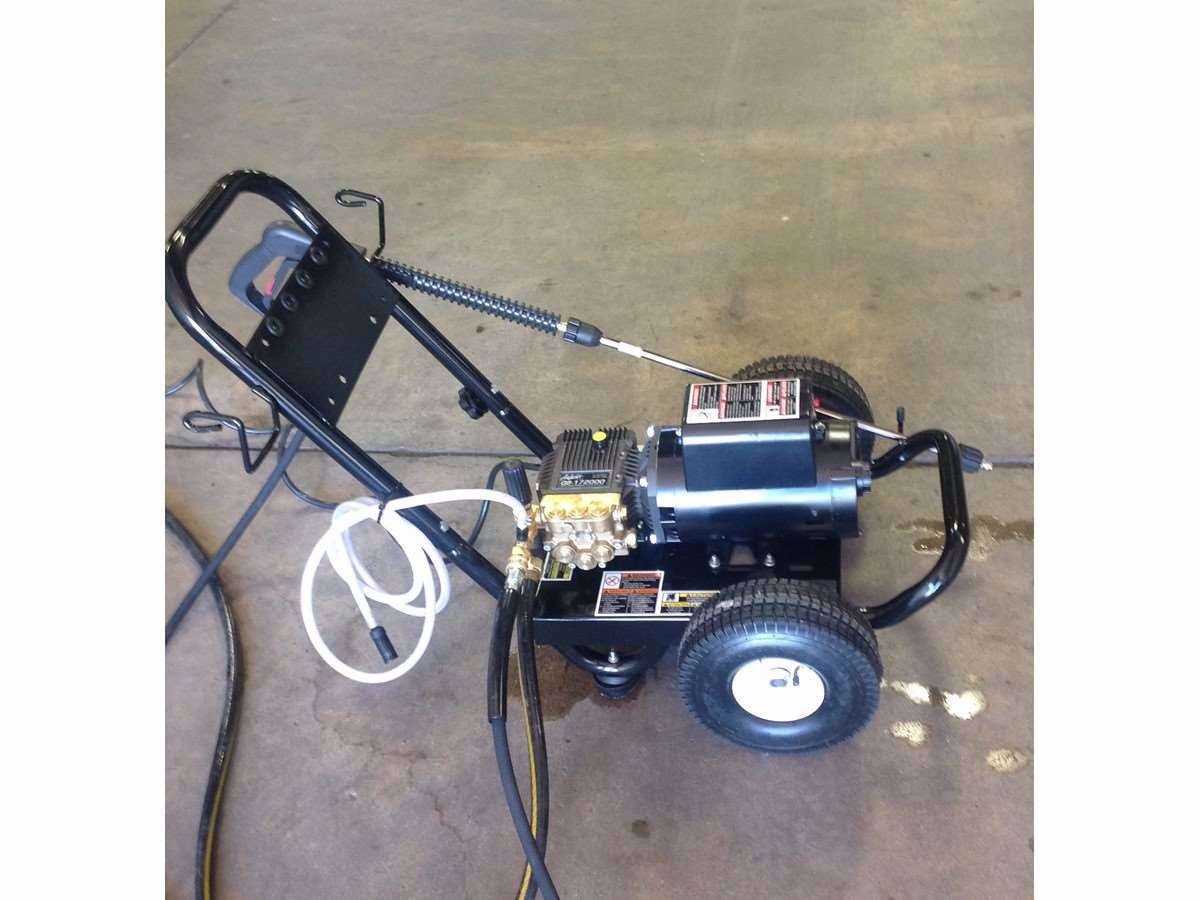

Motor and Pump Assembly

The motor and pump assembly serves as the heart of the system, providing the necessary force to create high-pressure output. This combination ensures efficient fluid movement, allowing for versatile cleaning applications.

Hoses and Nozzles

Flexible hoses and specialized nozzles are vital for directing the flow of liquid. They facilitate easy maneuverability and enable users to adjust the spray pattern, making them indispensable for achieving desired results in various environments.

Common Issues and Solutions

Understanding the frequent challenges faced by users of cleaning equipment can significantly enhance their experience and efficiency. Many users encounter operational hiccups, often stemming from wear and tear or improper maintenance. Addressing these issues promptly can prevent further complications and extend the lifespan of the device.

One common problem is insufficient water flow, which may arise from clogged hoses or filters. Regularly inspecting and cleaning these components can restore proper function. Additionally, if the unit fails to start, checking the power supply and ensuring all connections are secure can often resolve the issue.

Another frequent concern involves fluctuating pressure levels. This may indicate a need for nozzle replacement or an assessment of the pump. Ensuring all fittings are tight and leak-free can also help maintain consistent performance. By proactively addressing these challenges, users can ensure optimal operation and longevity of their equipment.

Maintenance Tips for Longevity

To ensure your equipment remains functional and efficient over time, regular upkeep is essential. Implementing a few straightforward practices can greatly enhance its lifespan and performance, saving you time and money in the long run.

Regular Cleaning

Maintaining cleanliness is vital. After each use, remove debris and residues that could lead to corrosion or malfunction. A simple rinse can prevent buildup and ensure optimal operation.

Routine Inspections

Conduct frequent checks on all components to identify any wear or damage early. Addressing minor issues promptly can prevent more significant problems down the line. Ensure that all connections are secure and lubricated where necessary.

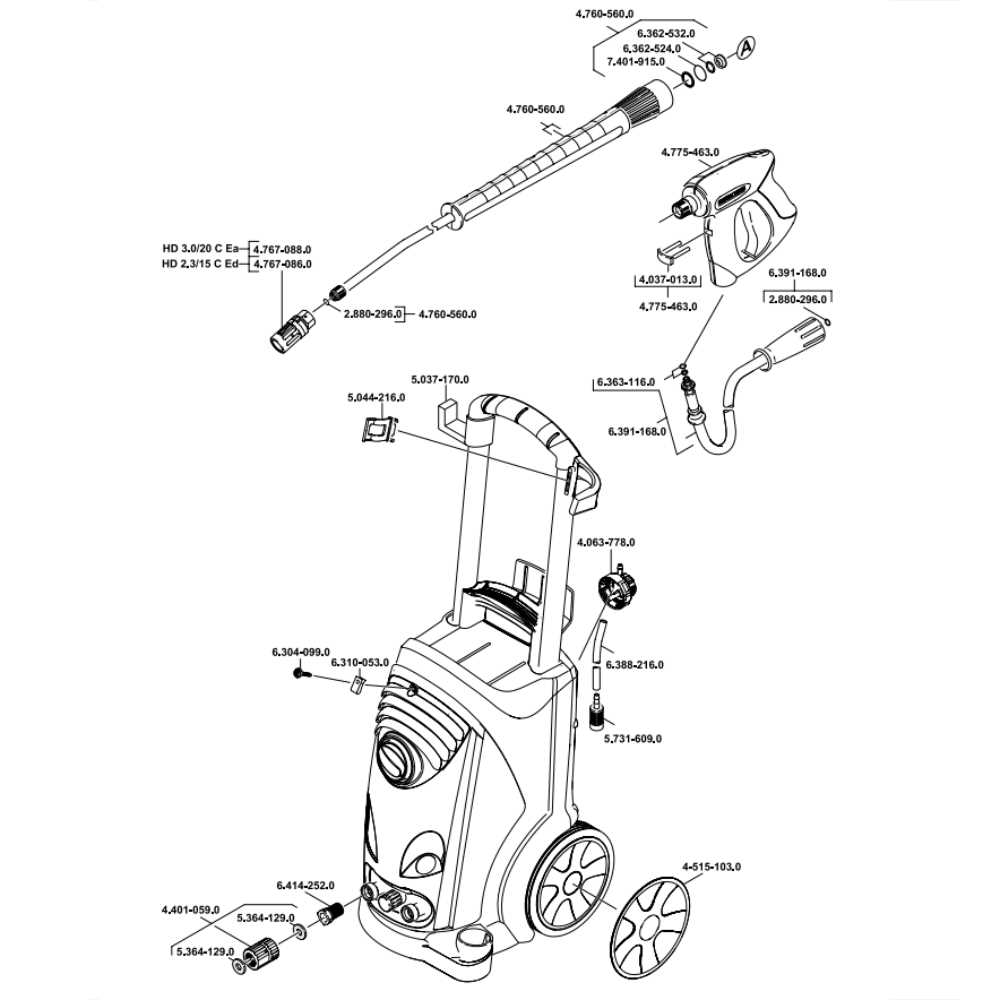

How to Identify Replacement Parts

Understanding how to locate suitable components for your equipment is essential for maintaining optimal functionality. This guide provides key insights on identifying the necessary replacements effectively.

To ensure you select the correct items, follow these steps:

- Consult the Manual: Review the user guide to find specifications and recommendations for each component.

- Identify Model Number: Locate the model number on your device, usually found on a label or engraved on the chassis. This information is crucial for sourcing compatible items.

- Visual Inspection: Examine the current components for any wear or damage. Take note of their size and shape to compare with potential replacements.

- Use Online Resources: Visit manufacturer websites or third-party suppliers to view catalogs and diagrams that can aid in identifying specific components.

By following these steps, you can ensure a successful replacement process, leading to enhanced performance and longevity of your equipment.

Assembly Guide for New Owners

This section provides essential instructions for setting up your new equipment efficiently. Proper assembly is crucial to ensure optimal performance and longevity.

Preparation Steps

- Unpack all components and verify the items against the checklist.

- Find a suitable location with ample space for assembly and operation.

- Gather necessary tools, such as screwdrivers and wrenches.

Assembly Instructions

- Begin by attaching the base to the main body, ensuring all connectors are aligned.

- Secure the handle firmly using the provided screws, checking for stability.

- Connect any additional components, such as hoses and connectors, as per the guidelines.

- Perform a final inspection to confirm all parts are properly fitted and secure.

Safety Precautions While Operating

Ensuring a secure environment during equipment usage is paramount to prevent accidents and injuries. Adhering to established guidelines and practices can significantly enhance safety and efficiency.

- Always wear appropriate personal protective equipment, including gloves, goggles, and sturdy footwear.

- Inspect the machinery before each use to identify any signs of damage or wear.

- Ensure that the area is free of obstructions and that bystanders are at a safe distance.

- Read and understand the operating manual thoroughly to familiarize yourself with the equipment’s features and limitations.

- Never aim the nozzle at people, animals, or fragile surfaces to avoid potential harm.

Regular maintenance and attention to safety practices can greatly minimize risks and enhance the overall effectiveness of your tasks.

Accessories to Enhance Performance

Incorporating various tools can significantly elevate the efficiency and effectiveness of your cleaning tasks. These enhancements not only optimize operation but also extend the lifespan of your equipment.

Quality nozzles are essential, as they allow for adjustable spray patterns tailored to different surfaces, ensuring thorough cleaning. Additionally, extension wands can reach high or distant areas, making them indispensable for comprehensive maintenance.

Moreover, surface cleaners can dramatically improve the cleaning process on flat surfaces, reducing the time and effort required. Detergent dispensers are also beneficial, facilitating the application of cleaning agents that boost overall results.

Finally, investing in replacement filters and accessory kits ensures that your equipment operates at peak performance, ultimately enhancing your overall cleaning experience.

Finding OEM Parts and Resources

When maintaining or repairing your cleaning equipment, sourcing original components is crucial for ensuring optimal performance and longevity. Reliable resources help you identify the necessary items while providing you with quality options that match your machine’s specifications.

Here are some valuable resources for locating genuine components:

| Resource | Description |

|---|---|

| Manufacturer’s Website | Direct access to the official site often provides a comprehensive catalog of original components and accessories. |

| Authorized Dealers | Local dealers can assist in obtaining specific items and may offer expert advice on installation and compatibility. |

| Online Retailers | Many e-commerce platforms specialize in OEM items, making it easy to compare prices and availability. |

| Community Forums | Engaging with fellow users can yield recommendations for reliable suppliers and tips for maintenance. |

Utilizing these resources will facilitate a smoother experience in securing the right components for your equipment needs.

Comparative Analysis of Models

This section explores the distinctions between various models, highlighting their unique features, performance capabilities, and suitability for different tasks. By examining these variations, users can make informed decisions based on their specific needs and preferences.

| Model | Power (HP) | Flow Rate (GPM) | Weight (lbs) | Special Features |

|---|---|---|---|---|

| Model A | 3.0 | 2.5 | 50 | Compact design, adjustable nozzle |

| Model B | 4.0 | 3.0 | 65 | Heavy-duty motor, extended hose |

| Model C | 2.5 | 2.0 | 40 | Lightweight, easy to maneuver |