Exploring the intricate layout of off-road machinery offers enthusiasts a comprehensive understanding of their functionality. Each vehicle consists of numerous elements, all working in harmony to provide an exceptional experience in rugged terrains. By grasping the relationship between these components, users can enhance their maintenance skills and ensure longevity.

Identifying the crucial elements within these machines can significantly improve performance and safety. Whether you are a novice or a seasoned expert, familiarizing yourself with the various sections will ultimately empower you to tackle repairs and upgrades more effectively. This knowledge not only enhances your vehicle’s reliability but also contributes to a deeper appreciation for its engineering.

Diving into the specifics allows for a more profound connection with the vehicle, revealing the thought and innovation behind its design. Understanding how each part interacts can transform a routine operation into an engaging journey, making every ride more enjoyable and fulfilling.

Overview of John Deere Trail Buck 650

This section provides an insightful look into a popular off-road utility vehicle, known for its versatility and rugged performance. It caters to both recreational enthusiasts and those requiring a dependable workhorse for various tasks. Users appreciate its balance of power and maneuverability, making it suitable for diverse environments.

Key Features

One of the standout attributes of this vehicle is its robust engine, which delivers impressive torque and acceleration. Additionally, the design emphasizes stability and traction, enabling it to navigate challenging terrains with ease. Enhanced safety features ensure a secure experience, while the spacious cargo area adds practicality for hauling equipment or supplies.

Maintenance and Support

Regular upkeep is essential to maximize the longevity of this utility vehicle. Access to a comprehensive range of accessories and service components ensures that users can maintain optimal performance. Support from various sources, including manuals and online resources, aids in troubleshooting and repair, ensuring a seamless ownership experience.

Importance of Parts Diagrams

Understanding the assembly of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools, allowing users to identify components, streamline repairs, and enhance overall efficiency. These illustrations simplify complex systems, ensuring that operators can approach tasks with confidence.

Facilitating Repairs

Visual guides offer clarity when addressing mechanical issues, enabling technicians to pinpoint faults quickly. With a clear view of each element, they can undertake repairs with precision, reducing the likelihood of errors.

Enhancing Maintenance

Regular upkeep is vital for longevity. Reference materials provide insights into maintenance routines, ensuring that essential tasks are not overlooked. By following illustrated instructions, operators can maintain their equipment in optimal condition.

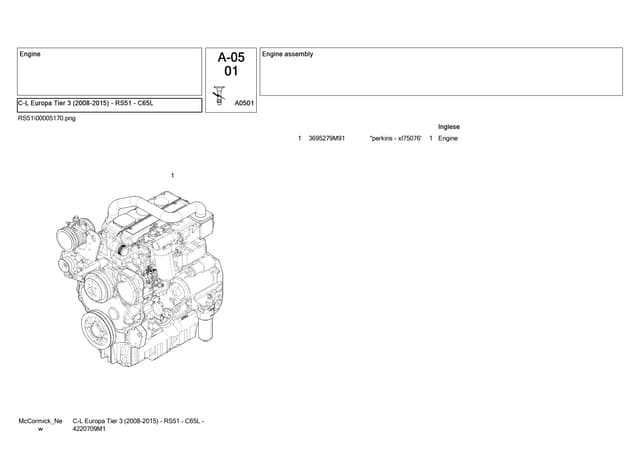

Key Components of the Trail Buck

Understanding the essential elements of this vehicle is crucial for maintaining its performance and longevity. Each component plays a significant role in ensuring optimal functionality and user experience.

- Chassis: The foundational framework providing stability and support.

- Engine: The power source that drives the entire system.

- Transmission: Facilitates gear changes, enhancing maneuverability.

- Suspension: Absorbs shocks for a smoother ride over rough terrain.

- Wheels: Critical for traction and overall control.

- Braking System: Ensures safety by providing reliable stopping power.

- Electrical System: Powers accessories and lights, crucial for visibility and convenience.

Each of these elements contributes to the vehicle’s ultimate performance, making it essential for users to be familiar with them for effective maintenance and operation.

How to Access the Diagram

Accessing detailed illustrations of machinery components can greatly assist in understanding their structure and function. Whether you’re performing maintenance or repairs, having the correct visuals at hand simplifies the process.

Here are some effective methods to obtain the necessary illustrations:

- Manufacturer’s Website: Most manufacturers provide digital resources on their official websites. Look for sections dedicated to support or resources.

- User Manuals: Check any user manuals that came with your equipment. These often contain valuable visual references.

- Online Forums: Join forums or communities focused on machinery. Members often share diagrams and helpful tips.

- Third-party Websites: Several online platforms specialize in selling or providing access to technical resources. Search for trusted sites that offer what you need.

Once you locate the appropriate source, you can download, print, or view the illustrations directly on your device. This ensures you have a clear understanding of the components involved in your equipment.

Understanding Each Part’s Function

Grasping the functionality of various components within machinery is crucial for efficient operation and maintenance. Each element plays a specific role that contributes to the overall performance and reliability of the equipment. By understanding these roles, operators can troubleshoot issues effectively and ensure optimal performance.

Main Components Overview

The core elements of the equipment can be categorized based on their function. Below is a summary of these categories and their respective roles:

| Component | Function |

|---|---|

| Engine | Converts fuel into mechanical energy, powering the machinery. |

| Transmission | Transfers power from the engine to the wheels, enabling movement. |

| Hydraulic System | Facilitates the operation of attachments and enhances lifting capabilities. |

| Chassis | Provides structural integrity and supports various components. |

| Control System | Allows the operator to manipulate the machinery effectively. |

Specialized Elements

In addition to the main components, specialized parts also contribute significantly. Understanding these can lead to improved functionality and extended service life:

| Component | Function |

|---|---|

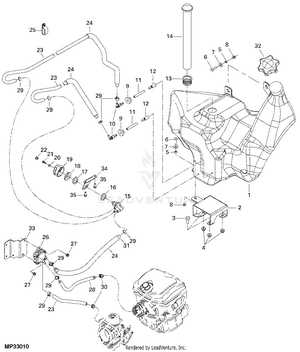

| Cooling System | Maintains optimal operating temperatures to prevent overheating. |

| Fuel System | Stores and delivers fuel to the engine for combustion. |

| Electrical System | Powers lighting and ignition systems, ensuring reliable operation. |

| Brake System | Controls speed and ensures safety during operation. |

Common Repairs and Replacements

In the realm of outdoor equipment maintenance, certain components frequently require attention due to wear and tear. Understanding these common issues can help users anticipate repairs and ensure their machinery operates smoothly.

Engine Maintenance: Regular servicing of the engine is crucial. This may include oil changes, air filter replacements, and checking spark plugs. Keeping the engine in optimal condition enhances performance and extends its lifespan.

Transmission Issues: Transmission systems often face challenges that lead to reduced efficiency. Routine inspections and timely fluid changes can prevent serious damage. Replacing worn gears and seals is also a common necessity.

Hydraulic System Repairs: The hydraulic system is vital for operational functionality. Common replacements involve hoses, seals, and pumps. Addressing leaks promptly can prevent further complications and costly repairs.

Tire Wear: Tires endure significant stress and require regular examination. Replacing tires that show signs of wear ensures better traction and safety. Maintaining proper air pressure is essential to prolonging tire life.

Electrical Components: Electrical issues can arise unexpectedly, often related to batteries and wiring. Regular checks and replacing corroded connections can prevent breakdowns. Keeping an eye on lights and indicators ensures safety during operation.

Where to Find Authentic Parts

Locating genuine components for your machinery can significantly enhance performance and longevity. Authentic replacements ensure compatibility and reliability, ultimately saving you time and money in repairs and maintenance.

Authorized Dealers

One of the most reliable sources for authentic components is through authorized dealers. They provide a range of options directly sourced from the manufacturer, ensuring quality and proper fit.

Online Marketplaces

Reputable online marketplaces also offer a selection of genuine components. It’s essential to verify the seller’s credibility and read customer reviews before making a purchase.

| Source | Benefits |

|---|---|

| Authorized Dealers | Guaranteed quality, expert advice |

| Online Marketplaces | Convenience, wider selection |

| Manufacturer’s Website | Direct access to original parts |

Maintenance Tips for Longevity

Ensuring the durability of your outdoor machinery requires consistent care and attention. By implementing a regular maintenance routine, you can extend the lifespan of your equipment and enhance its performance. Below are essential practices to keep your machinery running smoothly and efficiently.

Regular Inspections

Conducting frequent checks helps identify potential issues before they escalate. Look for signs of wear, loose components, or any leaks that could affect performance. Early detection is key to preventing costly repairs.

Proper Cleaning

Debris buildup can lead to overheating and mechanical failure. After each use, make it a habit to clean your equipment thoroughly. Pay attention to filters, air intakes, and any areas prone to collecting dirt or grime.

| Maintenance Task | Frequency |

|---|---|

| Check fluid levels | Weekly |

| Inspect belts and hoses | Monthly |

| Sharpen blades | Every 10 hours of use |

| Change oil | Every 50 hours of use |

Comparing Models: Trail Buck Variants

This section explores the various versions of a specific all-terrain vehicle, highlighting their unique features and specifications. Each model offers distinct advantages tailored to different user needs and preferences.

When considering these vehicles, it’s essential to evaluate key aspects that differentiate them:

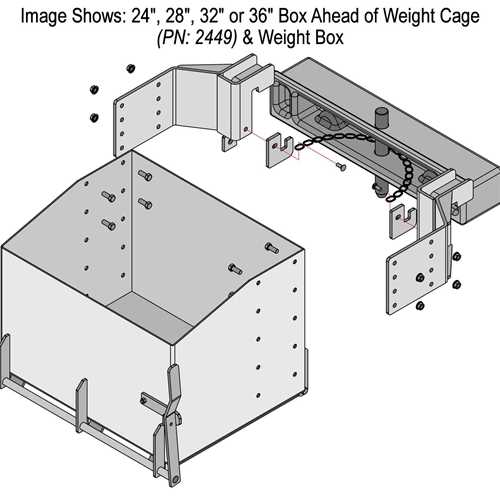

- Engine Performance: Variants may come with different engine sizes, impacting power and efficiency.

- Load Capacity: The ability to carry weight varies significantly across models, influencing their suitability for specific tasks.

- Suspension System: Different suspension setups affect ride comfort and handling on rough terrain.

- Fuel Economy: Variations in fuel consumption can lead to long-term cost savings or expenses.

By assessing these elements, potential buyers can make informed decisions that best match their operational requirements. Here’s a brief overview of some popular variants:

- Model A: Known for its robust engine and superior towing capacity, ideal for heavy-duty tasks.

- Model B: Offers exceptional fuel efficiency, making it suitable for longer excursions.

- Model C: Features advanced suspension for a smoother ride over challenging landscapes.

Ultimately, understanding the differences between these models allows users to select the one that aligns perfectly with their specific demands and preferences.

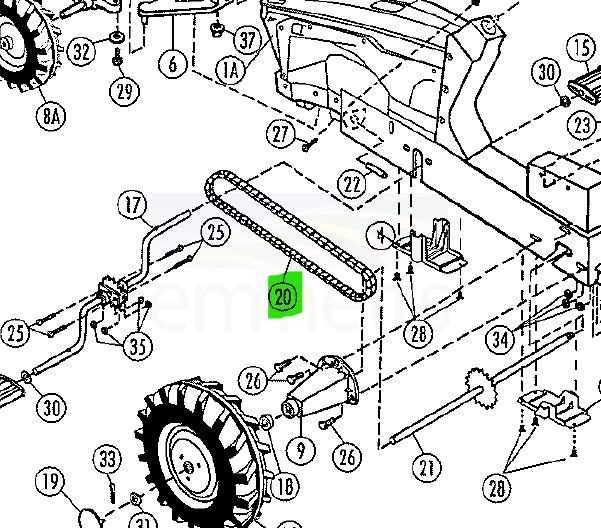

DIY Repairs Using the Diagram

When tackling repairs on your equipment, having a detailed visual reference can significantly enhance your understanding of the assembly. This resource enables you to identify components and comprehend their interconnections, facilitating effective maintenance and repairs without needing professional assistance.

| Component | Common Issues | DIY Solutions |

|---|---|---|

| Engine | Overheating | Check coolant levels and inspect for leaks. |

| Transmission | Shifting problems | Adjust linkage and verify fluid levels. |

| Wheels | Wear and tear | Replace tires and check alignment. |

Utilizing this visual guide empowers you to address common issues proactively, ensuring your machinery operates efficiently. Delve into the specifics, and you’ll discover the ultimate satisfaction in completing repairs on your own.

Expert Insights on Parts Upgrades

Enhancing your equipment’s performance often hinges on the right modifications. By exploring superior components, users can significantly improve efficiency and durability. This section focuses on valuable perspectives that guide enthusiasts and professionals in making informed choices.

Understanding Component Functionality

To maximize performance, it’s essential to grasp how individual elements interact within the system. Upgrading specific components can lead to enhanced functionality, enabling smoother operations and greater reliability. Always consider the ultimate synergy between upgraded elements and existing systems.

Choosing Quality Over Cost

Investing in high-quality replacements often yields better long-term results. While budget options may seem appealing, they can compromise performance and longevity. Prioritize trusted brands and well-reviewed alternatives to ensure optimal functionality and satisfaction.

Troubleshooting Common Issues

When operating machinery, encountering problems can be a common occurrence. Identifying and resolving these issues promptly is essential for maintaining optimal performance. This section aims to provide guidance on diagnosing frequent challenges and their potential solutions.

Electrical Problems

Electrical failures can manifest in various forms, such as starting issues or malfunctioning components. Checking connections, fuses, and the battery can often reveal the source of the problem.

| Issue | Possible Cause | Solution |

|---|---|---|

| Won’t Start | Dead Battery | Charge or replace the battery. |

| Lights Not Working | Blown Fuse | Replace the blown fuse. |

Mechanical Issues

Mechanical malfunctions can lead to reduced efficiency and safety hazards. Regular inspections and timely maintenance can help prevent such problems from escalating.

| Issue | Possible Cause | Solution |

|---|---|---|

| No Movement | Hydraulic Fluid Low | Refill hydraulic fluid. |

| Strange Noises | Worn Bearings | Inspect and replace bearings as needed. |