Silencer: This component helps to further dampen sound emissions, ensuring quieter

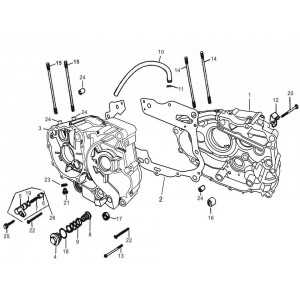

Analyzing the Frame and Chassis Assembly

Understanding the construction of the frame and chassis is crucial when examining any all-terrain vehicle’s overall durability and performance. These components provide the foundation for handling, stability, and support, especially when subjected to off-road conditions. A closer look at their structure reveals how well the vehicle can withstand stress during demanding rides.

Frame Design

The framework is typically constructed to provide a balance between strength and flexibility. Materials such as lightweight metals are often used to ensure durability while maintaining manageable weight. The design also allows for the attachment of various components without compromising structural integrity.

- High-tensile materials for durability

- Weight distribution for enhanced control

- Support for key mechanical elements

Chassis Assembly

Brake System Components and Configuration

The brake system plays a crucial role in ensuring safe and effective stopping power, relying on a combination of interconnected elements. Understanding how these components work together enhances both maintenance and performance of the braking setup.

The core elements include the brake lever, which initiates the process, connected to a cable or hydraulic line that transmits force to the caliper. The caliper then clamps onto the brake disc, creating friction that slows down the vehicle. Additionally, the system features brake pads that provide the necessary friction surface, while the disc or drum serves as the rotating part that the pads grip onto.

Proper configuration of these components is essential to ensure optimal braking performance. Factors such as pad alignment, fluid pressure in hydraulic systems, and cable tension in mechanical setups all affect the responsiveness and effectiveness of the

Understanding the Carburetor Structure

The carburetor plays a crucial role in the performance of an engine, responsible for mixing air and fuel in the appropriate ratio. Its design directly influences the efficiency and power output of the machine. A thorough comprehension of its components is essential for effective maintenance and troubleshooting.

Typically, a carburetor consists of several key elements:

- Float Chamber: This section maintains a consistent fuel level, allowing for stable operation.

- Venturi: A narrowing in the airflow pathway that creates a vacuum, drawing fuel into the air stream.

- Jets: These small openings regulate the amount of fuel delivered based on engine demands.

- Throttle Valve: Controls the amount of air-fuel mixture entering the engine, directly affecting acceleration.

- Choke: A mechanism used to restrict airflow during starting, enriching the mixture for easier ignition.

Each component has a specific function, contributing to the overall operation of the carburetor. Understanding these parts helps in diagnosing issues and optimizing performance, ensuring the engine runs smoothly.

Electrical Parts Placement and Functions

This section focuses on the arrangement and roles of various electrical components within the vehicle. Understanding the layout and operation of these elements is crucial for effective maintenance and troubleshooting.

Key Components and Their Locations

- Battery: Positioned under the seat, the battery supplies power to the ignition system and other electrical accessories.

- Starter Relay: Located near the battery, this component enables the engine to start by connecting the battery to the starter motor.

- Ignition Coil: Typically found on the frame near the engine, the ignition coil transforms low voltage from the battery into the high voltage needed to ignite the fuel-air mixture.

- Regulator/Rectifier: Usually mounted close to the engine, this part converts alternating current (AC) produced by the stator into direct current (DC) to charge the battery.

- Wiring Harness: Running throughout the frame, this collection of wires connects all electrical components, ensuring they function harmoniously.

Functions of Electrical Components

- Power Distribution: Each component plays a role in distributing electrical energy, ensuring that all systems receive the necessary power.

- Starting the Engine: The interaction between the battery, starter relay, and ignition coil is vital for initiating the engine’s operation.

- Charging System: The regulator/rectifier maintains the battery’s charge while the engine runs, preventing electrical failures.

- Safety Features: Components such as fuses protect the system from overloads and shorts, enhancing overall reliability.

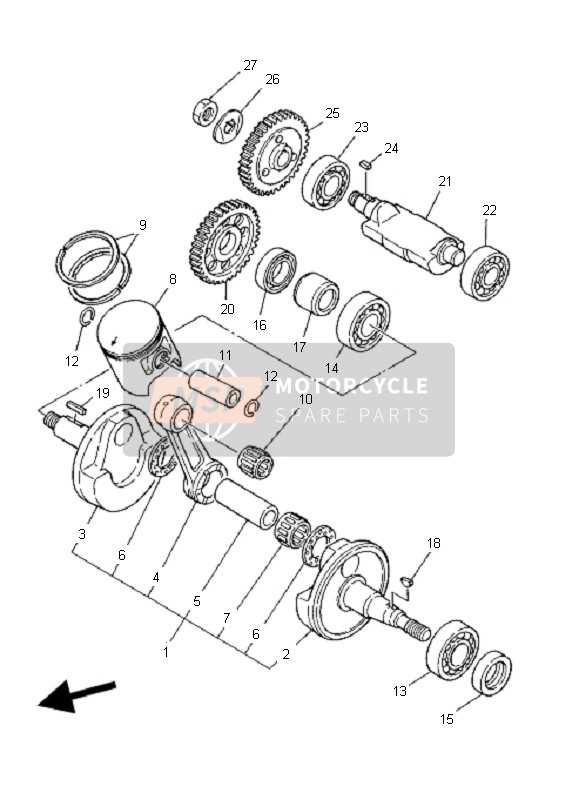

Transmission Assembly and Gearbox Design

The transmission assembly plays a crucial role in the overall performance of a vehicle, facilitating power transfer from the engine to the wheels. This complex system is designed to optimize speed and torque while ensuring smooth operation across various conditions. Understanding its components and their arrangement is essential for effective maintenance and performance enhancement.

The gearbox design incorporates various elements that contribute to its functionality:

- Gears: Essential for altering speed and torque, these components come in different sizes and shapes, tailored to specific performance requirements.

- Shafts: These play a vital role in connecting gears and transferring motion throughout the assembly.

- Bearings: Providing support and reducing friction, bearings enhance the efficiency and longevity of the transmission.

- Clutch Mechanism: This component allows for smooth engagement and disengagement of gears, facilitating seamless transitions during operation.

In addition to these key components, the layout and configuration of the assembly significantly influence overall performance. A well-designed gearbox ensures optimal power distribution, contributing to improved acceleration and responsiveness. Regular inspection and maintenance of these elements are crucial for sustaining functionality and preventing premature wear.

By understanding the intricacies of the transmission assembly and gearbox design, enthusiasts and technicians alike can appreciate the engineering that underpins effective power management in vehicles.

Front and Rear Axle Breakdown

The axle system is a crucial component in the overall functionality and performance of any all-terrain vehicle. This section delves into the various elements that make up the front and rear axles, highlighting their roles, configurations, and the importance of each part in ensuring optimal handling and stability.

Front Axle Components: The front axle is designed to support the weight of the vehicle while allowing for steering and suspension movement. Key elements include the spindles, which connect the wheels to the axle, and the hub assembly, which facilitates smooth wheel rotation. Additionally, ball joints play a pivotal role in providing articulation between the axle and the steering mechanism.

Rear Axle Features: The rear axle serves a dual purpose of supporting the vehicle’s weight and transmitting power from the engine to the wheels. This section encompasses the drive shaft, which transfers torque, and the differential, which enables smooth turning by allowing wheels to rotate at different speeds. Furthermore, axle shafts are critical for maintaining structural integrity under various loads and conditions.

Understanding the breakdown of these components not only aids in effective maintenance but also enhances the overall performance and safety of the vehicle, ensuring an enjoyable riding experience.

Fuel System Parts and Connections

The functionality of an engine relies significantly on its fuel management system. This intricate network is designed to ensure a seamless flow of fuel, which is vital for optimal performance. Understanding the components and their interrelations within this system is essential for effective maintenance and troubleshooting.

At the core of this assembly is the fuel tank, which stores the fuel before it is delivered to the engine. Connected to the tank is the fuel pump, responsible for moving the fuel through the system. Once the fuel is pumped, it travels through the fuel lines towards the carburetor or fuel injection system, where it is mixed with air to form a combustible mixture.

Additionally, the fuel filter plays a crucial role in maintaining the integrity of the fuel system by trapping impurities and contaminants. Ensuring that the filter is clean and free from blockages is vital for preventing engine performance issues. Proper connections and secure fittings throughout the system are essential for maintaining pressure and preventing leaks, which can lead to malfunctions or unsafe operating conditions.

In summary, a thorough understanding of the various components involved in the fuel management system allows for better maintenance practices and enhances the overall efficiency of the engine.

Cooling System Components and Functionality

The effectiveness of a thermal regulation setup is essential for maintaining optimal performance in any motorized vehicle. This system ensures that the engine operates within a safe temperature range, preventing overheating and potential damage. Understanding the various elements involved in this process is crucial for proper maintenance and troubleshooting.

Key Components

The cooling arrangement typically comprises several vital parts, including the radiator, water pump, and cooling fins. The radiator dissipates heat absorbed from the engine coolant, while the water pump circulates the coolant throughout the engine block. Additionally, the cooling fins increase surface area to enhance heat transfer, allowing for efficient temperature control.

Functionality Overview

In operation, the system draws in coolant from the engine, where it absorbs heat generated during combustion. This heated liquid then flows to the radiator, where it releases the heat into the air. As the coolant cools, it returns to the engine, ready to absorb more heat. This continuous cycle maintains optimal engine temperatures, ensuring reliability and performance.