When maintaining home appliances, it’s essential to have a clear understanding of their inner workings. Every device consists of various components that work together to ensure optimal performance. From water flow to mechanical movement, each part plays a critical role in the appliance’s efficiency and longevity. Having a visual guide can greatly assist in identifying the individual elements and comprehending their functions within the system.

For anyone looking to repair or upgrade their equipment, knowledge of these crucial pieces is indispensable. Whether you’re tackling a repair yourself or simply want to understand the mechanism better, familiarizing yourself with the layout and arrangement of the internal elements can make the process much smoother. Proper maintenance begins with identifying how the different sections interact and what each one contributes to the overall operation.

Efficiency is the key when it comes to keeping your appliances running smoothly, and understanding their structure is the first step in achieving that. By getting acquainted with the various pieces and how they connect, you’ll be better prepared to troubleshoot or enhance performance in a meaningful way. Being proactive about the care and attention given to these intricate parts is the best strategy for ensuring long-term functionality.

Frigidaire Dishwasher Key Components Overview

The key elements of any high-performance washing unit play a crucial role in ensuring effective cleaning and smooth operation. These components are designed to work in harmony, providing users with optimal efficiency during each cycle. Understanding these essential pieces is fundamental for maintaining and troubleshooting the appliance.

Water Distribution and Spray Mechanism

At the heart of the cleaning process is the water distribution system. This system consists of multiple nozzles and spray arms that ensure water reaches every corner of the interior. The spray arms rotate during cycles, dispersing water at varying pressures to remove dirt and debris from all types of dishware. The precise movement and functionality of these elements are critical for achieving optimal cleaning results.

Filtration and Drainage System

Equally important is the filtration and drainage system, which ensures that used water is effectively removed from the unit. This system prevents clogging and keeps water quality in check. The filter traps particles, while the drainage pump facilitates the expulsion of water after each cycle. Proper maintenance of these parts is essential for the unit’s longevity and consistent performance.

Understanding the Main Mechanical Parts

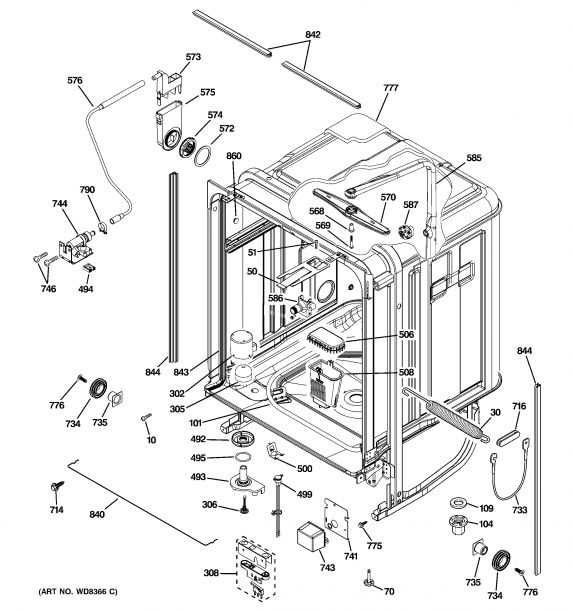

In every cleaning appliance, several core components work together to ensure efficient operation. These elements interact to facilitate water flow, optimize cleaning cycles, and manage energy consumption. Each component plays a crucial role in delivering the expected results during use.

The first key element is the motor, which drives various functions, including the circulation of water and the movement of racks. The pump is another essential piece, responsible for moving water through the system to reach all surfaces. This ensures proper cleaning action and effective rinsing. Additionally, the heating element is vital for maintaining water at the correct temperature, necessary for tackling grease and food residues. Together, these parts collaborate to make sure the appliance functions smoothly and reliably.

Other significant parts, such as the spray arms and filters, further enhance performance. Spray arms distribute water evenly, ensuring every corner is reached, while filters trap debris, preventing clogging and ensuring optimal efficiency. Each of these components contributes to the overall performance and longevity of the appliance, highlighting their importance in the cleaning process.

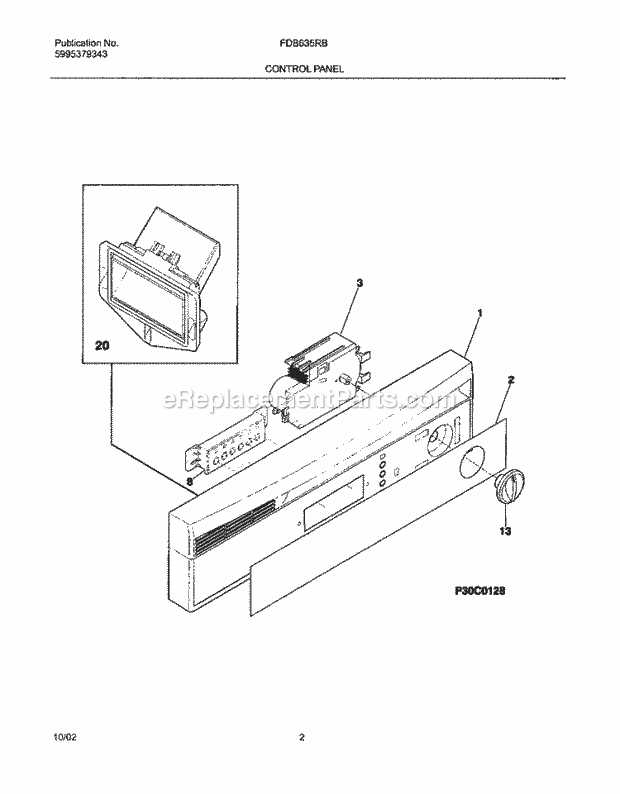

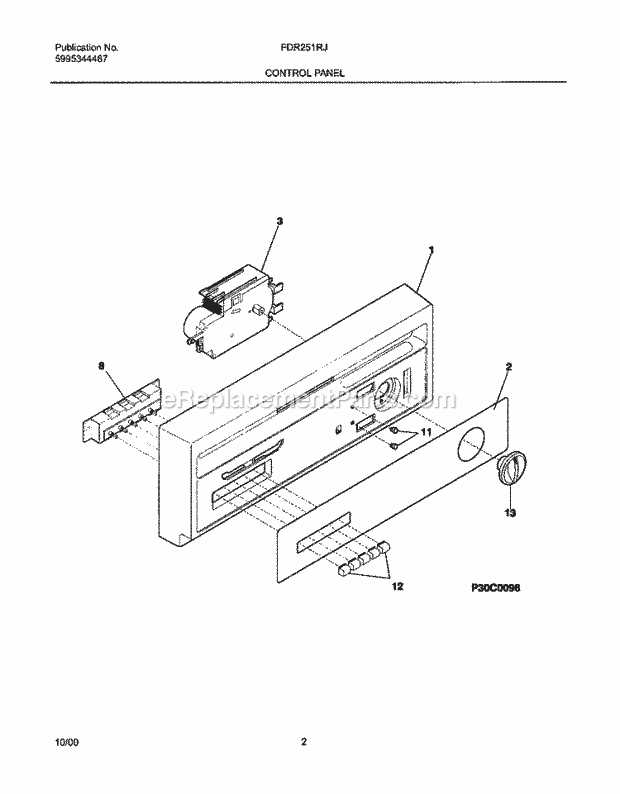

Common Electrical Elements in Frigidaire Models

In many home appliances, certain electrical components play a vital role in ensuring smooth and efficient operation. For users of various kitchen devices, understanding these components can help with troubleshooting and maintenance. These elements are designed to control specific functions within the system, allowing the device to work optimally. This section will explore the common electrical elements found in models from a popular appliance brand, shedding light on their functions and importance.

Power Supply and Circuit Control

At the core of any functioning appliance is the power supply. Electrical devices rely on a consistent power flow, which is managed by the power board. This element controls the distribution of electricity to other parts of the system, ensuring each part receives the appropriate power to operate. In some models, a thermal fuse is also incorporated into the circuit, acting as a safety measure in case of overheating, preventing damage to the electrical components.

Switches and Sensors

Switches and sensors are crucial for monitoring and controlling the appliance’s different cycles. Sensors detect water levels, temperature, or even leakage, providing feedback to the control board. This data allows the system to adjust operation accordingly. Similarly, user-operated switches trigger specific functions, such as starting or stopping cycles, or switching between various modes for cleaning or drying.

| Component | Function |

|---|---|

| Power Board | Distributes power to all internal components |

| Thermal Fuse | Prevents overheating by cutting power when necessary |

| Control Board | Manages electrical functions and responses to user input |

| Temperature Sensor | Monitors and adjusts the internal temperature for proper function |

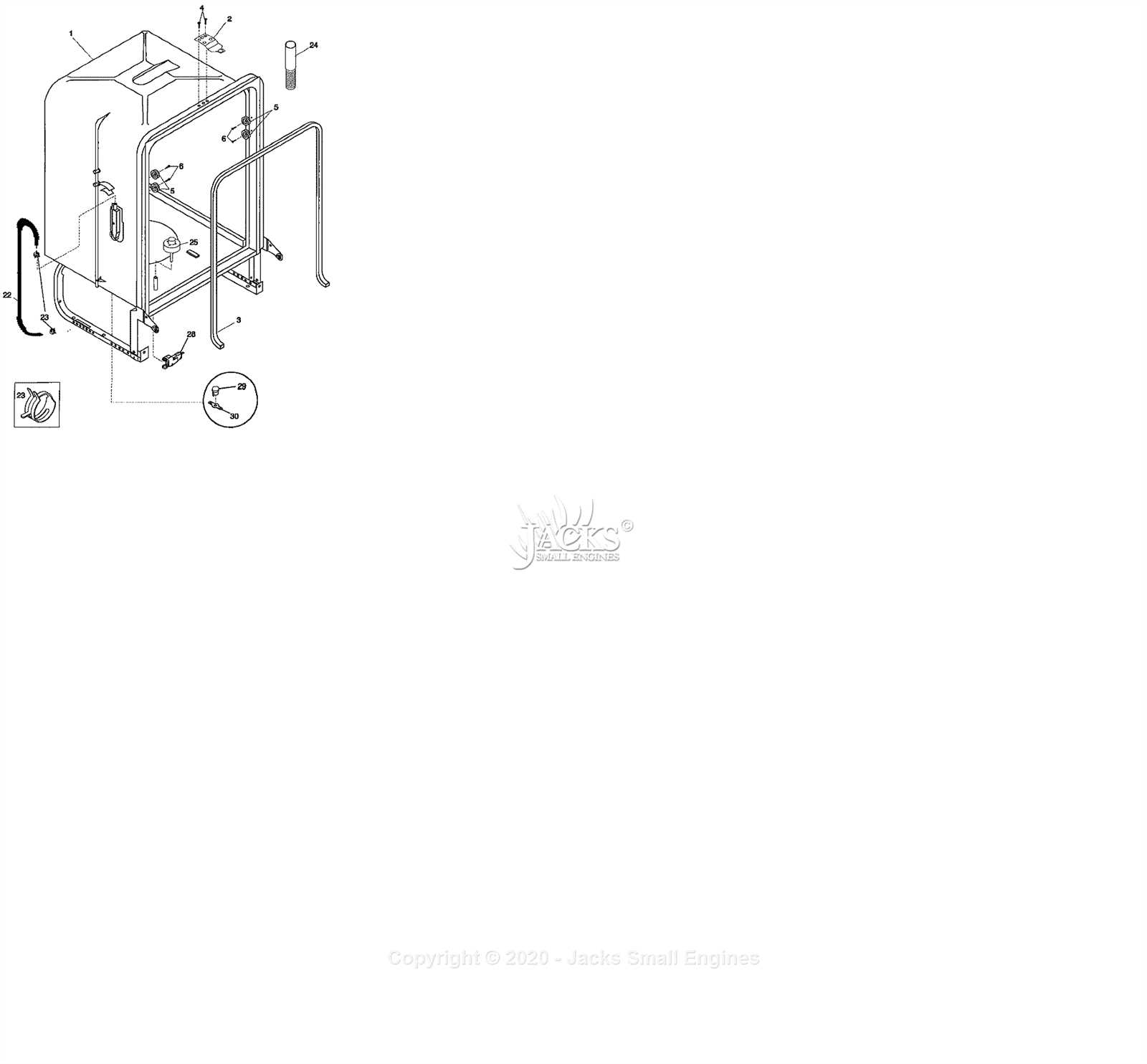

Water System Components Explained

The water system in modern cleaning appliances consists of several crucial elements that ensure effective washing. These components work in tandem to manage the intake, circulation, and drainage of water, allowing for optimal performance during the cleaning cycle. Understanding the different sections of the water system can help troubleshoot issues and improve maintenance practices.

Key Elements of the Water System

- Water Inlet Valve: Controls the flow of water into the appliance. It opens at the start of a cycle to fill the chamber and closes when the required level is reached.

- Spray Arms: Equipped with rotating nozzles, these arms distribute water evenly throughout the washing area to clean items effectively.

- Drain Pump: Ensures that used water is expelled at the end of the cleaning process, preventing buildup and ensuring fresh water is circulated during subsequent cycles.

- Heat Element: Heats the water to the appropriate temperature, optimizing the cleaning process for grease, stains, and detergent activation.

Water Circulation Process

The water is drawn in, mixed with detergent, and then pumped through the spray arms to provide thorough cleaning. After the washing stage, the used water is expelled through the drainage system. Proper water flow is essential for maintaining efficiency and achieving optimal results in every cycle.

Role of Filters in Proper Operation

Filters play a crucial role in ensuring the smooth and efficient functioning of any cleaning appliance. They are designed to capture debris, food particles, and other residues, preventing them from circulating within the system. Without effective filtration, the machine’s performance can be compromised, leading to incomplete cleaning cycles and potential damage over time.

Efficiency: A clean filter ensures that water flows freely through the system, optimizing the overall efficiency of the appliance. By trapping contaminants, the filter prevents them from clogging essential components, which can lead to mechanical issues if left unchecked.

Maintenance: Regularly maintaining and replacing filters is vital to prolong the lifespan of the unit. Filters that are clogged or dirty can force the machine to work harder, increasing energy consumption and causing wear and tear on internal mechanisms.

In conclusion, filters are indispensable for maintaining high performance and longevity, ensuring that the appliance operates effectively while preventing costly repairs.

Essential Spray Arm Functions and Types

Spray arms play a critical role in the cleaning process of home appliances designed for washing. These components are responsible for distributing water evenly throughout the interior, ensuring that every surface is thoroughly cleaned. Without an efficient spray arm, the effectiveness of the appliance diminishes significantly, leaving residue or incomplete cleaning.

Spray arms come in various types, each with specific designs suited to different washing needs. Some are mounted at the bottom, while others are positioned at the top or even in the middle, depending on the design of the machine. The main function remains the same: to deliver pressurized water that reaches dishes from multiple angles, providing an even clean.

There are two main types of spray arms: single-arm and multi-arm. The single-arm variant is simpler and typically positioned at the bottom, while the multi-arm design features several rotating arms that offer more extensive coverage and superior cleaning power. Multi-arm systems can often be found in higher-end models, as they provide a more thorough and uniform distribution of water.

Choosing the right type of spray arm system can greatly impact the overall performance of the appliance, depending on the user’s specific cleaning requirements.

Exploring the Pump and Motor Assembly

The pump and motor assembly is a crucial component of any cleaning appliance, as it drives the flow of water during cycles. This assembly ensures efficient water circulation, allowing for optimal performance. By understanding its structure and function, users can better maintain and troubleshoot their machines when issues arise. The pump works in tandem with the motor to deliver water to various sections, ensuring proper cleaning results each time.

Within this section, we will delve deeper into the key elements that make up the pump and motor assembly, focusing on their roles and how they interact with the other components. Whether you’re looking to repair a malfunction or simply understand its operation, knowledge of this assembly will help you gain insight into the appliance’s mechanics.

| Component | Description |

|---|---|

| Motor | Drives the pump, generating the force needed to move water through the system. |

| Pump | Transfers water from the basin to the spray arms, creating a flow that aids in cleaning. |

| Impeller | Part of the pump that helps in pushing water through the appliance’s system. |

| Seal | Prevents water leakage between the motor and pump, ensuring smooth operation. |

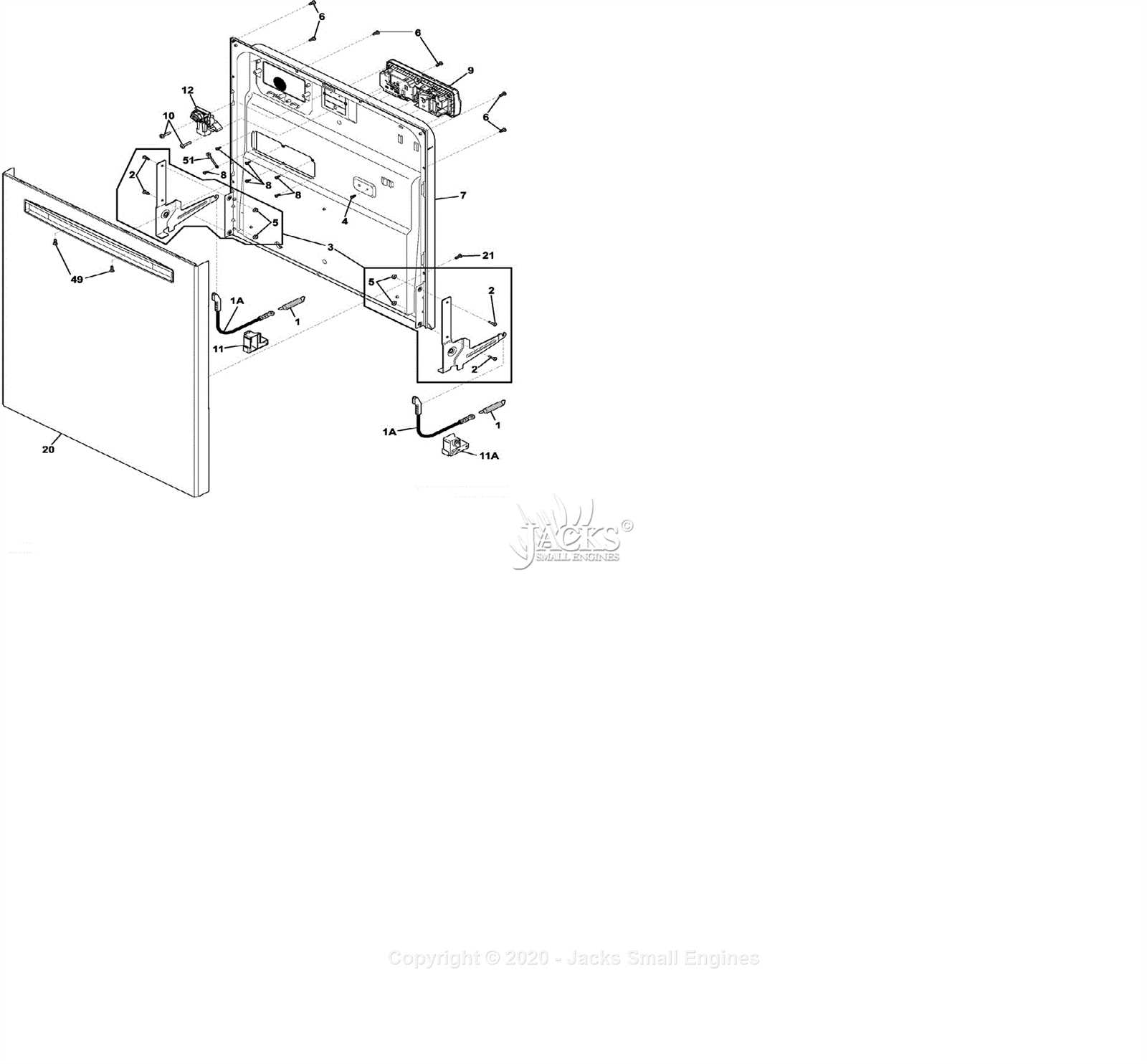

How Door Latches and Seals Work

The mechanism that ensures proper closure of the appliance’s door is essential for its effective operation. Latches and seals work together to provide a secure and airtight fit, preventing leaks and maintaining the necessary internal pressure. This combination of components allows the machine to perform optimally during the cleaning cycle, while also protecting against water damage or inefficient performance.

The Role of Door Latches

Door latches play a critical role in holding the door in place during operation. They are designed to lock the door securely, ensuring that it remains tightly closed throughout the cleaning process. A properly functioning latch will keep the door in position, avoiding any unintended openings that could disrupt the appliance’s functioning. Latches are typically triggered by a spring-loaded mechanism or an electronic control, depending on the model. When the door is closed, the latch clicks into place, providing a firm hold.

The Function of Seals

Seals are the protective barriers around the door, often made from flexible rubber or silicone material. Their primary purpose is to create a watertight seal when the door is shut, preventing leaks and ensuring that water remains inside the machine during operation. Seals are crucial in maintaining energy efficiency and optimal performance by minimizing water loss. Over time, seals may wear out or degrade, leading to potential leaks and the need for replacement to restore full functionality.

In summary, latches and seals are essential for the appliance’s effectiveness. Latches secure the door, while seals provide the necessary protection to prevent water from escaping, ensuring a smooth and efficient cleaning process.

Heating Element’s Function in Dishwashers

The heating component in cleaning machines plays a crucial role in ensuring optimal cleaning performance. It is responsible for raising the water temperature, which is essential for removing stubborn grease and food residues from dishes. By increasing the heat, it also aids in sanitizing the items, making them hygienically clean and safe for use. Without this element, the cleaning process would be much less effective, as lower temperatures struggle to dissolve detergents and eliminate bacteria effectively.

Moreover, this element is integral to the drying process. After washing, it heats the interior, evaporating any remaining moisture and ensuring that the cleaned items are dry and ready for use. It is particularly important in areas where humidity is high, as the drying step is essential for maintaining proper cleanliness and avoiding water spots or mildew formation on the items.

In essence, this heating element serves both a functional and hygienic purpose, allowing the machine to carry out its tasks with efficiency and precision. It ensures that every cycle delivers the highest quality results, from temperature-sensitive cleaning to effective drying.

Detergent Dispenser and Its Mechanism

The dispenser for cleaning agents plays a vital role in ensuring optimal performance during a cleaning cycle. This component is responsible for accurately releasing the detergent at the appropriate time, allowing for effective cleaning of utensils. The mechanism behind its operation involves a carefully engineered system that controls both the timing and quantity of detergent dispensed, ensuring that each load is treated appropriately.

At the heart of this system is a latch or spring-loaded mechanism that opens at the correct point in the cycle. When the cleaning machine begins its process, the detergent compartment is sealed until it is time for it to be released. The timing is controlled by the control board or a similar system, ensuring that the detergent is dispensed when the water temperature is optimal for activation. This ensures the cleaning agent is fully dissolved and performs at its best.

Additionally, the dispenser may feature various compartments, each intended for different cleaning agents such as powder or liquid formulations. Depending on the configuration, the release could occur either automatically or be triggered manually, based on the user’s settings. This flexibility ensures that each type of cleaning product is properly utilized for maximum effectiveness, keeping the cleaning process efficient and the load sparkling clean.

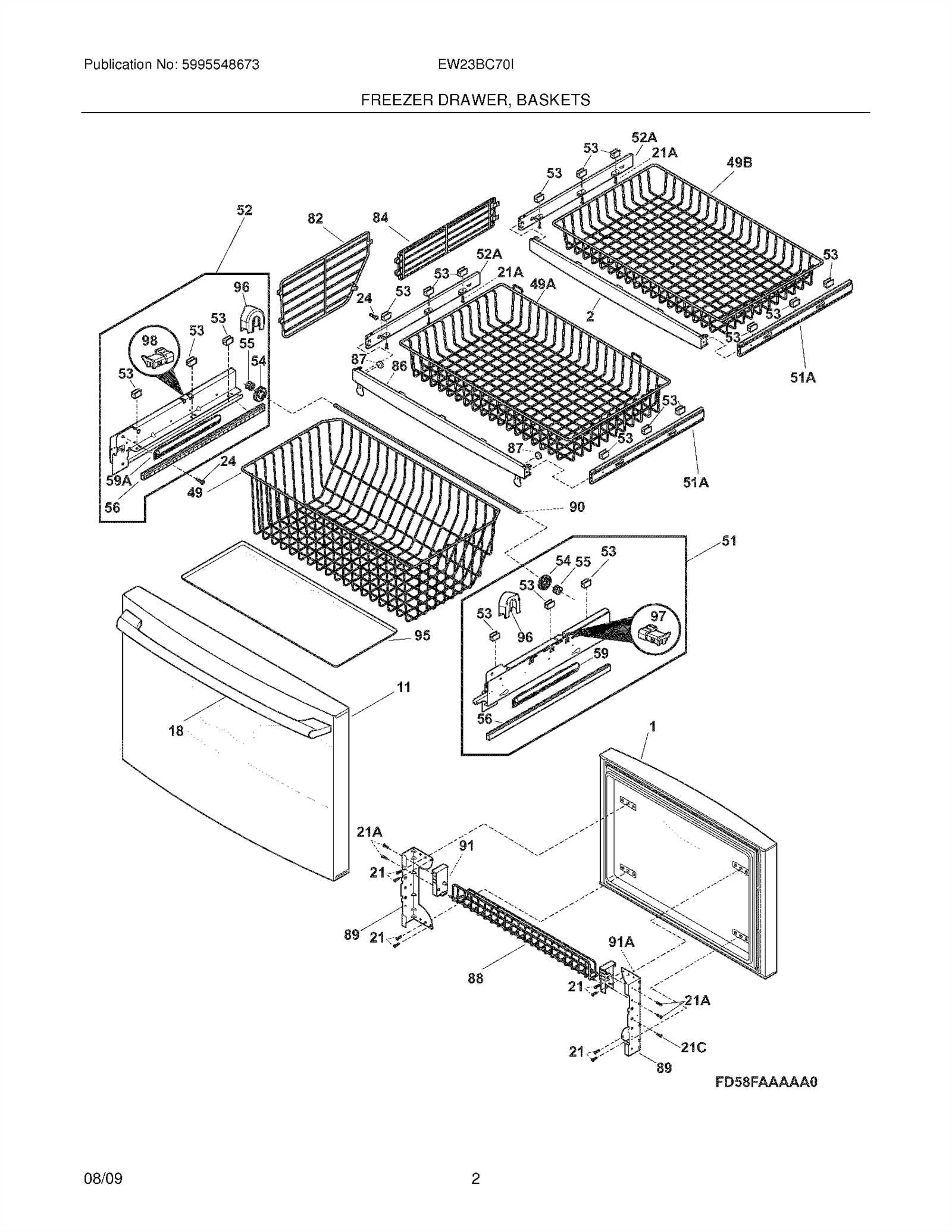

Racks and Trays: Their Design and Purpose

Racks and trays are integral components of any cleaning system, serving as the foundation for organizing and holding items during the washing cycle. These elements are designed with functionality and efficiency in mind, ensuring that each item is placed in a way that maximizes cleaning potential while preventing damage.

- Design Considerations: The layout and structure of racks and trays are carefully crafted to accommodate a variety of item types, from delicate glasses to sturdy pots. The spacing between bars or slots is optimized to ensure proper water flow and air circulation, promoting effective cleaning.

- Materials: Most racks and trays are made from durable materials like stainless steel or plastic coatings that resist corrosion and damage from high temperatures. The materials chosen are selected for their ability to withstand constant exposure to moisture and heat without compromising performance.

- Adjustability: Some models feature adjustable racks, allowing users to customize the arrangement depending on the size and shape of the items being cleaned. This feature enhances flexibility and ensures a better fit for larger or bulkier objects.

- Purpose: The primary goal of racks and trays is to hold items securely while ensuring that water jets or cleaning solutions can reach all surfaces evenly. This organization helps achieve thorough cleaning and allows for efficient use of space.

Steps to Diagnose Part Failures

Understanding how to identify component malfunctions can significantly improve the efficiency of troubleshooting any malfunctioning home appliance. Proper diagnosis starts with a systematic approach to ensure no possible issue goes unnoticed. By following a step-by-step procedure, it becomes easier to isolate faulty elements and determine the best solution for repair.

- Begin by examining the overall behavior of the unit during operation. Look for irregular sounds, leaks, or performance issues that could indicate an underlying issue.

- Inspect the connections and wiring. Loose or damaged electrical connections can often be a root cause of malfunctioning mechanisms.

- Check the functionality of each individual mechanism, such as the pump or motor. Use a multimeter or similar tool to test electrical continuity and voltage to verify component health.

- Ensure all moving parts are free of blockages or obstructions. Sometimes, debris or foreign objects can hinder proper functioning.

- Test the water flow system. A malfunction in the water distribution network may lead to poor performance or complete failure of the appliance.

- If necessary, refer to the technical manual for specific guidelines on testing particular components and verifying their operation against factory standards.

- After identifying the malfunctioning part, consider the repair options, which may include replacement or professional servicing, depending on the severity of the issue.