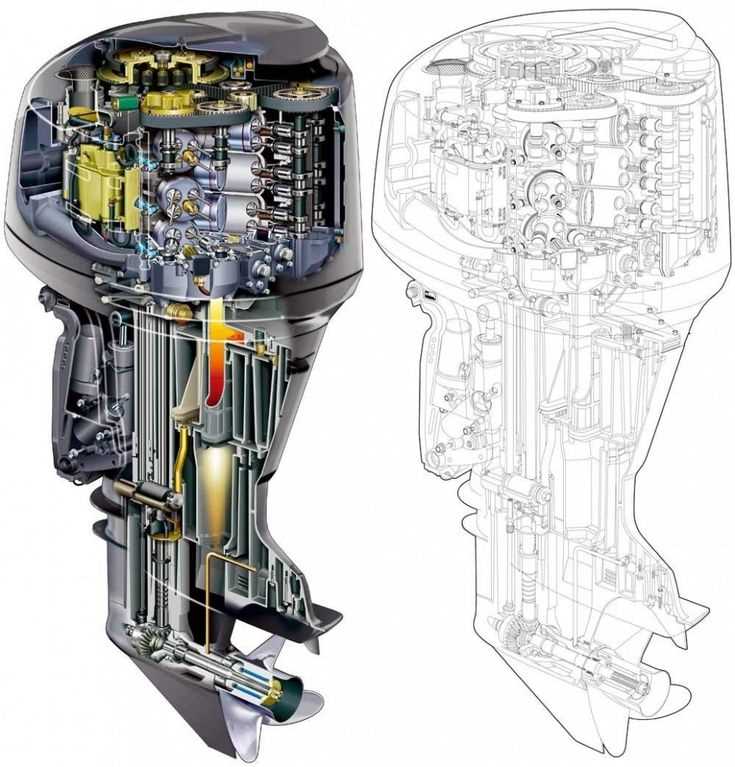

Maintaining a marine engine is essential for ensuring reliable performance on the water. In this guide, we will explore the various elements that make up a robust motor system used in boating. From the inner workings to external attachments, knowing how each piece functions can enhance your understanding and help with upkeep.

Each motor is designed with multiple interconnected systems. These include mechanical and electrical features that operate in harmony to provide power and stability. By familiarizing yourself with the core elements and their roles, you’ll be better equipped to handle repairs and replacements when necessary.

This guide will offer a detailed look at the engine’s structure, covering everything from essential components to lesser-known elements that contribute to overall functionality. Understanding these parts is key to maintaining smooth operation and avoiding potential issues down the line.

Yamaha 250 Outboard: Key Components Overview

The propulsion system is a complex assembly of various mechanical and electrical elements that work together to ensure smooth and efficient operation. Understanding the essential components is crucial for anyone involved in maintenance or repair, as it allows for better diagnostics and performance tuning.

Power Generation and Delivery

The engine’s core function revolves around transforming fuel into energy, which is then transmitted to the propeller. This process involves several key elements, including the ignition system, fuel injectors, and crankshaft, all working in sync to generate and deliver power.

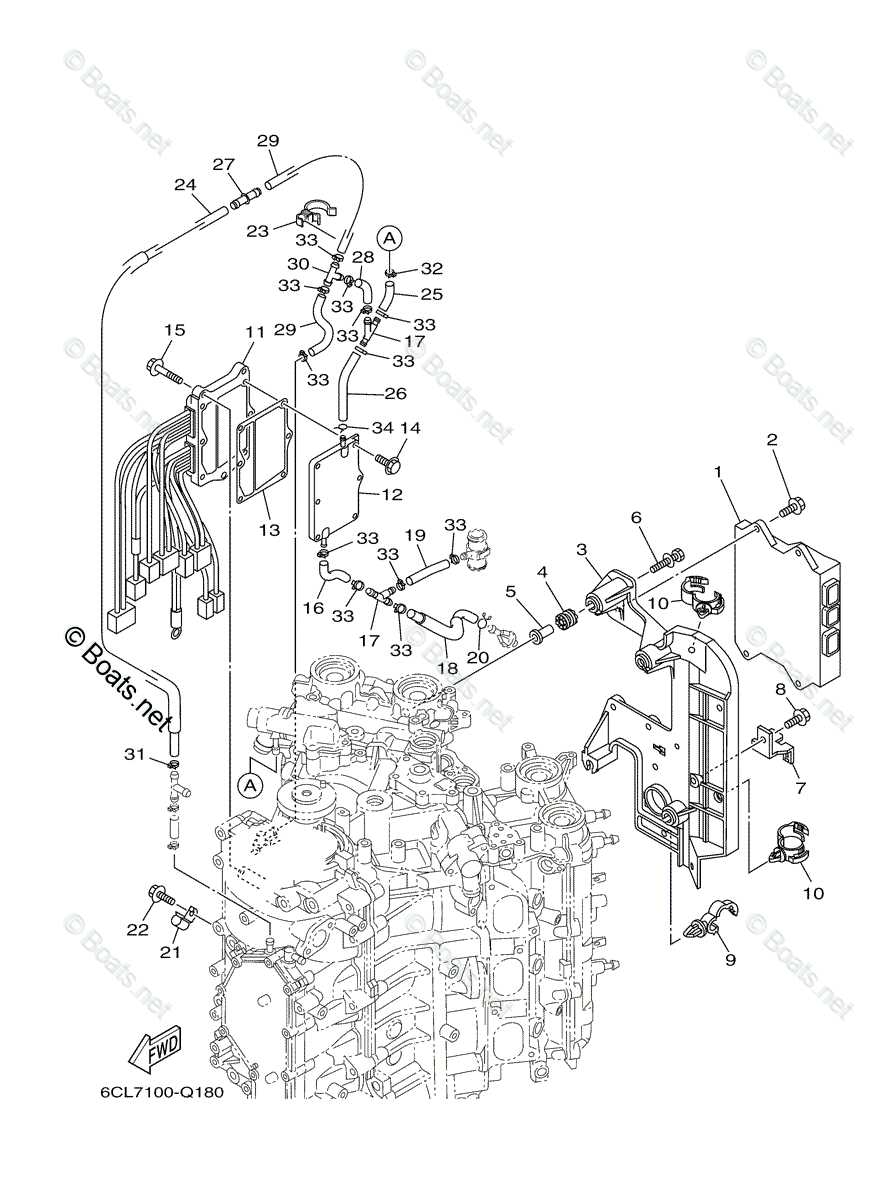

Cooling and Exhaust Systems

To ensure optimal performance, the unit relies on an efficient cooling system that prevents overheating. The water pump, thermostats, and related channels play vital roles in regulating temperature. Simultaneously, the exhaust system safely directs fumes away from the engine, keeping it running smoothly.

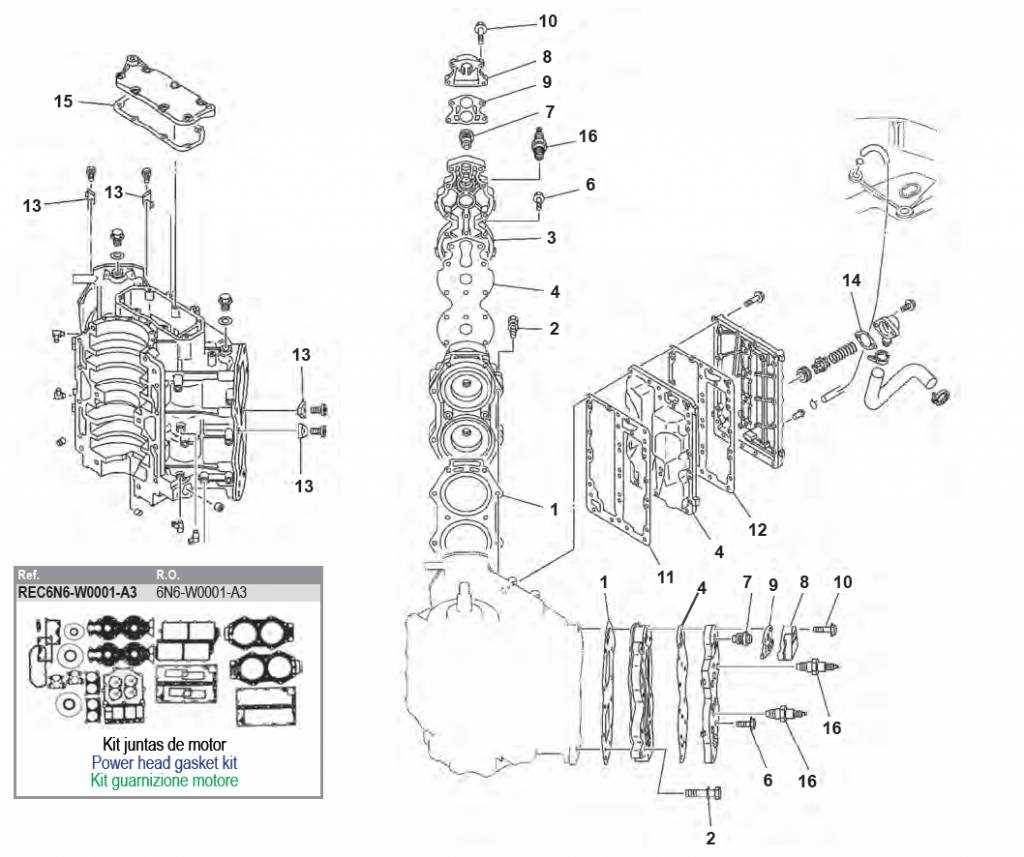

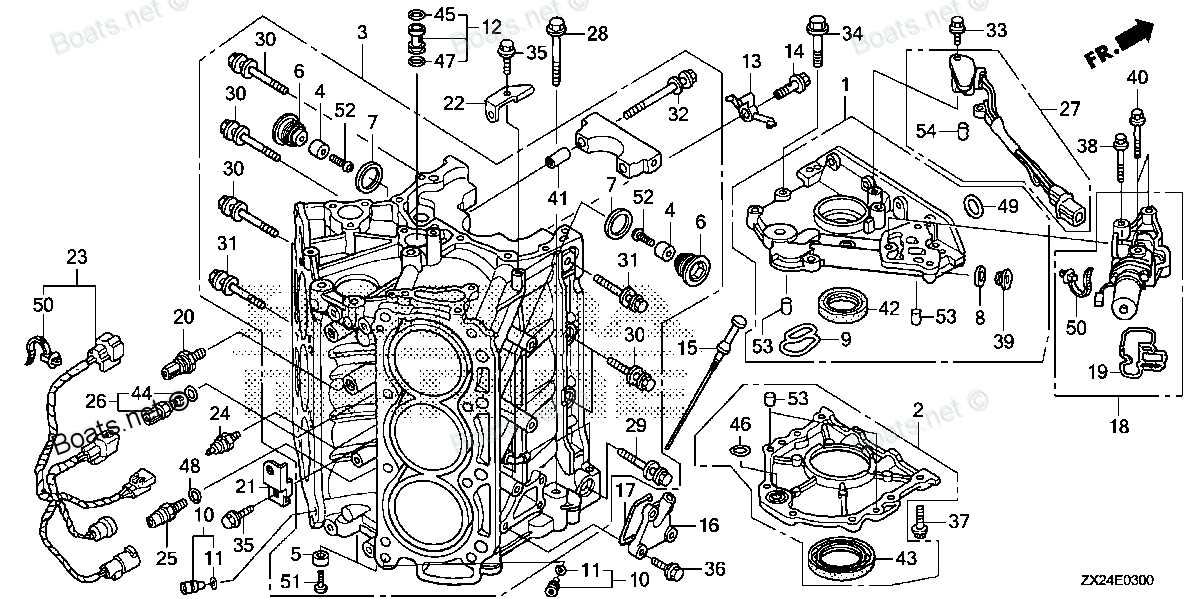

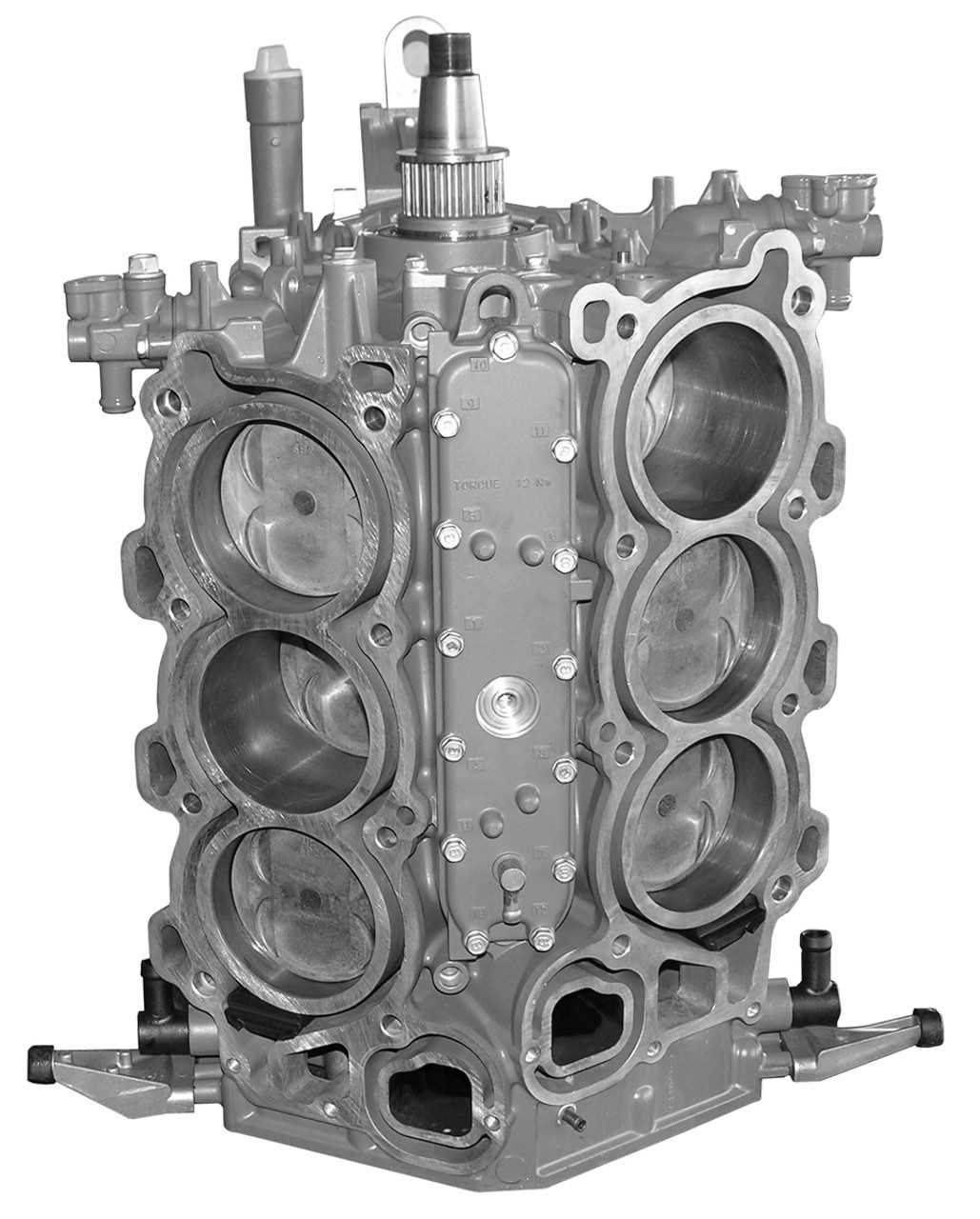

Understanding the Structure of the Engine Block

The engine block serves as the foundation of any motor system, providing a solid base for all essential components. It houses various critical elements that work in unison to generate power and ensure smooth operation. By exploring its structure, we can better comprehend how the different sections work together to maintain engine performance and reliability.

- Cylinder Layout: The arrangement of cylinders within the block plays a key role in determining the engine’s power output and efficiency. Properly aligned cylinders enable smooth combustion and optimized fuel use.

- Cooling Channels: The engine block contains passages that facilitate coolant flow, helping to regulate the temperature and prevent overheating during operation.

- Crankshaft Housing: The lower section of the block encloses the crankshaft, which converts the linear motion of the pistons into rotational force, driving the engine.

- Mounting Points: Strategically placed mounts ensure the stability of the entire assembly, securely attaching it to the frame and reducing vibration.

These elements, when integrated correctly, ensure the motor operates efficiently, providing durability and performance over time. Understanding this structure is key to diagnosing potential issues and improving mainte

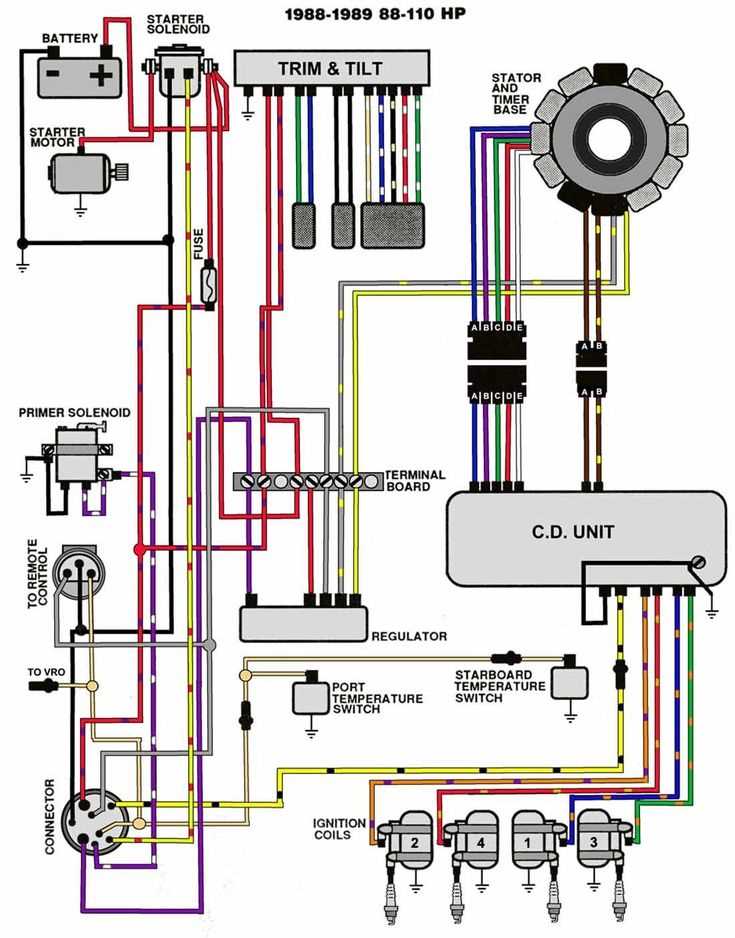

Electrical System: Essential Parts and Functions

The electrical network plays a vital role in ensuring the smooth operation of various components in marine engines. This system is responsible for distributing power, managing signals, and enabling the seamless performance of critical functions that support the engine’s overall efficiency. Understanding the key elements within this setup is crucial for maintaining the reliability of the entire mechanism.

One of the primary components is the alternator, which generates power to recharge the battery and sustain the electrical flow during operation. The battery stores energy to start the engine and power other essential features. Cables and connectors link these parts, ensuring that energy is transferred efficiently throughout the system. Circuit breakers and fuses offer protection by interrupting the flow of electricity in case of overload, preventing damage.

Another key element is the ignition system, which provides the necessary spark to ignite fuel. The regulator helps control the voltage, maintaining stable power levels to avoid fluctuations that could harm sensitive equipment. Switches, relays, and sensors work together to manage the flow of electricity, responding to different commands and conditions during use.

Maintaining these components ensures the electrical system remains reliable, enhancing performance and reducing the risk of malfunctions on the water.

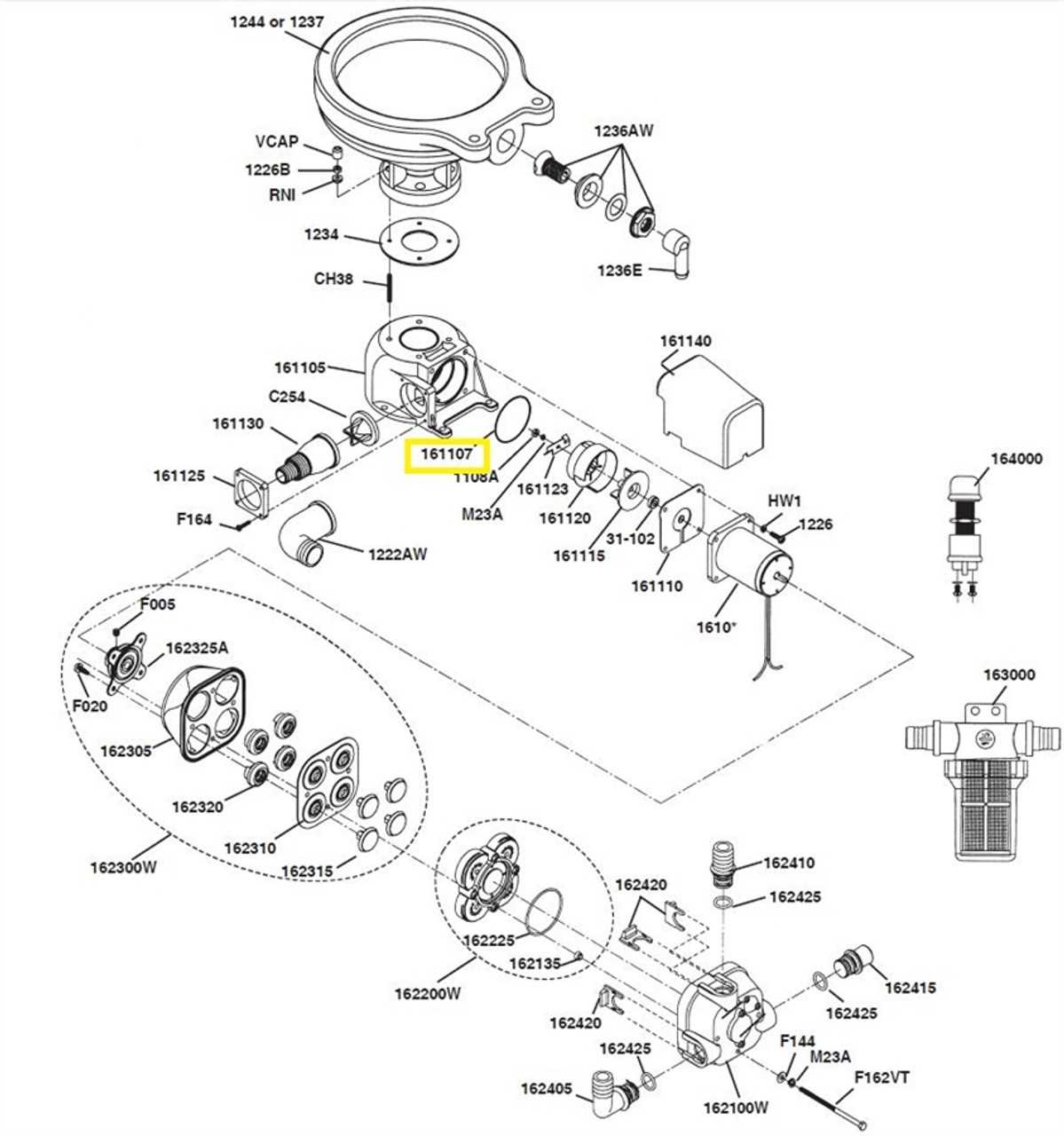

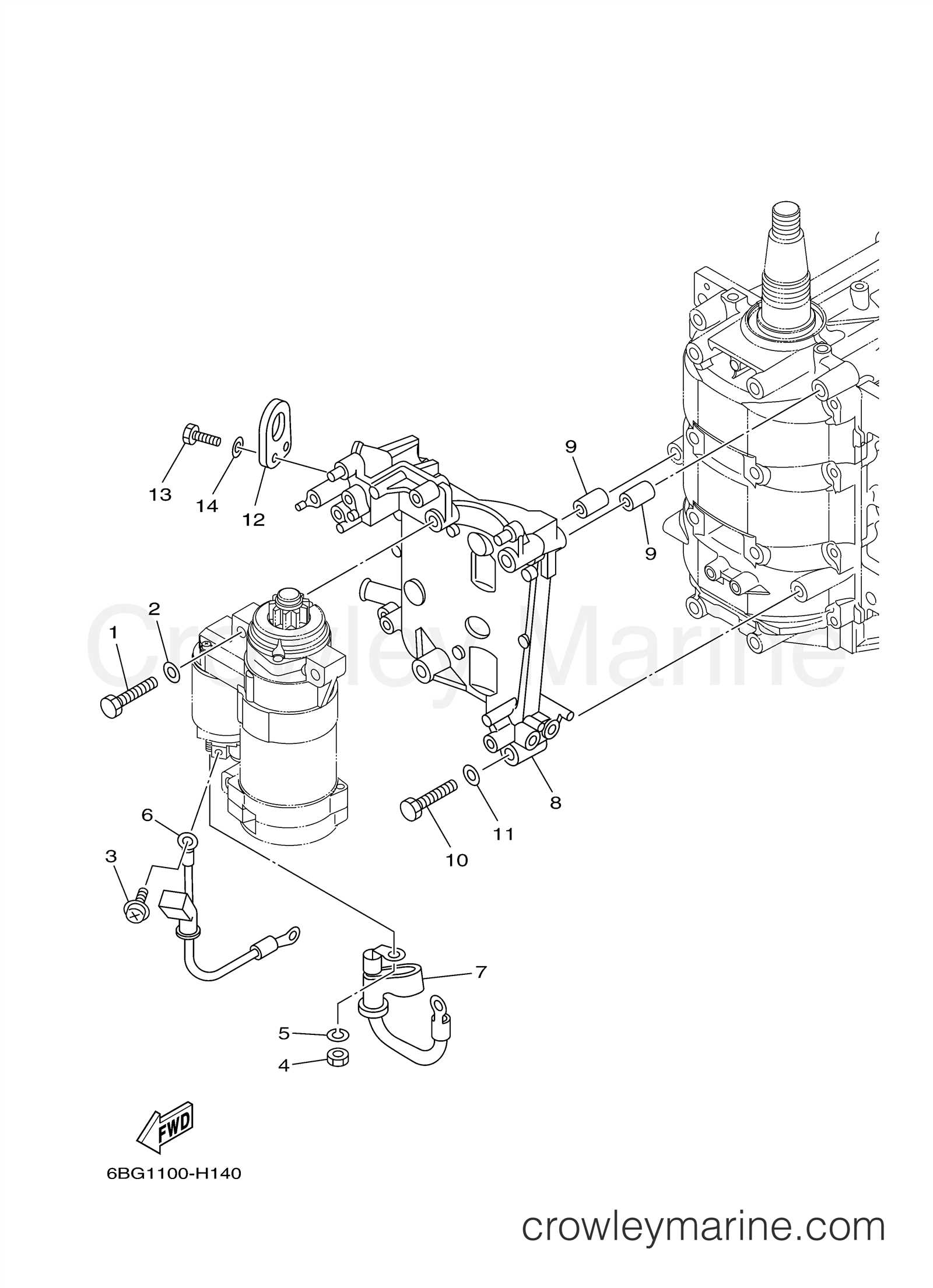

Fuel Delivery System Breakdown

The fuel delivery system is an essential component ensuring efficient engine performance. By understanding its individual sections and how they work together, it becomes easier to identify potential issues and ensure smooth operation. This section provides a detailed look at the key elements responsible for transporting fuel from the tank to the engine, with a focus on maximizing performance and minimizing malfunctions.

Main Components

At the core of the fuel delivery system are several interconnected parts that work together to maintain a consistent flow of fuel. These include the fuel pump, lines, and filters, each playing a critical role in the overall process. A proper understanding of how each component functions can help with troubleshooting and maintaining optimal fuel efficiency.

Fuel Delivery Flow

| Component | Function | |

|---|---|---|

| Fuel Pump | Pressurizes fuel for efficient delivery to the engine. | |

| Fuel Lines | Transport fuel from the tank to the engine. | |

| Fuel Filters | Remove impurities from the fuel to protect the engine. |

| Component | Function |

|---|---|

| Thermostat | Regulates coolant flow based on temperature, ensuring optimal heat management. |

| Water Pump | Circulates coolant throughout the engine and cooling system. |

| Heat Exchanger | Dissipates heat from the coolant to maintain safe engine temperatures. |

| Hoses | Facilitate the movement of coolant between the engine, pump, and heat exchanger. |

Regular inspection and maintenance of these components are crucial for preventing overheating and ensuring reliable performance. By understanding the function of each element, users can effectively troubleshoot issues and maintain their engines in peak condition.

Lubrication Components for Efficient Operation

Proper lubrication is essential for the optimal functioning of any marine engine system. It ensures smooth operation, minimizes wear and tear, and enhances overall performance. By maintaining adequate lubrication, operators can extend the lifespan of their equipment and ensure reliable performance in various conditions.

The key components involved in the lubrication process include pumps, filters, and oil reservoirs. Each element plays a vital role in ensuring that lubricants circulate effectively, reducing friction and preventing overheating. Understanding these components is crucial for anyone looking to maintain their marine machinery effectively.

| Component | Description | Function |

|---|---|---|

| Lubrication Pump | Device that circulates lubricant throughout the engine | Ensures continuous flow of oil to critical areas |

| Oil Filter | Removes impurities from the lubricant | Maintains clean oil for optimal performance |

| Oil Reservoir | Storage container for lubricant | Holds a sufficient supply of oil for the system |

| Cooling System | Component that helps regulate oil temperature | Prevents overheating and maintains viscosity |

By understanding these elements and their functions, users can effectively manage their lubrication systems, ensuring efficiency and reliability. Regular maintenance and timely replacement of worn components will lead to improved performance and longevity of the entire system.

Ignition System Layout and Details

The ignition mechanism is a vital component that ensures the engine operates efficiently and reliably. This system initiates the combustion process by producing a high-voltage spark, igniting the air-fuel mixture within the cylinders. Understanding its structure and functionality is essential for optimal performance and maintenance.

Components of the Ignition System

- Ignition Coil: Transforms the battery voltage into a high-voltage spark needed to ignite the fuel.

- Spark Plug: Delivers the electric spark to the combustion chamber, facilitating the ignition process.

- Power Pack: Regulates the timing and intensity of the spark, ensuring proper ignition timing.

- Trigger Sensor: Monitors the position of the engine and signals the power pack to deliver the spark at the right moment.

- Wiring Harness: Connects all components of the ignition system, allowing for the flow of electricity.

Functionality Overview

The ignition system operates through a series of coordinated actions. When the engine cranks, the trigger sensor detects the position of the crankshaft, sending signals to the power pack. The power pack then activates the ignition coil, which generates a high-voltage spark. This spark travels through the wiring harness to the spark plug, igniting the air-fuel mixture in the cylinder. Proper maintenance of each component is crucial to prevent misfires and ensure smooth operation.

Regular inspection and timely replacement of worn-out parts can significantly enhance engine performance and longevity.

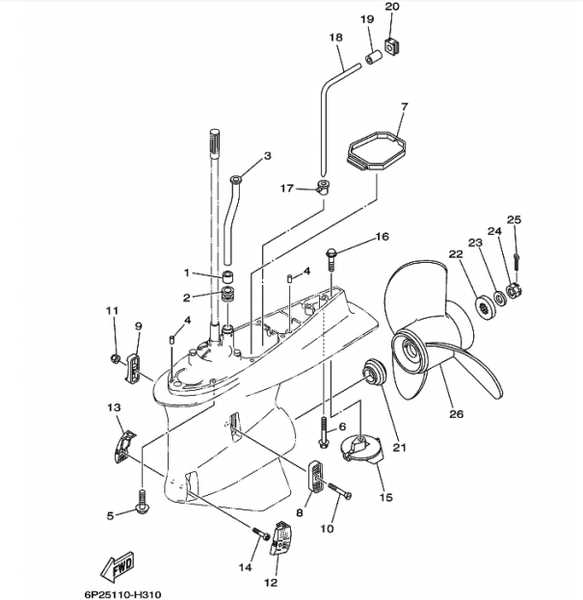

Steering Mechanism and Control Elements

The steering system is a crucial component that ensures precise maneuverability and control of the vessel. It integrates various elements that work in harmony to provide responsiveness and ease of navigation. Understanding the components involved in this mechanism is essential for maintaining optimal performance and safety while operating the boat.

Components of the Steering System

At the heart of the steering assembly lies the helm, which serves as the primary interface for the operator. Connected to the helm are cables or hydraulic lines that transmit the steering input to the actual rudder or drive unit. This connection facilitates smooth movement and adjustments in direction, allowing for an agile response to changes in navigation.

Control Elements

The control elements, including throttle and gear shift mechanisms, complement the steering functions. These controls enable the operator to manage speed and direction effectively. Proper calibration and maintenance of these elements are vital for achieving seamless operation and enhancing the overall boating experience.

Regular inspection and servicing of the steering assembly and control elements are recommended to prevent potential issues. Ensuring that all components are functioning correctly contributes to both the longevity of the system and the safety of those on board.

Exhaust System Components in Focus

The exhaust system is a crucial aspect of any marine engine, playing a vital role in maintaining optimal performance and ensuring environmental compliance. This system is designed to expel combustion gases efficiently while minimizing noise and emissions. Understanding the various elements involved can enhance maintenance practices and extend the lifespan of the engine.

Key Components of the Exhaust Assembly

The exhaust assembly comprises several integral components, each serving a specific purpose to facilitate the smooth operation of the system. These parts work together to manage the flow of exhaust gases while preventing back pressure and maintaining engine efficiency.

| Component | Description |

|---|---|

| Exhaust Manifold | A vital part that collects exhaust gases from the engine cylinders and directs them toward the outlet. |

| Water Jacket | This component cools the exhaust gases as they pass through, reducing the risk of overheating. |

| Silencer | Reduces noise generated by the exhaust gases, ensuring a quieter operation. |

| Exhaust Pipe | Transports exhaust gases from the manifold to the outside atmosphere, facilitating proper venting. |

Importance of Regular Maintenance

Regular inspection and maintenance of the exhaust components are essential for optimal performance and longevity. Ensuring that all parts are in good condition helps prevent potential issues such as leaks and excessive noise, ultimately contributing to a more efficient and environmentally friendly operation.

Maintenance Tips for Key Outboard Parts

Ensuring the longevity and performance of your marine engine requires regular attention to its essential components. By adopting a proactive approach to maintenance, you can enhance reliability and prevent potential issues during your outings on the water.

-

Regular Cleaning:

Keep the exterior clean by removing salt, dirt, and debris. A gentle wash with freshwater can prevent corrosion and buildup.

-

Fluid Checks:

Monitor oil levels and quality. Change the oil according to the manufacturer’s recommendations to ensure smooth operation.

-

Inspect Fuel System:

Check fuel lines for leaks and ensure filters are clean. This helps in maintaining optimal fuel flow and efficiency.

-

Battery Maintenance:

Inspect battery terminals for corrosion. Clean them regularly and ensure connections are secure to prevent starting issues.

-

Check Propeller Condition:

Regularly examine the propeller for nicks or damage. Proper alignment and condition are crucial for performance and fuel efficiency.

-

Examine Cooling System:

Ensure the cooling system is functioning effectively. Regularly check for obstructions and maintain proper fluid levels to avoid overheating.

By incorporating these maintenance practices, you can ensure your engine operates efficiently and reliably throughout the boating season. A little attention to detail goes a long way in preserving the performance of your marine equipment.