Understanding the layout and functionality of various mechanical elements is crucial for maintaining and optimizing the performance of any vehicle. A well-structured overview helps enthusiasts and technicians alike to navigate through the essential features, ensuring smooth operation and timely replacements.

Each component plays a significant role in the overall performance, and having a clear guide to their arrangement can make routine checks and repairs more efficient. This detailed overview provides insight into the positioning and interaction of the main mechanical systems, offering a reliable reference for all maintenance tasks.

By exploring the structure of crucial systems, you will gain a better understanding of how each element supports the vehicle’s functionality. This knowledge empowers users to make informed decisions regarding repairs and upgrades, ensuring long-lasting reliability and efficiency.

Overview of the 2007 Yamaha Grizzly 700 Components

The structure of this all-terrain machine is composed of various interconnected elements that ensure its smooth operation and durability. Each individual unit is carefully designed to handle rough terrains and provide maximum efficiency. From the essential engine components to the external features that protect and support the vehicle, every piece plays a crucial role in the overall performance of the system.

Key mechanical elements are engineered for strength and longevity, ensuring the vehicle operates reliably in different conditions. The core of the vehicle is supported by a robust frame, while vital systems such as the suspension, steering, and braking mechanisms ensure a stable and safe ride. These components are seamlessly integrated to work together, allowing the vehicle to withstand demanding environments while maintaining control and agility.

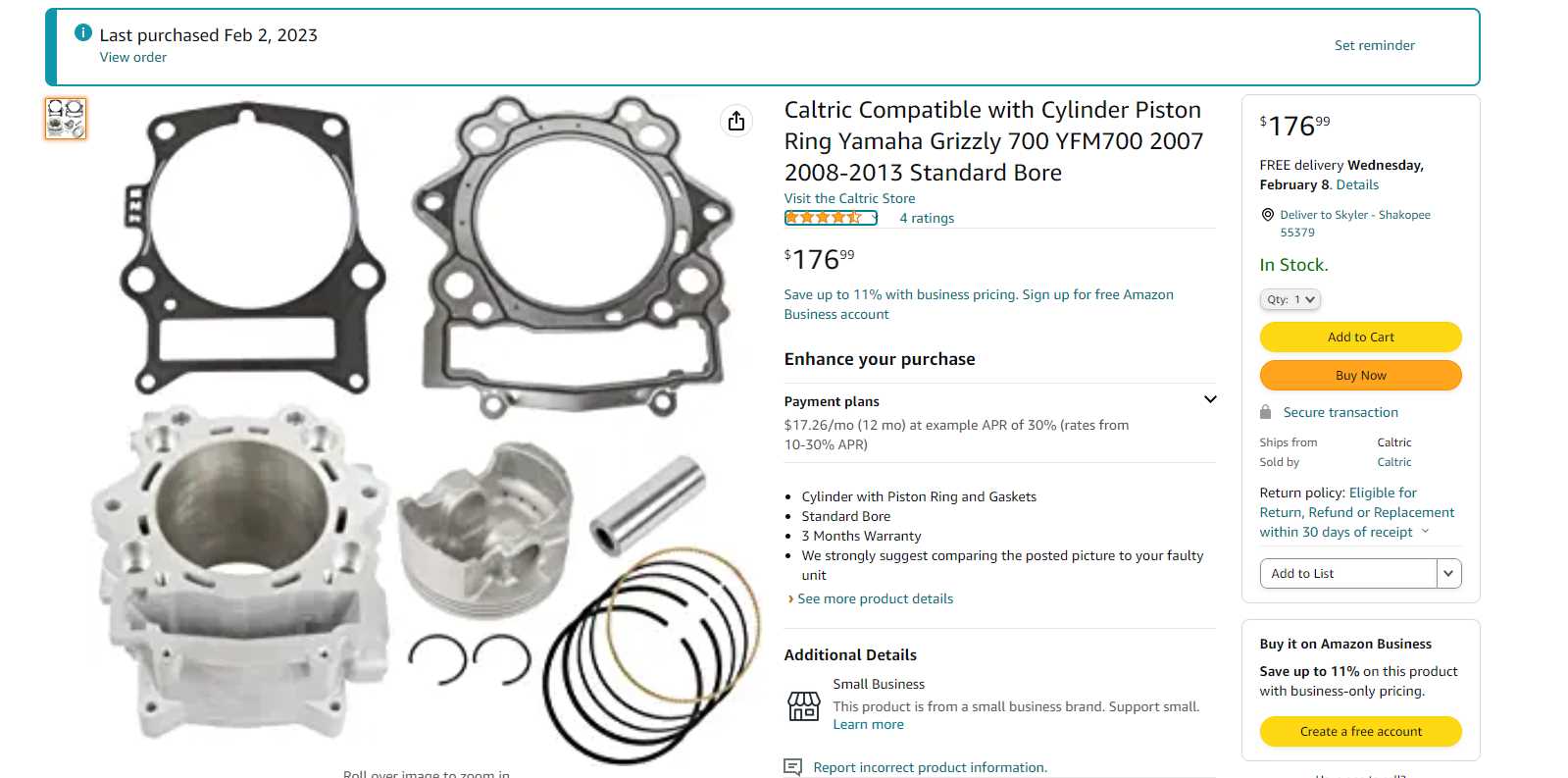

Engine Parts Breakdown for Yamaha Grizzly 700

The internal components of the engine play a crucial role in ensuring optimal performance and durability. Understanding how each element functions together provides valuable insights into maintaining and servicing the motor. In this section, we will explore the key mechanisms and their specific roles in the overall operation, ensuring the machine runs smoothly and efficiently.

Main Components of the Engine

The motor’s essential mechanisms include a variety of moving and stationary parts that work together to create power. These include the core elements responsible for combustion, air intake, and fuel processing, as well as cooling and lubrication systems that prevent overheating and wear. Each of these systems has its unique function and requires proper care to extend the longevity of the machine.

Additional Mechanisms

Aside from the primary components, several supplementary systems support the engine’s overall performance. These include the electrical systems that manage ignition and fuel delivery, as well as various sensors that monitor temperature and pressure. Regular checks of these systems ensure consiste

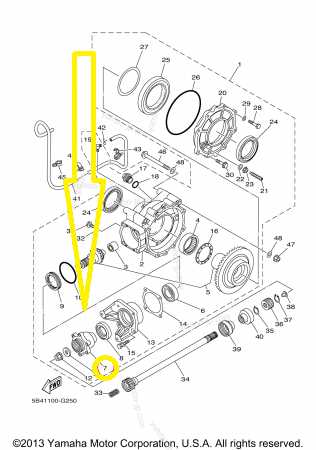

Transmission System Diagram and Key Parts

The transmission system plays a crucial role in ensuring smooth power delivery and vehicle performance. Understanding the various components within this mechanism helps in maintaining optimal functionality and prolonging the life of the system. In this section, we will explore the key elements that contribute to the efficient operation of the transmission and highlight their functions.

Main Components of the Transmission

The core of the transmission includes gears, shafts, and clutches that work in harmony to transfer power. The primary gear is responsible for managing the speed, while the secondary shaft transmits power to the wheels. Proper alignment and lubrication of these components are essential for preventing wear and tear.

Supporting Elements

Additional elements, such as bearings and seals, provide support and minimize friction during operation. The clutch assembly also plays a key role in engaging and disengaging the power flow, ensuring a smooth transition between gears. Regular inspection of these parts ensures the longevity and efficiency of the entire transmission system.

Understanding the Fuel System Layout

The fuel system plays a crucial role in ensuring the smooth operation of any off-road vehicle, providing the engine with the correct mixture of air and fuel for efficient combustion. A clear understanding of the components and their arrangement can help identify potential issues and maintain optimal performance.

Key Components of the Fuel System

- Fuel Tank: Stores the gasoline that powers the engine.

- Fuel Pump: Ensures consistent fuel flow to the engine.

- Fuel Filter: Removes impurities before the fuel reaches the engine.

- Fuel Injectors: Precisely deliver fuel into the combustion chamber.

How the System Works

The fuel is drawn from the tank by the pump, passes through the filter, and is then delivered to the injectors. The injectors atomize the fuel into fine particles, ensuring it mixes efficiently with air before combustion. This process is vital for maintaining performance and fuel efficiency.

Electrical System Overview for Grizzly 700

The electrical configuration of this all-terrain vehicle plays a crucial role in ensuring smooth operation across various functions. This system is designed to manage and distribute power efficiently, supporting everything from ignition to lighting and onboard electronics. Understanding how these components interact can provide valuable insight into maintaining optimal performance and troubleshooting potential issues.

Key Components of the Power Network

The vehicle’s power distribution includes several essential elements. The battery acts as the main energy source, while a regulator ensures voltage remains stable. The starter motor engages the engine, and fuses protect the wiring from damage. Each part works together to keep the electrical system reliable.

Common Maintenance Tips

To maintain the electrical setup, regular checks are recommended. This includes inspecting wiring connections, cleaning battery terminals, and verifying that the voltage regulator is functioning correctly. Following these steps can prevent issues related to power delivery and ensure long-term reliability.

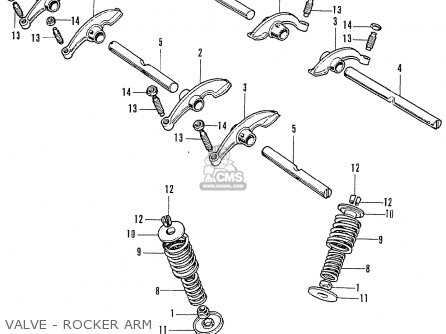

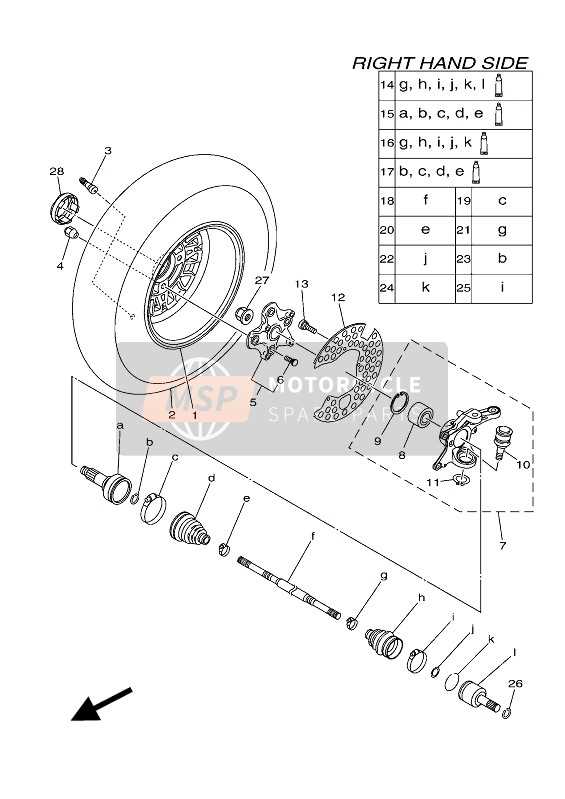

Front Suspension Parts and Structure

The front suspension system of an all-terrain vehicle plays a crucial role in ensuring stability and comfort during operation. It comprises various components that work in harmony to absorb shocks, maintain traction, and enhance maneuverability. Understanding the structure and function of these elements is essential for effective maintenance and optimal performance.

Key Components of the Front Suspension

At the heart of the front suspension are the shock absorbers, which dampen the impact from uneven terrain. These components are designed to control the oscillations of the vehicle, providing a smoother ride. Additionally, the control arms connect the suspension to the vehicle frame, allowing for vertical movement while maintaining alignment.

Importance of Proper Maintenance

Regular inspection and maintenance of the front suspension are vital for ensuring safety and longevity. Worn or damaged components can lead to decreased handling capabilities and an uncomfortable driving experience. By keeping these elements in good condition, operators can enhance the overall functionality and durability of the vehicle.

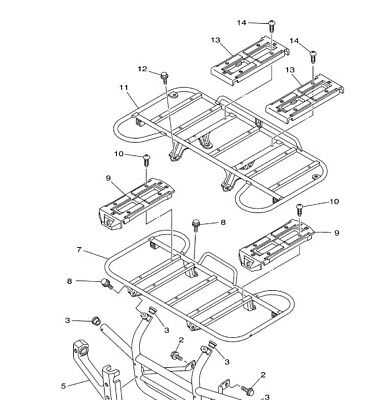

Rear Suspension Components of the Grizzly 700

The rear suspension system plays a crucial role in enhancing the performance and comfort of an all-terrain vehicle. This system is responsible for absorbing shocks, maintaining traction, and ensuring stability while navigating various terrains. Understanding the key components of this mechanism is essential for proper maintenance and optimal performance.

Key Elements of the Rear Suspension System

- Shock Absorbers: These components are designed to dampen the impact of bumps and irregularities in the terrain, providing a smoother ride.

- Swing Arm: This pivotal structure connects the rear wheels to the vehicle frame, allowing for vertical movement during travel.

- Coil Springs: Working in conjunction with shock absorbers, coil springs support the vehicle’s weight and contribute to ride height adjustments.

- Rear Axle: This vital part transmits power from the engine to the wheels, facilitating movement and handling.

Maintenance Tips

- Regularly inspect shock absorbers for leaks and signs of wear.

- Ensure that coil springs are not corroded and are securely mounted.

- Check the swing arm for any signs of bending or damage.

- Lubricate moving parts to prevent friction and ensure smooth operation.

Brake System Parts and Functionality

The brake system is a crucial component in any vehicle, ensuring safety and control during operation. This section will explore the various elements of the braking mechanism, highlighting their roles and how they contribute to effective stopping power.

| Component | Description |

|---|---|

| Brake Lever | The primary control that the operator engages to initiate braking. |

| Brake Cable | A vital link that transmits the force from the lever to the braking mechanism. |

| Caliper | Holds the brake pads and applies pressure to the brake rotor, creating friction to slow down the vehicle. |

| Brake Pads | Friction material that presses against the rotor to provide stopping power. |

| Brake Rotor | The disc that the brake pads clamp down on, converting kinetic energy into thermal energy through friction. |

| Master Cylinder | Generates hydraulic pressure that assists in activating the brake system. |

| Brake Fluid | Transmits the force from the master cylinder to the brake calipers, enabling efficient braking action. |

Understanding these components and their interconnections is essential for maintaining optimal performance of the braking system. Regular inspection and maintenance can prevent failures, ensuring a safe driving experience.

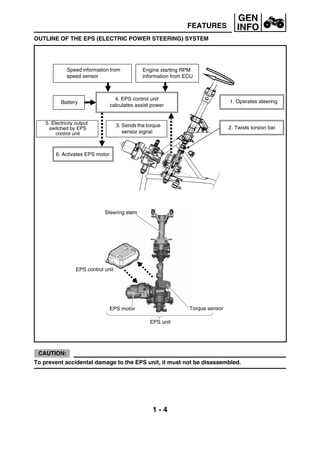

Steering System Diagram for Optimal Handling

The steering mechanism plays a crucial role in enhancing the overall performance and maneuverability of a vehicle. A well-designed system allows for precise control, ensuring that the operator can navigate various terrains with confidence. Understanding the intricacies of this assembly is essential for maintaining and optimizing the handling characteristics of your machine.

Components of the Steering Mechanism

Key elements of the steering assembly include the steering wheel, linkage, and front wheels. Each part works in harmony to deliver responsive handling. The connection between the steering wheel and the wheels is facilitated by a series of joints and rods that translate the driver’s input into directional movement. Regular inspection of these components can prevent wear and ensure longevity.

Maintenance Tips for Enhanced Performance

To maintain optimal functionality, it is important to regularly check the alignment and tightness of the connections within the steering system. Lubrication of moving parts will reduce friction and wear. Additionally, monitoring for any unusual sounds or vibrations can help identify potential issues early, allowing for timely adjustments and repairs.

Cooling System Layout and Essential Components

The cooling system plays a vital role in maintaining the optimal operating temperature of the engine, preventing overheating and ensuring efficient performance. This section outlines the configuration and key elements that contribute to effective heat management in the vehicle.

Key Components of the Cooling System

The cooling mechanism comprises several integral parts that work together to dissipate heat generated by the engine. These components include radiators, water pumps, thermostats, and coolant hoses, each serving a specific function to facilitate the flow and temperature regulation of the coolant.

Configuration Overview

Understanding the layout of the cooling system is essential for troubleshooting and maintenance. The coolant circulates through the engine and the radiator, where it releases heat to the atmosphere before returning to the engine. This cycle helps maintain a stable operating temperature, promoting longevity and performance.

| Component | Function |

|---|---|

| Radiator | Dissipates heat from the coolant. |

| Water Pump | Circulates coolant through the system. |

| Thermostat | Regulates coolant flow based on temperature. |

| Coolant Hoses | Transport coolant between components. |

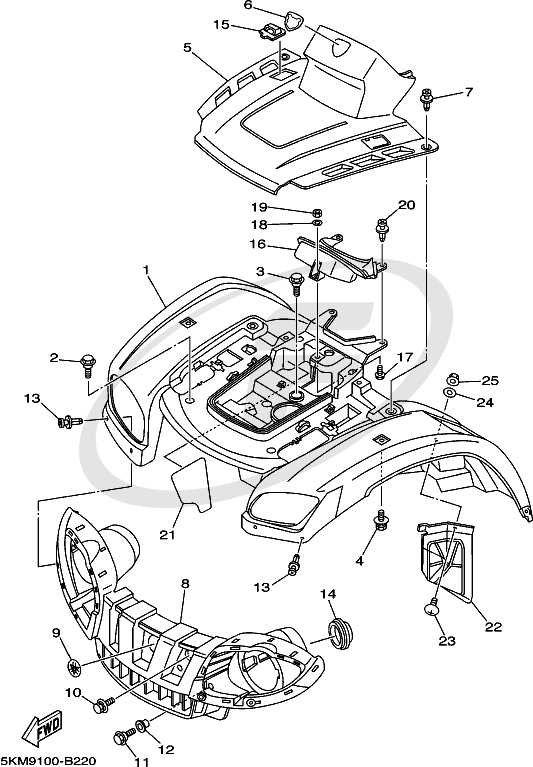

Body Panels and Exterior Component Overview

The body structure and outer components of an all-terrain vehicle play a crucial role in its overall functionality and aesthetics. These elements not only protect internal mechanisms from environmental factors but also enhance the vehicle’s appearance and aerodynamics. Understanding the design and layout of these features is essential for maintenance and modifications.

Material Composition and Durability

Exterior components are typically crafted from a range of materials, including high-impact plastics and metal alloys. These materials are chosen for their resilience against wear and tear, as well as their ability to withstand harsh weather conditions. Additionally, the choice of materials impacts the vehicle’s weight, which can influence performance and fuel efficiency.

Attachment Mechanisms and Accessibility

Each panel and component is secured through various attachment methods, ensuring a stable fit while allowing for easy removal when necessary. Fasteners, clips, and bolts are commonly utilized, promoting accessibility for repairs or upgrades. Proper maintenance of these connections is vital for maintaining the integrity of the vehicle’s exterior and ensuring optimal performance.