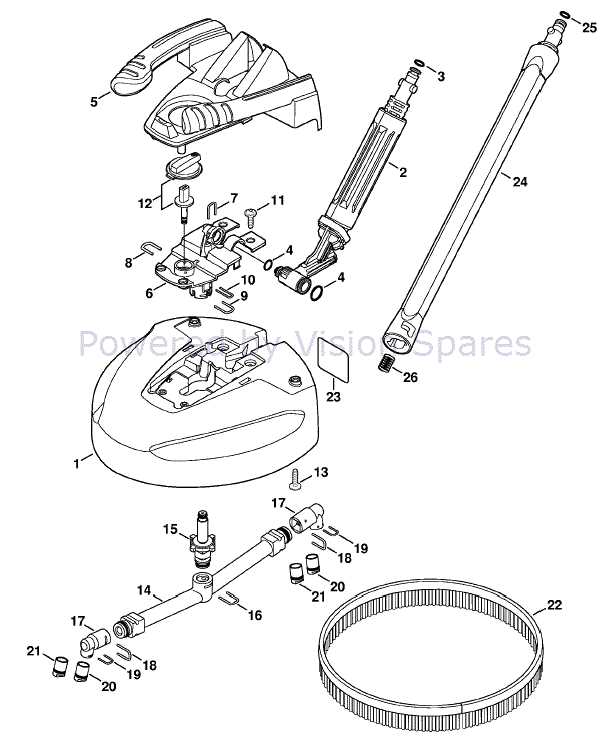

Understanding the internal structure and elements of modern cleaning machines is crucial for effective maintenance and repair. Each device is made up of various interconnected mechanisms that ensure its smooth operation, allowing users to tackle a range of cleaning tasks with efficiency. This section provides a detailed overview of the key elements that make up these tools, helping users familiarize themselves with the intricate design of the equipment.

Key elements play a vital role in ensuring the long-lasting performance of the machinery. From high-pressure nozzles to various filters and seals, each part works together to deliver optimal functionality. Knowing the function and location of these components allows for easier identification and replacement, ensuring that the equipment remains in top condition.

Whether you are performing routine maintenance or troubleshooting issues, a clear understanding of the machine’s design is essential. This guide will highlight the

Understanding the Components of Pressure Washers

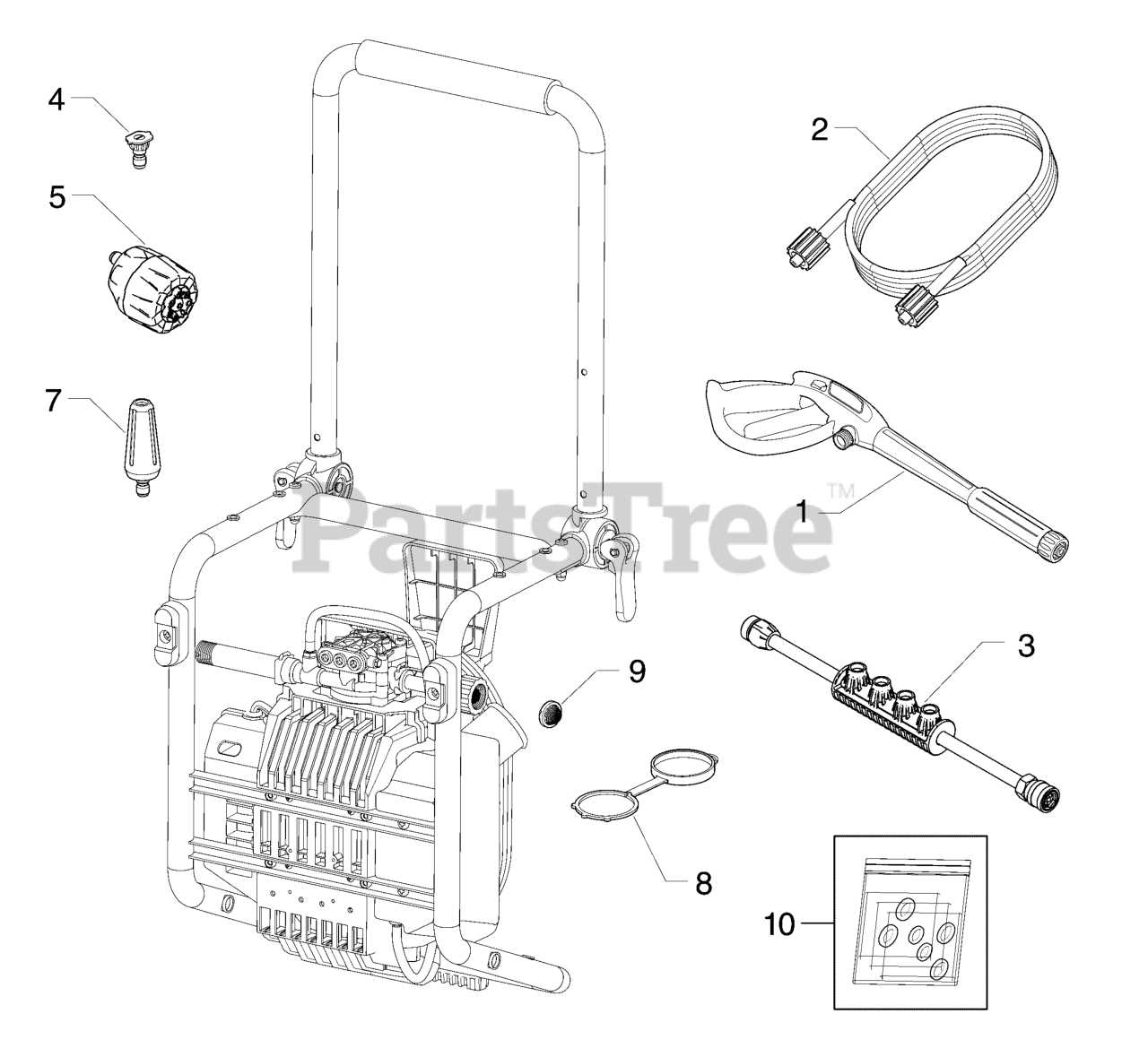

Every cleaning system with water-based technology is built from essential components that work together to ensure efficient performance. Knowing the key elements of such systems helps users maintain, troubleshoot, and get the most out of their equipment. Let’s explore some of the primary elements that are critical for these machines to function optimally.

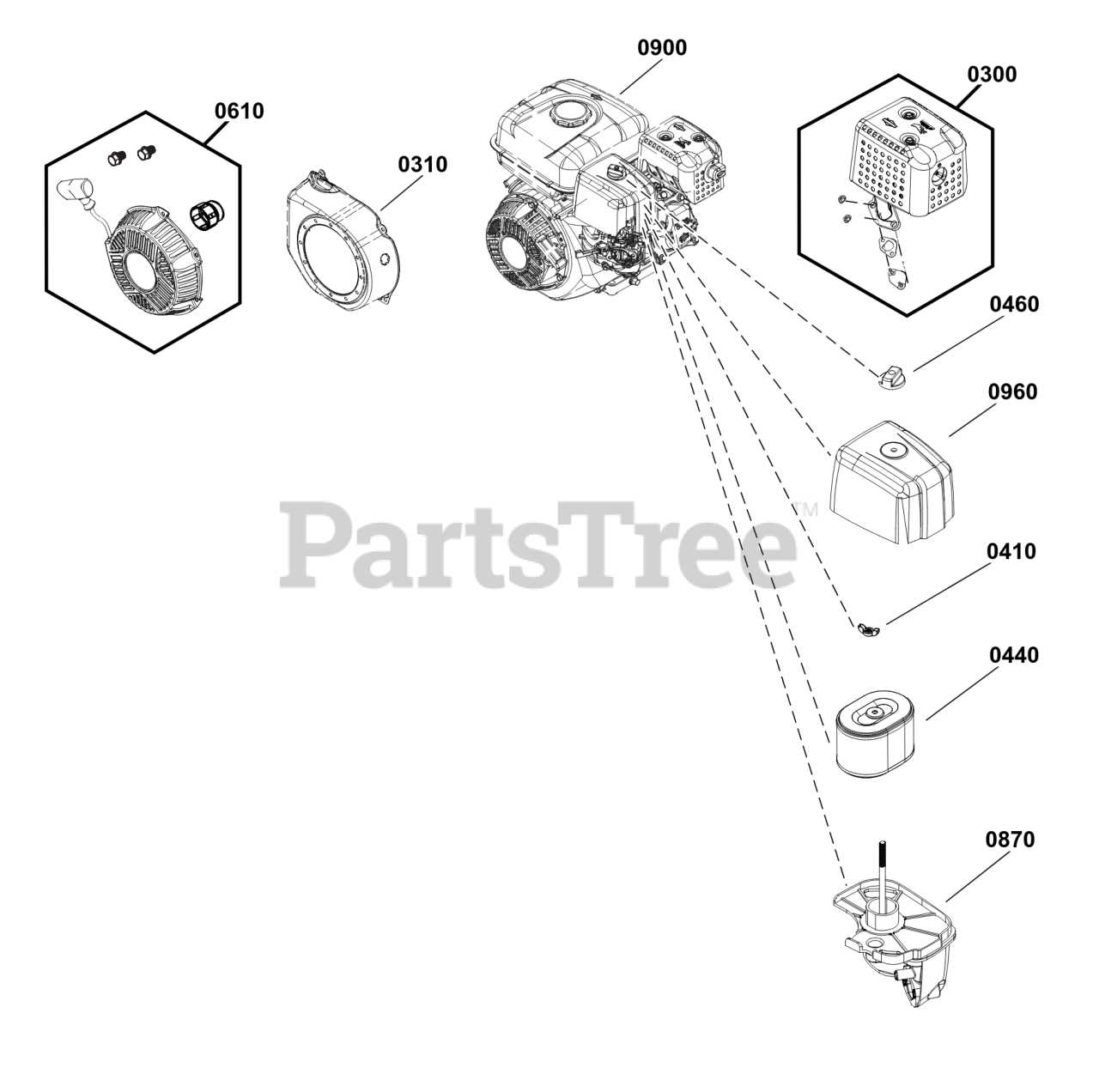

Motor and Pump

The motor powers the entire system, driving the pump that pushes water through the unit. The pump is the core of the device, and without it, water cannot reach the desired pressure level. Regular maintenance of both the motor and the pump ensures long-term reliability.

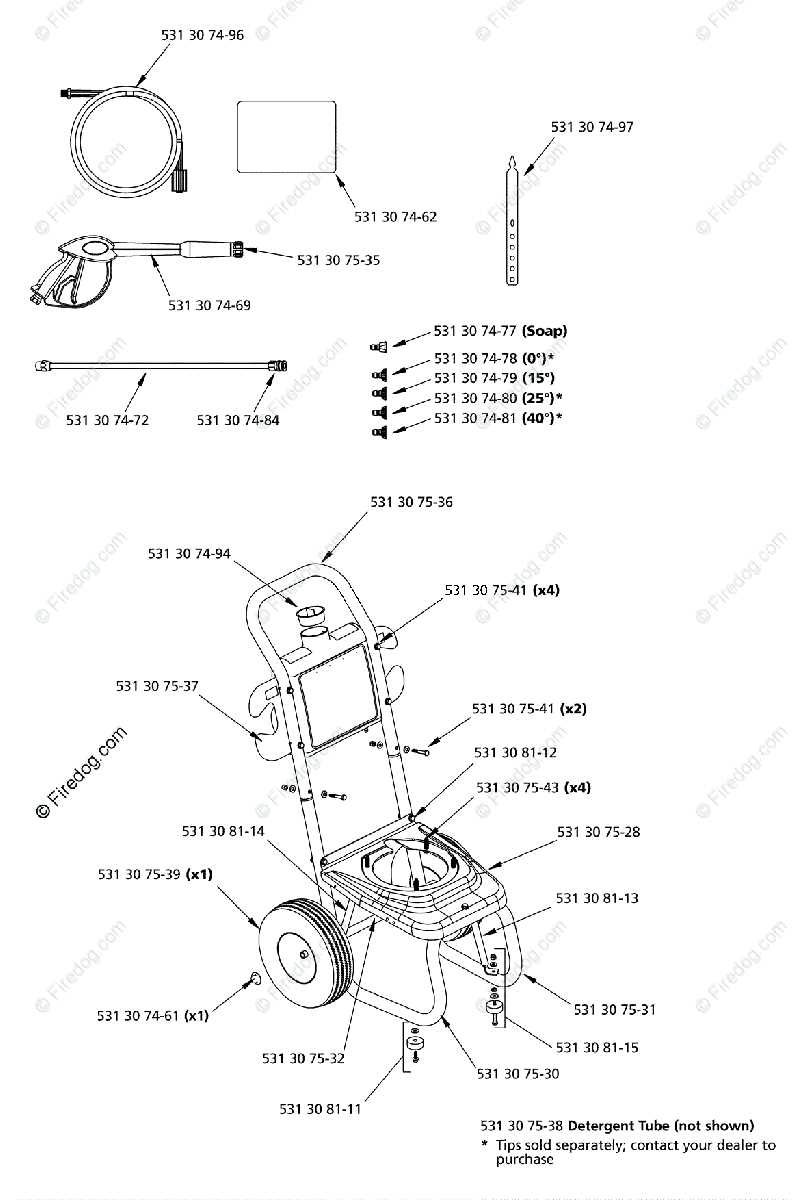

Hoses and Nozzles

Hoses direct the water flow, while nozzles control the water output,

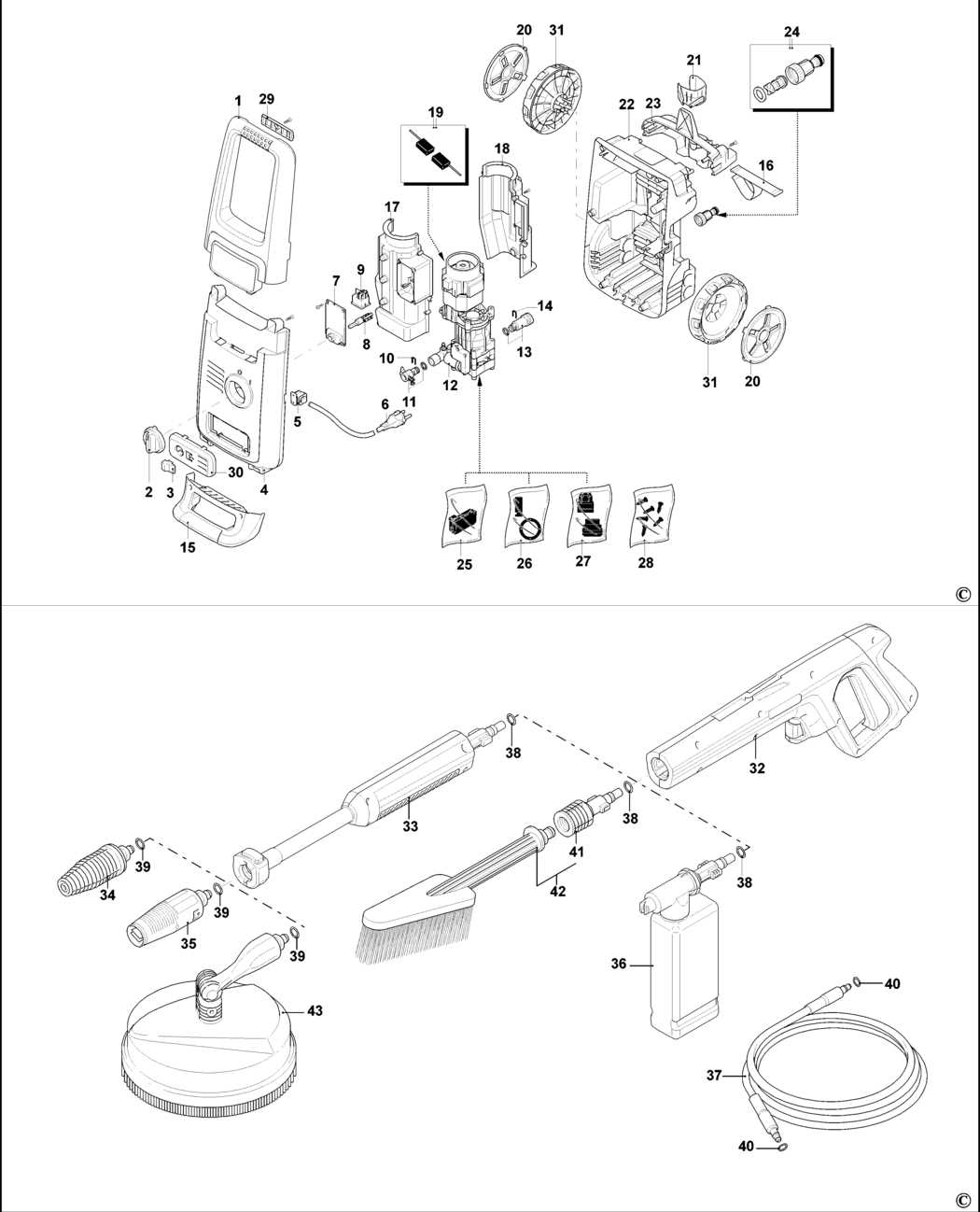

Key Elements in High-Pressure Systems

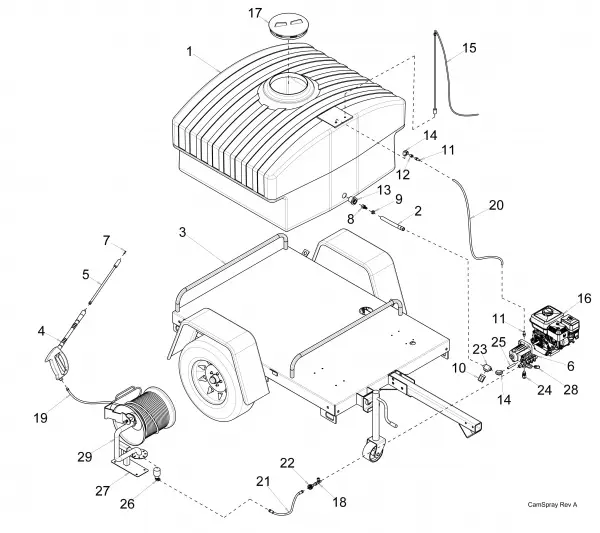

In systems designed for intensive water flow and cleaning, several core components work together to achieve optimal functionality. Each element plays a crucial role in ensuring efficiency and reliability, contributing to the overall performance of the equipment. Understanding these components helps in maintaining and enhancing the system’s operation.

One of the essential elements is the pump, responsible for driving the flow of liquid through the system. The power source, whether electric or fuel-driven, supplies the necessary energy for the system’s operation. Hoses and connectors, built to withstand high-force output, ensure safe and effective transmission of water.

Another key aspect is the control mechanism, which allows the user to adjust settings for various tasks. Proper filtration is also critical, preventing debris from entering the system and causing damage. Each of these components must work harmoniously to ensure smooth and effective operation.

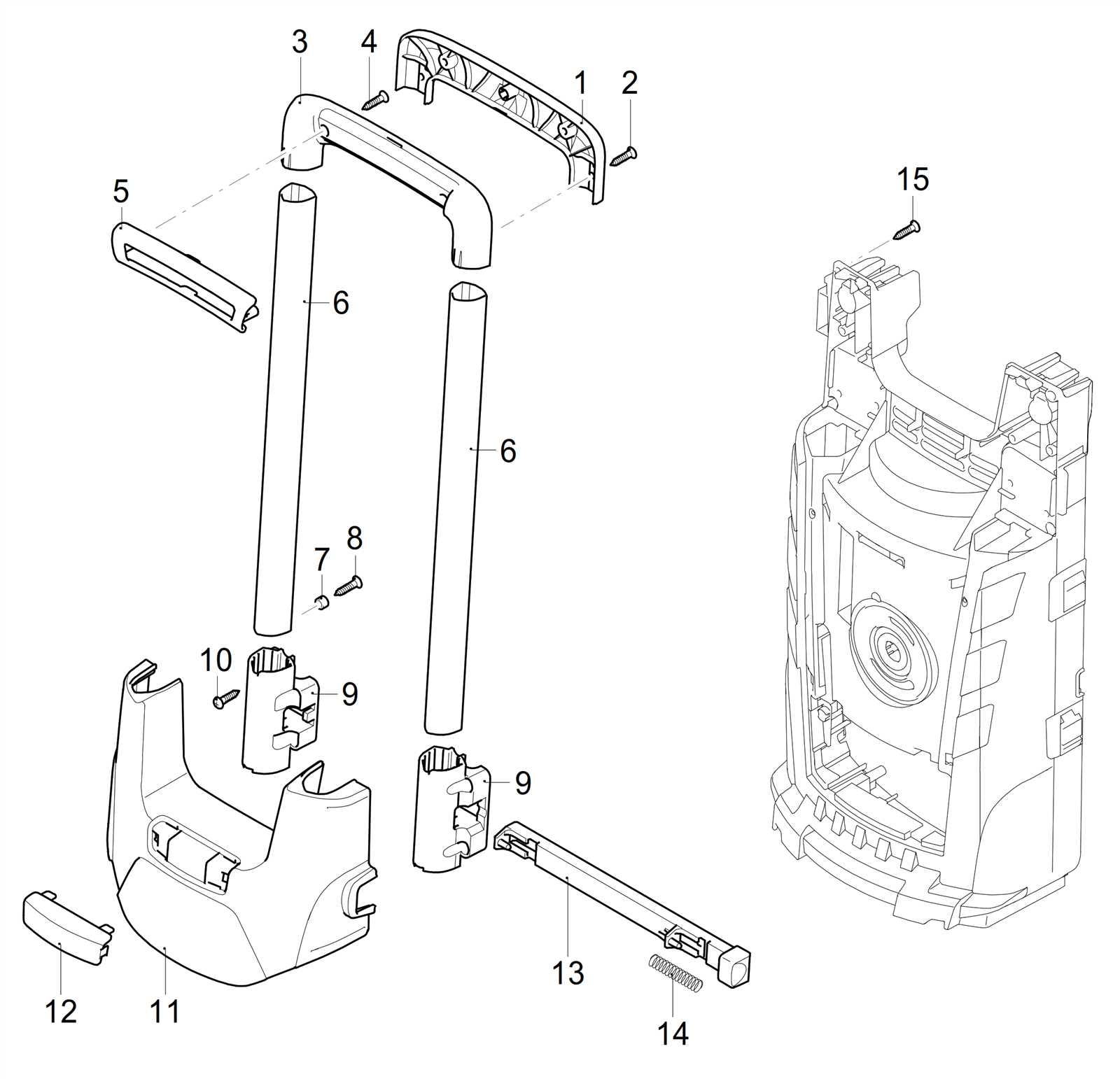

Identifying Vital Parts in a Washer

Understanding the key components of a cleaning machine is essential for its efficient use and maintenance. Each element plays a specific role in ensuring the device operates smoothly and effectively.

Motor: The driving force behind the machine, the motor powers the entire cleaning process. Without a well-functioning motor, the device cannot generate the required energy for operation.

Pump: The pump is the heart of the system, responsible for managing the flow of water. It regulates pressure, ensuring the right amount of force is applied during cleaning.

Nozzle: This component controls the spray pattern and intensity. Choosing the correct nozzle ensures you can tackle various surfaces with precision and efficiency.

Hoses and val

Essential Components for Optimal Performance

To achieve the best results, it’s crucial to understand the key elements that contribute to the overall effectiveness of your cleaning device. These components work together to ensure smooth operation, longevity, and reliable performance during heavy-duty tasks.

Motor: The engine plays a vital role in providing consistent power. A well-maintained motor ensures efficient function and supports extended usage without interruptions.

Nozzle Options: Various nozzle attachments allow for different levels of pressure, making them essential for tackling diverse surfaces and cleaning needs. Choosing the correct nozzle optimizes both time and effort.

Water Hose: A durable and flexible hose enhances the flow of water, reducing the risk of damage and ensuring that cleaning operations remain smooth. High-quality hoses are designed to withstand wear and tear over time.

Exploring Nozzle Variations and Functions

Nozzles play a crucial role in determining the efficiency and adaptability of cleaning systems. By altering water flow and pressure, different types of nozzles can greatly affect the performance, making them essential for various tasks. Each nozzle design is suited for specific applications, from gentle rinsing to more concentrated, powerful cleaning.

Types of Nozzles

- Standard Nozzle: Offers a balance between coverage and power, suitable for most general cleaning needs.

- Rotary Nozzle: Combines high power with a rotating motion, making it ideal for removing tough grime and stains.

- Fan Nozzle: Creates a wide spray pattern, perfect for covering large surfaces quickly.

- Turbo Nozzle: Maximizes pressure by

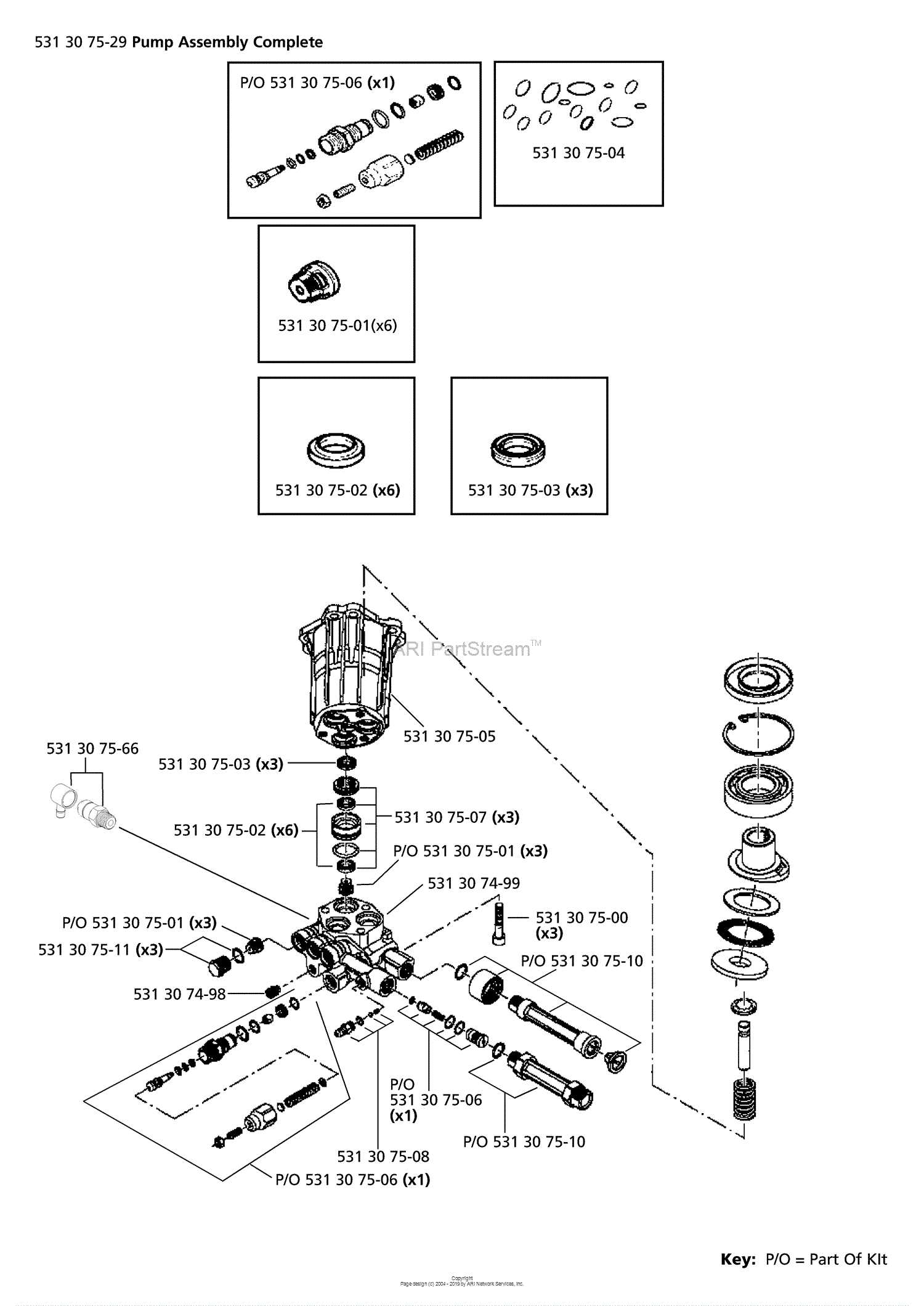

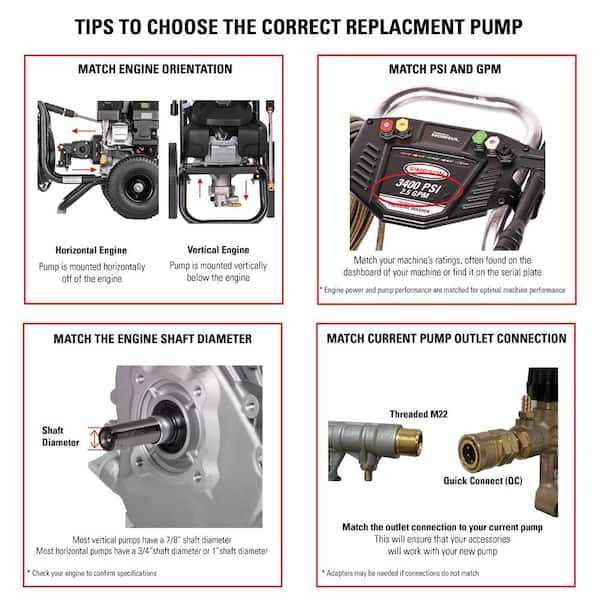

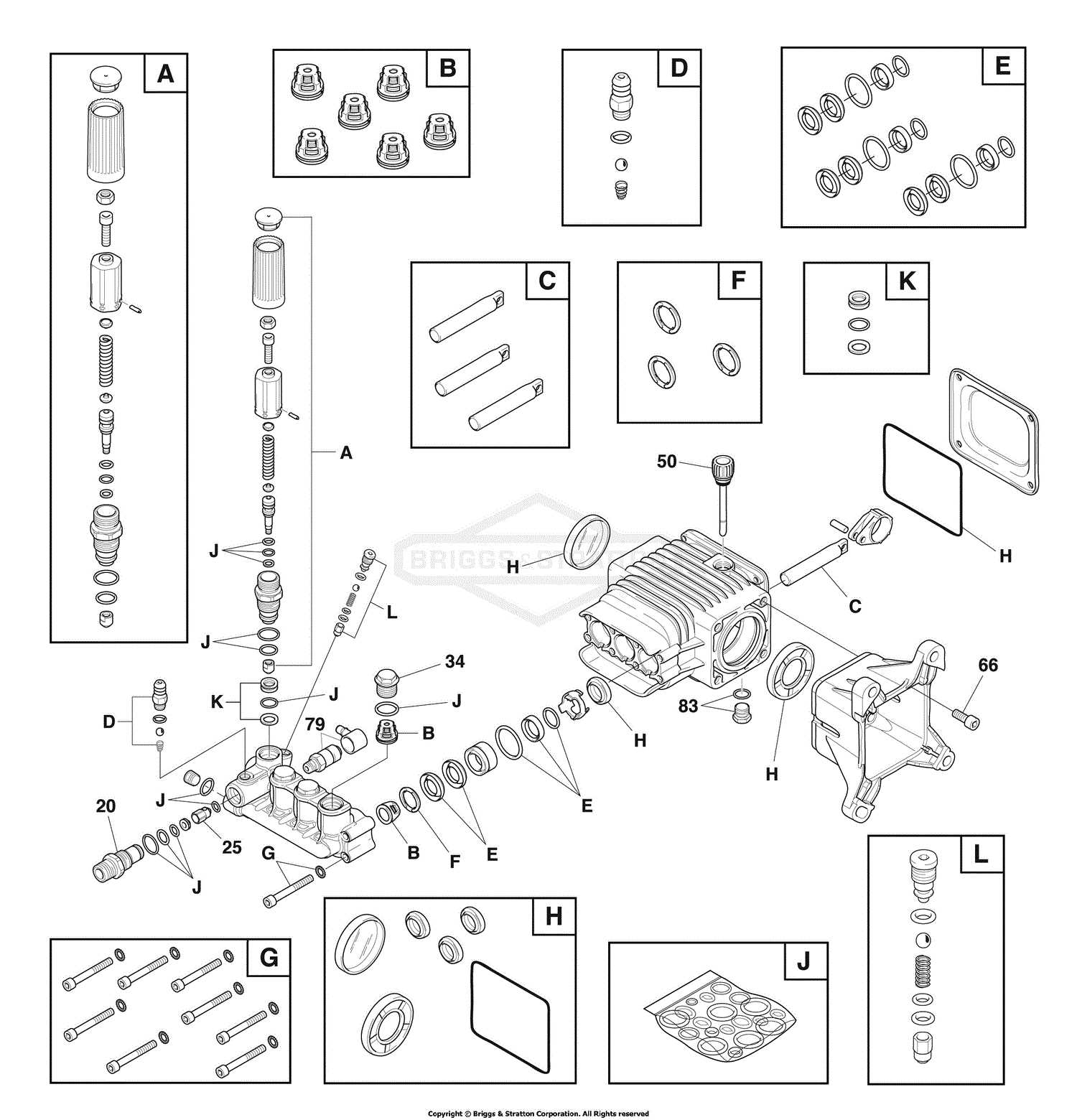

Pump Mechanism in Pressure Washers Explained

The pump system is a vital component in cleaning machines, responsible for generating high-pressure water flow. This mechanism converts the energy from a motor into hydraulic energy, enabling the equipment to effectively remove dirt and grime from various surfaces. Understanding how this mechanism functions helps in maintaining and troubleshooting the device efficiently.

How the Pump Operates

The operation of the pump involves several key stages. Initially, water enters the system through an inlet, where it is drawn into the pump’s chamber. As the motor runs, it activates the pump, which creates a vacuum effect, drawing in more water. This water is then pressurized through a series of pistons or diaphragms, ultimately forcing it out through the nozzle at high speed.

Key Components of the Pump System

Several essential components contribute to the efficient operation of the pump. These parts work together to ensure the reliability and effectiveness of the cleaning equipment.

Component Function Inlet Valve Controls water flow into the pump Piston Creates pressure by moving water Outlet Valve Regulates the release of pressurized water Motor Drives the pump mechanism How Filters Impact Efficiency

Filters play a crucial role in maintaining optimal performance and longevity of cleaning equipment. They are designed to remove contaminants from the fluid, ensuring that the system operates smoothly and efficiently. Without effective filtration, various components can suffer from wear and tear, leading to decreased functionality.

There are several ways in which filters enhance efficiency:

- Improved Fluid Quality: Filters prevent debris and particulates from entering the system, which helps maintain the purity of the fluid used.

- Extended Equipment Life: By removing harmful substances, filters reduce the risk of damage to internal components, thus prolonging the lifespan of the machine.

- Consistent Performance: Clean fluid flow allows for stable operation, ensuring that the equipment performs at its best under various conditions.

- Reduced Maintenance Costs: Efficient filtration minimizes the need for frequent repairs and replacements, leading to cost savings over time.

In summary, the importance of filters cannot be overstated. They are essential for ensuring that cleaning equipment functions optimally, reduces the likelihood of failures, and enhances overall efficiency.

Critical Hoses and Their Role in Cleaning

In the realm of effective cleaning solutions, certain flexible conduits play an essential role in ensuring optimal performance. These components facilitate the transfer of fluid, allowing for a powerful and efficient cleaning process. Understanding their significance can enhance the overall effectiveness of cleaning tasks.

Importance of High-Pressure Hoses

High-pressure hoses are designed to withstand intense force, delivering water at elevated speeds. This capability is crucial for removing stubborn dirt and grime from various surfaces. Their robust construction prevents leaks and ensures longevity, making them indispensable in any cleaning setup.

Flexible Connection Hoses

Flexible connection hoses provide versatility in maneuvering around obstacles. Their adaptability allows users to reach difficult areas, ensuring thorough cleaning. Additionally, the ability to easily detach and replace these hoses contributes to maintenance efficiency, prolonging the lifespan of the entire cleaning apparatus.

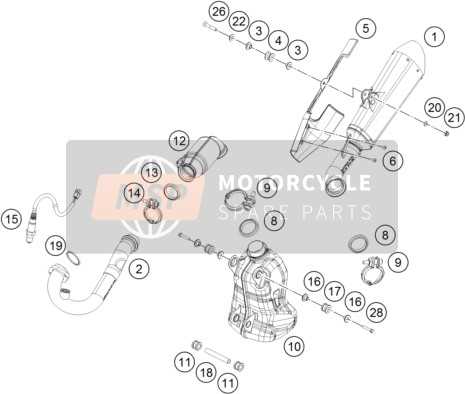

Power Supply and Electrical Connections

Ensuring a reliable energy source and proper electrical linkages is crucial for optimal functioning of cleaning equipment. The supply of power plays a vital role in the performance and efficiency of the device, as it affects how well it operates under various conditions. Understanding the configuration and maintenance of electrical components can greatly enhance the longevity and reliability of the machine.

Understanding Power Supply Requirements

Before operating the equipment, it is essential to verify that the voltage and amperage specifications match the requirements of the device. Utilizing a power source that does not meet these specifications can lead to malfunction or damage. Always consult the manufacturer’s guidelines to ensure compatibility with the local electrical system.

Electrical Connections and Safety Precautions

Proper connections are necessary to prevent hazards such as short circuits or electrical failures. It is important to inspect all cables and connectors for wear and tear regularly. Using high-quality extension cords and ensuring they are rated for the appropriate load can help maintain safe and efficient operation. Always disconnect the equipment from the power source before performing any maintenance or inspection to ensure safety.

Maintenance Tips for Long-Lasting Parts

Ensuring the longevity of your equipment requires proper upkeep and attention. Regular maintenance not only enhances performance but also prolongs the lifespan of individual components. By adopting simple yet effective practices, users can avoid premature wear and tear while maintaining optimal functionality.

1. Regular Cleaning: After each use, it’s essential to clean the components thoroughly. Remove any debris or residue that may have accumulated, as these can hinder performance and lead to damage over time.

2. Lubrication: Periodically apply suitable lubricants to moving parts to reduce friction. This practice minimizes wear and keeps mechanisms operating smoothly.

3. Check for Wear: Regularly inspect components for signs of wear or damage. Early detection of issues can prevent more significant problems and costly repairs in the future.

4. Store Properly: When not in use, store your equipment in a dry, sheltered area. This protects it from environmental factors that can cause corrosion or other forms of damage.

5. Follow Manufacturer Guidelines: Adhering to the manufacturer’s recommendations for maintenance and service intervals is crucial. These guidelines are designed to optimize performance and ensure reliability over time.

By implementing these maintenance tips, users can significantly extend the life of their equipment and ensure reliable operation for years to come.