In any efficient cleaning apparatus, the inner workings play a crucial role in its overall functionality. Grasping the layout and interactions of these key elements is essential for effective maintenance and troubleshooting. A thorough comprehension of these components not only enhances performance but also prolongs the lifespan of the equipment.

Identifying the specific features and their respective functions can empower users to make informed decisions regarding repairs and replacements. By familiarizing oneself with the intricate relationships among various elements, one can ensure optimal operation and reliability of the device. This knowledge is invaluable for both casual users and professionals seeking to maximize efficiency.

This guide aims to provide a comprehensive overview of the crucial components that contribute to the system’s effectiveness. With a focus on understanding how each piece fits into the larger assembly, we will explore the significance of these elements in delivering exceptional cleaning results.

Understanding Comet Pressure Washer Pumps

This section delves into the intricacies of high-performance equipment designed for efficient cleaning tasks. Knowing how these systems function is essential for optimal use and maintenance. Each component plays a critical role in ensuring reliability and effectiveness during operation.

Key Components and Their Functions

- Motor: Powers the entire mechanism, converting electrical energy into kinetic energy.

- Water Intake: Allows for the flow of water into the system, ensuring a steady supply for cleaning.

- Pressure Regulation: Maintains consistent output pressure, crucial for various cleaning tasks.

- Outlet Connection: Directs the flow of water to the cleaning nozzle, providing the necessary force.

Maintenance Tips

- Regularly check the motor for any signs of wear.

- Inspect the intake filter to prevent clogs.

- Ensure pressure settings are adjusted correctly for different applications.

- Clean the outlet regularly to avoid blockages.

Understanding these components and their roles helps users maximize the lifespan and efficiency of their cleaning equipment. Regular maintenance and attention to detail are key to achieving the best performance possible.

Essential Components of Pressure Washers

Understanding the key elements of high-performance cleaning devices is crucial for optimal operation and maintenance. Each component plays a vital role in the overall efficiency and effectiveness, contributing to the ultimate cleaning experience.

Motor or Engine: This is the powerhouse that drives the entire system, converting fuel or electrical energy into mechanical energy to facilitate water movement.

Water Inlet: The entry point for water, allowing the device to draw in fluid, which is essential for the cleaning process.

High-Pressure Hose: A durable conduit designed to withstand intense pressure, transporting water from the pump to the cleaning nozzle.

Nozzle: This component controls the spray pattern and intensity, enabling users to customize their cleaning approach for various surfaces.

Trigger Gun: The interface between the user and the machine, it regulates the flow of water and provides control over the cleaning process.

Detergent Tank: A reservoir for cleaning agents, allowing for enhanced cleaning capabilities when tackling tough grime and stains.

Frame: The structure that houses and supports all components, providing stability and ease of mobility during operation.

Common Issues with Pump Parts

Understanding the frequent challenges associated with components of liquid delivery systems is crucial for maintaining efficiency and prolonging their lifespan. Users often encounter various malfunctions that can lead to decreased performance or complete failure. Identifying these issues early can save time and resources.

Frequent Problems

Several common problems can arise, typically stemming from wear and tear, improper maintenance, or environmental factors. Below is a list of some of these issues:

| Issue | Description | Solution |

|---|---|---|

| Leaks | Fluid escaping from seals or connections, causing reduced efficiency. | Inspect seals for damage and replace them as necessary. |

| No Flow | Failure to deliver fluid as intended, often due to blockages. | Check for clogs in hoses or filters and clear them. |

| Noise | Unusual sounds indicating potential mechanical issues. | Examine moving parts for wear and lubricate as needed. |

Preventive Measures

To minimize these issues, regular maintenance is essential. Implementing a routine check of components and ensuring proper lubrication can significantly enhance performance and durability. Being proactive can help avoid more significant problems in the future.

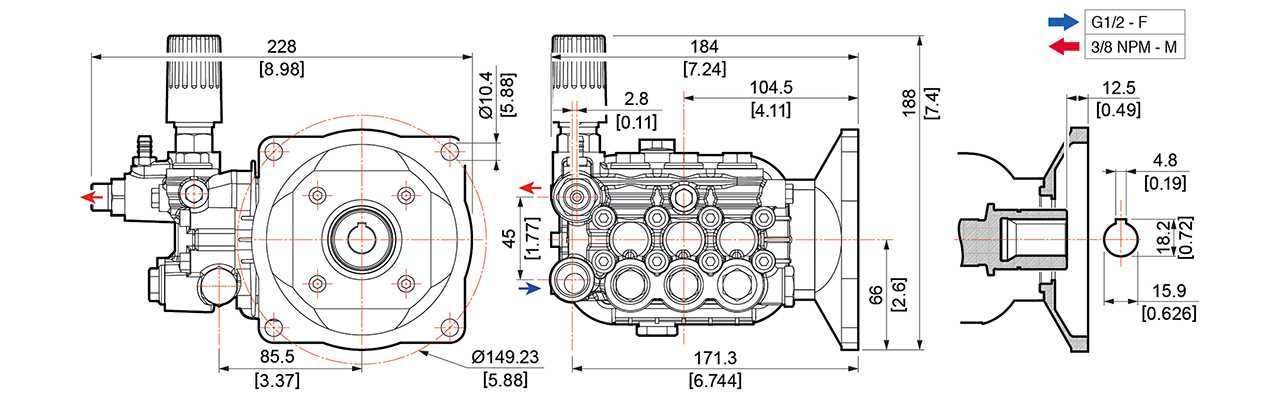

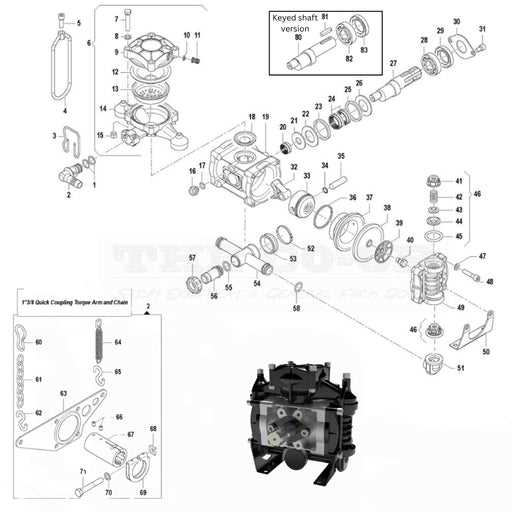

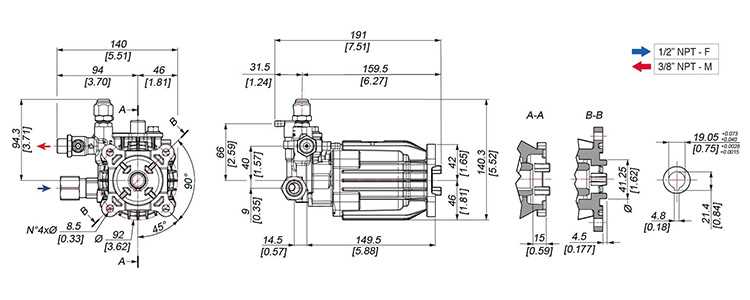

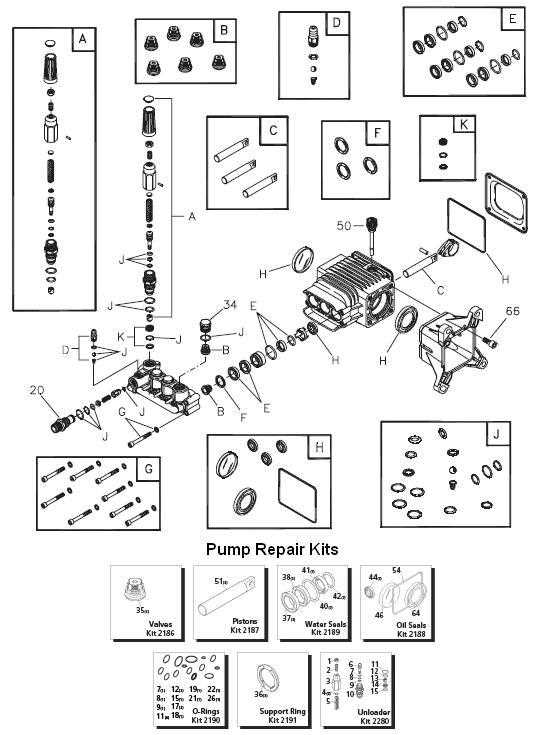

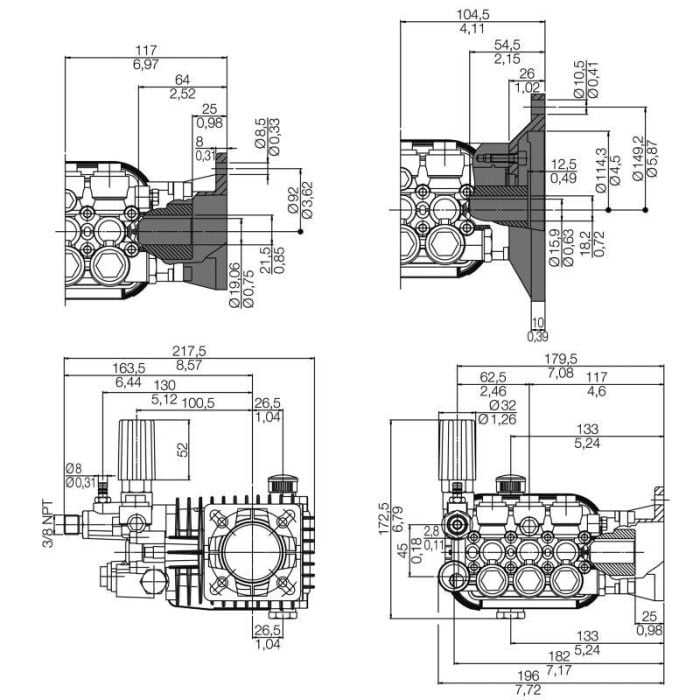

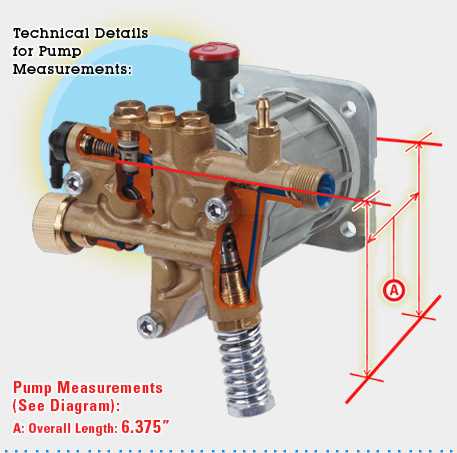

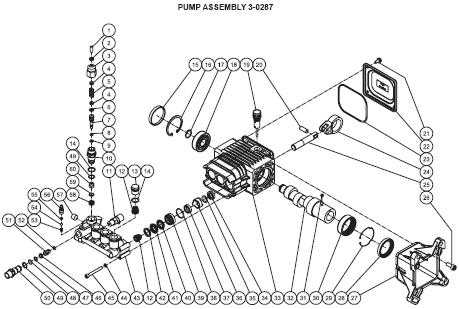

How to Read Pump Diagrams

Understanding technical illustrations is crucial for effective maintenance and repair. These visuals provide essential information about components, their arrangement, and functionality, enabling users to troubleshoot issues efficiently.

Familiarize yourself with the symbols and notations used in the illustration. Each symbol typically represents a specific component, while lines may indicate connections or flow directions.

Next, identify the main sections of the illustration. Components are often grouped by their function, making it easier to locate areas of interest, whether for repairs or upgrades.

Pay attention to labels and annotations. These notes often clarify measurements, specifications, or operational limits, offering deeper insights into each part’s role.

Lastly, practice makes perfect. The more you interact with these visual representations, the better you’ll become at interpreting them, ultimately enhancing your understanding of the entire system.

Importance of Maintenance and Repair

Regular upkeep and timely repairs are essential for ensuring the longevity and optimal performance of any mechanical device. Neglecting these aspects can lead to decreased efficiency, unexpected failures, and ultimately higher costs in the long run. Understanding the significance of maintenance can save users from unnecessary inconveniences.

Consistent attention to the functionality of machinery not only enhances its lifespan but also improves safety and operational reliability. Users should be aware of the common issues that may arise and the importance of addressing them promptly.

| Aspect | Benefits |

|---|---|

| Regular Maintenance | Increases lifespan and efficiency |

| Timely Repairs | Prevents larger, costly failures |

| Safety Checks | Enhances user safety and reliability |

| Cost Management | Reduces long-term operational costs |

Types of Comet Pump Models

Understanding the various models available in this category is essential for selecting the right equipment for specific tasks. Each design serves distinct applications and offers unique features that cater to diverse user needs. This section explores the most common variants, highlighting their functionalities and ideal uses.

1. Triplex Models: These are known for their robust construction and efficiency. Typically featuring three pistons, they provide a smooth flow of liquid and are well-suited for heavy-duty operations. Their durability makes them a popular choice for industrial applications.

2. Axial Models: Designed for lighter tasks, axial variants utilize a single piston mechanism. They are often favored for residential use due to their simplicity and ease of maintenance. These units deliver adequate performance for smaller jobs.

3. Gear Models: Characterized by a gear-driven mechanism, these versions excel in applications requiring consistent pressure. They are often employed in scenarios where steady flow is critical, such as in agricultural settings.

4. Electric Models: These are powered by electric motors and are typically quieter and more environmentally friendly. They are ideal for users seeking convenience without the need for fuel. Their versatility allows for various residential and light commercial uses.

In conclusion, understanding these different types enables users to make informed choices tailored to their specific requirements, ensuring optimal performance and satisfaction in their tasks.

Identifying Wear and Tear Signs

Recognizing the signs of deterioration is crucial for maintaining the efficiency of your equipment. Over time, components may exhibit various indicators that suggest they require attention. By being vigilant, you can prevent more significant issues and ensure longevity.

| Indicator | Description |

|---|---|

| Cracks | Visible fractures on surfaces that may compromise functionality. |

| Leaks | Any fluid escaping from seals or joints, signaling potential failure. |

| Discoloration | Change in color indicating heat damage or chemical exposure. |

| Noise | Unusual sounds during operation that suggest internal issues. |

| Wear Patterns | Uneven surfaces or grooves that reveal excessive use or strain. |

Choosing the Right Replacement Parts

Finding the appropriate components for your equipment is crucial for optimal performance and longevity. Selecting the right replacements can significantly impact efficiency and reliability, ensuring that your device operates smoothly.

When considering options, quality should always be a top priority. Look for components made from durable materials that can withstand wear and tear. Compatibility with your specific model is equally essential; always verify that the replacements match your device’s specifications.

Additionally, researching manufacturer recommendations can guide you in making informed choices. Customer reviews and expert insights can provide valuable information on the reliability of various alternatives available on the market.

Tools Needed for Pump Repair

Repairing a water-moving device requires specific instruments to ensure efficiency and effectiveness. Having the right tools at your disposal not only facilitates the process but also enhances the quality of the work performed. Below is a list of essential equipment that will aid in any maintenance or repair task.

Wrenches and Sockets: A variety of wrenches, including adjustable and socket types, are crucial for loosening and tightening fasteners. They provide the necessary grip and leverage to handle stubborn bolts.

Screwdrivers: Both flathead and Phillips screwdrivers are essential for removing screws and accessing internal components. A set of precision screwdrivers may also be useful for more delicate tasks.

Pliers: Needle-nose and slip-joint pliers are invaluable for gripping, twisting, and cutting wires or small components. Their versatility makes them a staple in any repair kit.

Sealant and Adhesives: High-quality sealants or adhesives are important for ensuring a watertight fit when reassembling parts. This helps to prevent leaks and maintains the device’s overall performance.

Cleaning Tools: Brushes and cloths are necessary for removing debris and old sealant. A clean work area and components are critical for a successful repair.

Safety Equipment: Always prioritize safety by using goggles and gloves. Protecting yourself while working with tools and components is essential to avoid injuries.

Equipped with these tools, you can tackle repairs with confidence and ensure your device operates optimally. Proper preparation sets the stage for a smooth and effective maintenance experience.

Step-by-Step Repair Process

This section outlines a comprehensive guide for troubleshooting and restoring essential components of a high-performance cleaning device. By following a systematic approach, users can effectively identify issues and implement solutions to ensure optimal functionality.

- Gather Necessary Tools

- Screwdrivers (flathead and Phillips)

- Wrenches (adjustable and socket)

- Pliers

- Replacement components

- Lubricants and sealants

- Disconnect the Device

- Ensure the unit is powered off.

- Disconnect any water supply and hoses.

- Inspect External Components

- Check for visible signs of wear or damage.

- Examine seals and connections for leaks.

- Open the Housing

- Remove screws and fasteners carefully.

- Lift off the cover to access internal mechanisms.

- Assess Internal Mechanisms

- Inspect components for damage or blockage.

- Clean any debris or buildup that may hinder performance.

- Replace Damaged Parts

- Remove faulty components using appropriate tools.

- Install new parts, ensuring secure connections.

- Reassemble the Unit

- Carefully place the housing back on.

- Reattach screws and fasteners to secure the cover.

- Test Functionality

- Reconnect the water supply and power source.

- Perform a test run to confirm proper operation.

By adhering to these steps, users can restore their cleaning equipment efficiently, enhancing its performance and longevity.

Safety Precautions During Repairs

When engaging in maintenance or troubleshooting activities, it is essential to prioritize safety. Proper precautions can prevent accidents and ensure that repairs are conducted efficiently and effectively. Below are important measures to consider before and during the repair process.

- Wear Appropriate Personal Protective Equipment (PPE): Always use safety goggles, gloves, and non-slip footwear to protect against potential hazards.

- Ensure a Clean Work Area: A tidy workspace minimizes the risk of accidents. Remove any unnecessary tools or materials that could cause tripping or injury.

- Disconnect Power Sources: Before starting any repair, ensure that all electrical connections are safely disconnected to avoid shocks or other electrical hazards.

- Use Proper Tools: Always utilize the correct tools for the job. Improvised tools can lead to injuries or damage to equipment.

- Follow Manufacturer Guidelines: Adhere to the instructions provided by the manufacturer to avoid mishaps and ensure the longevity of the equipment.

By following these precautions, individuals can significantly reduce the likelihood of injury and ensure that the repair process is smooth and successful.

Upgrading Your Pump for Performance

Enhancing the efficiency and output of your equipment can significantly improve your overall cleaning tasks. By focusing on critical components and exploring advanced alternatives, you can achieve better results and longevity. This section will guide you through the essential upgrades that can elevate your system’s performance to new heights.

Identifying Key Components for Improvement

Start by assessing the core elements that impact the effectiveness of your unit. Look for options that offer increased durability and higher flow rates. Replacing standard items with high-performance equivalents can lead to noticeable enhancements in operation and reliability.

Benefits of Upgrading

Investing in superior components not only boosts the effectiveness of your setup but also minimizes downtime due to repairs. Enhanced parts often lead to better energy efficiency and reduced maintenance costs, making your cleaning tasks more economical in the long run.

Where to Find Quality Parts Online

In today’s digital age, locating high-quality components for your equipment has never been easier. Numerous online platforms offer a wide selection of items, ensuring that you can find exactly what you need to keep your machinery running smoothly. This section highlights some effective strategies for sourcing reliable products on the internet.

Reputable Online Retailers

Start by exploring well-known online retailers that specialize in tools and machinery. These platforms often provide extensive catalogs and detailed descriptions of their offerings, making it simple to identify the right items for your needs. Additionally, customer reviews can provide valuable insights into the reliability and performance of the components you are considering.

Manufacturer Websites

Another excellent option is to visit the official websites of manufacturers. Here, you can find original components that meet specific quality standards. Manufacturers often offer the latest innovations and accessories, ensuring compatibility with your equipment. Look for dedicated sections that list authorized distributors to ensure you are purchasing genuine items.

By utilizing these resources, you can confidently find the components required for your machinery, ensuring optimal performance and longevity.