Understanding the internal structure of a modern cleaning appliance is essential for effective maintenance and repair. By familiarizing yourself with the arrangement of various components, you can quickly identify areas that may require attention. This guide provides a clear view of how each element fits together in a typical unit.

At the heart of the unit lies the main frame, which holds all the critical elements in place. Key sections include the motor assembly responsible for powering the machine, the spray arms that distribute water evenly, and the filter system, which ensures that debris is collected efficiently. Each component works together to ensure smooth and effective operation.

The appliance features a complex system for managing water flow. The inlet valve regulates the flow of water into the unit, while the pump ensures that it moves through the system. Once the cycle is complete, the drainage system removes the remaining water, keeping the unit ready for the next use. This system is essential for the overall functionality and performance of the appliance.

Understanding how the essential components work together ensures optimal performance and longevity of the appliance. Each element plays a significant role in the process, contributing to effective operation and reliable cleaning results.

By keeping these core elements functioning properly, the machine can deliver consistent results while reducing the risk of malfunctions or damage.

The internal workings of modern cleaning appliances consist of various interconnected components that collaborate to efficiently carry out the washing process. Understanding the key mechanisms inside these devices provides insight into how they function, ensuring a thorough and effective cleaning cycle. The design of such systems involves a combination of water circulation, heating, and mechanical movement, all controlled by integrated electronics to deliver optimal performance.

| Component |

Function |

| Water Pump |

Circulates water through the system, enabling high-pressure cleaning and rinsing. |

| Heating Element |

Raises water temperature to improve cleaning efficiency and sanitation. |

| Spray Arms |

Rotate to distribute water evenly across all surfaces, ensuring thorough coverage. |

| Filtration System |

Removes debris from the water, preventing recirculation of dirt and maintaining cleanliness. |

| Electronic Controller |

Regulates the operation of the entire system, from water intake to cycle completion. |

Main Elements of Dishwasher Structure

Understanding the internal structure of this appliance is crucial for ensuring its proper function and maintenance. The core components work together to achieve efficient cleaning, from the initial water intake to the drying phase. Each part plays a distinct role in supporting the overall operation, ensuring that tasks are performed smoothly and effectively.

The water inlet valve is responsible for controlling the flow of water into the system. It opens and closes at precise intervals, ensuring the correct amount of water enters at the right time. Following this, the pump assembly circulates water through the internal mechanisms, propelling it towards the cleaning arms.

At the heart of the system, the spray arms distribute water evenly across the interior, reaching every corner for optimal results. Beneath the surface, filters ensure that food debris is trapped and removed from the water before it is reused. Finally, a heating element ensures the water reaches the desired temperature, aiding in both the cleaning and drying stages.

Water Flow System in Viking Dishwashers

The efficient circulation of liquid through household cleaning equipment is crucial for maintaining performance and ensuring thorough cleanliness. A well-designed fluid distribution mechanism ensures that every item inside the unit is properly rinsed and cleaned. Understanding how water moves through various stages allows for better maintenance and troubleshooting, leading to optimal operation and longevity of the appliance.

Main Components of the Flow Mechanism

The process begins with the inlet valve, which regulates the amount of water entering the system. Once the liquid is admitted, it is directed to different zones via strategically positioned jets and nozzles. The recirculation pump plays a key role in maintaining continuous motion, ensuring that the liquid reaches all surfaces during cleaning cycles.

Efficient Water Distribution

Once the liquid reaches the spray arms, these components rotate to distribute it evenly across the load. The design of the arms ensures a high-pressure flow, which is essential for removing food particles and other residues. After passing through the cleaning stages, the used liquid is drained, completing the cycle and preparing the system for the next round.

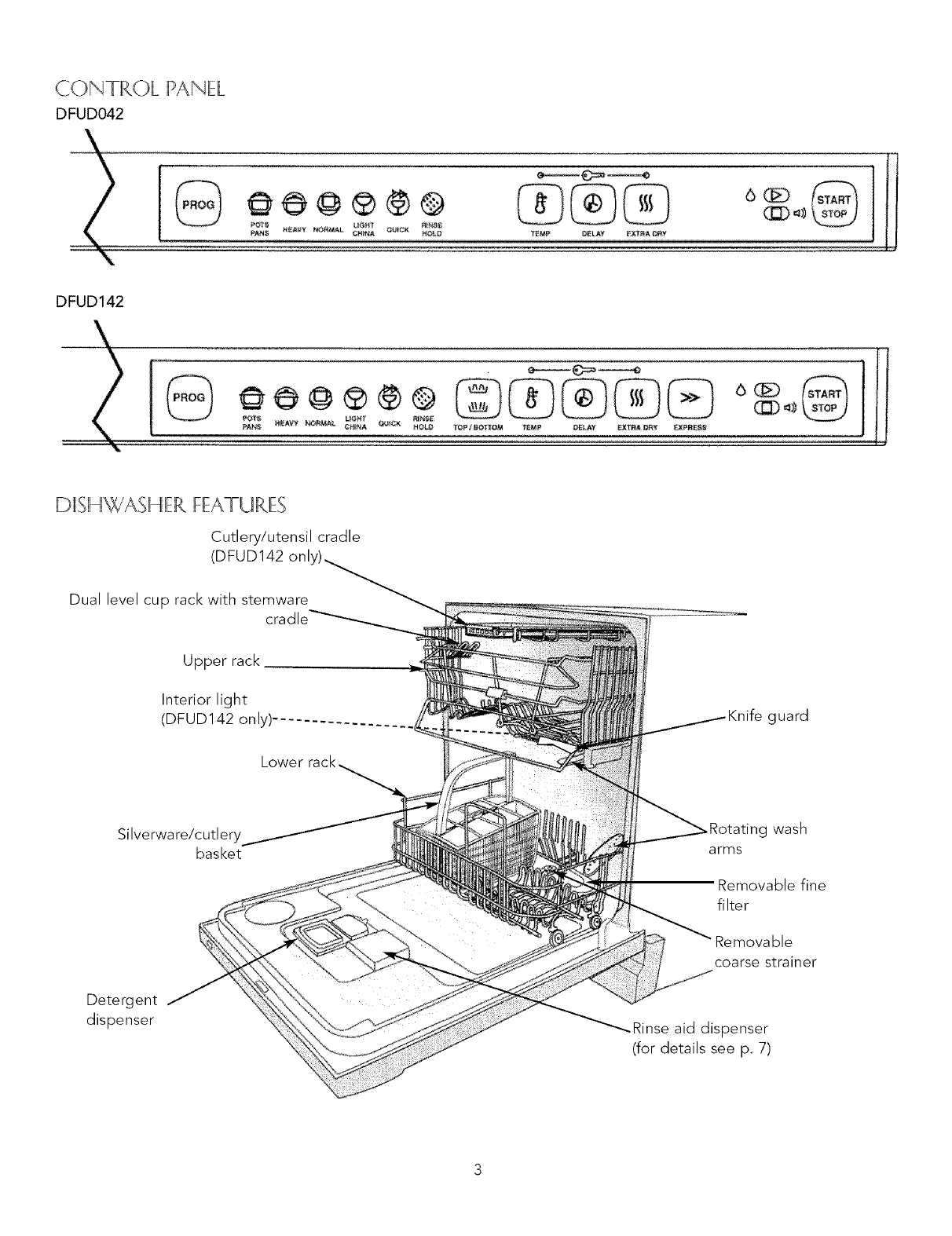

Control Unit and Operational Features

The control system plays a crucial role in managing the overall performance of the machine, ensuring efficient operation and smooth functionality. This central unit regulates various processes, allowing the device to operate according to user inputs and pre-programmed settings. Through precise coordination of internal mechanisms, the control unit is responsible for both activating and adjusting different functions during the cleaning cycle.

Key operational features include the ability to adjust settings for optimal performance based on specific needs. From regulating water usage to selecting different cleaning modes, these features ensure that each cycle runs efficiently. The system also monitors and responds to various conditions, such as temperature and load size, making real-time adjustments to maintain consistent and reliable output.

With enhanced operational flexibility, the control system provides users with a range of customizable options, including timers, temperature settings, and specialized modes. This adaptability allows for tailored performance, ensuring that each cycle delivers the desired results while maintaining energy efficiency and minimizing resource consumption.

Spray Arms and Cleaning Efficiency

The effectiveness of any modern cleaning device largely depends on how well its internal mechanisms distribute water throughout the unit. One of the key components that ensures even coverage and optimal washing performance is the rotating arm system. These moving elements are designed to spray water at various angles, targeting all areas to remove food residue and stains efficiently.

Proper design and positioning of the spray elements are crucial for maximizing the flow of water. If they are well-maintained and free from obstructions, these components help ensure that every surface gets thorough exposure, contributing to superior hygiene and cleaning results.

Over time, blockages or wear in the moving elements may affect their ability to rotate freely, which can lead to reduced washing quality. Regular maintenance, such as cleaning nozzles or checking for debris, ensures continued functionality and prolongs the lifespan of the system.

Drain and Filtration System Overview

The drain and filtration setup plays a critical role in maintaining the cleanliness and efficiency of the appliance. This system ensures that water is properly evacuated and filtered, preventing clogs and ensuring smooth operation. Without a well-functioning drainage mechanism, the cleaning process could be severely compromised, leading to potential malfunctions.

Key Components of this system work together to manage water flow and debris removal. The filtration unit captures larger particles, protecting internal parts from buildup, while the drain ensures that dirty water is effectively expelled. Each element has a specific function, contributing to the overall reliability of the system.

Proper maintenance of the filtration and drainage mechanisms is essential to ensure the longevity and performance of the device. Regular inspection and cleaning help prevent blockages and other common issues that could hinder water flow or cause damage.

Dishwasher Rack Design and Adjustments

Proper organization and flexibility within the interior of a cleaning appliance are crucial for efficient use. The structure inside is thoughtfully designed to maximize space while accommodating various kitchenware items. Key elements of this design focus on adjustable features that cater to different load sizes and shapes, providing both versatility and convenience.

Innovative Rack Configurations

Modern designs often incorporate multiple levels, allowing users to place items of different sizes without overcrowding. These configurations enhance water circulation, ensuring thorough cleansing of all items. Shelving and holders are often customizable, letting users rearrange sections to fit larger cookware or delicate glassware securely.

Height and Angle Adjustments

One of the most useful aspects of these systems is the ability to modify the height and angle of the racks. This adaptability is essential for accommodating taller items like pots and pans, which can be difficult to fit in standard settings. Lever mechanisms and sliding tracks make adjustments quick and intuitive, enhancing overall ease of use.

Efficient loading and optimized placement of kitchenware in these systems ensure that everything is cleaned thoroughly, without unnecessary energy or water consumption. Such adaptability makes the experience more seamless, reducing the need for multiple cleaning cycles.

Heating Elements and Drying Process

The heating components play a crucial role in ensuring that the items being cleaned are not only sanitized but also efficiently dried. These elements generate the necessary heat to elevate the temperature of the water, speeding up the drying phase. The process involves converting the heat energy into a form that is effective for removing moisture from the washed objects, allowing them to be ready for use quickly.

Heating elements are responsible for providing consistent heat during the final stages of the cleaning cycle. This heat not only assists in drying but also helps to break down any remaining residues, leaving surfaces spotless. Once the water has been heated, the drying procedure begins, often utilizing a combination of air circulation and radiant heat to ensure a dry and polished finish.

Efficient drying systems rely on properly calibrated heating mechanisms to optimize energy usage while maintaining a high standard of cleanliness. The design of these elements is critical for achieving both speed and effectiveness in the drying stage.

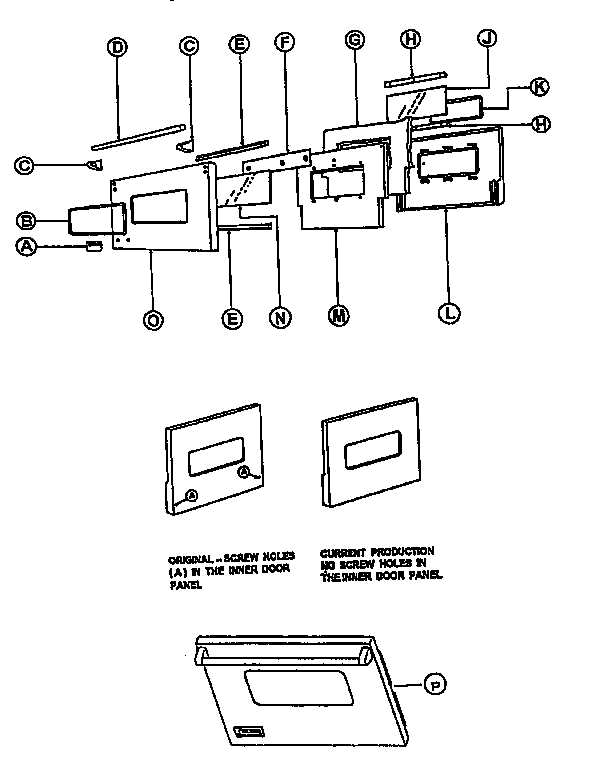

Understanding Viking Dishwasher Door Mechanism

The door system of a modern kitchen appliance plays a crucial role in ensuring smooth operation and secure sealing during cycles. This mechanism includes several components that allow the door to open, close, and lock efficiently, preventing leaks and ensuring optimal performance. A detailed understanding of how these elements interact can help in troubleshooting issues related to door functionality, such as difficulty in closing or improper sealing.

The key to the effective operation of the door lies in the hinge and latch mechanisms. These parts must work in harmony to provide a tight seal and resist wear from frequent use. Additionally, certain designs include damping systems that reduce noise and impact when the door is shut. Ensuring these components are functioning properly is essential for maintaining the appliance’s efficiency and longevity.

Troubleshooting Common Part Failures

When your appliance is not functioning as expected, it is often due to an issue with one or more of its components. Identifying the root cause can save time and prevent unnecessary replacements. By understanding how different elements work together, you can better pinpoint and address common malfunctions.

- Water Not Draining: This issue may stem from a clogged drainage system or a malfunctioning pump. Start by checking the drainage hose for any blockages, and ensure the pump is running properly.

- Uneven Cleaning Results: If the cleaning efficiency is compromised, inspect the spray arms and water inlet valve. Obstructions or damage in these parts can prevent water from reaching all areas, leading to poor results.

- Unusual Noise: Strange sounds often indicate something is obstructing moving parts. Check for loose items or debris in the mechanism. Also, examine the motor and pump for any signs of wear or damage.

- Water Leaks: Leaks can occur from worn-out seals or gaskets. Inspect the door seals, hose connections, and any other areas where water might escape. Replacing faulty seals can often fix this issue.

- Failure to Start: If the unit doesn’t power up, the problem might lie with the control board or power supply. Verify that the appliance is correctly plugged in and check the fuse or circuit breaker for faults.