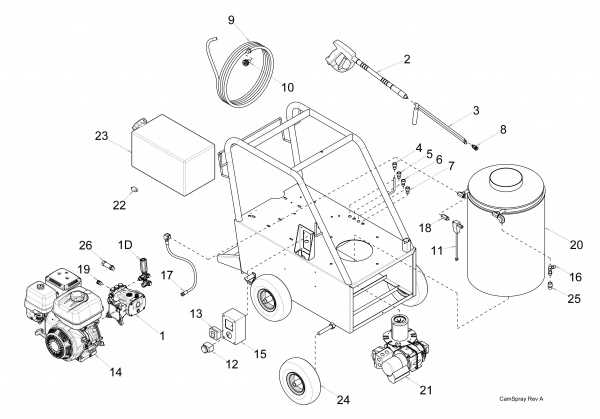

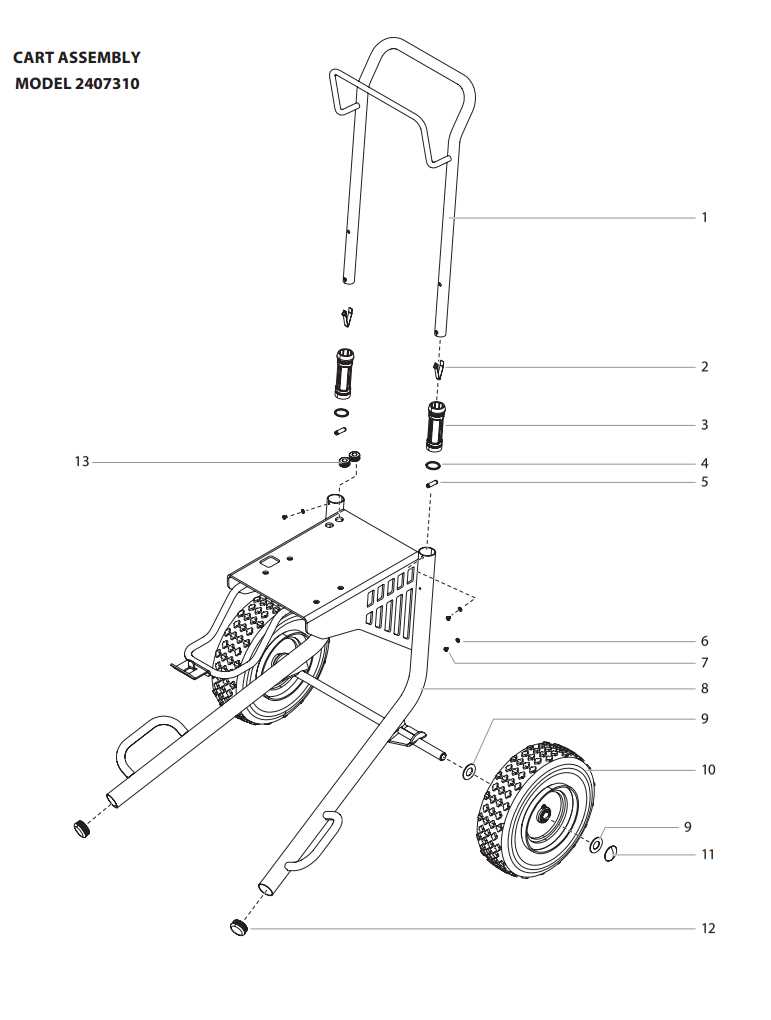

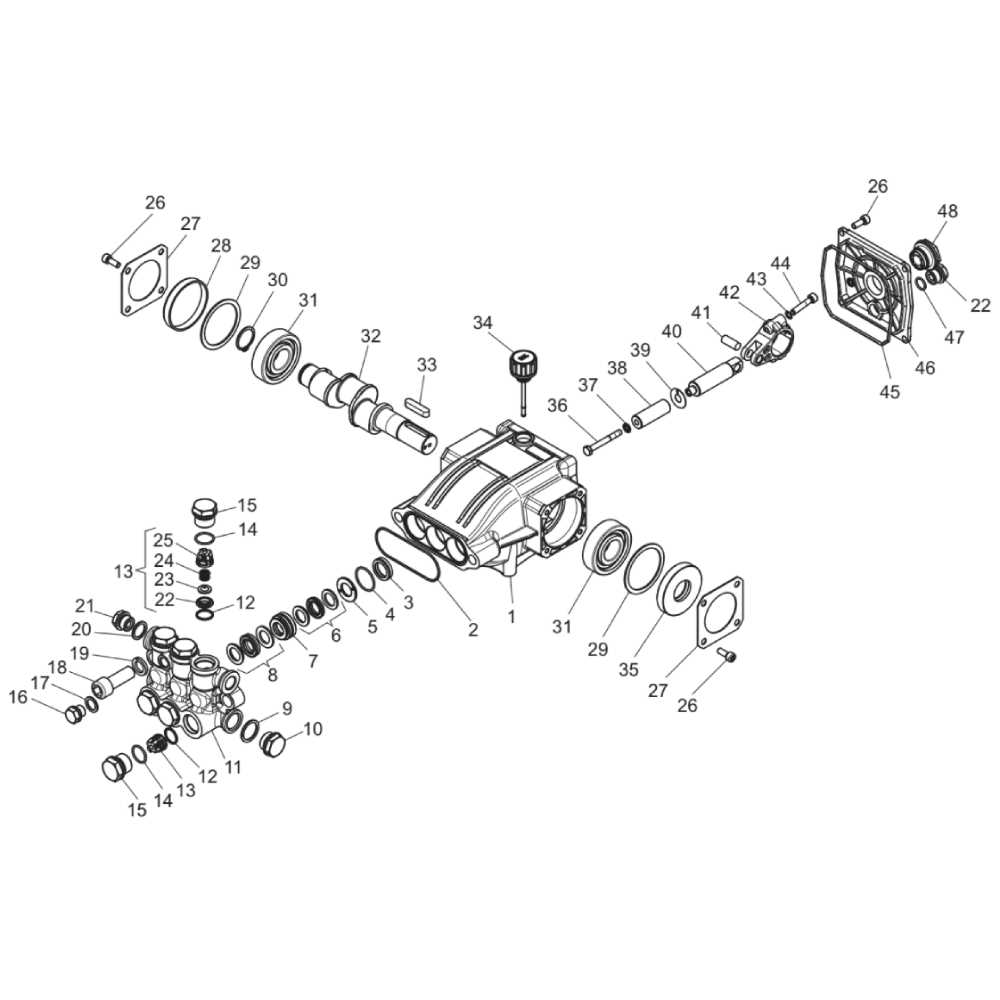

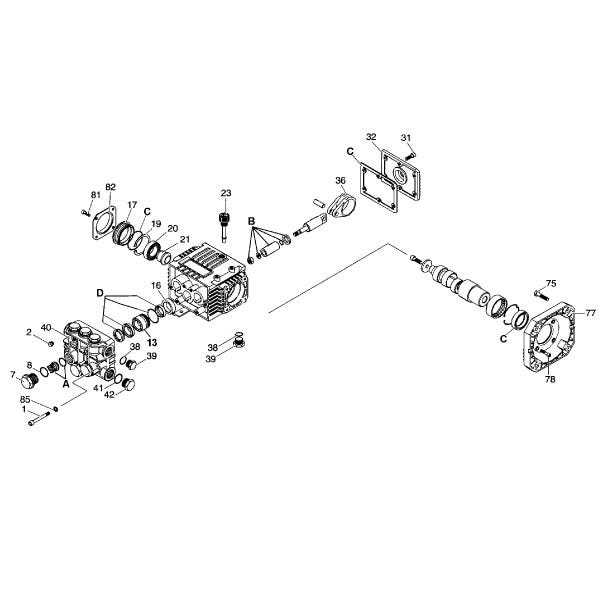

Understanding the essential elements of complex systems is crucial for ensuring their proper functionality and longevity. In this section, we will explore the various interconnected units that make up the core of the equipment. Each part has a specific role, contributing to the overall performance and durability of the system.

We’ll examine the individual components, how they interact, and their significance in maintaining efficient operation. By visualizing the arrangement and understanding the functions of these elements, you can better address any issues that may arise and optimize the use of your device.

Whether you’re performing regular maintenance or troubleshooting, having a clear picture of how everything fits together will provide invaluable insight into the system’s workings, making it easier to identify and replace any malfunctioning elements.

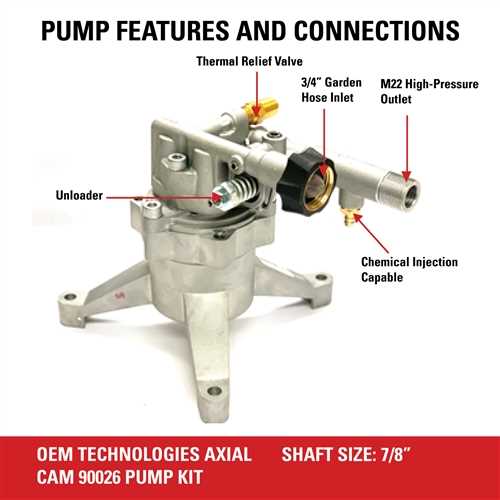

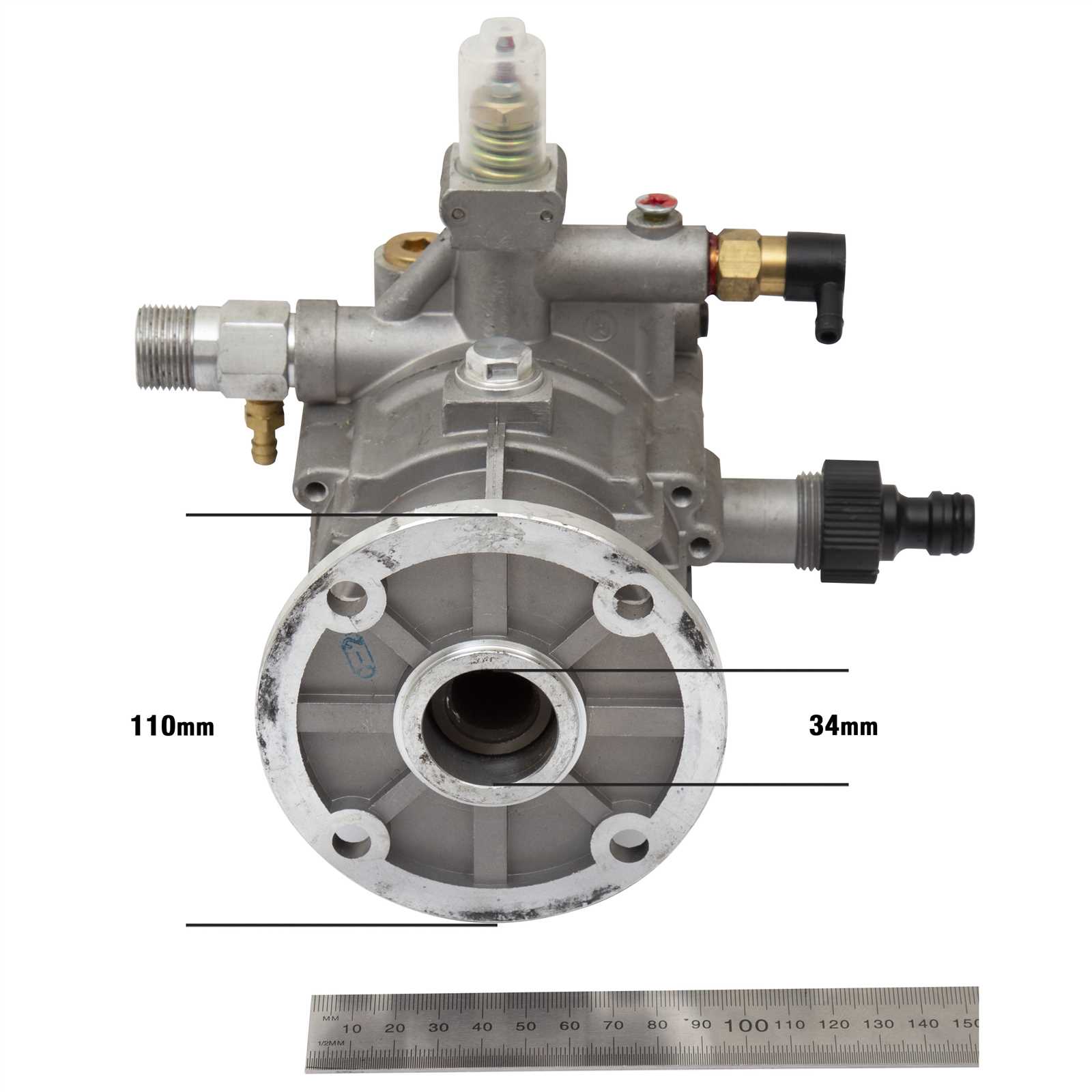

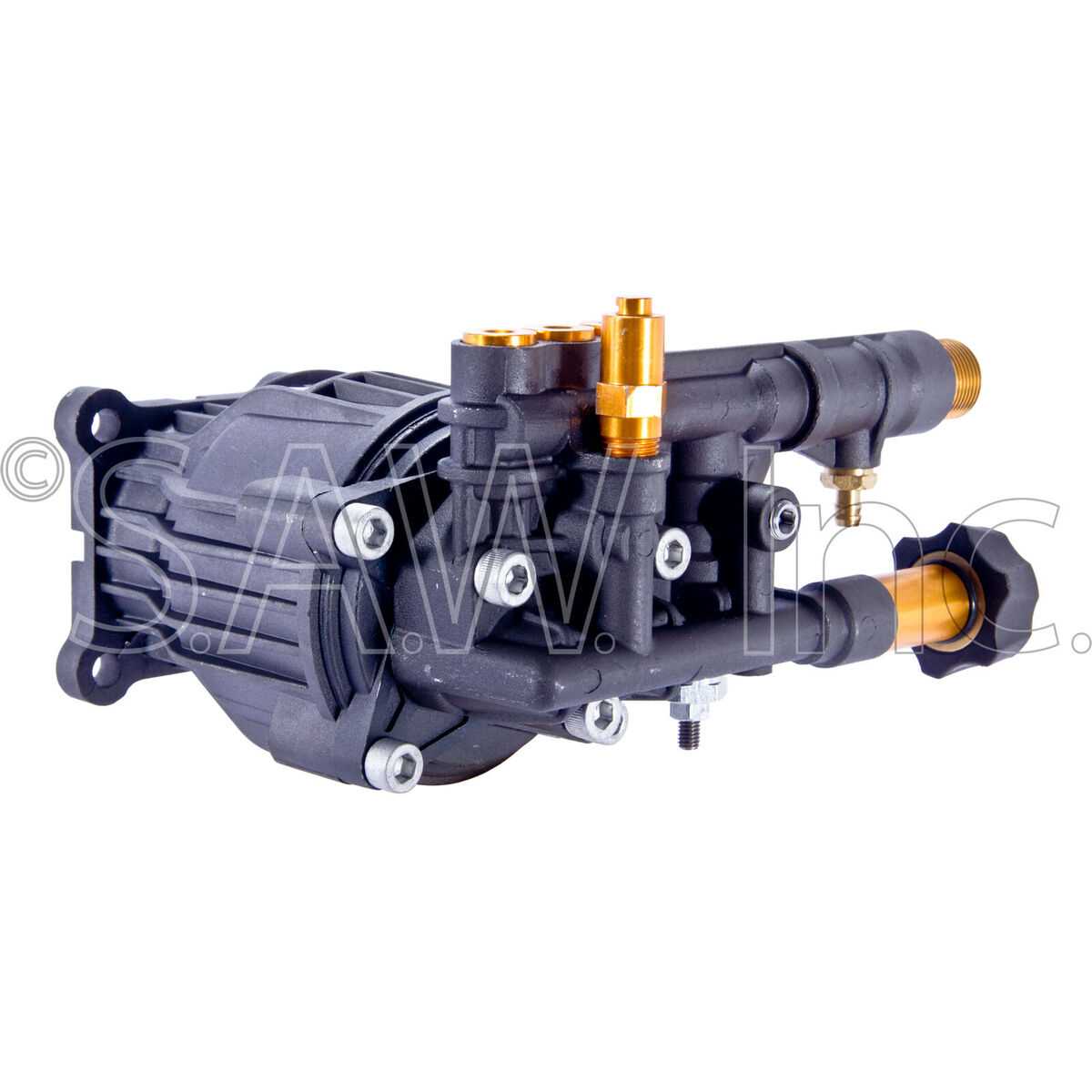

Simpson Pressure Washer Pump Overview

The core mechanism driving high-powered cleaning devices is a crucial element designed to deliver consistent water flow at the necessary force. This component ensures that water is propelled through the system with enough intensity to effectively remove dirt, grime, and other substances from various surfaces. Its structure consists of various intricate parts working together to achieve optimal performance.

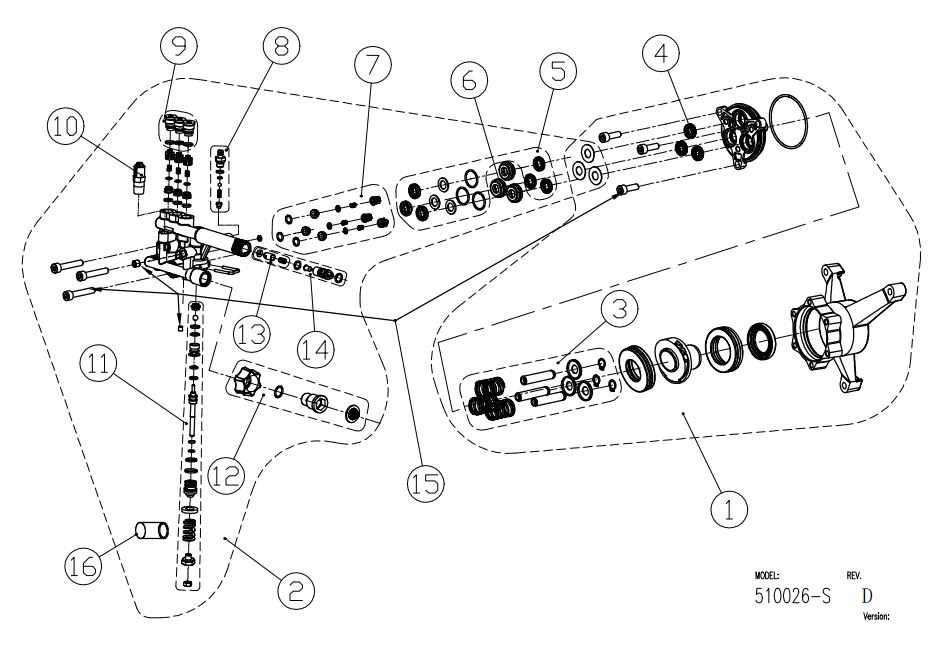

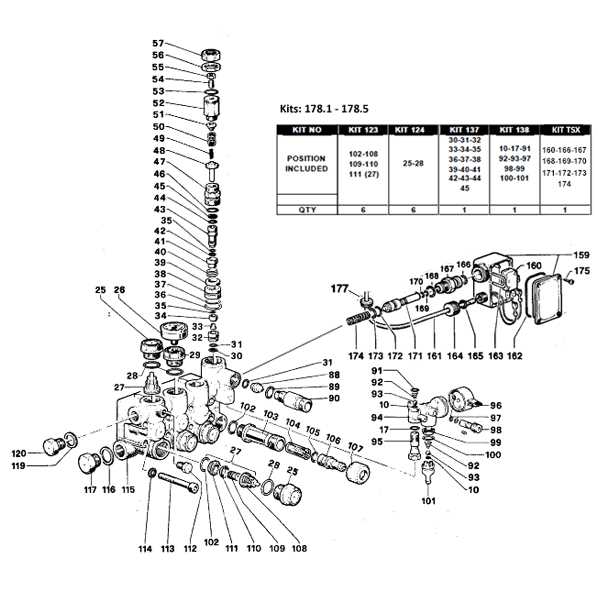

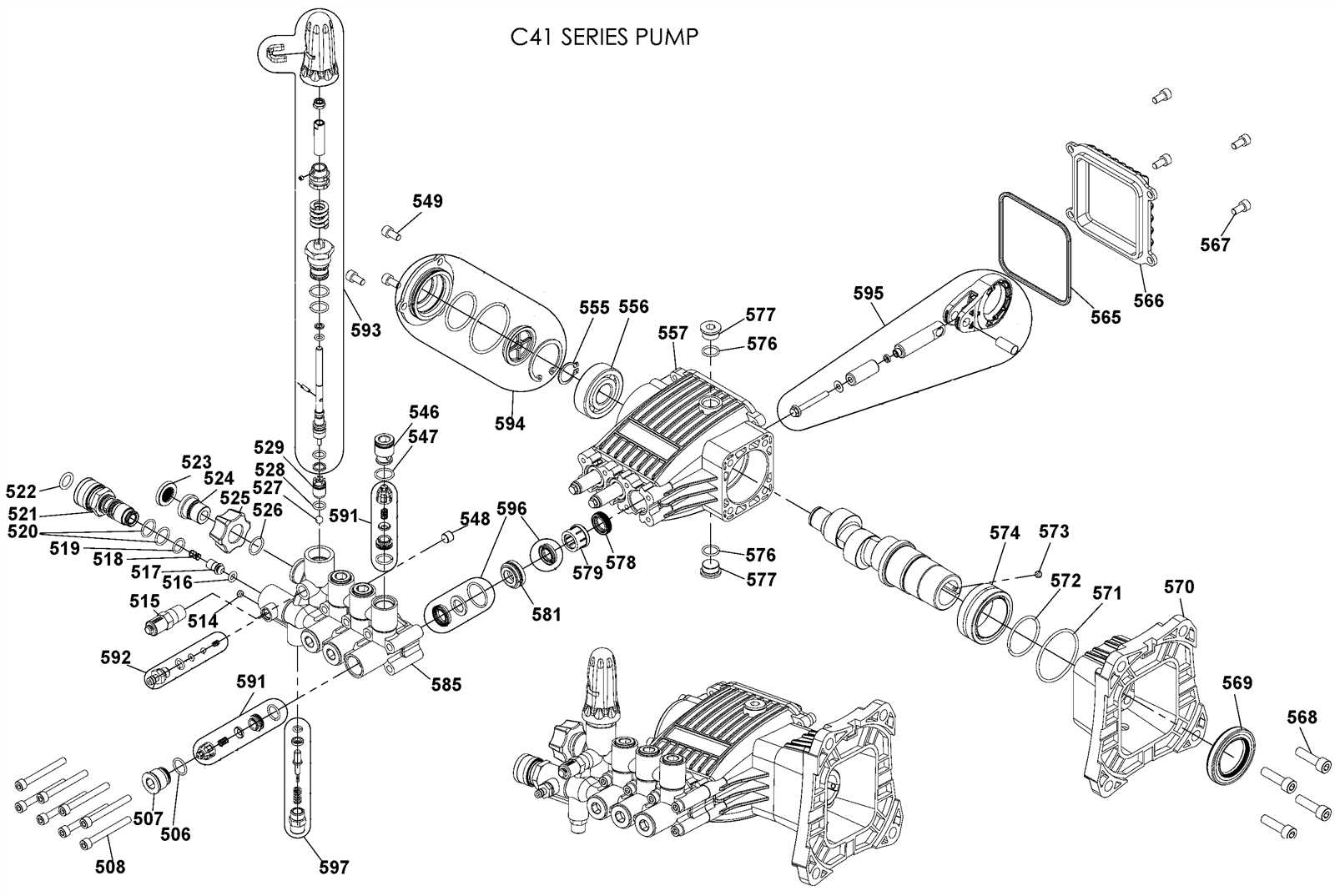

Key Components and Functions

The main assembly features several key elements that work in unison to maintain efficiency. These include valves, pistons, and seals, all of which are essential in ensuring smooth operation. Each part has a distinct role in regulating fluid dynamics and preventing leakage, thereby enhancing the durability of the entire system.

Material and Durability

The materials used in crafting the core assembly are carefully selected to withstand high levels of wear and tear. Most of these components are made from corrosion-resistant metals, ensuring long-term functionality even under strenuous use. This helps the device maintain its effectiveness over time.

| Issue | Description | Solution | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Loss of Pressure | Insufficient water pressure can occur due to blockages or leaks in hoses. |

| Function | Impact on System |

|---|---|

| Compression of fluid | Increases pressure and flow rate |

| Sealing | Prevents leaks and ensures efficiency |

| Movement | Facilitates the cyclical operation of the system |

Understanding the mechanics behind pistons allows for better maintenance and optimization of the entire assembly. Regular checks and timely replacements can prevent malfunctions, ensuring consistent performance and extending the lifespan of the machinery.

Preventing Wear and Tear in the Pump

Maintaining optimal performance and extending the lifespan of your equipment requires a proactive approach to reducing degradation. By adopting effective practices, users can minimize wear and ensure reliable functionality over time.

Regular Maintenance Procedures

- Inspect components regularly for signs of damage or excessive wear.

- Clean filters and screens to prevent clogging and ensure smooth operation.

- Check and replace any seals or gaskets that show signs of deterioration.

- Keep the surrounding area free of debris to avoid unnecessary strain on the machinery.

Usage Recommendations

- Avoid running the equipment for extended periods without breaks to prevent overheating.

- Use the correct fluids and lubricants as specified by the manufacturer to enhance efficiency.

- Store the machine in a dry place to prevent moisture-related damage.

- Follow operating guidelines to ensure that the equipment is not overworked or misused.

By implementing these strategies, users can significantly reduce wear and maintain optimal performance, ensuring a longer service life for their machinery.

Benefits of Regular Pump Cleaning

Maintaining the functionality of your equipment is crucial for optimal performance and longevity. Regular cleaning of the internal mechanisms can prevent buildup that leads to inefficiencies and malfunctions. By ensuring that your device remains free of debris and contaminants, you can enhance its operational lifespan and reliability.

Here are some key advantages of consistently keeping the internal components clean:

- Improved Efficiency: A clean system operates more smoothly, allowing for better performance and reduced energy consumption.

- Extended Lifespan: Regular maintenance minimizes wear and tear, prolonging the life of the equipment and reducing the need for costly replacements.

- Reduced Risk of Damage: Removing debris and buildup can prevent clogs and other issues that may lead to severe damage.

- Enhanced Safety: Keeping components clean helps maintain safe operating conditions, reducing the likelihood of accidents caused by malfunctions.

- Cost-Effectiveness: Investing time in routine cleaning can save money in the long run by decreasing repair costs and extending the intervals between professional servicing.

Incorporating regular cleaning into your maintenance routine not only enhances the overall functionality of your equipment but also contributes to a safer and more efficient working environment.

Upgrading Your Pump for Better Efficiency

Improving the efficiency of your cleaning device can lead to enhanced performance and reduced operational costs. By considering upgrades to specific components, you can achieve a more effective cleaning experience while maximizing water usage and energy consumption. This section explores various options to enhance your system’s functionality.

Choosing High-Quality Components

Investing in superior components can significantly impact the overall performance of your cleaning equipment. Upgrading to more durable materials can enhance longevity and reliability. Look for options that offer better resistance to wear and tear, as this can prevent breakdowns and reduce the need for frequent replacements.

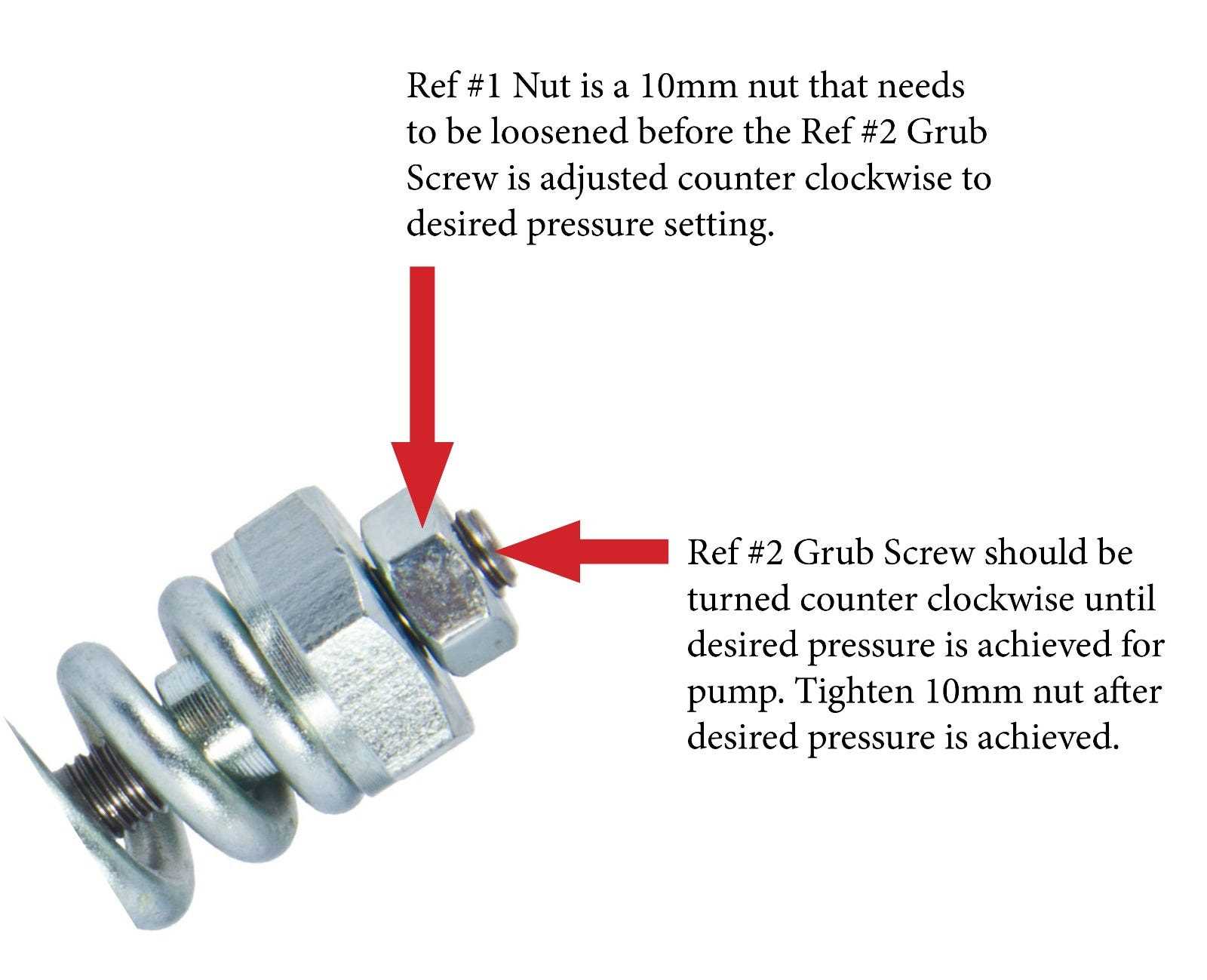

Optimizing Flow and Pressure

Enhancing the flow rate and pressure can dramatically improve cleaning efficiency. Consider replacing the existing components with higher-capacity alternatives that maintain optimal performance. This adjustment not only speeds up the cleaning process but also ensures that surfaces are thoroughly cleaned, ultimately saving time and effort.

In summary, by focusing on quality upgrades and optimizing key functionalities, you can significantly improve the efficiency of your cleaning apparatus, leading to a more productive and cost-effective operation.