Auto-lock Feature: Ensures that the system automatically secures the door once a cycle starts, reducing risks.

Detergent Dispenser Setup and Maintenance

Ensuring the proper functionality of the compartment for cleaning agents is key to achieving optimal cleaning results. The compartment is responsible for evenly distributing the cleaning solution during various stages of the process. Regular care and correct setup will prevent issues and ensure consistent performance.

To prepare the compartment, make sure to follow the recommended guidelines for the amount and type of cleaning solution used. Each section of the compartment is designed for a specific purpose, whether for liquid, powder, or softening agents. Adjust the settings according to your cleaning needs.

Routine maintenance is equally important. Clean the compartment regularly to avoid clogs or buildup of residues. Remove any leftover solution and ensure that water flows freely through the compartment. If buildup occurs, it

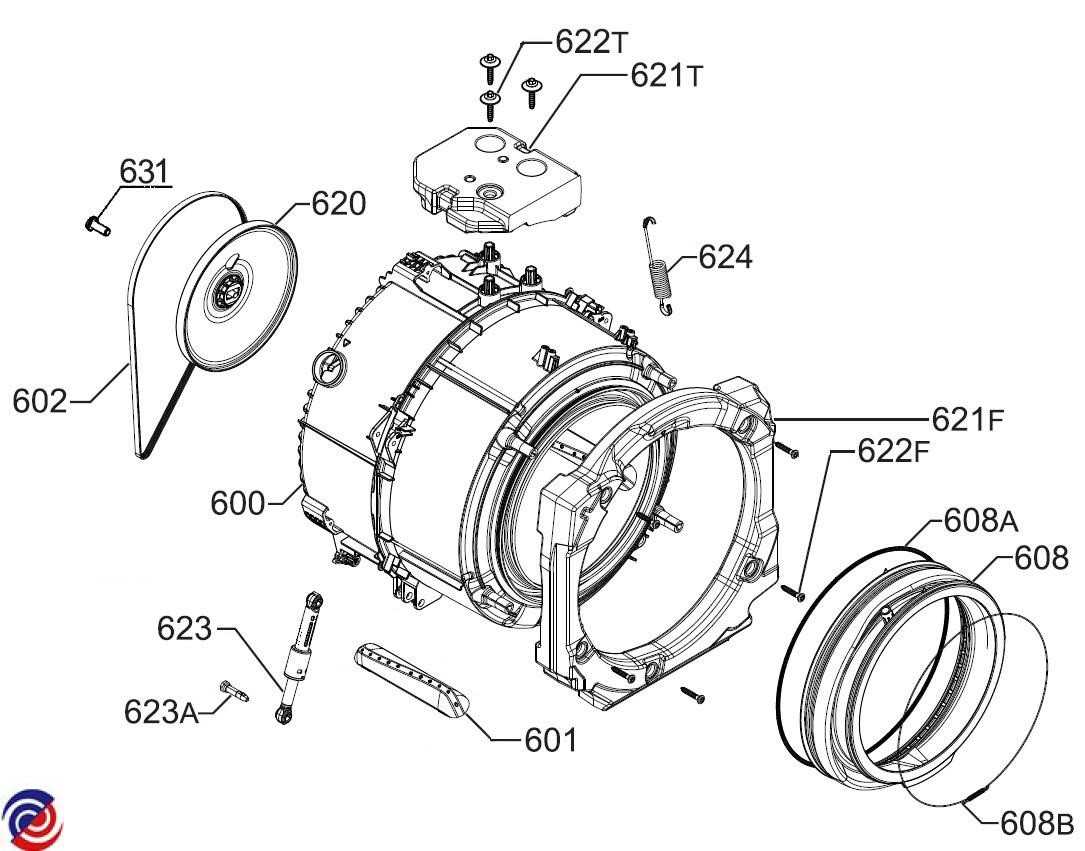

Pump System and Water Circulation Components

The efficiency of any cleaning appliance heavily relies on its fluid management mechanisms. These mechanisms are designed to facilitate the movement and distribution of water throughout the system, ensuring optimal performance during each cycle. Understanding the components involved in this process can provide insights into their functionality and maintenance requirements.

Main Circulation Pump

The primary component responsible for moving water within the system is the circulation pump. This device plays a crucial role in transporting water to and from the various sections of the unit. By creating a steady flow, it ensures that the appropriate amount of liquid reaches the drum, aiding in effective cleaning and rinsing.

Drainage System

The drainage mechanism works in tandem with the circulation pump to remove used water from the unit. After each cleaning cycle, the system must efficiently expel wastewater to prevent contamination and promote hygiene. Key elements in this process include the drainage hose and filter, which work together to facilitate smooth water expulsion.

Regular maintenance of these components is essential to ensure long-term functionality and prevent issues such as leaks or blockages. Understanding the role of each part can empower users to conduct appropriate checks and servicing when necessary.

Electrical Wiring and Sensor Placement

This section provides an overview of the critical elements involved in the electrical connections and sensor arrangements essential for optimal operation. Understanding how components interact within the system is vital for ensuring efficiency and reliability.

Wiring Configuration: Proper configuration of electrical connections is fundamental to achieving effective functionality. Each wire must be positioned accurately to prevent shorts and ensure smooth communication between the various components. Adhering to the recommended wiring layout will not only enhance performance but also extend the lifespan of the equipment.

Sensor Positioning: The placement of sensors plays a significant role in the machine’s ability to monitor and respond to different conditions. Sensors should be installed in designated areas to accurately detect temperature, pressure, and moisture levels. Optimal sensor alignment ensures precise readings, contributing to the machine’s overall effectiveness and safety.

In conclusion, a thorough understanding of the electrical connections and sensor placements is crucial for maintaining proper function. By following guidelines and best practices, one can ensure that the system operates smoothly and efficiently.

Heating System and Temperature Control Parts

The effectiveness of laundry appliances significantly depends on their ability to maintain optimal temperatures during operation. This section delves into the components responsible for regulating heat and ensuring that fabrics are treated with the proper care. By understanding these elements, users can better appreciate how their machines function and identify any potential issues.

Key components within this system include temperature sensors, heating elements, and control boards, each playing a vital role in maintaining the desired environment for washing. Proper functioning of these components ensures efficient energy use and enhances the longevity of the appliance.

| Component |

Description |

Function |

| Heating Element |

A coil or metal part that heats water and air within the appliance. |

Generates heat to warm water for effective cleaning. |

| Thermostat |

A device that monitors and regulates temperature levels. |

Ensures water reaches the desired temperature and prevents overheating. |

| Temperature Sensor |

Measures the actual temperature within the machine. |

Provides feedback to the control board for adjustments. |

| Control Board |

The electronic circuit that manages the operation of heating components. |

Coordinates the heating cycle based on sensor inputs and user settings. |

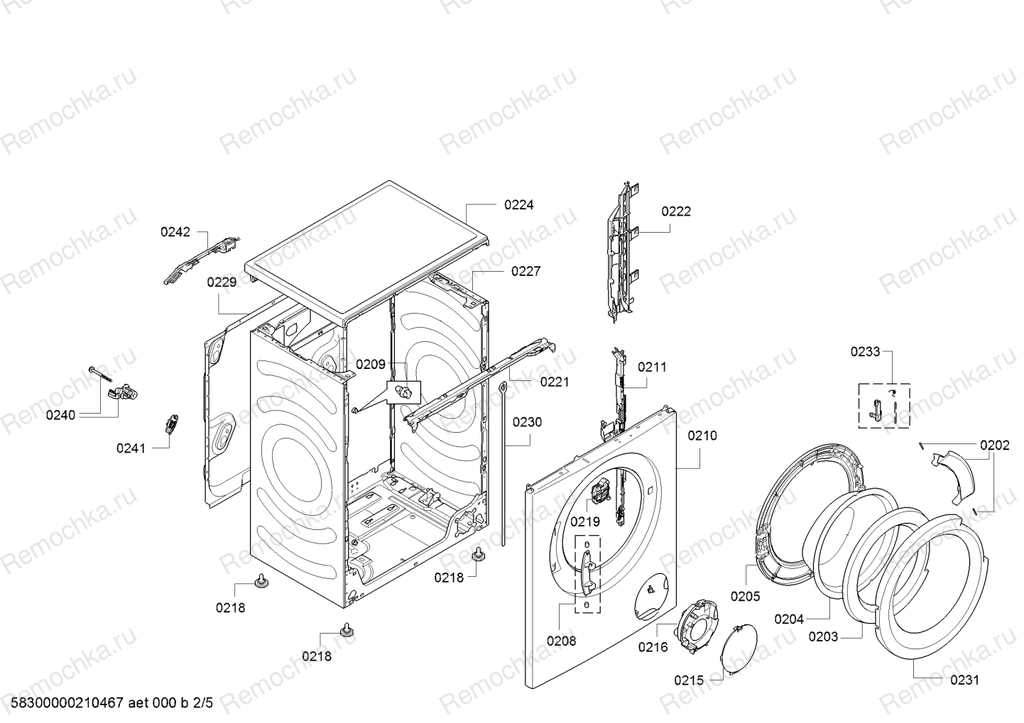

Outer Casing and Protective Panels Explained

The external structure and shielding components of a laundry appliance play a vital role in its overall functionality and safety. These elements are designed to safeguard the internal mechanisms from external damage while contributing to the device’s aesthetic appeal. Understanding their purpose can enhance the user’s appreciation for the appliance’s design and durability.

Exterior Shell serves as the primary line of defense against wear and tear. Constructed from robust materials, it protects delicate internal systems from moisture, dust, and physical impacts. Additionally, this casing often contributes to the appliance’s thermal insulation, preventing overheating during operation.

Protective Panels are integral to maintaining the integrity of the machine. Positioned strategically, these panels prevent accidental contact with moving parts and electrical components, ensuring user safety. Furthermore, they are designed to be easily removable for servicing and maintenance, allowing for quick access without compromising the overall structure.

Replacing Common Wearable Components

Over time, certain elements of household appliances can experience wear and tear, leading to decreased efficiency and functionality. Regular maintenance and timely replacement of these components can significantly enhance performance and prolong the life of the machine.

When considering replacements, it’s important to focus on the following commonly affected components:

- Drive Belts: These are essential for the proper functioning of the machine, connecting the motor to the drum. Signs of wear include squeaking or slipping sounds.

- Seals and Gaskets: These components help prevent leaks and ensure a tight fit. Over time, they may degrade, leading to water leakage and other issues.

- Filters: Clogged filters can hinder performance and lead to complications. Regular cleaning or replacement is necessary to maintain optimal operation.

- Spray Arms: If these components become damaged or clogged, the washing process may become ineffective. Inspect and replace them as needed.

To ensure a successful replacement, follow these steps:

- Identify the specific component that needs attention.

- Consult the manufacturer’s guide for detailed instructions on removal and installation.

- Purchase high-quality replacement items to guarantee compatibility and longevity.

- Carefully remove the worn component and install the new one, ensuring all connections are secure.

- Test the appliance to confirm that the replacement has resolved any issues.

By prioritizing the replacement of these frequently worn components, users can maintain optimal performance and extend the life of their appliances.