The functionality of a 40 horsepower marine engine is dependent on various integral elements that work together seamlessly. Each component plays a crucial role in ensuring optimal performance, efficiency, and reliability on the water. A comprehensive understanding of these elements is essential for maintenance and troubleshooting.

Within the intricate assembly of a marine engine, different parts contribute uniquely to the overall operation. By exploring these components, one can gain insights into how each element interacts with others. This knowledge is invaluable for those looking to repair, replace, or enhance their marine engines.

Whether you are a seasoned technician or a passionate boat owner, familiarizing yourself with the layout and function of these essential components can significantly enhance your boating experience. Grasping the mechanics behind each part empowers you to make informed decisions regarding upkeep and improvements, ensuring that your vessel remains in prime condition.

Understanding the different models of marine engines is essential for both enthusiasts and professionals. Each variant possesses unique components that contribute to its performance and functionality. This article aims to provide a structured overview of critical aspects related to a specific model, helping users navigate the complexities of engine maintenance and repair.

- Overview of Marine Engine Types

- Key Components of Marine Power Systems

- Importance of Regular Maintenance

- Common Issues and Solutions

- Identifying Engine Specifications

- Understanding Fuel Systems

- Cooling Mechanisms in Marine Engines

- Electrical Systems and Their Functions

- Gearbox and Propeller Interactions

- Understanding Control Systems

- Analyzing Engine Performance Metrics

- Future Trends in Marine Engine Technology

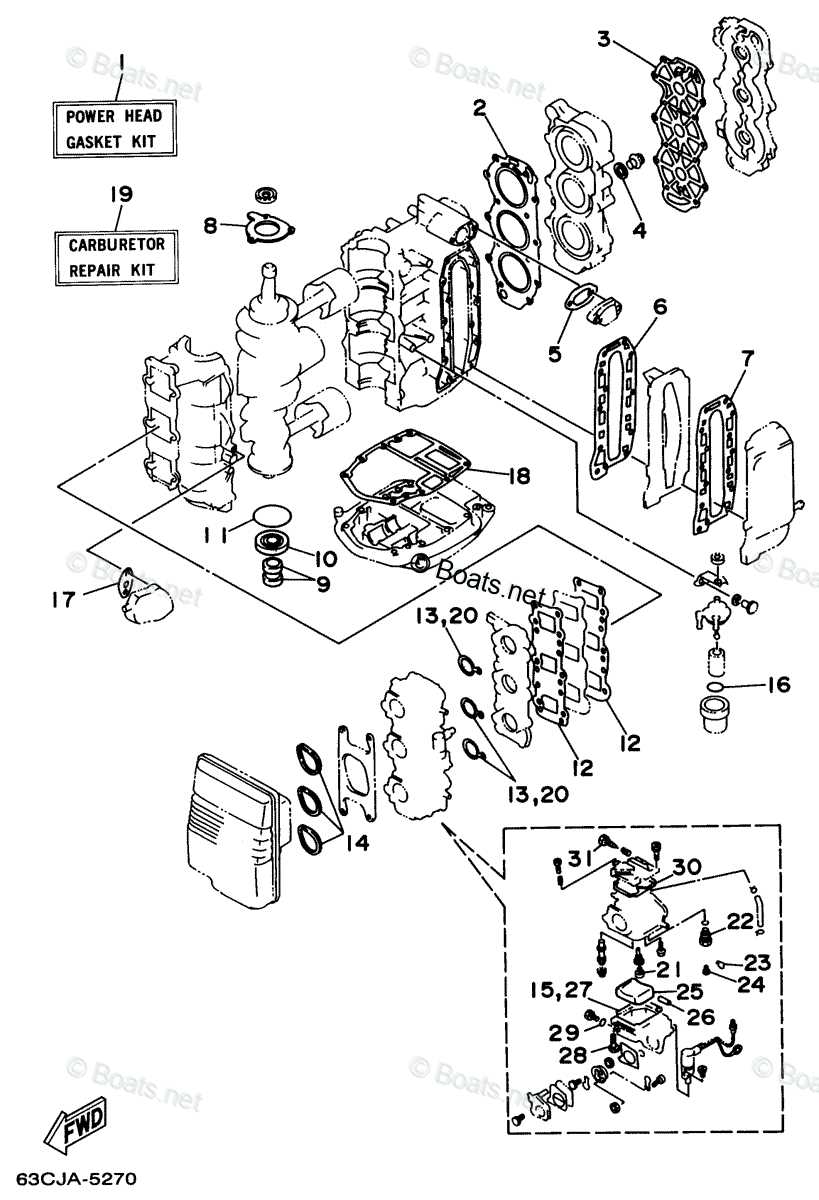

Essential Components of 40 HP Engine

The functionality of a 40 horsepower motor relies on several critical elements working in harmony. Understanding these vital components is crucial for maintenance and troubleshooting. Each part plays a significant role in ensuring the engine operates smoothly and efficiently, contributing to the overall performance.

Key Elements

At the heart of the engine lies the cylinder block, which houses the cylinders where combustion occurs. Additionally, the piston moves within these cylinders, creating the necessary force to drive the engine. The crankshaft converts the linear motion of the pistons into rotational motion, powering the propeller.

Supporting Mechanisms

Other important components include the fuel system, responsible for delivering the right mixture of air and fuel for combustion. The ignition system ignites this mixture, ensuring the engine runs efficiently. Lastly, the cooling system prevents overheating, maintaining optimal operating temperatures for peak performance.

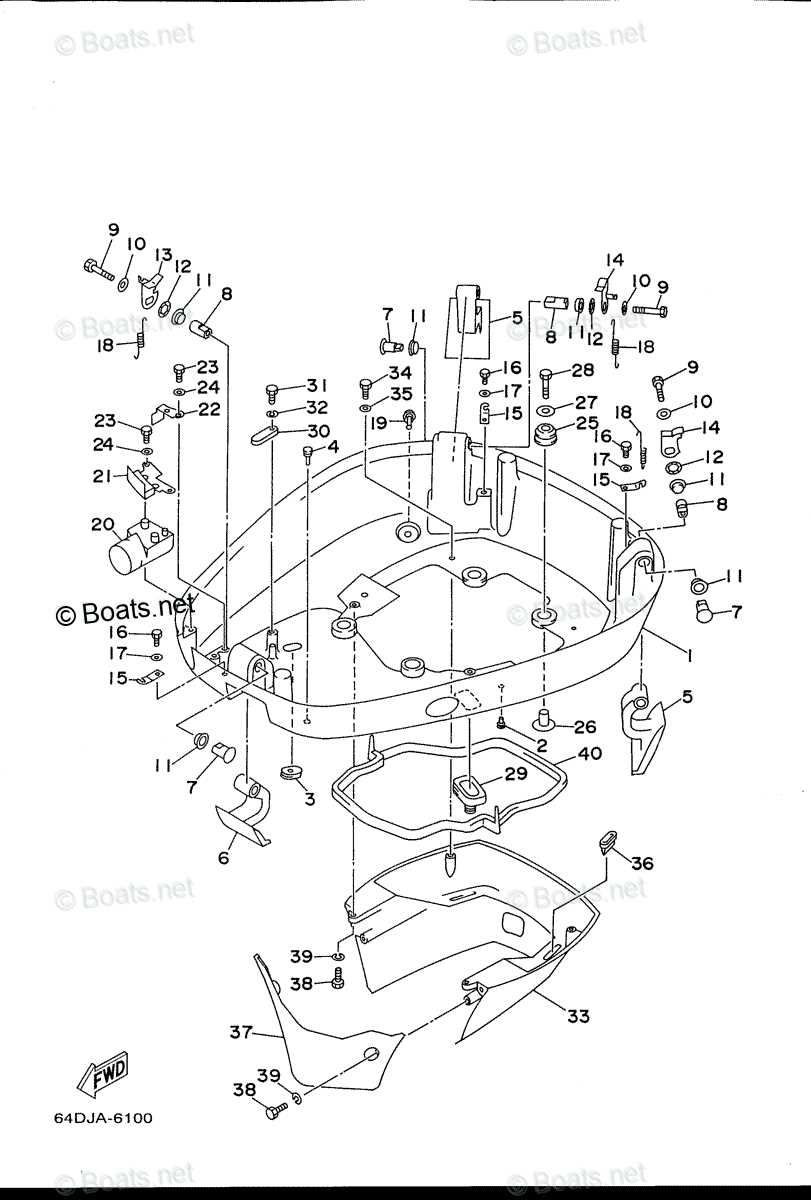

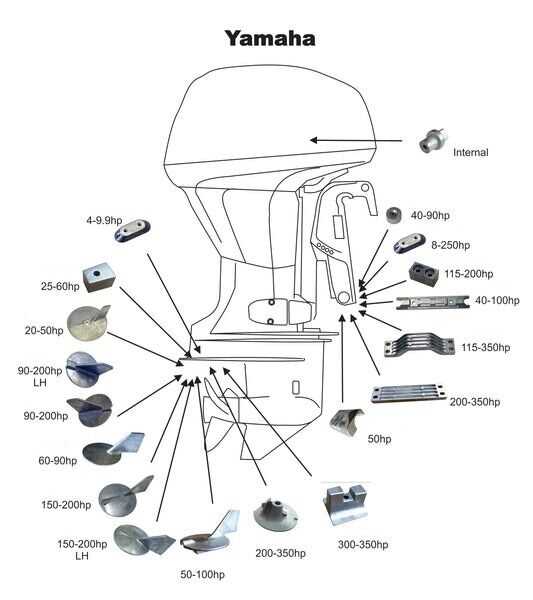

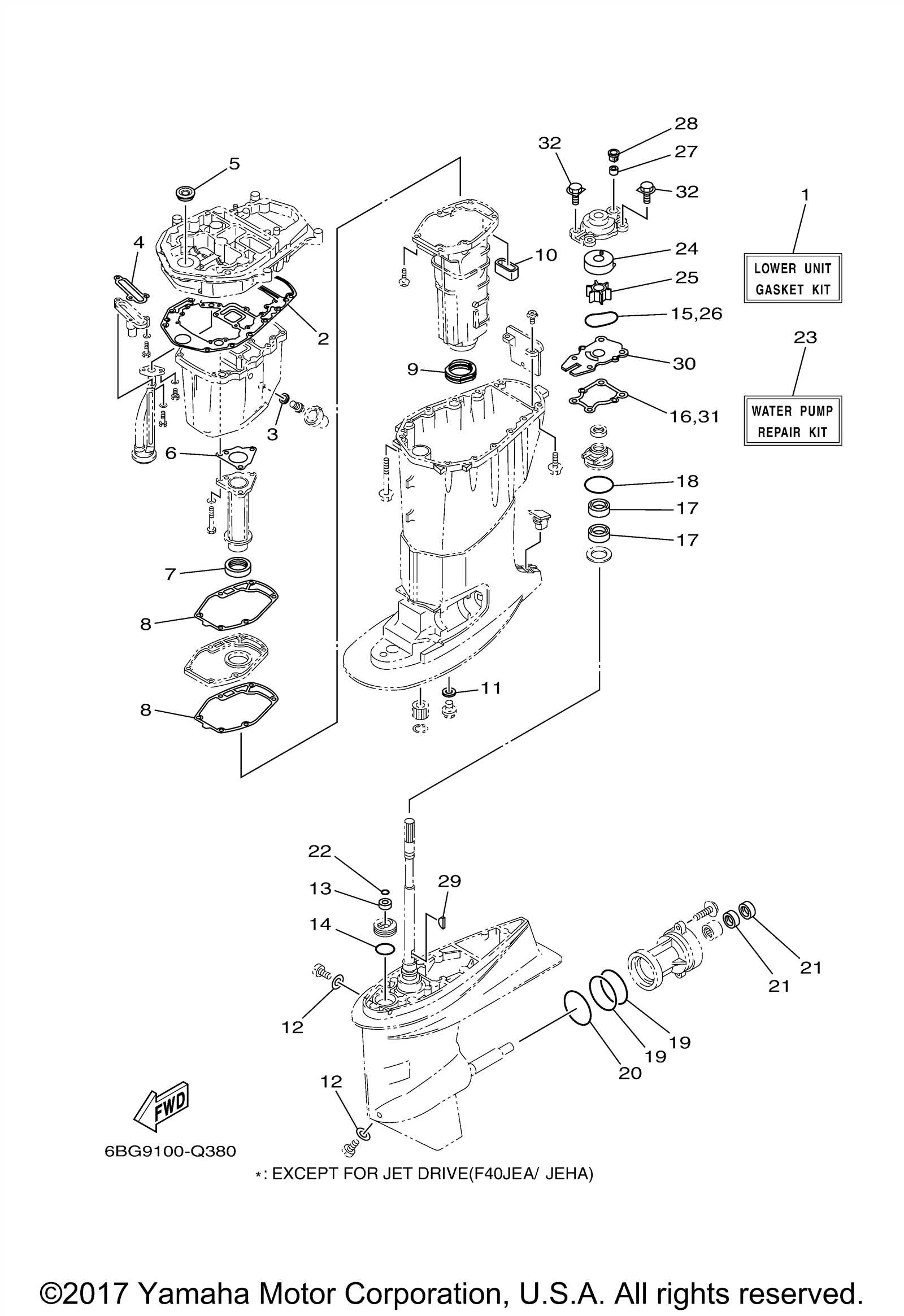

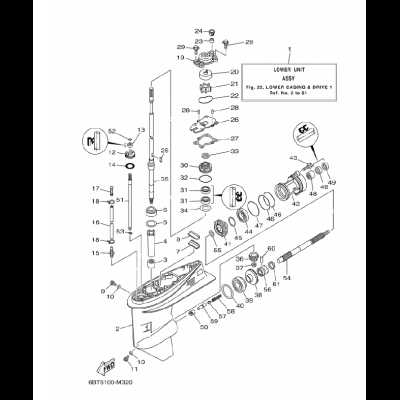

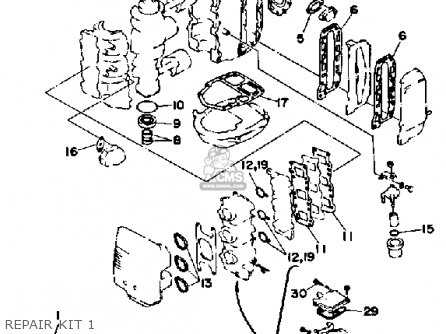

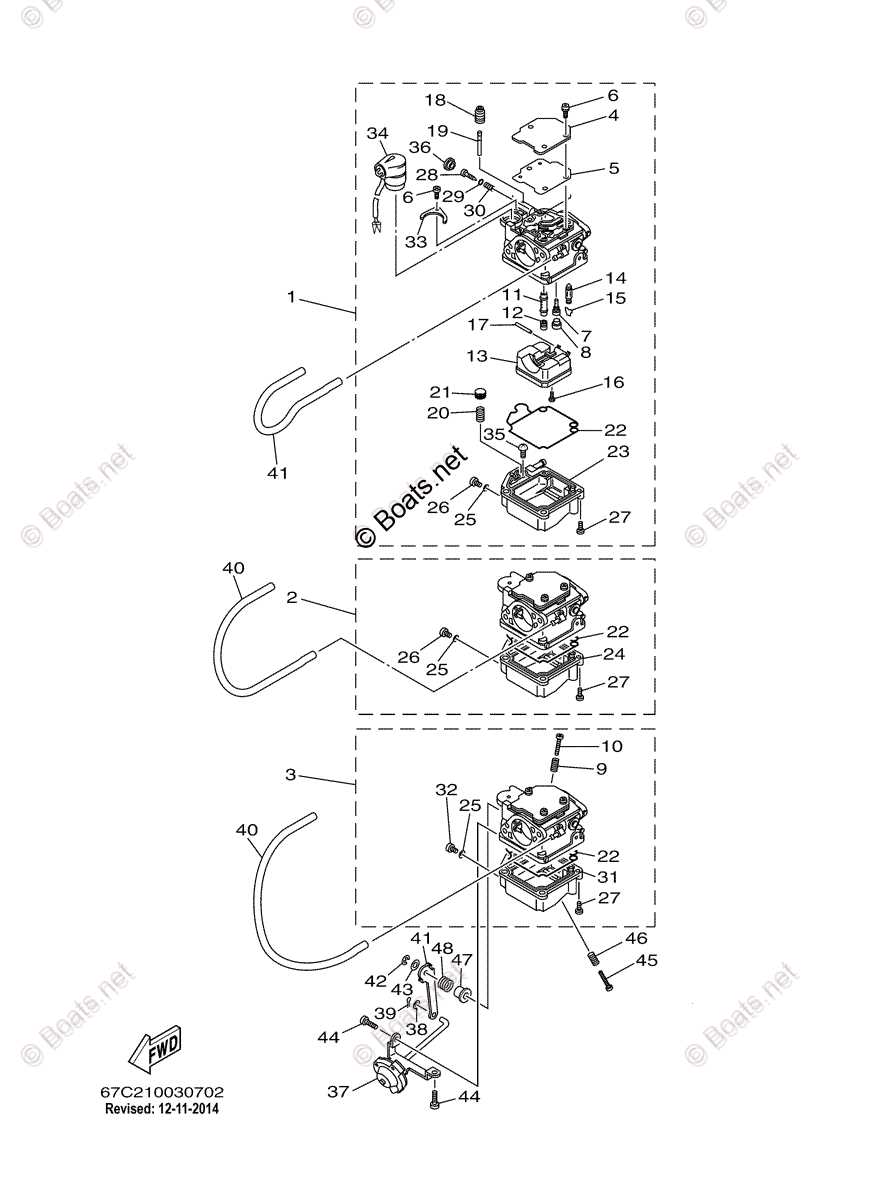

Parts Breakdown for Yamaha Outboards

This section provides a comprehensive overview of the various components that make up a specific marine propulsion system. Understanding the arrangement and function of these elements is crucial for effective maintenance and repair, ensuring optimal performance on the water. Each segment plays a vital role in the overall functionality, and familiarity with these components can aid in troubleshooting and upgrades.

Essential Components Overview

The structure of a marine propulsion mechanism consists of multiple critical segments. Below is a brief description of some of the primary constituents:

| Component | Description |

|---|---|

| Powerhead | The engine assembly that generates propulsion. |

| Lower Unit | Houses the gears and drive shaft, facilitating movement. |

| Fuel System | Includes fuel lines, filters, and injectors for proper delivery. |

| Cooling System | Ensures the engine maintains optimal operating temperature. |

Understanding Component Interactions

Each element interacts with others to create a cohesive system. For instance, the powerhead’s performance is directly influenced by the fuel system’s efficiency. Recognizing these relationships can enhance the user’s ability to maintain their marine propulsion system effectively.

Importance of Regular Maintenance

Consistent upkeep of marine engines is crucial for ensuring optimal performance and longevity. By adhering to a routine maintenance schedule, boat owners can prevent unforeseen issues that may arise from neglect. This practice not only enhances reliability but also maximizes efficiency, allowing for a more enjoyable experience on the water.

Preventive measures play a significant role in identifying potential problems before they escalate. Regular inspections can reveal wear and tear on components, ensuring timely replacements and adjustments. Moreover, maintaining the engine and its systems contributes to improved fuel efficiency, which can lead to cost savings over time.

Furthermore, proper maintenance fosters safety during operation. A well-maintained vessel is less likely to encounter breakdowns or malfunctions, reducing the risk of accidents on the water. Ultimately, prioritizing maintenance not only protects the investment but also enhances the overall boating experience.

Common Issues with 40 HP Models

When dealing with 40 horsepower engines, several recurring problems can impact performance and reliability. Understanding these common challenges can help owners maintain their equipment effectively and avoid costly repairs. Issues may stem from mechanical failures, fuel system complications, or electrical malfunctions, each requiring careful attention.

Mechanical Failures

One of the frequent concerns involves mechanical components such as the lower unit or powerhead. Wear and tear can lead to severe consequences if not addressed promptly. Regular inspections and maintenance can prevent major breakdowns and extend the life of the engine.

Fuel System Complications

Fuel delivery issues often arise, affecting the engine’s efficiency. Clogged filters or malfunctioning fuel pumps can result in inadequate fuel flow, causing performance drops or starting difficulties. Ensuring clean fuel and timely replacements of filters is crucial for optimal operation.

Tools for Outboard Repairs

Maintaining marine engines requires a range of specialized tools that ensure effective repairs and servicing. These instruments facilitate various tasks, from routine maintenance to complex repairs, making them essential for any technician or enthusiast. Having the right equipment not only improves efficiency but also enhances the quality of the work performed.

Essential Equipment for Maintenance

Various tools are indispensable for successful upkeep of marine engines. Below is a list of some fundamental instruments that every mechanic should have on hand:

| Tool | Purpose |

|---|---|

| Socket Set | For removing and tightening bolts and nuts |

| Screwdriver Set | For handling screws of various sizes and types |

| Wrench Set | For adjusting fittings and securing components |

| Multimeter | For diagnosing electrical issues |

| Fuel Line Wrench | For safe removal of fuel lines without damage |

Additional Useful Tools

In addition to the basic tools, several other items can enhance repair tasks and improve outcomes. Investing in high-quality equipment will pay off in the long run by ensuring reliability and longevity of the engine.

| Tool | Function |

|---|---|

| Pliers | For gripping and twisting wires and components |

| Torque Wrench | For applying precise torque to fasteners |

| Parts Cleaner | For cleaning components effectively |

| Diagnostic Scanner | For troubleshooting complex issues |

| Impact Driver | For loosening stubborn screws and bolts |

Exploring Fuel System Components

The fuel system is a crucial aspect of any aquatic propulsion mechanism, ensuring that the engine receives the proper mixture of fuel and air for optimal performance. Understanding the individual components of this system can greatly enhance maintenance efforts and troubleshooting processes. By examining each part, one can gain insights into how they contribute to the overall efficiency and functionality of the mechanism.

Key Elements of the Fuel System

Within this intricate network, several key components play significant roles:

- Fuel Tank: The reservoir that stores the fuel, providing a reliable supply to the engine.

- Fuel Pump: Responsible for transporting fuel from the tank to the engine, ensuring adequate pressure for combustion.

- Fuel Filter: This component removes impurities and contaminants from the fuel, protecting the engine and enhancing performance.

- Carburetor or Fuel Injector: These elements mix air and fuel in the appropriate ratio, vital for efficient combustion.

Maintenance Tips

Regular inspection and maintenance of these components are essential for optimal operation. Keeping the fuel filter clean, ensuring the fuel pump functions correctly, and monitoring the fuel lines for leaks can prevent costly repairs and ensure smooth operation. Additionally, using high-quality fuel can further enhance the longevity and efficiency of the system.

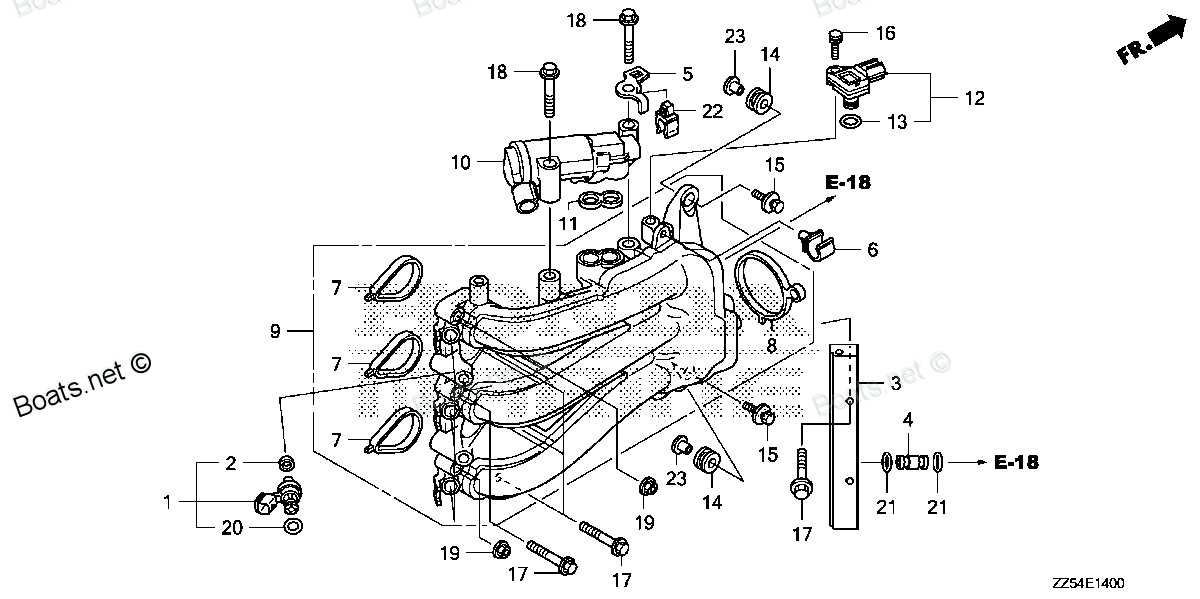

Electrical Parts Overview

Understanding the electrical components of marine engines is essential for ensuring optimal performance and reliability. This section provides a comprehensive look at the various electrical elements that play a crucial role in the functionality of these systems. Each component has a specific purpose, contributing to the overall operation and efficiency of the machinery.

Power Generation is primarily handled by the generator, which converts mechanical energy into electrical energy, supplying power to various systems. Ignition coils are vital for generating the high voltage required to ignite the fuel-air mixture, ensuring smooth operation. The starter motor is another essential element, enabling the engine to start by turning the flywheel.

Additionally, wiring harnesses connect all electrical components, ensuring proper communication and functionality. Fuses protect the system from electrical overloads, while switches control the flow of electricity to different parts, allowing for efficient operation and user control.

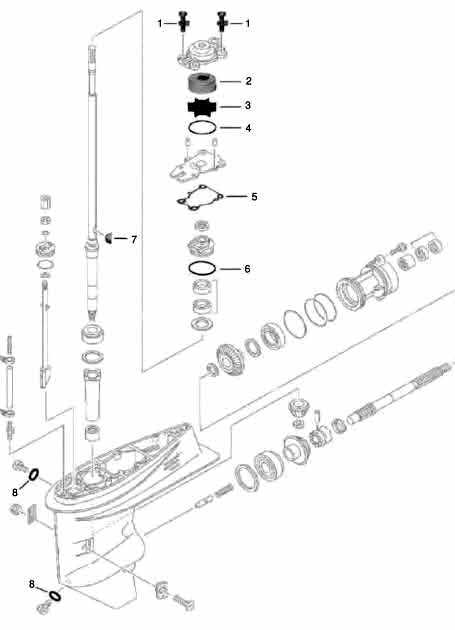

Cooling System Functionality Explained

The cooling mechanism is a vital aspect of any marine engine, ensuring optimal performance by maintaining appropriate operating temperatures. This system prevents overheating, which can lead to significant damage and reduced efficiency. By facilitating a constant flow of coolant, it regulates the heat produced during operation, allowing the engine to function smoothly over extended periods.

Understanding the components involved in this system can help users maintain their equipment effectively. Each element plays a specific role in directing coolant to various sections of the engine, contributing to its longevity and reliability. Below is a brief overview of the main components and their functions:

| Component | Function |

|---|---|

| Water Pump | Circulates coolant through the engine and the heat exchanger. |

| Thermostat | Regulates coolant flow based on temperature, ensuring optimal engine heat. |

| Heat Exchanger | Transfers heat from the engine coolant to the surrounding water. |

| Cooling Hoses | Transport coolant to and from the engine and other components. |

| Intake Screen | Prevents debris from entering the cooling system, protecting components. |

By regularly inspecting these components, users can ensure the efficiency and durability of their marine engines, leading to a more enjoyable and trouble-free experience on the water.

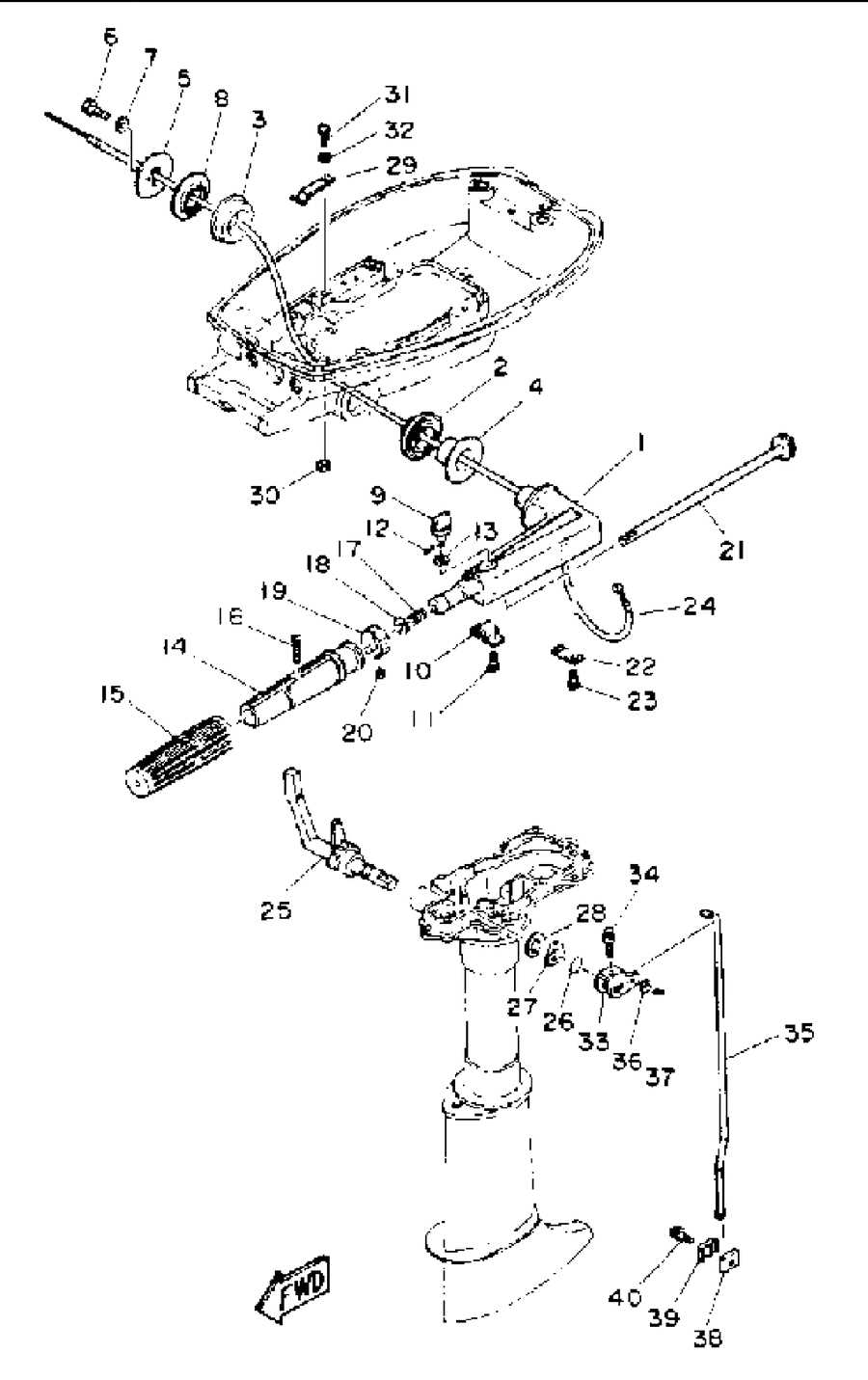

Transom and Mounting Specifications

This section outlines the essential aspects related to the rear mounting area and installation requirements for marine propulsion units. Understanding these specifications is crucial for ensuring optimal performance and stability while navigating various water conditions.

Transom Height: The height of the rear section where the propulsion unit is mounted is a vital measurement. It affects the engine’s efficiency and performance. Proper alignment with the hull is necessary to avoid complications during operation.

Mounting Bracket: The assembly designed to secure the engine to the transom must be robust and compatible with the dimensions of the rear section. It should provide a secure fit to withstand the forces experienced during operation.

Weight Distribution: Ensuring an even weight distribution is essential for maintaining stability. Proper mounting will prevent excessive tilting or imbalance, which could adversely affect handling and control.

Installation Guidelines: Adhering to the manufacturer’s instructions during installation is imperative. This includes torque specifications for fasteners and alignment procedures to ensure safe and effective operation.

Overall, following these specifications will enhance the functionality and longevity of the marine propulsion system.

Wiring Diagrams for Yamaha Outboards

Understanding the electrical schematics is essential for anyone involved in marine engine maintenance and repairs. These visual representations serve as a guide for technicians and enthusiasts alike, illustrating the connections and relationships between various components. Properly interpreting these layouts can lead to more efficient troubleshooting and enhancements in performance.

Importance of Electrical Schematics

Electrical layouts play a crucial role in the maintenance and repair of marine engines. They not only provide insights into the wiring connections but also help in identifying potential issues before they escalate. By following these guides, users can ensure proper installation and functionality of various elements, enhancing the overall reliability of their watercraft.

Components Illustrated in Schematics

These visual tools depict a range of components crucial for the effective operation of marine engines. Some of the key elements include:

| Component | Description |

|---|---|

| Ignition System | Responsible for initiating the combustion process. |

| Power Supply | Delivers electrical energy to various components. |

| Control Switches | Used for activating different functions of the engine. |

| Starter Motor | Engages the engine to start the operation. |

Finding Replacement Parts Online

In today’s digital age, sourcing components for marine engines has become remarkably convenient. The internet offers a plethora of resources that facilitate the search for necessary replacements, ensuring that your watercraft operates smoothly and efficiently. From specialized retailers to general e-commerce platforms, there are numerous avenues to explore when looking for quality components.

Utilizing Specialized Websites

One effective approach is to visit websites dedicated specifically to marine equipment. These platforms often provide detailed catalogs, allowing you to filter options based on your requirements. By entering the model and specifications, you can quickly narrow down the selection and find the exact components needed for your engine.

Leveraging Online Marketplaces

Additionally, popular online marketplaces offer a vast range of components from various sellers. Here, you can compare prices, read reviews, and check ratings to ensure quality. This method not only helps you find competitive pricing but also enables you to explore alternatives that may fit your needs perfectly.

Upgrading Components for Enhanced Performance

Improving the efficiency of marine engines can significantly enhance the overall boating experience. By focusing on key components, enthusiasts can achieve better speed, fuel efficiency, and reliability. Upgrading specific elements not only boosts performance but also extends the lifespan of the entire system.

Several components are essential for optimizing performance. When considering enhancements, it is important to evaluate the compatibility and functionality of each element within the system.

| Component | Benefit | Recommended Upgrade |

|---|---|---|

| Fuel System | Improved fuel efficiency | High-performance fuel pump |

| Propeller | Increased speed and maneuverability | High-pitch propeller |

| Ignition System | Faster response time | Upgraded ignition coils |

| Cooling System | Prevention of overheating | High-capacity water pump |

| Lubrication | Enhanced engine protection | Synthetic oil |