Maintaining an efficient cutting tool is essential for any outdoor enthusiast. Having a clear overview of the intricate elements that make up these machines can significantly enhance their performance and longevity. This section will explore the various components that contribute to the functionality of a high-quality cutting device.

In the world of power tools, knowledge is power. By delving into the structure of your equipment, you can identify potential issues before they escalate. Understanding how each element interacts will lead you to the ultimate maintenance strategies, ensuring that your tool remains in top condition.

Whether you are a seasoned user or a novice, grasping the essentials of your chain saw’s configuration will empower you to make informed decisions. This guide aims to provide clarity on the critical parts, helping you navigate repairs and enhancements with ease.

Understanding the Stihl MS181 Diagram

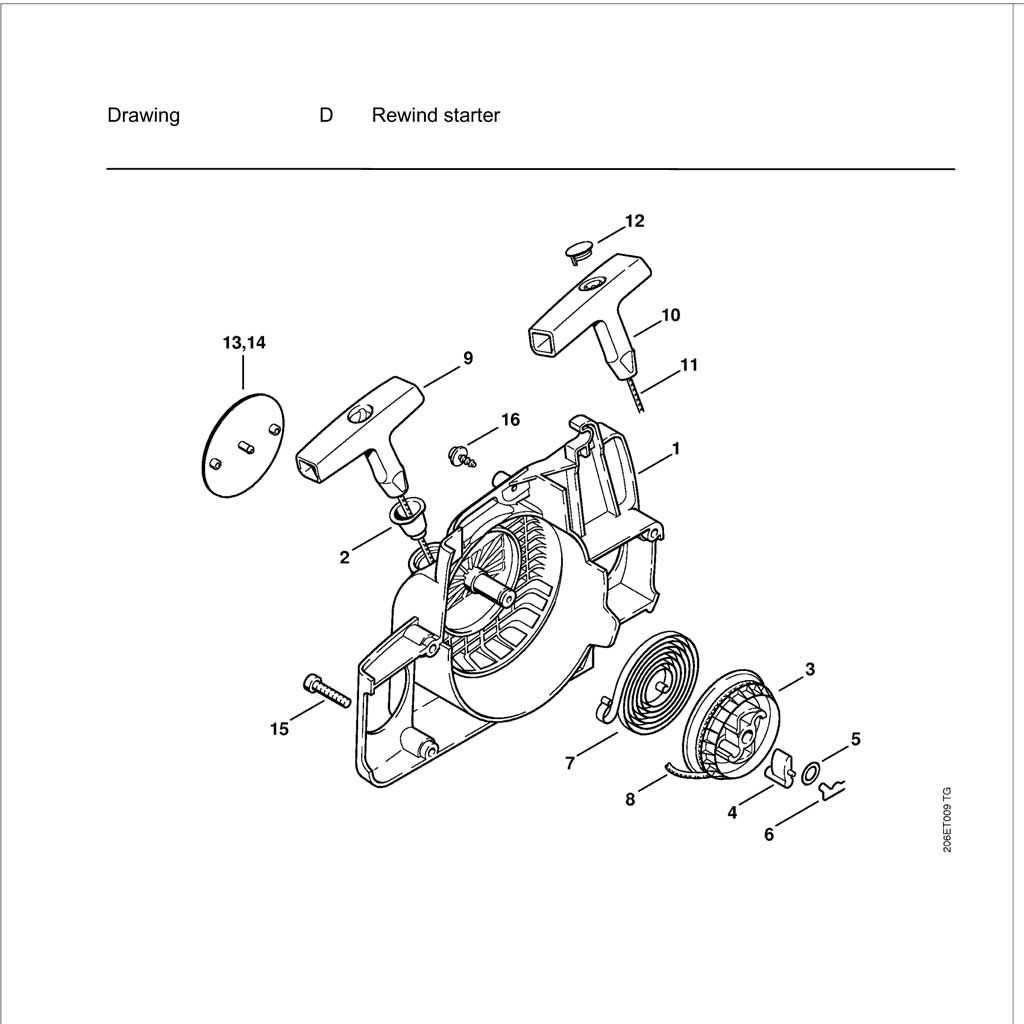

When exploring the intricacies of a power tool, having a clear visual representation is essential. Such illustrations serve as invaluable resources for both maintenance and repair, allowing users to grasp the relationships between various components. By examining these visuals, one can enhance their understanding of how each piece functions within the larger assembly.

Familiarity with these illustrations enables users to identify specific sections quickly, facilitating efficient troubleshooting. Additionally, it can help in recognizing wear and tear, thus informing timely replacements. Comprehending the layout of the tool not only boosts confidence in handling it but also promotes safety during use.

By delving into the details presented in these visual guides, enthusiasts and professionals alike can ensure their equipment operates at peak performance. Ultimately, a solid grasp of the internal organization contributes significantly to the longevity and reliability of the device.

Key Components of Stihl MS181

Understanding the essential elements of this powerful outdoor tool is crucial for effective maintenance and optimal performance. Each part plays a vital role in ensuring smooth operation and longevity.

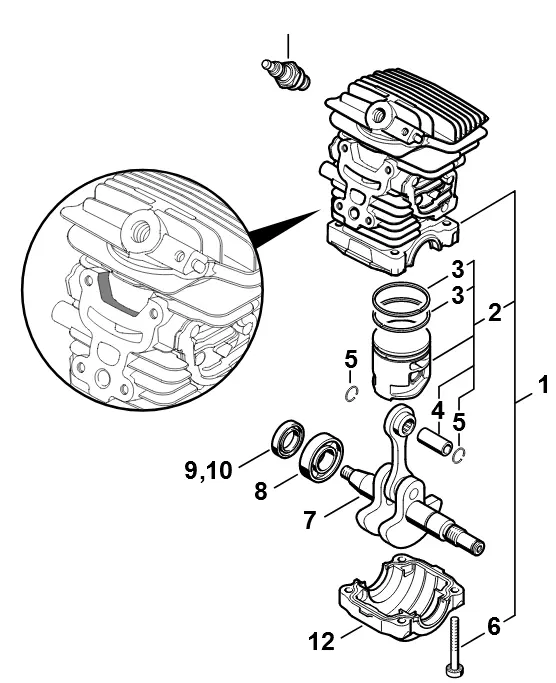

- Engine: The heart of the device, responsible for converting fuel into mechanical energy.

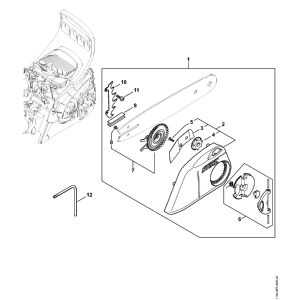

- Bar and Chain: These components work together to cut through wood, with the bar providing support and the chain executing the cutting action.

- Air Filter: Vital for maintaining engine efficiency, it keeps dirt and debris from entering the combustion chamber.

- Fuel System: Includes the tank and lines, ensuring a steady supply of fuel to the engine.

- Starter Mechanism: Facilitates the initial ignition of the engine, crucial for starting the machine.

Regular inspection and maintenance of these key components will help extend the life of the tool and enhance its performance.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components offers numerous advantages that significantly enhance the performance and longevity of your machinery. These parts are specifically designed to fit and function seamlessly with your equipment, ensuring optimal efficiency and reliability.

One of the primary benefits is the assurance of quality and durability. OEM components are manufactured to the same exacting standards as the original items, minimizing the risk of failure or malfunction. This consistency leads to improved safety and peace of mind during operation.

Moreover, using genuine components often results in better compatibility, which translates to enhanced overall performance. When every piece is designed to work in harmony, you can expect a smoother operation and reduced wear and tear on your machinery.

Additionally, opting for original parts can help maintain the warranty on your equipment. Many manufacturers stipulate that only OEM items should be used to preserve the guarantee, thus protecting your investment in the long run.

Lastly, choosing these authentic components can ultimately lead to cost savings. While the initial price may be higher, the longevity and reliability often mean fewer replacements and repairs over time, making it a wise financial decision.

How to Read a Parts Diagram

Understanding a visual representation of components is crucial for effective maintenance and repairs. These illustrations provide a detailed look at the individual elements of a machine, helping users identify what they need and how parts interact.

1. Familiarize Yourself with Symbols: Different symbols represent various components, so take time to learn what each icon signifies. This knowledge will streamline your search for specific elements.

2. Follow the Flow: Most illustrations are organized in a logical sequence, often from top to bottom or left to right. This layout reflects the assembly process, making it easier to comprehend how pieces fit together.

3. Note the Numbering System: Components are typically numbered for easy reference. Cross-referencing these numbers with a list can clarify which parts are needed for repairs or replacements.

4. Check for Additional Information: Many visuals include notes or legends that provide extra context. Be sure to review these annotations, as they can contain essential details about assembly or specific tools required.

By mastering these elements, you’ll ultimately enhance your ability to tackle repairs confidently and efficiently.

Common Repairs for Stihl MS181

Maintaining your cutting tool is essential for optimal performance and longevity. Over time, various components may require attention due to wear and tear. Understanding common issues and their solutions can save both time and money, ensuring your equipment operates smoothly when you need it most.

Fuel System Issues: One of the frequent problems involves the fuel system. Clogs in the fuel filter or issues with the fuel lines can hinder performance. Regularly checking and replacing the fuel filter, along with inspecting the lines for cracks, can prevent operational failures.

Chain Tension Problems: The chain may become loose or overly tight, affecting cutting efficiency. Adjusting the tension is straightforward; ensure it is neither too tight nor too slack to promote safe and effective use.

Air Filter Maintenance: A clogged air filter can significantly reduce engine efficiency. Cleaning or replacing the filter at regular intervals allows for better airflow, improving the overall function of the engine.

Spark Plug Replacement: Over time, spark plugs can wear out, leading to starting difficulties and poor performance. Inspecting and replacing them periodically ensures reliable ignition and smoother operation.

Bar and Chain Care: The bar and chain require regular maintenance to prevent excessive wear. Cleaning the bar groove and ensuring proper lubrication will enhance cutting efficiency and extend the lifespan of these components.

Identifying Parts by Number

Understanding how to recognize components by their unique identifiers is essential for efficient maintenance and repairs. This knowledge allows users to quickly locate the necessary elements for servicing their equipment, ensuring optimal performance and longevity.

Benefits of Accurate Identification

Accurate identification minimizes errors during repairs and replacements. When users know exactly what number corresponds to each component, they can avoid purchasing incorrect items, saving both time and money in the long run.

Steps to Identify Components

To effectively identify parts, start by consulting a reliable reference source that lists the specific identifiers. Cross-reference these numbers with the physical components to ensure proper matches. This method streamlines the repair process and enhances overall efficiency.

Tools Needed for Maintenance

Regular upkeep of your equipment ensures optimal performance and longevity. Having the right instruments on hand is essential for efficient maintenance tasks. Below is a list of necessary tools to facilitate this process.

- Wrench Set: Various sizes are crucial for tightening or loosening components.

- Screwdriver Set: Both flathead and Phillips options are needed for different screws.

- Replacement Blades: Keeping extra blades ensures you can quickly swap out worn ones.

- Oil Can: For lubrication of moving parts to prevent wear and tear.

- Cleaning Brushes: Essential for removing debris and maintaining cleanliness.

- Protective Gloves: To ensure safety while handling sharp or heavy components.

- Fuel Mix Container: For preparing the correct fuel mixture for optimal performance.

By gathering these essential tools, you can effectively maintain your equipment, ensuring it remains in top working condition for years to come.

Where to Find Replacement Parts

When your outdoor equipment requires new components, locating reliable sources for these items is essential. The market offers a variety of options, ensuring you can find what you need to keep your tools in optimal working condition.

Authorized Dealers

One of the best ways to ensure quality and compatibility is to purchase from authorized retailers. These establishments typically provide:

- Genuine components

- Expert advice from knowledgeable staff

- Warranty on parts purchased

Online Marketplaces

The internet has made it easier than ever to source components. Popular online platforms often feature:

- A wide selection of items

- Competitive pricing

- Customer reviews to guide your choices

Be sure to verify the seller’s reputation to avoid counterfeit products.

Common Issues and Solutions

Understanding the typical problems that can arise with power tools is essential for maintaining their performance and longevity. This section outlines some frequent challenges users may encounter and offers practical solutions to address them.

- Starting Difficulties:

If the equipment fails to start, check the fuel mixture and spark plug condition.

- Chain Stalling:

Ensure the chain is properly tensioned and lubricated to avoid stalling during operation.

- Overheating:

Monitor the cooling system and clean any debris from vents to prevent overheating.

- Vibrations:

Excessive vibrations can indicate loose components. Inspect and tighten as needed.

- Poor Cutting Performance:

Regularly sharpen the cutting blade to maintain optimal performance and efficiency.

By addressing these common issues promptly, users can enhance their tool’s effectiveness and lifespan.

Maintenance Tips for Longevity

Proper care and regular maintenance are essential to ensure the durability and efficiency of your equipment. By following some straightforward guidelines, you can extend the life of your machinery, reduce the likelihood of malfunctions, and improve overall performance.

Regular Cleaning

Keeping your tools clean is vital. Dirt and debris can lead to wear and tear, affecting functionality.

- Remove any sawdust or residues after each use.

- Inspect and clean air filters regularly to maintain airflow.

- Use appropriate cleaning agents that won’t harm components.

Routine Inspections

Frequent checks can help identify potential issues before they escalate. Here are key areas to focus on:

- Examine the chain and bar for signs of damage or excessive wear.

- Check fuel and oil levels to ensure optimal operation.

- Inspect electrical connections and wires for fraying or corrosion.

Comparing MS181 with Other Models

This section explores the distinctions between a specific model and its counterparts in the same category. By analyzing various features, users can determine which machine best suits their needs.

Key Features to Consider

- Engine Power

- Weight and Maneuverability

- Cutting Capacity

- Fuel Efficiency

- Ease of Maintenance

Model Comparisons

-

Model A: Known for its lightweight design, making it ideal for prolonged use.

-

Model B: Offers superior power, suitable for more demanding tasks.

-

Model C: Balances efficiency and performance, appealing for general users.

By understanding these differences, users can delve into the ultimate choice for their specific requirements.

Understanding Warranty and Support

When purchasing equipment, it’s essential to grasp the protection and assistance offered by the manufacturer. Warranty terms outline the duration and conditions under which repairs or replacements are provided, ensuring that users can operate their machinery with confidence.

Types of Coverage

Most warranties encompass defects in materials and craftsmanship, while some may include specific components. It’s crucial to read the fine print to identify what is and isn’t included, as exclusions can vary significantly.

Accessing Support Services

In case of issues, manufacturers typically offer various support channels, such as customer service lines, online resources, and authorized service centers. Utilizing these resources effectively can greatly enhance your experience and prolong the lifespan of your equipment.

Upgrades and Accessories for MS181

Enhancing your equipment can significantly improve performance and user experience. Various upgrades and accessories can provide added functionality, comfort, and efficiency, allowing you to get the most out of your tool.

- Chains: Consider a high-performance chain for smoother cuts and better durability.

- Bar Length: Switching to a longer or shorter guide bar can adapt your tool for different tasks.

- Fuel Mixture Enhancers: Specialized additives can improve engine performance and reduce emissions.

- Safety Gear: Investing in quality protective equipment ensures safe operation while working.

These enhancements not only optimize functionality but also prolong the lifespan of your device, making your tasks easier and more efficient.