The internal construction of household devices used for garment cleaning can often seem complex. However, by exploring the detailed configuration of these systems, you can gain a clearer understanding of how each element contributes to the overall functionality. This guide focuses on the specific elements found in commonly used fabric care appliances, helping you navigate their functions and maintenance requirements.

In this comprehensive overview, we’ll break down the essential elements that make up these fabric cleaning units, explaining their purpose and the role they play in the device’s operation. From the electrical elements to mechanical parts, each component works in harmony to deliver reliable performance over time.

Whether you are a technician or a curious owner, this detailed look at internal structures will offer insights that enhance your ability to maintain and repair these appliances effectively. By familiarizing yourself with the layout and function of each piece, you can ensure that your equipment continues to operate smoothly for years to

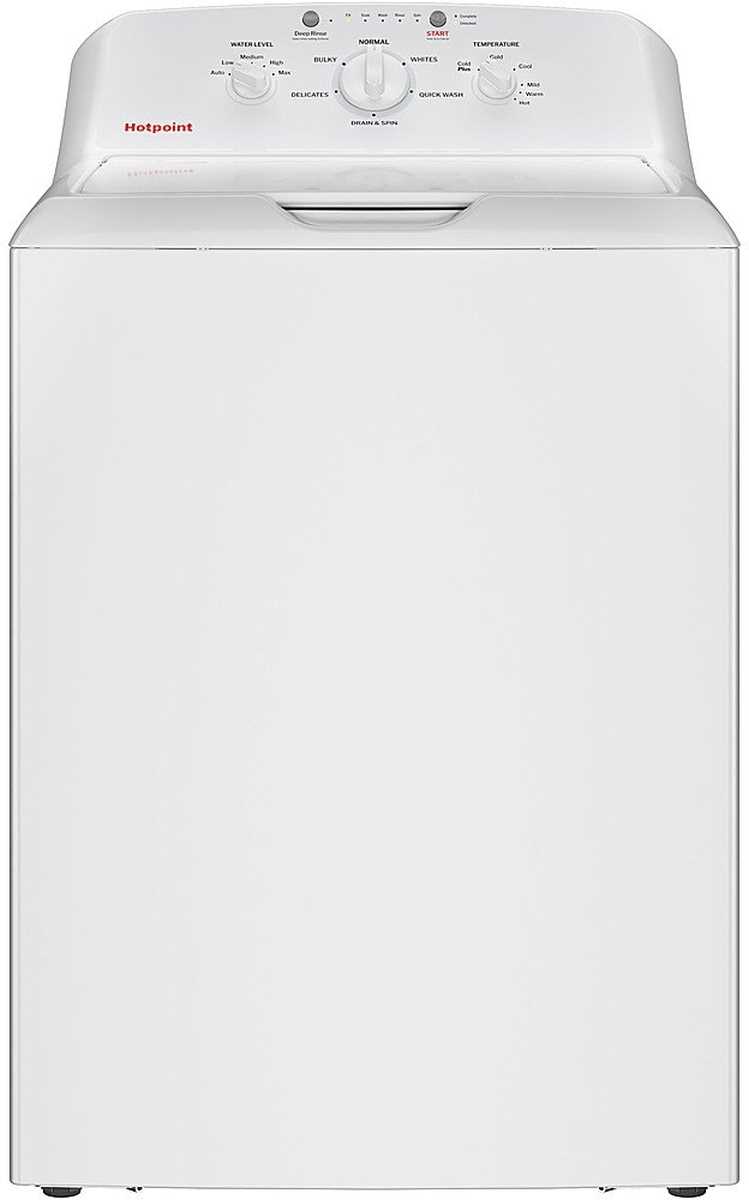

Understanding the Main Components of Speed Queen Washers

In this section, we will explore the fundamental elements that ensure the efficient and reliable operation of these laundry appliances. Each part has a specific role, contributing to the overall performance and durability of the equipment. Understanding these elements can help users with maintenance, troubleshooting, and overall care of their unit.

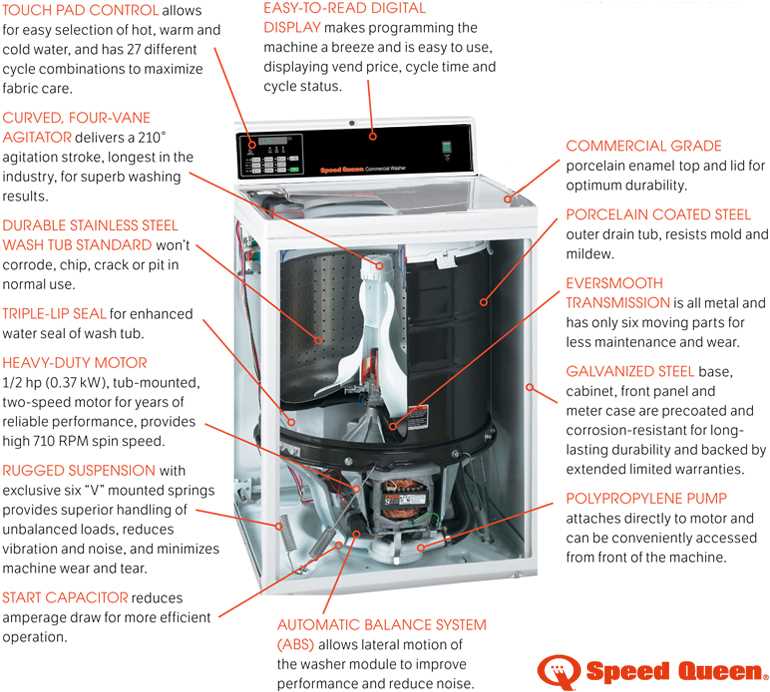

One of the most essential elements is the control panel, which allows users to select various settings and cycles for optimal results. Another critical part is the drum, where garments are placed, ensuring they are cleaned thoroughly during operation. The agitator or impeller, located inside the drum, is responsible for moving the items around, helping to remove dirt effectively.

The motor powers the rotation of the drum and agitator, providing the necessary force for the cleaning process. Additionally, the water inlet valve manages the flow of water into the appliance, while the pump and drainage system work together to remove used water after each cycle.

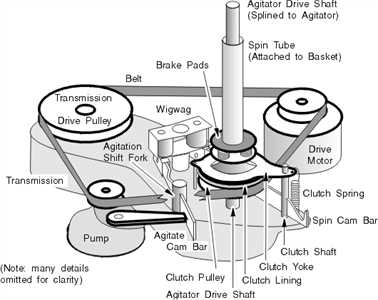

Top-Load Washer Mechanism Overview

The internal structure of vertical drum cleaning appliances revolves around several interconnected components designed to facilitate efficient and smooth operation. Understanding the core functions of these elements allows for better maintenance and troubleshooting when needed. Each element plays a crucial role in ensuring that the system operates seamlessly during every cycle.

Core Drive System

At the heart of the appliance lies a robust drive system responsible for powering the spinning motion of the drum. This includes a combination of belts, motors, and pulleys that work together to rotate the drum, allowing for consistent and reliable cleaning performance. Proper alignment and tension of these parts are essential to avoid disruptions or malfunctions.

Agitation and Water Flow

Agitation mechanisms ensure the thorough movement of clothing during cycles, enhancing the cleaning process. This movement is synchronized with water inlets and outlets, controlled by

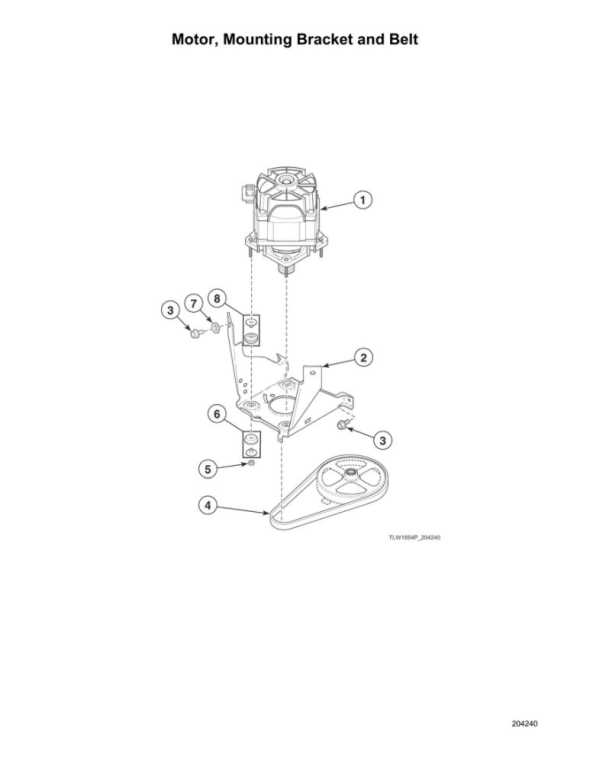

Key Functions of the Drive Belt

The drive belt plays a crucial role in the operation of many household appliances, ensuring smooth and efficient performance by connecting various moving components. Its purpose is to transfer energy between mechanical parts, allowing for the proper coordination of motions. Without it, the system would struggle to function optimally, leading to potential breakdowns and disruptions.

Energy Transmission: The primary function of this component is to transmit energy from the motor to other moving parts. It ensures that power is distributed effectively, enabling synchronized movement throughout the system.

Movement Coordination: By maintaining tension and controlling the movement of other elements, the belt helps achieve consistent and reliable performance. Its design allows for precise coordination, ensuring smooth operations.

Durability and Flexibility: Built from materials designed to handle constant motion and stress, the belt must endure various operational conditions while retaining its flexibility and strength. This ensures longevity and reduced need for frequent maintenance.

Role of the Agitator in Wash Cycles

The agitator is a crucial component within various laundry processes, ensuring optimal interaction between fabrics and water. It facilitates the effective distribution of cleaning agents, helping to loosen dirt and stains from the items being cleaned. This motion ensures a thorough cleanse by moving the garments efficiently throughout the cycle.

A standard agitator operates with a combination of rotational and vertical movements, which create currents that move water and clothing around. These currents provide the necessary friction to aid in removing grime without damaging delicate textiles. Different models may feature varying types of agitators, each contributing uniquely to the overall performance.

| Type | Movement | Benefits | ||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dual-Action | Rotational and oscillating | Enhanced fabric care and stain removal | ||||||||||||||||||||||||||||||

| Component |

|---|

| Feature | Description |

|---|---|

| Cycle Selection | Allows users to choose different operational modes based on their needs. |

| Timer Settings | Enables precise control over the duration of each phase in the process. |

| Indicator Lights | Provides visual feedback on the current status of the operation. |

Importance of the Lid Switch Assembly

The lid switch assembly is a critical component in the operation of laundry appliances. It plays a vital role in ensuring safe and efficient functionality. By detecting whether the lid is open or closed, this assembly prevents the appliance from operating when it is unsafe to do so, safeguarding both the user and the unit.

In addition to enhancing safety, the lid switch assembly contributes to the overall performance of the appliance. A malfunctioning switch can lead to various issues, such as failure to start or incomplete cycles, which can disrupt the laundry process. Regular inspection and timely replacement of this component can help maintain optimal efficiency and prolong the lifespan of the unit.

Moreover, understanding the significance of the lid switch assembly allows users to recognize warning signs of potential problems early on. By addressing these issues promptly, users can avoid costly repairs and ensure their appliance operates smoothly, providing reliable service for years to come.

Functionality of the Motor Coupler

The motor coupler serves as a crucial component in the operation of various appliances, playing a vital role in the transfer of energy from the motor to the drum. Its design and function ensure that mechanical power is effectively transmitted, facilitating the smooth operation of the entire unit.

Role in Energy Transfer

This essential device connects the motor to the drum, enabling the rotational force needed for efficient performance. By absorbing shocks and vibrations, it prevents potential damage to both the motor and the drum, enhancing the durability of the overall system.

Signs of Wear and Tear

Over time, the motor coupler may exhibit signs of deterioration, impacting functionality. Users may notice issues such as unusual noises or reduced efficiency during operation. Regular maintenance and timely replacement of this component can ensure optimal performance and longevity.

Pump Assembly and Drainage System

The efficiency of any appliance greatly relies on its fluid transfer components. In this section, we will explore the essential mechanisms that facilitate the movement of water, ensuring proper operation and performance. Understanding these elements is crucial for maintenance and troubleshooting.

The assembly dedicated to the circulation and expulsion of water comprises several key components:

- Water Pump: This component is responsible for drawing water from the tub and directing it to the drainage outlet.

- Drain Hose: A flexible conduit that transports wastewater away from the unit, preventing any blockages or backups.

- Filter Screen: A protective element that captures debris and prevents clogging within the pump and hose.

- Check Valve: This mechanism allows water to flow in one direction only, preventing any backflow into the tub.

- Drain Port: The opening through which water exits the system, connecting to the household drainage system.

Regular inspection and maintenance of these components can significantly enhance the lifespan of the appliance and prevent common issues such as leaks or inefficient drainage.

In summary, understanding the configuration and function of the fluid transfer components is vital for optimal operation. Keeping these parts in good condition ensures seamless performance and reduces the likelihood of malfunctions.

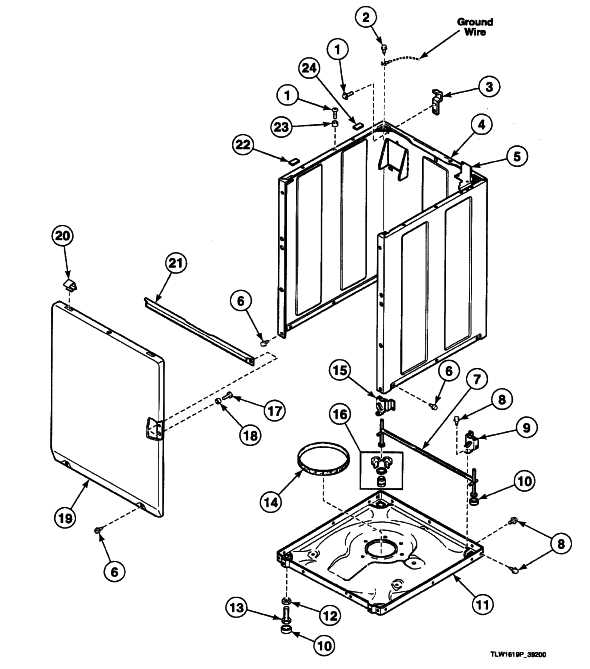

Inspecting the Suspension System

The suspension framework of a home appliance plays a crucial role in maintaining stability and ensuring smooth operation. It absorbs vibrations and helps to balance loads during operation. Regular examination of this system is essential to prevent potential issues and enhance the overall performance of the unit.

Key Components to Check

When evaluating the suspension framework, focus on the following components to ensure they are functioning correctly:

| Component | Function | Signs of Wear |

|---|---|---|

| Shock Absorbers | Dampen vibrations during operation | Leaking fluid, unusual noise |

| Springs | Support the drum and maintain balance | Visible damage, sagging |

| Mounting Brackets | Secure the suspension components | Loose fittings, rust |

Inspection Procedure

To conduct a thorough inspection, follow these steps:

- Unplug the unit for safety.

- Remove any necessary panels to access the suspension framework.

- Visually inspect each component for damage or wear.

- Test the shock absorbers and springs by applying pressure to see if they respond properly.

- Replace any damaged components as needed to ensure optimal performance.

Diagnosing Issues with the Transmission

Understanding the nuances of a unit’s transmission system is essential for effective troubleshooting. A well-functioning transmission is vital for the smooth operation of any appliance, ensuring optimal performance and longevity. When problems arise, identifying the underlying causes can prevent further damage and facilitate timely repairs.

Common symptoms of transmission issues may include:

- Unusual noises during operation

- Inconsistent drum movement

- Failure to engage in specific cycles

- Leaking fluid around the unit

To accurately diagnose transmission problems, consider the following steps:

- Listen for Sounds: Pay attention to any grinding, clunking, or whining noises, which may indicate internal damage.

- Inspect for Leaks: Check the area around the base for any signs of fluid leakage, as this can point to a faulty seal or gasket.

- Test Cycle Performance: Run various cycles to observe any irregularities in operation, noting if the drum spins consistently.

- Examine Components: Inspect belts, pulleys, and the motor for wear and tear that may affect transmission efficiency.

By following these guidelines, users can effectively troubleshoot and identify issues related to the transmission system, paving the way for necessary repairs and ensuring reliable performance.

Water Level Pressure Switch Explained

The water level pressure switch is a crucial component in controlling the fluid levels within a specific appliance. This device ensures that the appropriate amount of liquid is present for optimal operation, preventing overfilling or underfilling. Understanding its function and significance can help in maintaining the efficiency and longevity of the unit.

Functionality and Operation

This switch operates by monitoring the pressure created by the liquid in the system. As the fluid level rises or falls, the pressure changes, triggering the switch to either activate or deactivate the fill mechanism. This feedback loop is vital for maintaining balance and ensuring the appliance functions correctly.

Common Issues

Several problems can arise with the water level pressure switch, leading to inefficient performance. Users may encounter issues such as inaccurate readings, failure to fill, or excessive overflow. Identifying and addressing these concerns promptly can prevent further complications.

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Inaccurate Readings | Clogged tubing, faulty switch | Inspect and clean tubing; replace the switch if needed |

| Failure to Fill | Blocked inlet valve, defective switch | Check the inlet valve for blockages; test or replace the switch |

| Excessive Overflow | Stuck switch, faulty pressure sensor | Manually reset the switch; consider replacing the pressure sensor |

Maintenance Tips for Washer Parts Longevity

Ensuring the durability of your laundry appliance requires regular care and attention. By implementing simple maintenance practices, you can extend the lifespan of various components, reducing the need for costly repairs and replacements. This section provides essential tips to help you keep your appliance in optimal condition.

Regular Cleaning

Routine cleaning is vital for the upkeep of your device. Accumulation of detergent residue and fabric lint can lead to malfunctions. To prevent this, wipe down the exterior frequently and clean the interior surfaces, including the drum and seals. Use a damp cloth with mild soap, and consider running a hot water cycle occasionally to eliminate any built-up grime.

Inspection and Replacement

Frequent inspections of the essential components are crucial for early detection of wear and tear. Look for signs of damage, such as cracks or fraying. Pay attention to hoses and connections, replacing them promptly if you notice any leaks. Keeping a checklist for replacement schedules can help maintain functionality and performance over time.