Understanding the inner structure of household equipment can significantly improve maintenance and repair tasks. Whether troubleshooting an issue or simply aiming to enhance its efficiency, having a clear overview of the device’s internal elements is essential. This section offers a closer look at how various components come together to ensure smooth operation.

In many cases, even small parts play a critical role in the appliance’s functionality. Identifying how these elements interact can help detect potential malfunctions early. Knowing the arrangement of key elements also empowers users to perform simple repairs without external help, saving time and effort.

Detailed insights into component placement not only assist in repairs but also offer a better understanding of how to prolong the lifespan of frequently used devices. With this guide, readers will gain practical knowledge for navigating complex equipment layouts effectively.

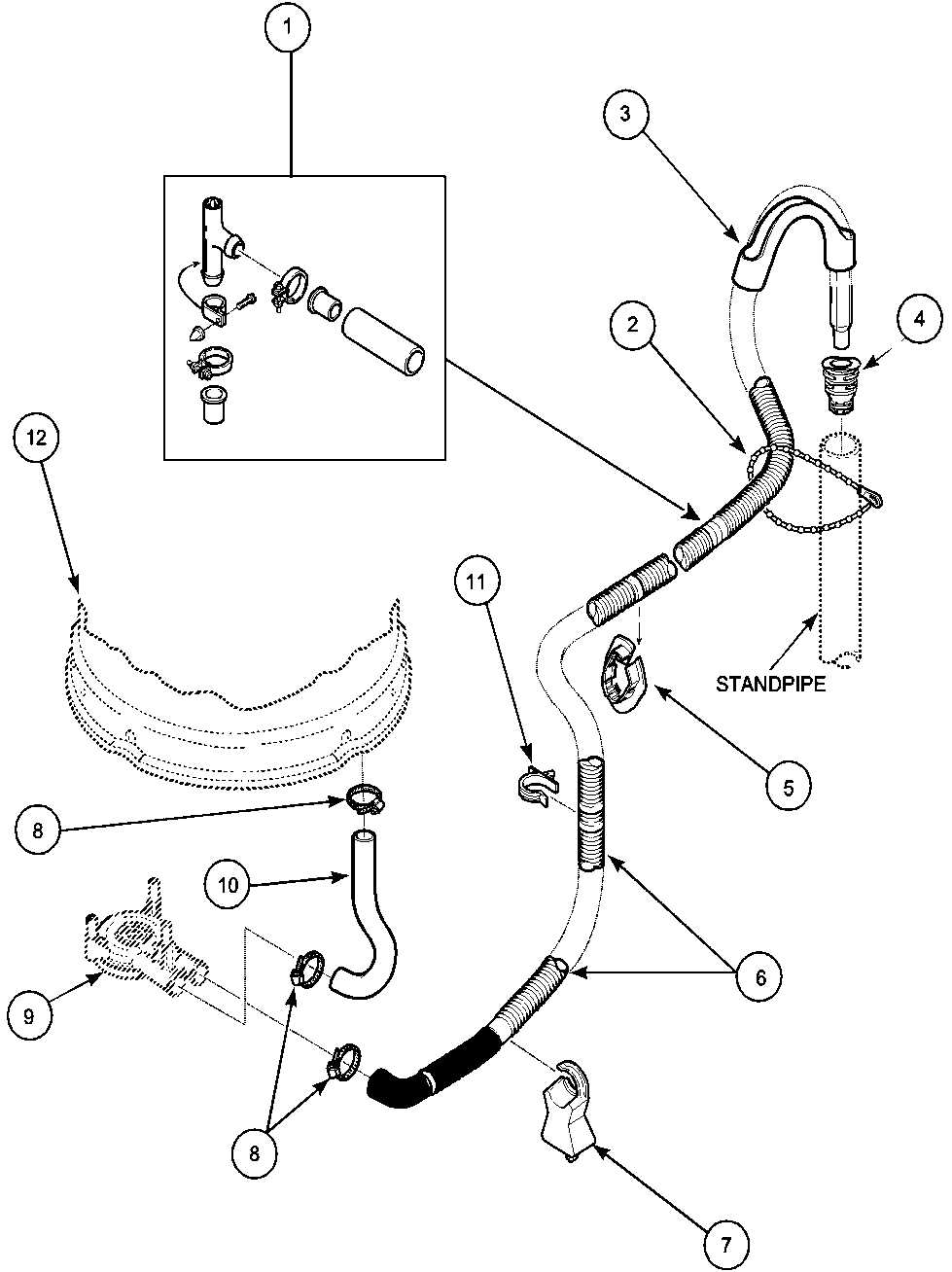

Amana Washing Machine Parts Diagram

This section provides an overview of the essential elements found in home cleaning devices. It focuses on identifying how different internal and external elements come together to ensure smooth operation, durability, and maintenance ease.

- Control Panel: The interface responsible for user input and operation settings, allowing for easy program adjustments.

- Drum Assembly: A rotating container where garments are placed, designed for thorough cleaning while protecting fabrics.

- Pump and Motor: Critical components responsible for circulating and draining fluids during cleaning cycles.

- Hoses and Valves: These ensure efficient water intake and drainage, helping maintain proper water levels throughout the process.

- Suspension System: A set of springs and dampers that minimizes vibration and stabilizes the device during operation.

Each of these elements plays a vital role in ensuring seamless operation. Their correct alignment and functionality contribute to consistent results and prolong the device’s lifespan.

Understanding the Control Panel Layout

The layout of control panels plays a crucial role in ensuring ease of operation. Recognizing how each button, knob, and display interacts allows users to achieve the desired settings efficiently. Familiarity with the arrangement can also help minimize errors and improve the overall experience.

Main Functions and Settings

Control panels often feature distinct areas dedicated to essential functions such as program selection, time adjustments, and start or stop actions. These areas are intuitively organized to help users quickly access frequently used options. Knowing the purpose behind each section aids in streamlining the setup process.

Quick Reference Table of Key Features

| Control | Description |

|---|---|

| Program Selector | Allows choosing

How the Motor Powers the MachineThe motor plays a central role in driving the entire operation by converting energy into mechanical movement. Its function is essential for creating the momentum needed to move other components in a synchronized manner. Without it, the entire system would remain idle, unable to perform its tasks effectively. Energy Transformation in Action

Key Components Driven by the Motor

By connecting various parts into a cohesive system, the motor ensures each stage works in harmony. Exploring the Water Inlet SystemThe water inlet system plays a key role in managing how liquid flows into home appliances. It ensures that the right amount of water is delivered efficiently, providing a smooth operation. Understanding this system can help with identifying any issues related to water control and flow management. Components of the Inlet SystemThis system typically includes valves, hoses, and filters. Valves act as gateways, regulating the water supply, while hoses transport water from external sources. Filters, on the other hand, prevent debris from entering and causing blockages, maintaining consistent performance. How the System OperatesWhen the appliance initiates a water cycle, the valves open to allow water in. Sensors or control modules monitor the amount, ensuring the process completes without overfilling or leaks. Once the necessary water level is reached, the valves close automatically, stopping the flow to avoid unnecessary waste. Role of the Drum in Washing CyclesThe central component responsible for ensuring garments are thoroughly cleaned is the rotating chamber. This element interacts with water and detergent, contributing significantly to the treatment of fabrics during the process. Its movements and structure are essential for achieving effective cleansing through dynamic engagement. How Motion Affects Fabric CareThe rotating action plays a crucial role in gently agitating textiles, ensuring even distribution of water and soap. Different speed settings allow the chamber to adapt to delicate materials or robust fabrics. This motion not only removes dirt but also protects the integrity of the clothing, reducing wear over time. Drum Perforation and EfficiencyThe chamber’s surface design, with carefully placed holes, helps drain water effectively while maintaining a continuous flow during rinsing. This structure enhances energy efficiency by minimizing water retention. Additionally, it aids in preventing clothes from tangling, ensuring smooth operation throughout the entire cycle. Identifying the Drive Belt’s PositionUnderstanding the location of the drive belt is essential for efficient operation. The drive belt plays a critical role in the overall functionality of the equipment. Its proper placement ensures that the components work harmoniously, contributing to the smooth operation. To locate the drive belt accurately, consider the following steps:

In addition to these steps, keep an eye out for any wear or damage on the belt itself. Regular checks can prevent larger issues down the line. The Purpose of Agitators and ImpellersIn the realm of cleaning appliances, certain components play a crucial role in ensuring effective fabric care. These elements are designed to facilitate the movement and distribution of water and detergent, enhancing the overall cleaning process. Agitators are typically found in traditional models and are characterized by their central post and fins. They create a turbulent motion, which helps to lift and move items within the container. This action ensures that all surfaces of the fabrics come into contact with the cleaning solution, resulting in a thorough cleansing experience. On the other hand, impellers serve as a more modern alternative. These flat, rotating discs provide a gentler motion, pushing water and items around the tub without the aggressive action of agitators. This method minimizes wear and tear on delicate fabrics while still delivering effective results. The choice between these two components often depends on the specific cleaning requirements and the desired care for various textiles. Locating Filters for MaintenanceRegular upkeep of home appliances often includes identifying key components that require attention, particularly filtration systems. These elements play a crucial role in ensuring optimal performance and longevity of the equipment. Understanding where these filters are situated can significantly enhance the efficiency of routine maintenance tasks. Typically, filters are located in accessible areas designed for easy removal and cleaning. They may be found at the rear, beneath the lid, or within dedicated compartments. It is essential to consult the user manual for specific locations related to your equipment. Proper identification of these areas allows for efficient access and ensures that the filtration systems are maintained correctly, promoting overall functionality. Checking and replacing filters at regular intervals is vital for maintaining performance. Neglected filters can lead to reduced efficiency and potential issues down the line. Therefore, knowing how to locate these components is imperative for effective maintenance practices. How the Pump Manages Water FlowThe component responsible for circulating liquid plays a crucial role in the overall functionality of any appliance designed for laundry. Its operation is essential for ensuring that water is efficiently directed during various cycles, enhancing the effectiveness of the cleaning process. At its core, the pump utilizes a series of mechanisms to create the necessary pressure for movement. This allows the fluid to be drawn in and expelled at the correct times, depending on the cycle selected by the user. When the system engages, the pump activates and initiates the flow, maintaining the balance required for effective performance. Moreover, the design of the pump facilitates the management of water levels, ensuring that the correct amount is available for rinsing and soaking. This not only optimizes the use of resources but also prevents overflow, making the entire process more efficient and environmentally friendly. Regular maintenance of this vital component ensures longevity and consistent results. Differences Between Timers and Sensors

In various mechanical systems, two essential components play critical roles in operational efficiency: timers and sensors. These elements serve different purposes, influencing the overall functionality and performance of the equipment. Understanding the distinction between them helps in identifying the appropriate applications for each type. Timers are devices designed to control the duration of specific actions within a system. They ensure that certain operations occur at predefined intervals or for specified lengths of time. This functionality is crucial in scenarios where precise timing is essential, such as in regulating cycles or sequences of operations. On the other hand, sensors are responsible for detecting changes in the environment or the condition of the system. They gather data about various parameters, such as temperature, moisture, or pressure, and relay this information to the control unit. This feedback enables the system to respond appropriately to different conditions, enhancing its adaptability and efficiency. While both timers and sensors contribute to the effective functioning of devices, their unique characteristics highlight their distinct roles. Timers focus on managing time-related functions, whereas sensors emphasize monitoring and feedback mechanisms. Together, they create a balanced and responsive system. Connection Points for Hoses and PipesThis section focuses on the essential connection areas for flexible tubes and rigid pipelines within the appliance framework. Understanding these locations is crucial for efficient water flow and proper functionality. Key Locations

Installation Considerations

Where to Find Seals and GasketsFinding the right sealing components is essential for maintaining optimal performance. These elements play a crucial role in preventing leaks and ensuring proper functionality. Whether you are repairing or upgrading, knowing where to source these materials can save time and effort. Online RetailersNumerous online platforms specialize in providing a wide range of sealing materials. Websites dedicated to home appliance supplies often have detailed catalogs. These resources allow for easy comparison of prices and availability. Be sure to check user reviews to gauge the reliability of the products. Local Hardware StoresYour neighborhood hardware store may stock essential sealing components. Visiting in person allows for direct examination of the materials. Staff can often offer valuable insights and recommendations based on your specific needs. Troubleshooting Electrical ComponentsAddressing issues within electrical systems requires a systematic approach to identify and resolve malfunctions. Understanding how to effectively diagnose components can enhance performance and extend the lifespan of the equipment. Begin by following these essential steps:

By systematically evaluating electrical elements, it becomes easier to pinpoint issues and implement effective solutions, ensuring optimal operation and reliability. |