In the realm of marine engines, comprehending the arrangement of various components is crucial for effective maintenance and troubleshooting. A well-structured overview aids in identifying essential elements and ensures that enthusiasts and professionals alike can navigate their tasks with confidence. By grasping the configuration of these parts, one can enhance both the performance and longevity of the machinery.

Each segment of the engine plays a vital role, contributing to the overall functionality. Familiarity with these components allows for informed decision-making regarding repairs and replacements. Whether you are an experienced technician or a novice, having a clear reference can significantly simplify the process, ensuring that everything operates seamlessly.

Assembling the knowledge about the intricate details of engine layouts not only empowers users but also fosters a deeper appreciation for the engineering behind marine technology. This insight serves as a valuable resource for anyone looking to optimize their engine’s performance and reliability.

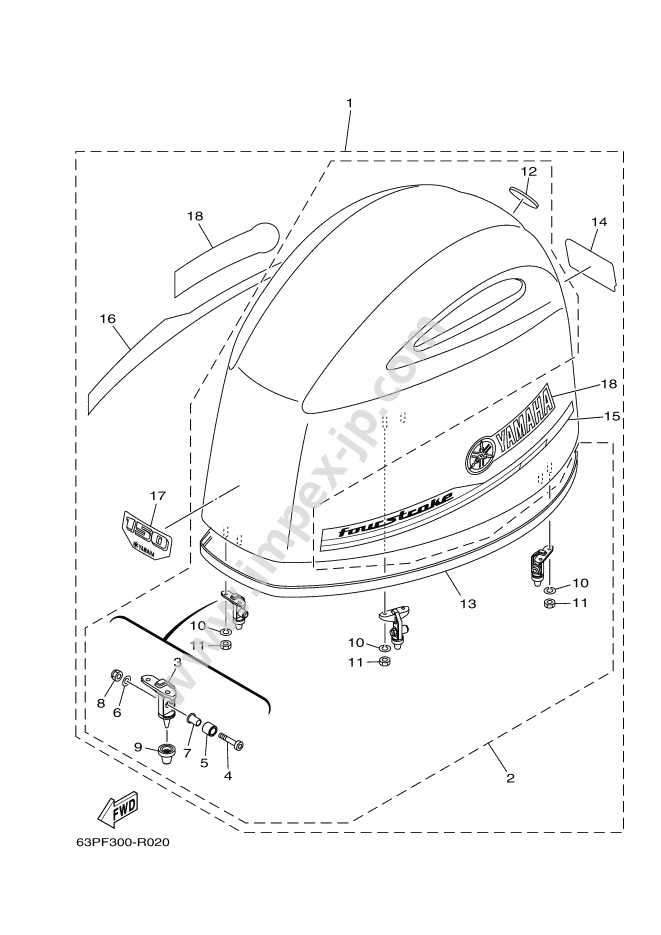

Overview of Yamaha F150TXR Components

This section provides a comprehensive examination of the various elements that constitute a specific marine propulsion system. Understanding these components is essential for effective maintenance, troubleshooting, and optimization of performance.

The primary engine is at the core of the system, delivering the necessary power for operation. Surrounding this central unit are critical accessories such as the cooling system, which regulates temperature, and the fuel delivery mechanisms that ensure efficient operation. Additionally, electrical systems play a vital role in controlling functionality, encompassing components like ignition systems and battery connections.

Furthermore, mechanical parts such as the gear system contribute significantly to overall performance, allowing for smooth transitions and effective propulsion. Each component is intricately designed to work harmoniously, emphasizing the importance of regular inspections and replacements to maintain optimal functionality.

Key Features of F150TXR Parts

The components of this marine engine are designed with precision to ensure optimal performance and durability. Each element plays a vital role in enhancing the overall functionality, ensuring a seamless experience on the water. Understanding these characteristics can help users maintain their equipment more effectively and appreciate its engineering excellence.

Durability and Reliability

One of the standout characteristics is the robust construction of each component. Designed to withstand harsh marine environments, these elements are crafted from high-quality materials that resist corrosion and wear. This durability translates into extended service life, minimizing the need for frequent replacements.

Enhanced Performance

Another key feature is the engineered design aimed at maximizing efficiency. Components work in harmony to improve fuel consumption and reduce emissions, leading to better overall performance. The thoughtful integration of these elements contributes to smoother operation and enhanced responsiveness, making every journey enjoyable.

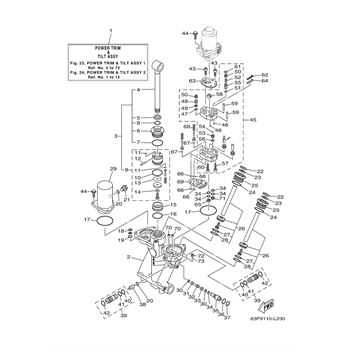

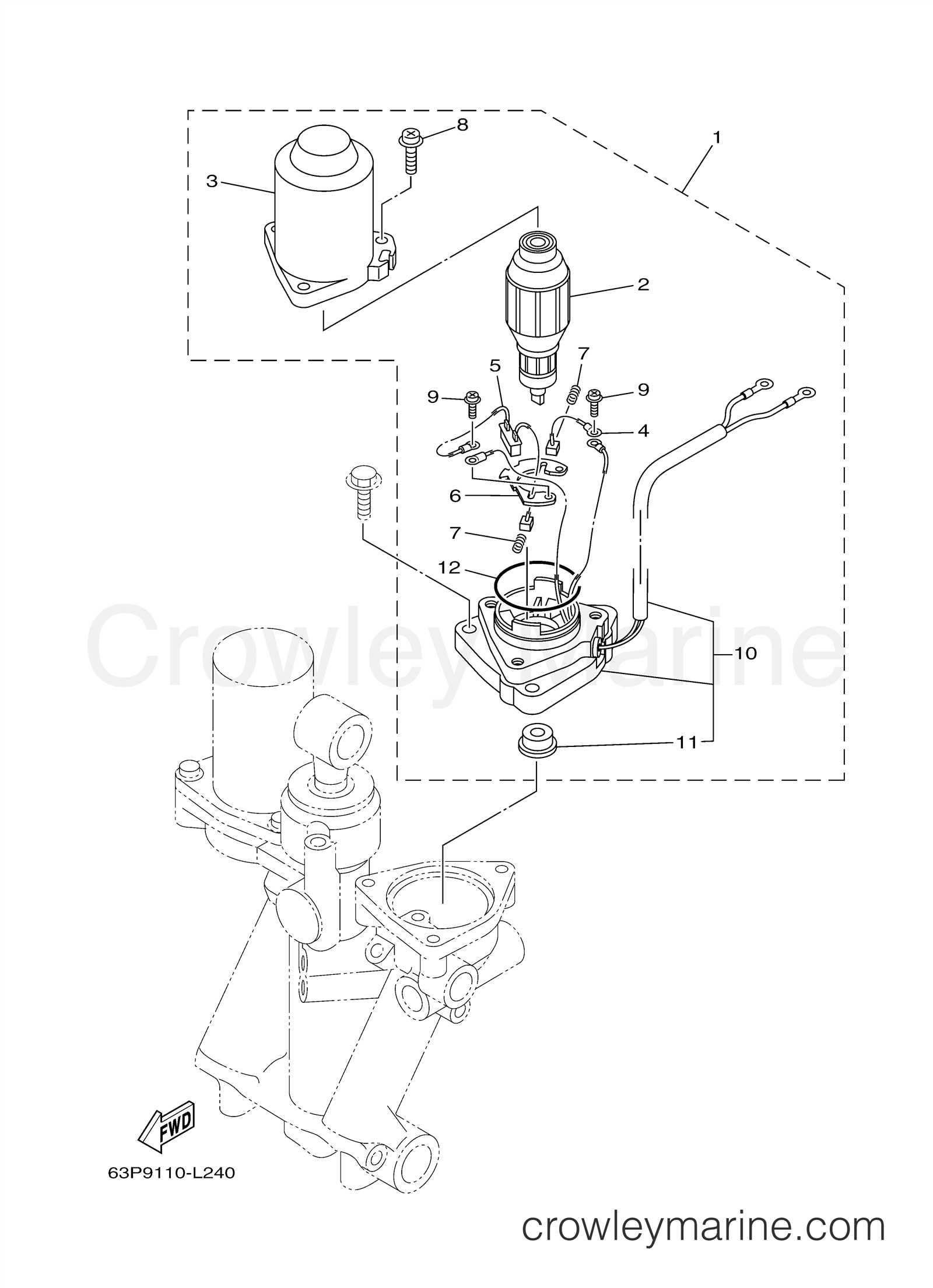

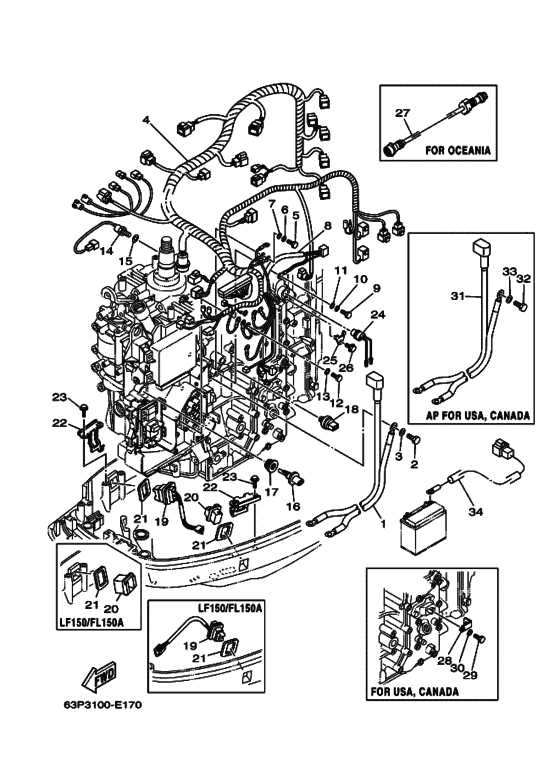

Understanding the Parts Breakdown

In this section, we delve into the visual breakdown that illustrates the various components comprising the system. The schematic provides a comprehensive view of the integral elements, each contributing uniquely to the overall functionality. This diagrammatic representation serves as a vital reference, facilitating clear identification and understanding of individual parts and their interrelationships.

| Component | Description |

| 1 | A fundamental element responsible for initiating specific actions within the mechanism. |

| 2 | Essential module that regulates and monitors crucial operational parameters. |

| 3 | Primary unit tasked with executing pivotal functions integral to the system’s performance. |

| 4 | An indispensable part contributing significantly to the overall efficiency and reliability. |

This structured representation not only aids in pinpointing individual components but also underscores their collective significance in ensuring optimal operational integrity. Understanding these parts fosters a deeper insight into the system’s mechanics, enhancing both maintenance practices and troubleshooting procedures.

Importance of Proper Maintenance

Regular upkeep of marine engines is crucial for ensuring longevity and optimal performance over time. Proper maintenance not only enhances the reliability of your equipment but also reduces the risk of unexpected failures that could lead to costly repairs.

By adhering to a scheduled maintenance routine, boat owners can prevent premature wear and deterioration of vital components. This includes regular inspections, lubrication of moving parts, and timely replacement of worn-out elements. Such practices help maintain the efficiency and safety standards of the vessel.

Furthermore, consistent maintenance promotes fuel efficiency and reduces emissions, contributing to environmental sustainability. It also preserves the resale value of the boat, as well-maintained engines are more attractive to prospective buyers.

In conclusion, prioritizing proper maintenance of marine engines is not just about extending their lifespan; it’s a commitment to reliability, efficiency, and responsible ownership.

Common Replacement Parts for F150TXR

When maintaining an outboard motor, understanding which components frequently require replacement is essential for optimal performance. Regular upkeep not only extends the life of the engine but also enhances its reliability and efficiency on the water. Below are some of the most commonly replaced items that every owner should be aware of.

Essential Components

One of the key components that often needs replacement is the fuel filter. This part ensures that impurities do not enter the fuel system, allowing for smooth operation. Another important item is the water pump impeller, which helps in cooling the engine by circulating water. Over time, these parts can wear out, affecting overall performance.

Maintenance Tips

In addition to the items mentioned, it’s advisable to check the sacrificial anodes regularly. These parts protect the engine from corrosion by attracting harmful elements. Replacing them periodically can prevent costly repairs in the long run. Always refer to your maintenance manual for specific intervals and guidelines for replacing these vital components.

Where to Find Genuine Yamaha Parts

When seeking authentic components for your outboard motor, it’s essential to know where to look to ensure quality and reliability. Numerous avenues exist to acquire these crucial elements, each with its advantages and potential drawbacks.

Official dealers often provide a wide range of original components, ensuring compatibility and performance. Additionally, online marketplaces can be a valuable resource, offering a selection from various sellers. However, it’s vital to verify the authenticity of the items before making a purchase.

Another option is specialized marine supply stores, which typically carry a curated selection of high-quality merchandise. Engaging with local boating communities can also yield recommendations for trustworthy sources, allowing enthusiasts to share insights and experiences.

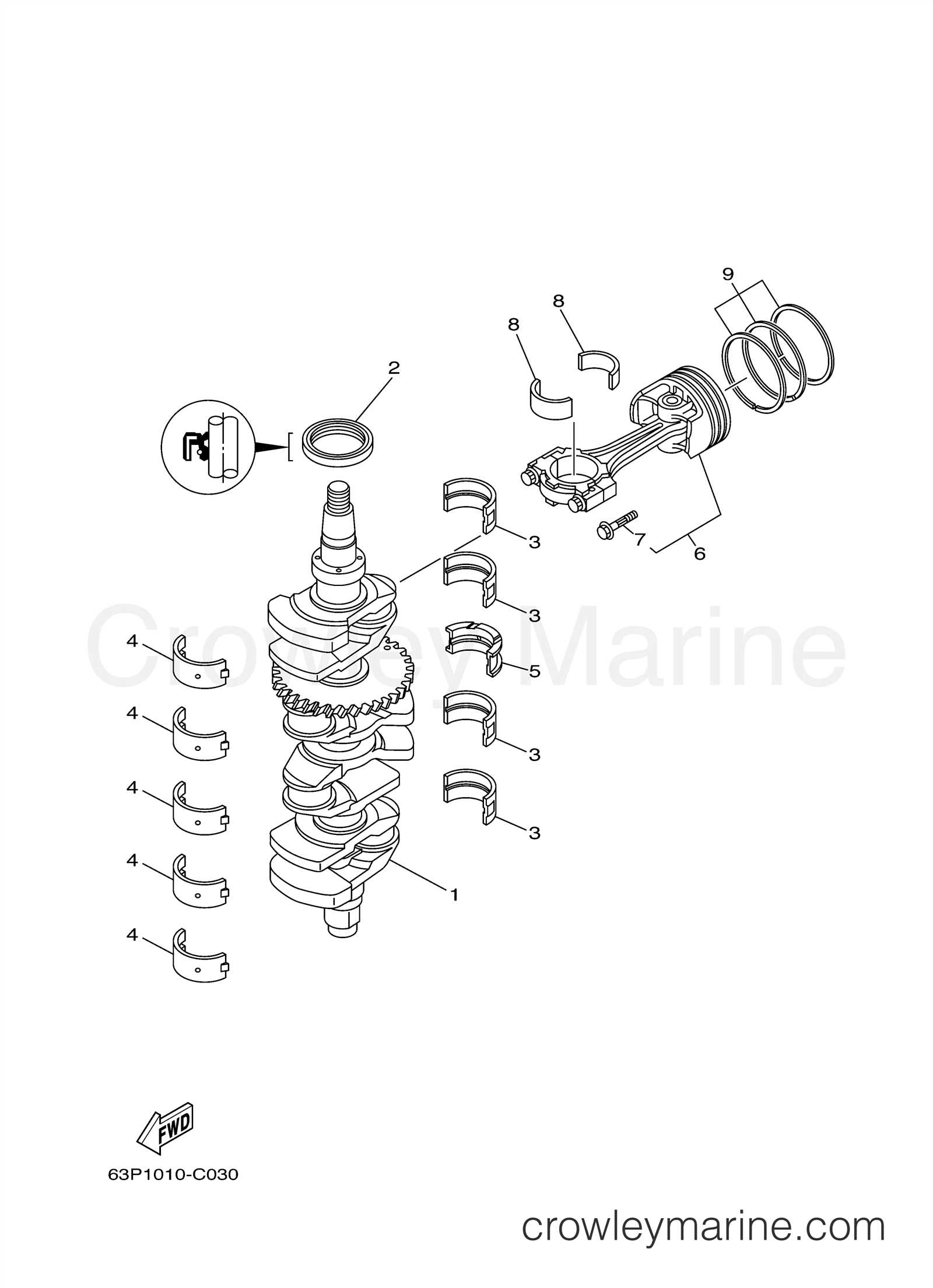

Identifying Each Component’s Function

Understanding the purpose of various elements within a marine engine is crucial for effective maintenance and repair. Each part plays a specific role that contributes to the overall performance and efficiency of the vessel. By familiarizing oneself with these components, operators can ensure optimal functionality and prevent potential issues.

- Engine Block: The main structure housing the cylinders and supporting various engine functions.

- Piston: Moves up and down within the cylinder, compressing the air-fuel mixture for combustion.

- Crankshaft: Converts the linear motion of the pistons into rotational motion, powering the propeller.

- Camshaft: Controls the opening and closing of the engine’s valves at the right timing.

- Fuel Pump: Delivers fuel from the tank to the engine, ensuring proper combustion.

- Ignition System: Responsible for igniting the fuel-air mixture, initiating the combustion process.

- Cooling System: Maintains optimal engine temperature by circulating coolant to dissipate heat.

- Exhaust System: Expels combustion gases from the engine, reducing back pressure and improving efficiency.

By recognizing each part’s role, operators can diagnose issues more effectively and carry out necessary repairs or maintenance, ensuring a smooth and reliable operation on the water.

Troubleshooting Common Issues

When operating marine engines, encountering difficulties is not uncommon. Understanding how to identify and address these problems can enhance performance and prolong the lifespan of the equipment.

- Engine Won’t Start:

- Check the battery charge and connections.

- Inspect the fuel system for blockages or leaks.

- Examine the ignition components for wear.

- Overheating:

- Verify the cooling system for obstructions.

- Ensure proper coolant levels are maintained.

- Inspect the thermostat for functionality.

- Poor Performance:

- Check for fuel quality and contamination.

- Examine propeller condition and size.

- Assess engine tuning and settings.

Addressing these common challenges requires careful examination and methodical troubleshooting. Regular maintenance is crucial to minimize these issues.

Step-by-Step Parts Replacement Guide

This guide provides a clear approach to replacing components in an outboard motor, ensuring that you can efficiently restore functionality. Following these steps will help you achieve optimal performance and longevity for your engine.

- Identify the component that needs replacement.

- Gather the necessary tools: a screwdriver, wrench set, and any specialty tools required.

- Disconnect the power supply and remove any relevant covers or panels.

- Carefully detach the faulty component, taking note of its placement and connections.

- Inspect surrounding areas for any additional wear or damage.

- Install the new component, ensuring a secure fit and proper alignment.

- Reconnect all wiring and covers, making sure everything is tightened appropriately.

- Restore power and perform a test run to confirm functionality.

Always consult the manufacturer’s specifications for precise instructions and safety guidelines.

Benefits of Using OEM Parts

Utilizing original components in maintenance and repairs offers numerous advantages that enhance the overall performance and longevity of equipment. These factory-made items are designed to meet specific standards, ensuring optimal compatibility and functionality.

Quality Assurance

- Manufactured under strict quality control processes.

- Consistent performance that meets original specifications.

- Durability that stands the test of time, reducing the need for frequent replacements.

Improved Reliability

- Enhanced safety features that adhere to the original design.

- Reduced risk of malfunctions due to superior craftsmanship.

- Peace of mind knowing that each item has been tested for optimal performance.

In conclusion, opting for original components not only guarantees a perfect fit but also significantly contributes to the overall efficiency and safety of your equipment.

Diagram Explanation for Beginners

This section aims to simplify the understanding of visual representations used in technical manuals. These illustrations serve as vital tools for identifying components and their functions, making complex systems more accessible to novices.

When exploring these visuals, it’s essential to grasp the following key aspects:

- Components: Each element depicted corresponds to a specific part of the system.

- Labels: Clear annotations help in recognizing the names and purposes of various items.

- Connections: Arrows or lines often indicate how different parts interact or relate to one another.

Understanding these basics will enhance your ability to interpret the visuals effectively, leading to a more profound comprehension of the overall system.