Marine engines play a crucial role in delivering power and efficiency on the water. When it comes to maintaining or repairing your engine, having a clear understanding of its internal structure is essential. Each piece, from the core mechanisms to the smaller elements, contributes to the overall performance and longevity of the motor. Exploring the layout of these elements can help in both troubleshooting and routine care.

The various elements of this marine engine work together in harmony to ensure smooth and reliable operation. Identifying these components and understanding their functions provides valuable insights for anyone looking to maintain or enhance the engine’s performance. Knowing how different sections are connected can assist in repairs and in optimizing the motor’s efficiency.

Whether you’re performing

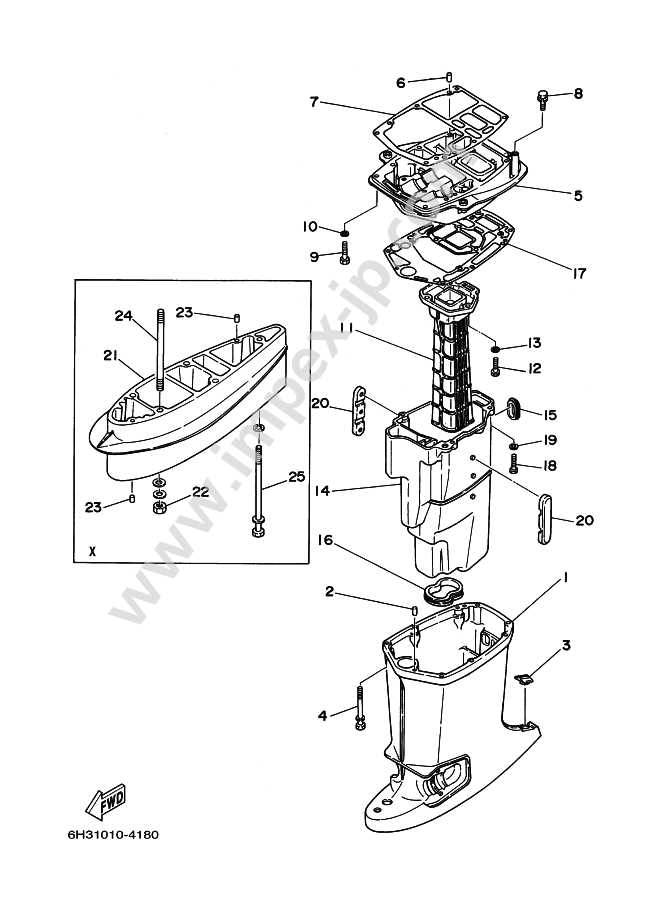

Understanding Key Components of Yamaha Outboards

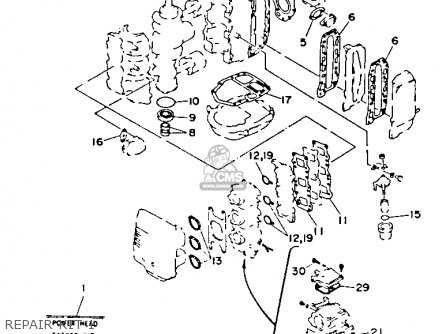

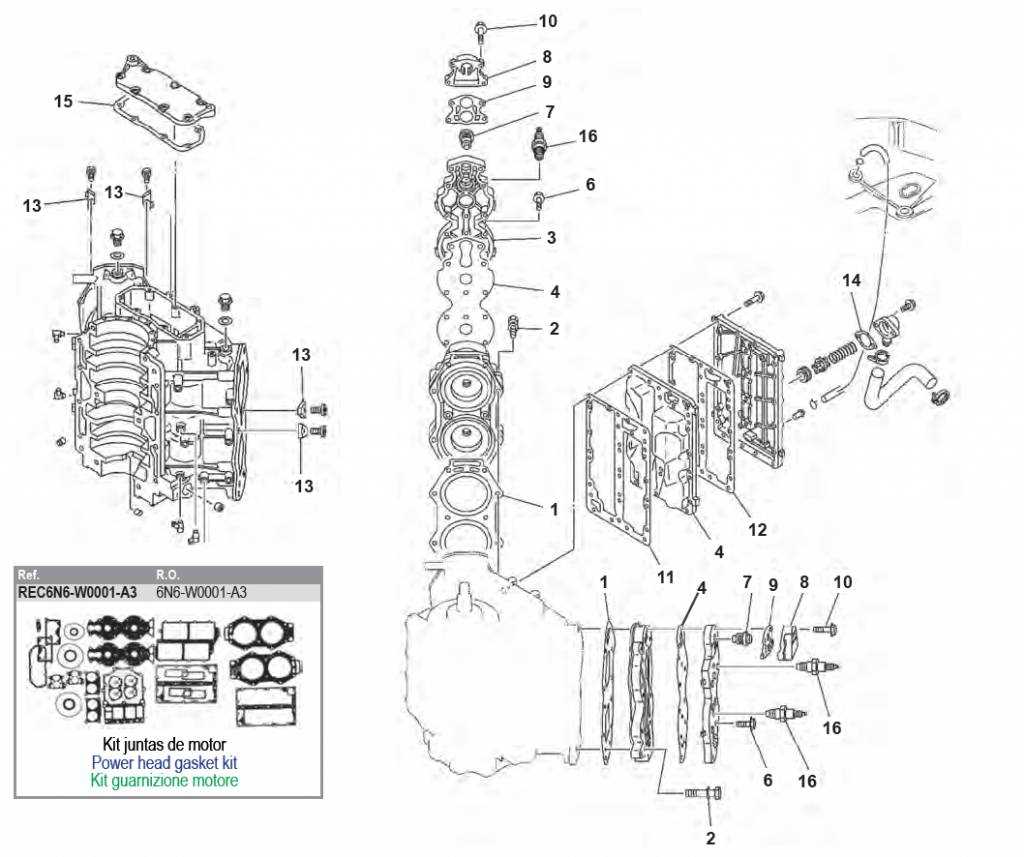

In any marine engine system, various elements work together to ensure smooth performance and durability. Recognizing these essential parts is crucial for maintaining and optimizing the engine’s functionality. Each component has a specific role that contributes to the overall reliability and power of the system, whether for navigation or high-speed operations.

Core Mechanical Elements

- Powerhead: The central unit responsible for generating the necessary force, driving the entire propulsion system.

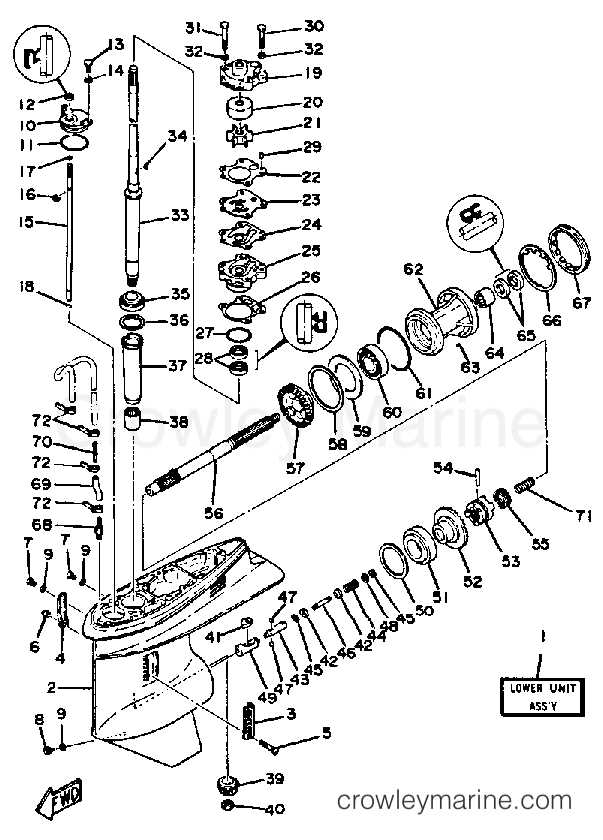

- Lower Unit: The mechanism that connects to the propulsion blade, transmitting energy from the engine to the water.

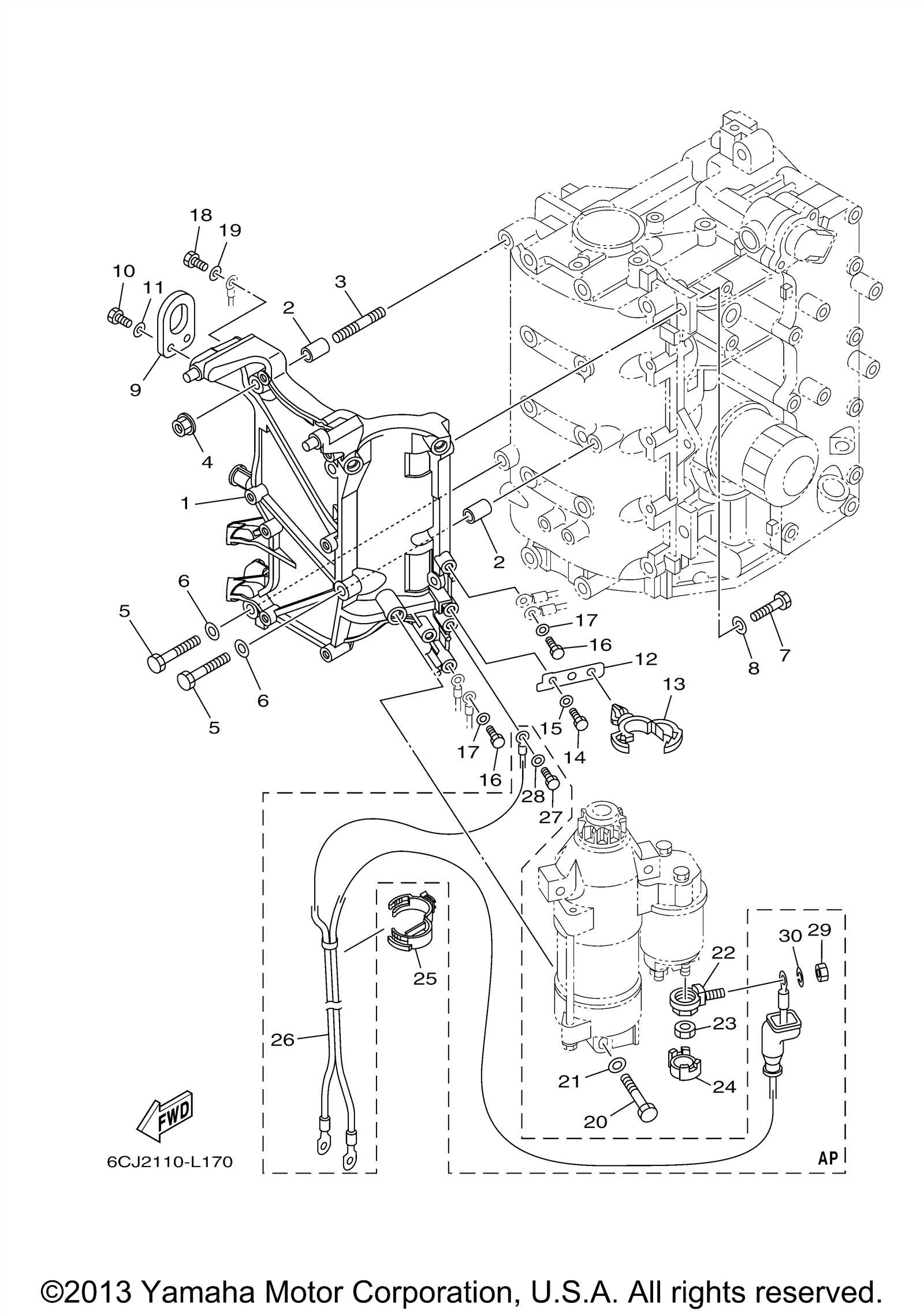

- Fuel Tank: The primary storage unit for the fuel, designed to ensure a clean and safe supply. Regular inspection is essential to avoid contamination and leaks.

- Fuel Lines: These tubes carry fuel from the tank to the engine. Proper maintenance, such as checking for cracks or blockages, is crucial for uninterrupted flow.

- Fuel Filter: A component that prevents debris and impurities from entering the system, prolonging the lifespan of the engine

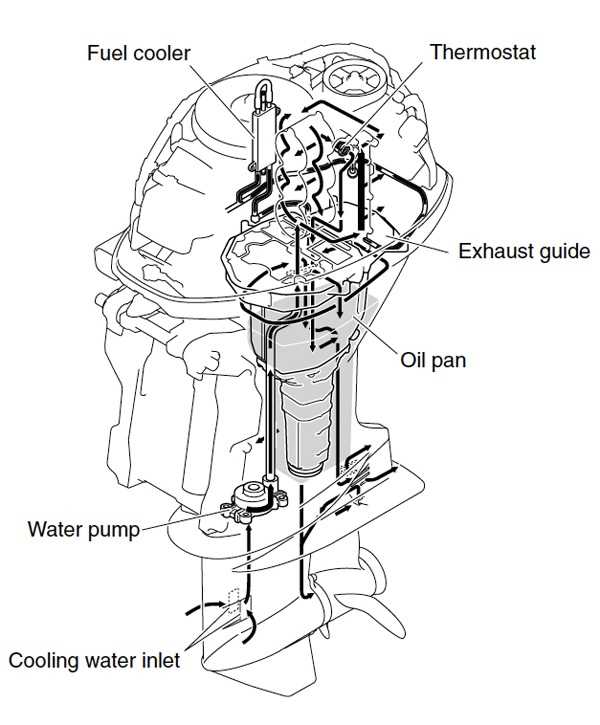

Examining the Cooling Mechanism in Yamaha Engines

The efficiency of any internal combustion engine relies heavily on its ability to manage heat. Effective temperature regulation is essential for optimal performance and longevity. Understanding the cooling processes in marine power units is crucial for maintaining their functionality and preventing overheating.

In these engines, a sophisticated system circulates coolant fluid to absorb excess heat generated during operation. This liquid is then directed through various channels and components to ensure uniform temperature distribution. The implementation of this cooling method not only enhances performance but also safeguards critical engine components from thermal damage.

Regular maintenance and inspection of the cooling system are vital. Components such as pumps, thermostats, and heat exchangers play a pivotal role in sustaining efficient cooling. Any malfunction within this system can lead to serious operational issues, emphasizing the need for diligent monitoring and timely repairs.

Understanding the intricacies of the cooling mechanism empowers operators to make informed decisions regarding maintenance and repairs. Being proactive in addressing potential cooling issues can significantly enhance the durability and reliability of marine engines, ensuring they perform at their best for years to come.

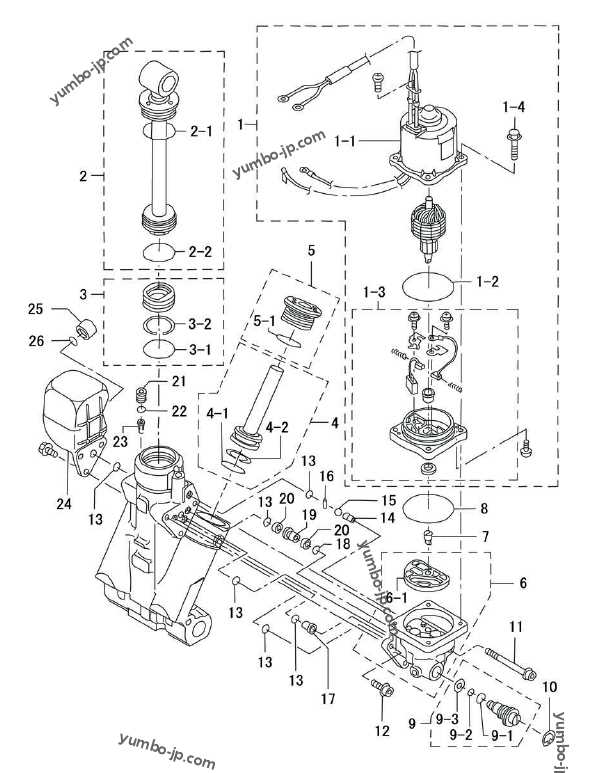

Ignition System Layout and Maintenance Tips

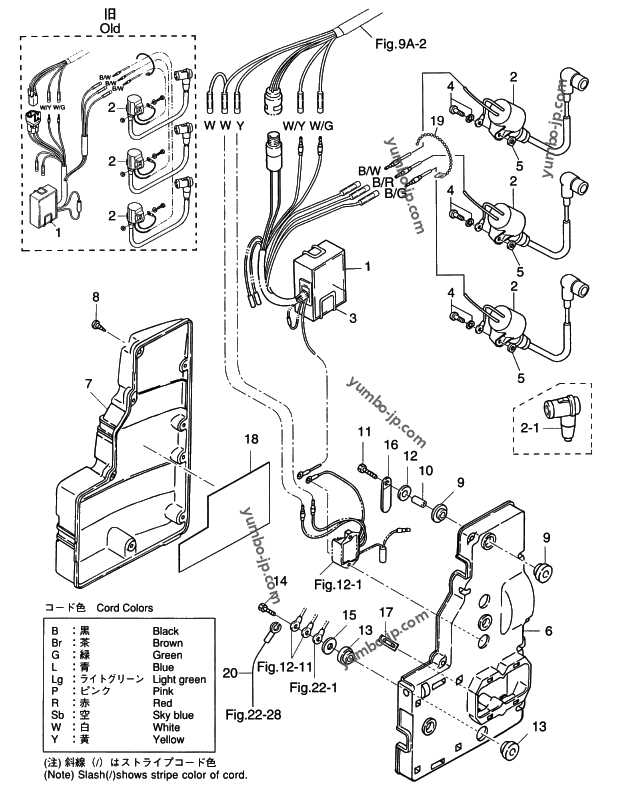

The ignition system is a crucial component in ensuring the reliable operation of marine engines. Understanding its configuration is essential for effective upkeep and troubleshooting. Proper maintenance not only enhances performance but also extends the lifespan of the entire power unit.

Understanding the Components

This system typically consists of various elements, including the spark plugs, ignition coil, wiring harness, and the timing mechanism. Each part plays a vital role in generating and delivering the spark needed to ignite the fuel-air mixture. Regular inspection of these components is important for identifying wear or damage, which can lead to performance issues.

Maintenance Best Practices

To keep the ignition system functioning optimally, ensure that the spark plugs are cleaned or replaced as recommended by the manufacturer. Checking the ignition coil for signs of corrosion or faults is also advisable. Additionally, inspecting the wiring for any frays or breaks can prevent unexpected failures. Implementing these practices can significantly improve reliability and efficiency.

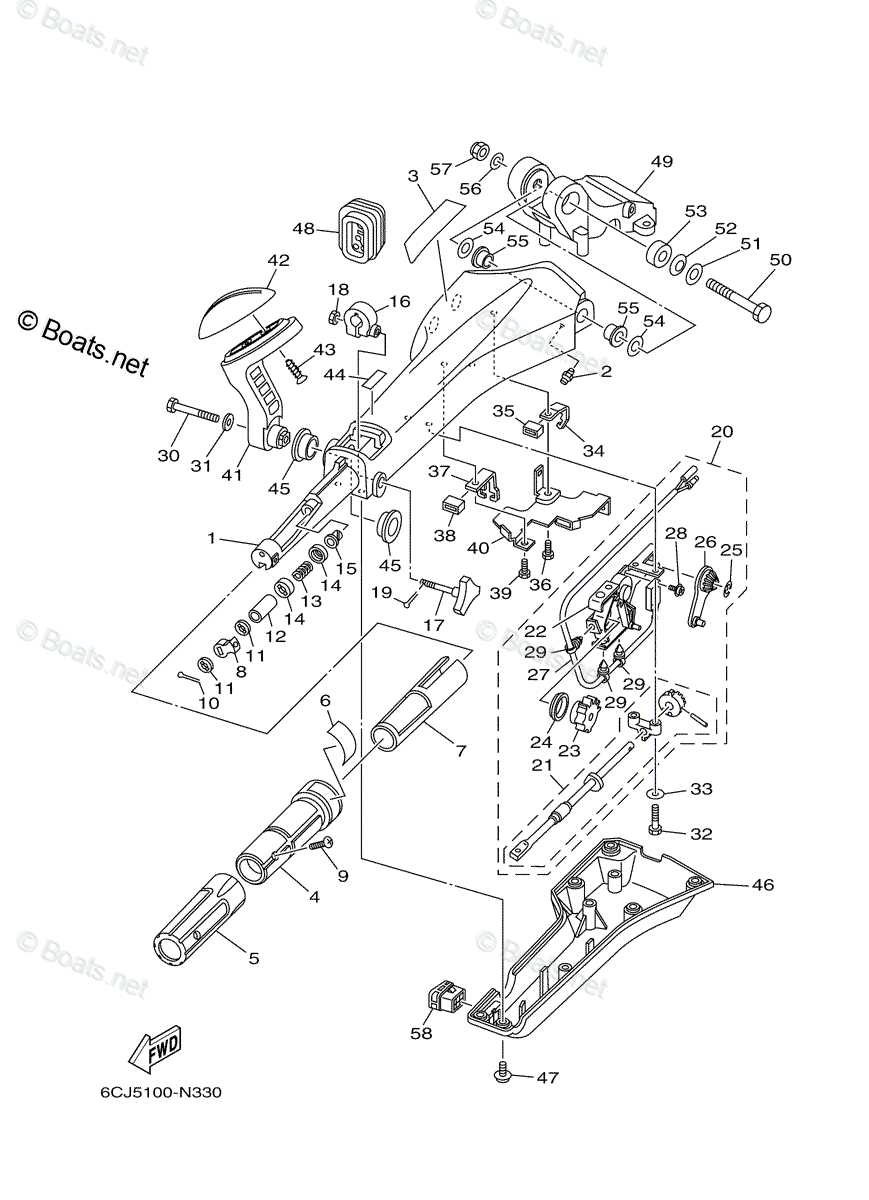

Throttle and Shift Linkage Overview

The connection between the throttle and shift mechanisms plays a crucial role in the overall performance of marine engines. Understanding how these components interact is essential for maintaining efficiency and ensuring smooth operation. This section delves into the primary elements involved in controlling speed and direction, highlighting their functions and significance.

Key Components

The assembly typically consists of several essential elements that work together harmoniously. These include the throttle cable, shift cable, control box, and various linkages. Each component must be correctly adjusted and maintained to prevent issues such as misalignment or failure to engage.

Functionality and Maintenance

Regular inspection and maintenance of the throttle and shift assembly are vital to ensure optimal performance. Lubrication of moving parts, checking for wear, and proper alignment are critical tasks that should not be overlooked. Keeping these components in top condition contributes to a reliable and responsive boating experience.

Component Function Throttle Cable Controls engine speed by regulating fuel flow Shift Cable Enables gear engagement for forward, neutral, and reverse Control Box Serves as the interface for operator commands Linkages Connects cables to the engine’s throttle and shift mechanisms Detailed View of Electrical Wiring and Connections

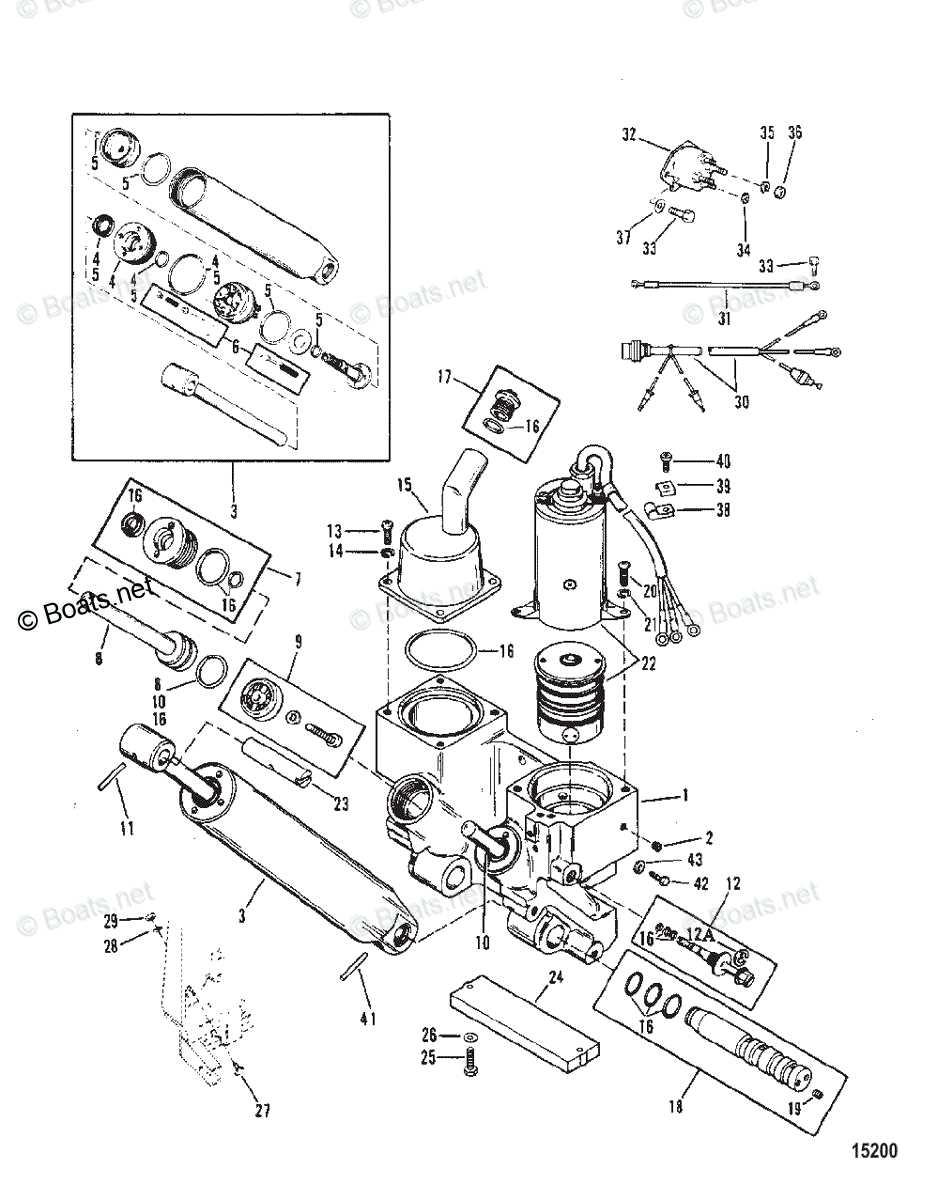

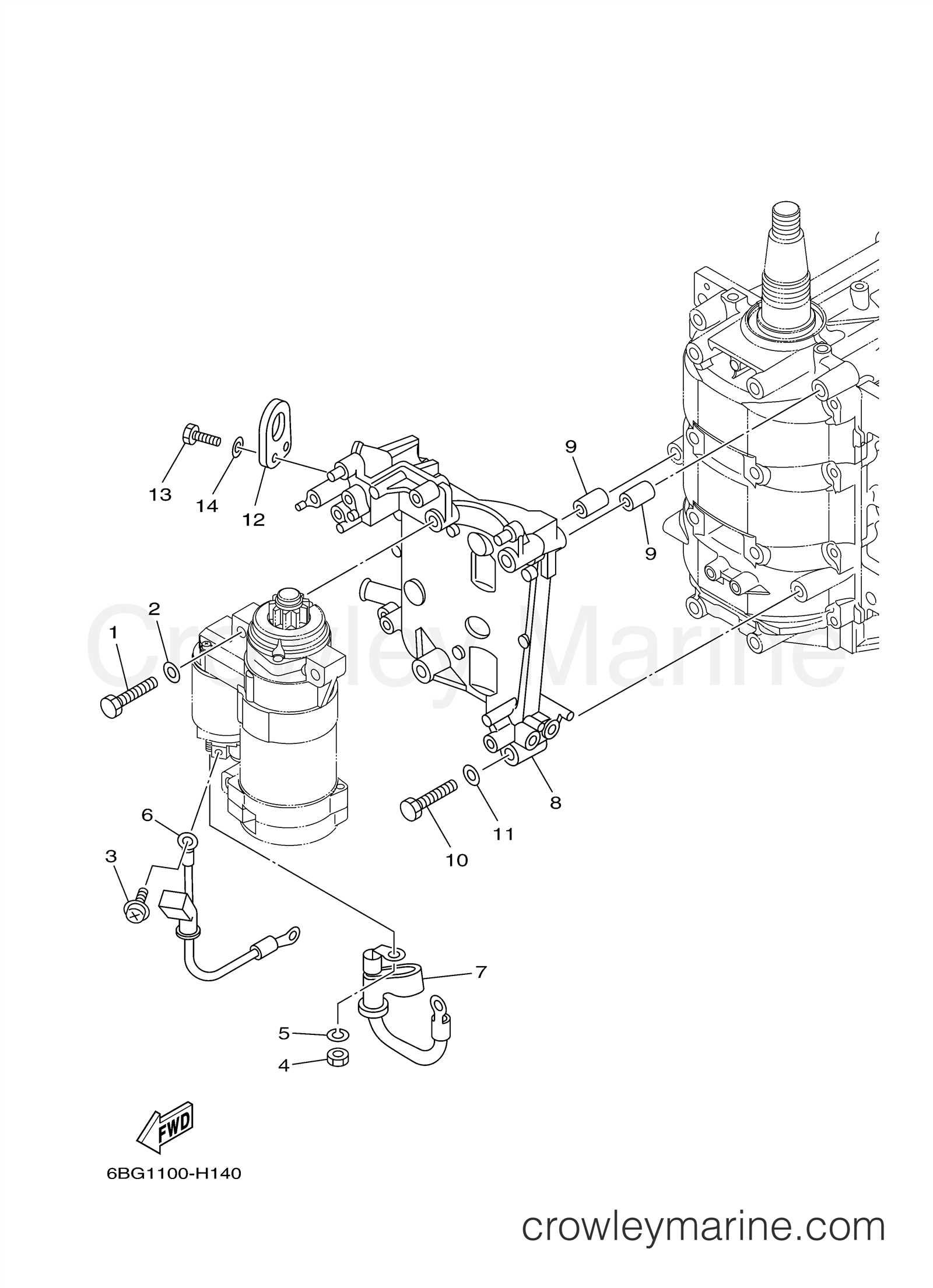

This section provides a comprehensive examination of the intricate network of electrical components and their interconnections within the marine engine. Understanding the configuration and relationships of these elements is crucial for effective troubleshooting and maintenance. The electrical system plays a vital role in the overall functionality, ensuring smooth operation and reliability.

Overview of Wiring Layout

The wiring layout consists of various cables, connectors, and terminals that facilitate communication between different units. Each wire has a specific function, contributing to the efficient operation of systems such as ignition, lighting, and control mechanisms. Recognizing the purpose of each wire helps in identifying potential issues that may arise during use.

Key Connections to Monitor

Among the essential connections to monitor are those related to power distribution and signal transmission. Power cables deliver electrical energy to critical components, while signal wires communicate operational statuses. Regular inspection of these connections can prevent malfunctions and ensure longevity of the equipment.

Propeller Assembly and Functionality

The propeller assembly plays a crucial role in the propulsion system, translating engine power into forward motion. This component is designed to interact with water, creating thrust that drives the vessel through various aquatic environments.

Key components of the propeller assembly include:

- Blades: The primary elements that generate thrust by pushing water backward.

- Hub: The central part that connects the blades and secures them to the shaft.

- Shaft: The rod that transmits rotational force from the engine to the propeller.

- Nuts and Washers: Fasteners that ensure secure attachment of the propeller to the shaft.

Understanding the functionality of each component is essential for optimal performance:

- Thrust Generation: The angle and shape of the blades influence how effectively water is pushed, impacting speed and efficiency.

- Torque Management: The assembly must withstand the twisting forces produced during operation, ensuring stability and durability.

- Balance: Proper alignment and weight distribution of the blades are crucial to minimize vibration and enhance overall handling.

Regular maintenance and inspection of the propeller assembly are vital for safe and efficient operation. This ensures that the vessel can perform optimally in various conditions, enhancing both speed and maneuverability.

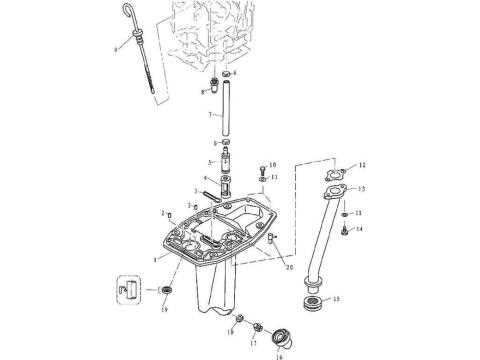

Gearbox Parts and Their Functions

The gearbox is a vital component of marine propulsion systems, responsible for transferring power from the engine to the propeller. Understanding the various elements within this mechanism is essential for efficient operation and maintenance. Each component plays a specific role in ensuring smooth gear shifts and optimal performance in diverse conditions.

Component Description Case Encloses and protects internal components from environmental factors while maintaining lubrication. Gear Set Transforms engine speed and torque to appropriate levels for efficient propulsion. Shift Mechanism Facilitates gear changes, allowing for smooth transitions between different speed settings. Bearings Reduces friction between moving parts, ensuring longevity and reliable performance. Seal Prevents fluid leakage, maintaining optimal lubrication and protecting components from contamination. Lubrication System Components and Role

The lubrication system is essential for maintaining the longevity and performance of marine engines. It ensures that all moving parts operate smoothly, reducing friction and wear. By distributing oil throughout the engine, this system plays a crucial role in preventing overheating and protecting critical components from damage.

Key Elements of the Lubrication System

The primary components of the lubrication system include the oil pump, oil filter, and various oil passages. The oil pump is responsible for circulating the lubricant throughout the engine, ensuring that every part receives adequate coverage. The oil filter serves to remove impurities and debris from the oil, maintaining its effectiveness and preventing contaminants from causing damage.

Functionality and Importance

Each element within the lubrication framework serves a specific function that contributes to overall engine health. The consistent flow of oil reduces friction between moving parts, enhancing efficiency and performance. Additionally, proper lubrication minimizes the risk of overheating and prolongs the life of the engine, making it a critical aspect of maintenance.

Exhaust System Structure in Yamaha Outboards

The exhaust assembly plays a critical role in the performance and efficiency of marine propulsion systems. Its design ensures that harmful gases are effectively expelled while minimizing noise and environmental impact. Understanding its components is essential for maintaining optimal functionality.

- Exhaust Manifold: This component collects exhaust gases from the engine cylinders and directs them toward the exhaust outlet.

- Exhaust Risers: These sections elevate the exhaust gases from the manifold to prevent water intrusion, allowing safe exit above the waterline.

- Water Injection System: Integrated within the exhaust path, this feature cools the hot gases and helps reduce emissions, ensuring compliance with environmental standards.

- Silencer: Designed to dampen noise, the silencer reduces the sound produced during exhaust gas expulsion, contributing to a quieter operation.

- Exhaust Outlet: The final point in the exhaust flow, this section allows the gases to exit into the atmosphere, often located above the waterline to prevent backflow.

Regular inspection and maintenance of the exhaust structure are vital to ensure longevity and peak performance. Each component contributes to the overall effectiveness of the system, directly influencing engine performance and environmental compliance.

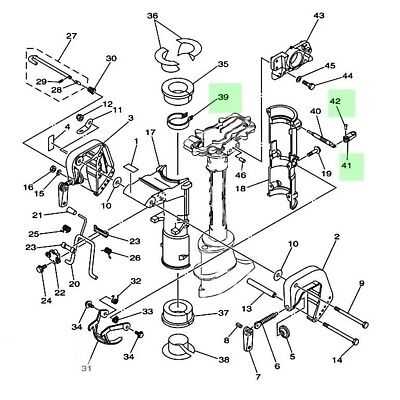

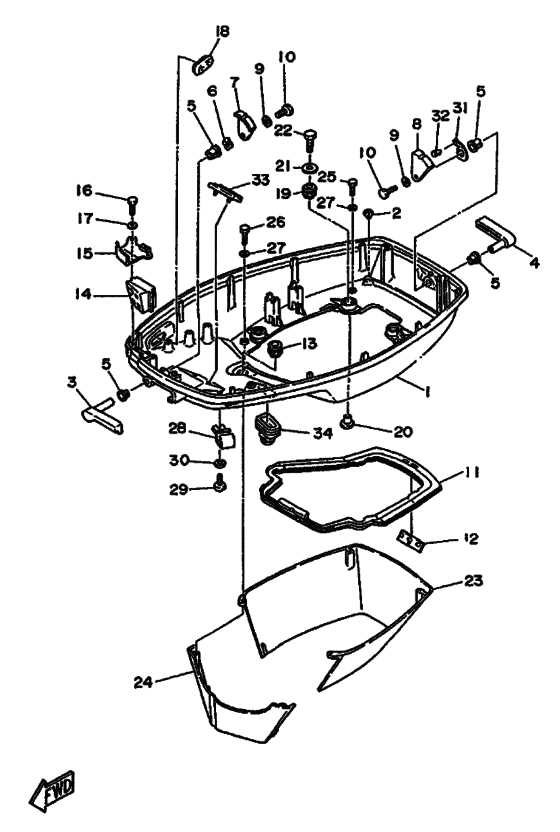

Steering Mechanism and Control Parts

The steering apparatus and control components play a crucial role in ensuring smooth navigation and responsiveness in watercraft. These elements work together to provide the operator with precise control over direction and movement, enhancing the overall experience on the water. Understanding the various components involved is essential for maintaining optimal performance and addressing any potential issues that may arise.

The main elements of the steering system include the helm, which serves as the control interface, and the associated linkages that transmit motion to the steering system. These components are designed to work in unison, allowing for seamless maneuvering of the vessel. The control mechanism also incorporates various levers and connectors that facilitate adjustments and fine-tuning, ensuring that the steering response aligns with the operator’s commands.

Regular maintenance of these systems is essential to avoid complications and ensure longevity. Routine inspections can help identify wear and tear on critical components, allowing for timely replacements and repairs. By understanding the intricacies of the steering and control systems, operators can enhance the reliability and safety of their maritime adventures.

How to Identify Wear and Tear on Key Parts

Regular inspection of essential components is crucial for maintaining optimal performance and longevity. Identifying signs of deterioration can prevent costly repairs and ensure smooth operation. Familiarity with common indicators of wear will enable proactive maintenance and timely replacements.

One of the primary areas to examine is the propeller. Look for dents, cracks, or bent blades, as these can significantly affect efficiency and handling. Additionally, inspect the shaft for any signs of rust or pitting, which may indicate corrosion. A thorough check for misalignment or excessive play in the joints can also reveal potential issues.

The engine cover should be examined for cracks or loose fittings, ensuring it provides adequate protection. Check the fuel lines for leaks, cracks, or signs of wear; these can compromise performance and safety. Lastly, pay attention to the battery; inspect terminals for corrosion and ensure secure connections to prevent power loss.

By keeping a vigilant eye on these components, one can easily detect early signs of wear and take corrective action, ultimately enhancing reliability and extending service life.

Fuel System Breakdown for Optimal Performance

Understanding the layout and function of the fuel system is key to ensuring consistent and efficient operation. Each element within the fuel delivery process plays a vital role in maintaining smooth performance, minimizing issues, and optimizing power output.