In the realm of mechanical devices, a clear visualization of individual elements is essential for effective maintenance and troubleshooting. Such representations facilitate a deeper understanding of how each part interacts within the overall assembly, ensuring optimal functionality and longevity. This knowledge is invaluable for both seasoned technicians and those new to the field.

By breaking down the intricate relationships among various components, users can quickly identify potential issues or necessary replacements. This clarity not only enhances the efficiency of repairs but also empowers users to undertake their maintenance tasks with confidence. A comprehensive overview serves as a roadmap, guiding users through the complexities of assembly and operation.

As we delve into the specifics of these layouts, we will explore the unique features of each segment, highlighting their roles and importance. Recognizing the distinct characteristics of each component aids in both understanding and practical application, paving the way for more informed decision-making in repair and enhancement endeavors.

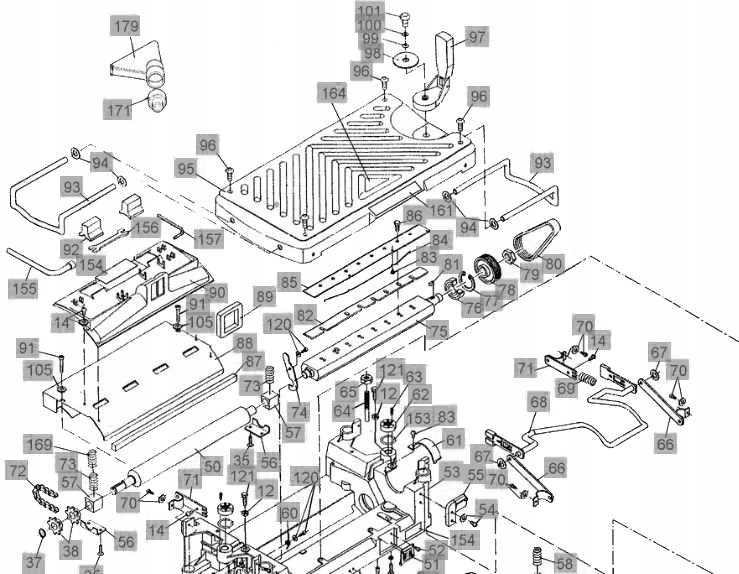

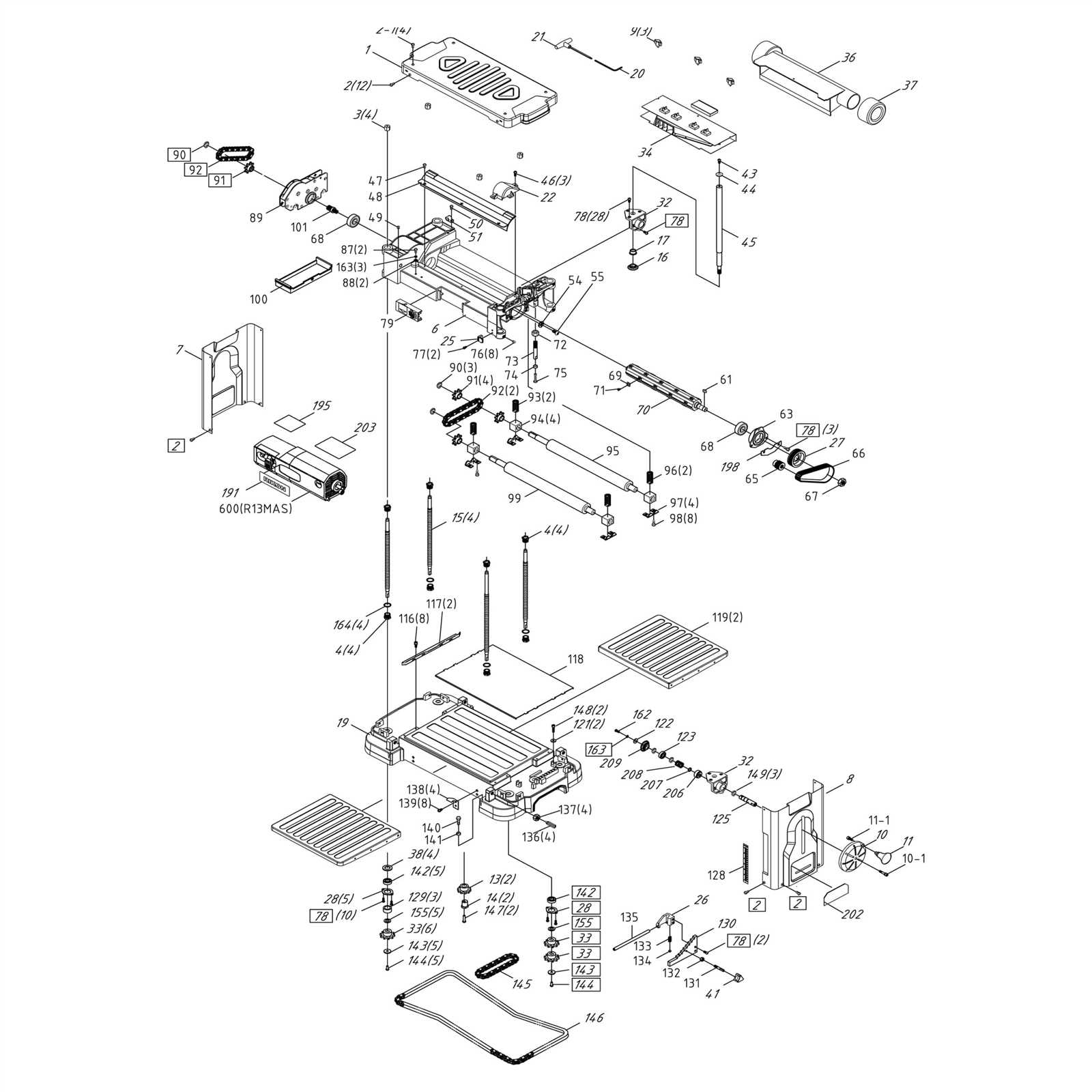

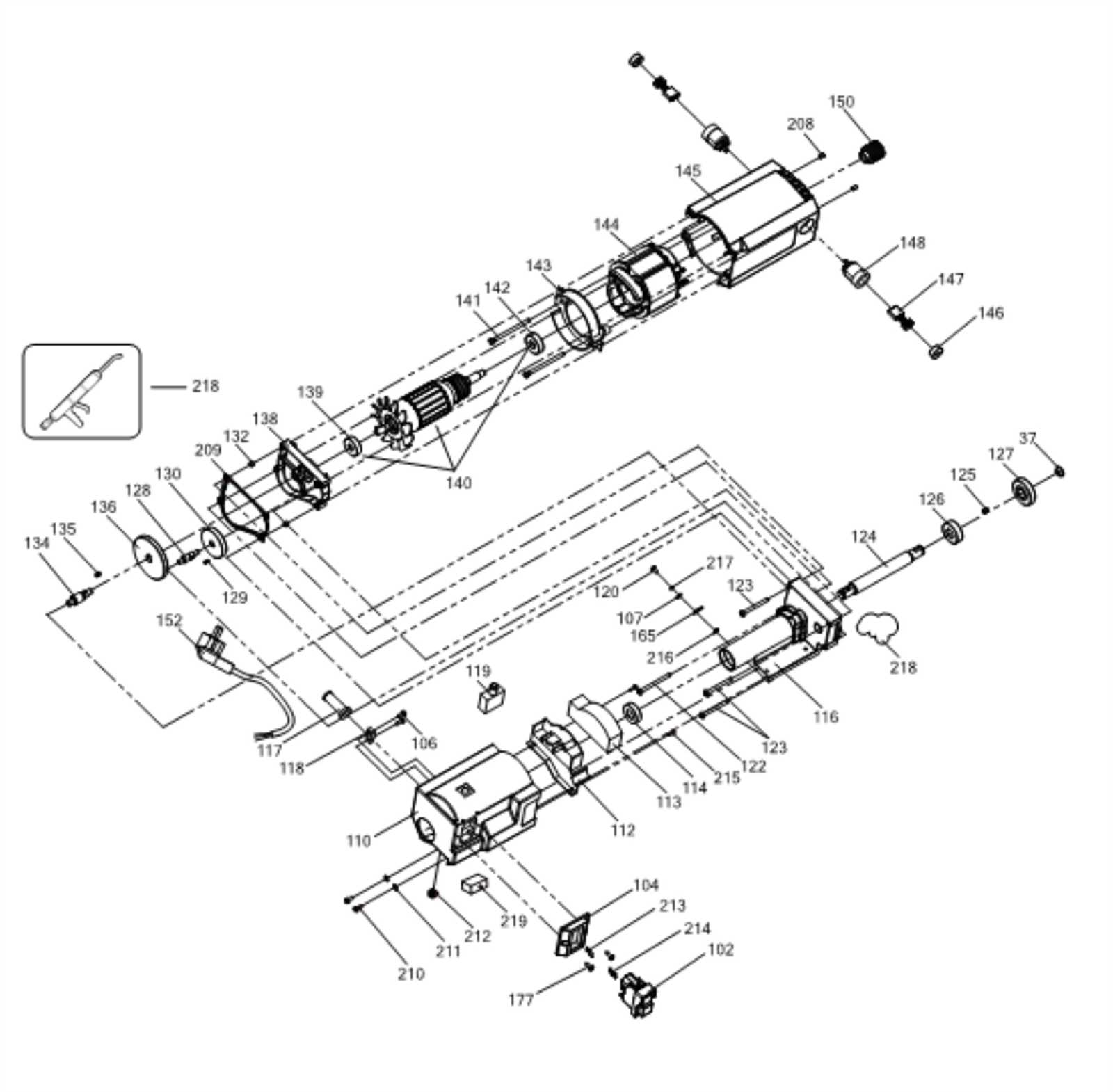

Understanding the DW733 Parts Diagram

Comprehending the components of a woodworking tool is essential for effective maintenance and repair. Familiarity with the assembly and function of each element can significantly enhance the tool’s performance and longevity. This section will delve into the intricacies of the visual representation that illustrates the various elements of a specific device.

Key Components Overview

When examining the illustration, it is crucial to identify the primary sections that contribute to the overall functionality. Each part plays a vital role in the tool’s operation. Here are some of the critical categories:

- Motor System: Powers the device and determines its efficiency.

- Cutting Mechanism: Responsible for the precision and quality of cuts.

- Frame and Housing: Provides structural integrity and support.

- Feed System: Controls the material movement through the tool.

- Adjustment Controls: Allows for customization of settings for different tasks.

Benefits of Familiarity

Understanding the layout of these components offers several advantages:

- Facilitates troubleshooting and identification of issues.

- Enhances ability to perform routine maintenance tasks.

- Promotes informed decision-making when replacing parts.

- Improves safety through awareness of operational mechanisms.

By mastering the relationships between each segment, users can ensure optimal functionality and extend the lifespan of their equipment.

Overview of DW733 Specifications

This section provides an in-depth look at the key features and characteristics of the device, highlighting its performance and functionality. Understanding these specifications is essential for evaluating its suitability for various tasks.

- Power Rating: Typically around 15 amps, ensuring robust performance.

- Cutting Capacity: Capable of handling a range of materials with precision.

- Speed Settings: Variable speeds allow for adaptability based on project requirements.

- Weight: Lightweight design enhances portability and ease of use.

- Safety Features: Equipped with several mechanisms to ensure user safety during operation.

These attributes collectively contribute to its reputation as a reliable tool for both professional and hobbyist applications.

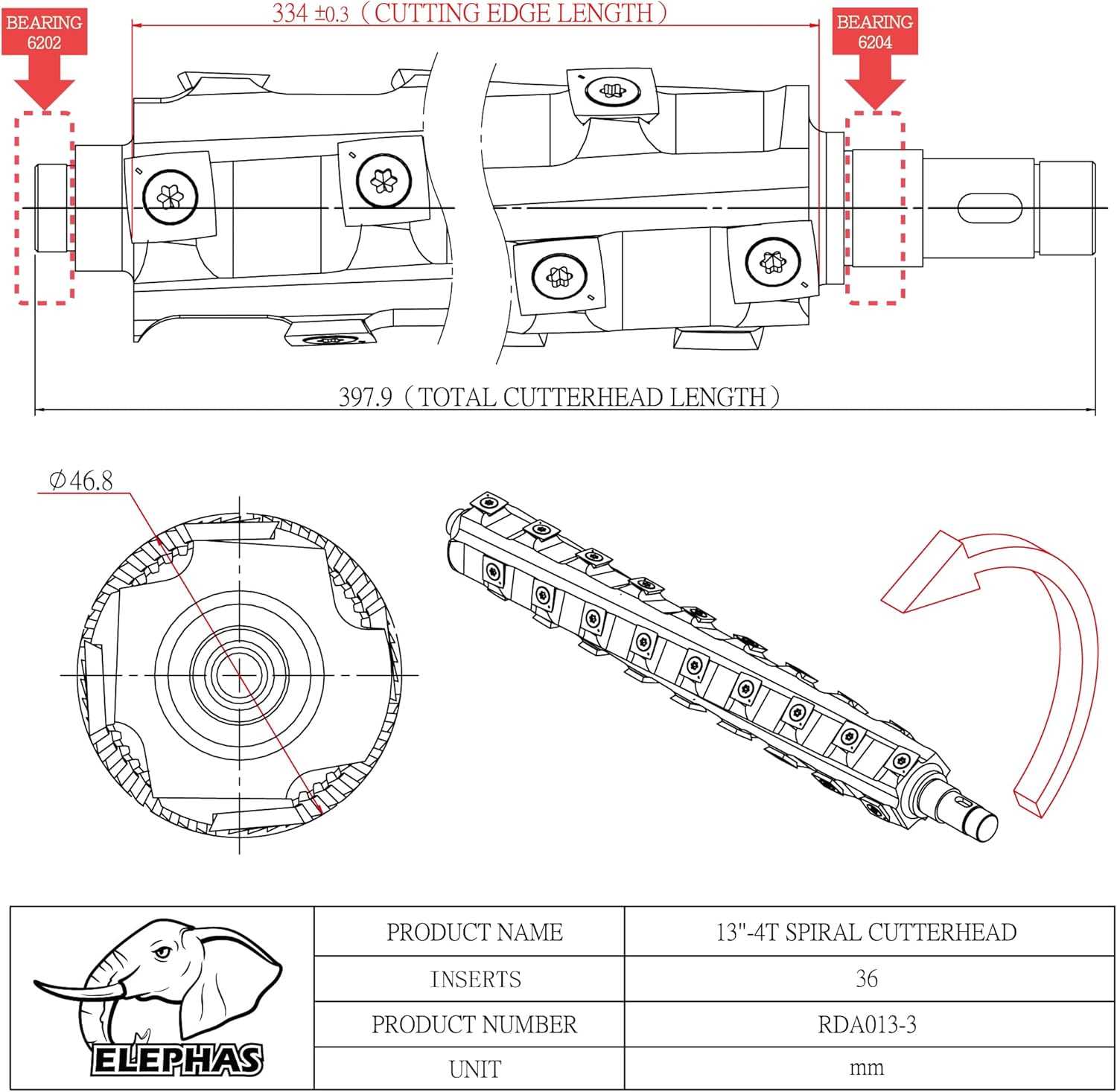

Key Components of the DW733

The efficient operation of any woodworking tool relies on its essential elements, each designed to perform specific functions that contribute to the overall performance and reliability of the device. Understanding these fundamental components can enhance both maintenance practices and the effectiveness of the equipment in various tasks.

Motor is the powerhouse of the unit, providing the necessary energy to drive all operations. Its robustness directly influences the tool’s capacity to handle various materials with ease and precision.

Blades play a crucial role in shaping and finishing wood. High-quality, sharp cutting edges ensure clean cuts and reduce the effort needed during use, making them integral to achieving optimal results.

Feed rollers facilitate smooth material movement through the tool, ensuring consistent pressure and alignment. Their design impacts the quality of the cut and the overall workflow.

Table serves as the primary surface where workpieces are positioned. A stable and adjustable table enhances user control, allowing for precise adjustments based on the specific requirements of each project.

Depth adjustment mechanism allows users to set the desired cutting depth, providing versatility for different woodworking applications. Accurate depth control is vital for achieving the intended results.

Each of these key components interacts seamlessly, contributing to the tool’s efficiency and effectiveness. Regular inspection and maintenance of these elements will ensure long-lasting performance and satisfaction in woodworking tasks.

Importance of Accurate Diagrams

Clear and precise visual representations are essential for effective understanding and communication in any technical field. These illustrations serve as crucial tools that facilitate the identification, assembly, and maintenance of complex machinery.

- Enhance clarity by simplifying complex information.

- Serve as a reliable reference for troubleshooting and repairs.

- Minimize errors by providing step-by-step guidance.

- Foster efficient training for new users and technicians.

Ultimately, having reliable visuals not only improves productivity but also ensures safety and longevity of equipment. Accurate representations play a vital role in achieving seamless operations.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective assembly, maintenance, or repair tasks. These illustrations serve as a guide, allowing users to identify individual elements and comprehend their relationships within a system. Mastering the art of interpreting these images can significantly enhance your efficiency and accuracy when working with machinery.

Key Elements to Focus On

When examining these visual aids, pay attention to the labels associated with each part. These annotations often include reference numbers or names that correspond to a list or catalog, providing clarity on the specific item in question. Additionally, note the connections depicted, as they indicate how different components interact and function together.

Understanding Symbols and Annotations

Different symbols may represent various types of components or functions. Familiarizing yourself with these icons is crucial for proper interpretation. Look for color codes and line styles, which can indicate different categories or levels of importance among the parts. Lastly, don’t overlook any notes or instructions included in the illustration, as they often contain valuable information that can aid in troubleshooting or assembly processes.

Common Issues with DW733 Parts

When using power tools, various components can face challenges that impact performance and reliability. Identifying these common difficulties is essential for effective maintenance and troubleshooting.

| Issue | Description | Possible Solution |

|---|---|---|

| Wear and Tear | Over time, frequent use can lead to degradation of components, affecting efficiency. | Regular inspection and timely replacement can mitigate this issue. |

| Improper Alignment | Misalignment can result in uneven cuts and increased strain on the motor. | Ensure components are correctly aligned before operation. |

| Electrical Failures | Wiring issues can lead to power loss or inconsistent performance. | Check connections and replace damaged wires as needed. |

| Overheating | Excessive use without proper cooling can cause overheating, leading to malfunctions. | Allow adequate cooling time and avoid prolonged use under heavy loads. |

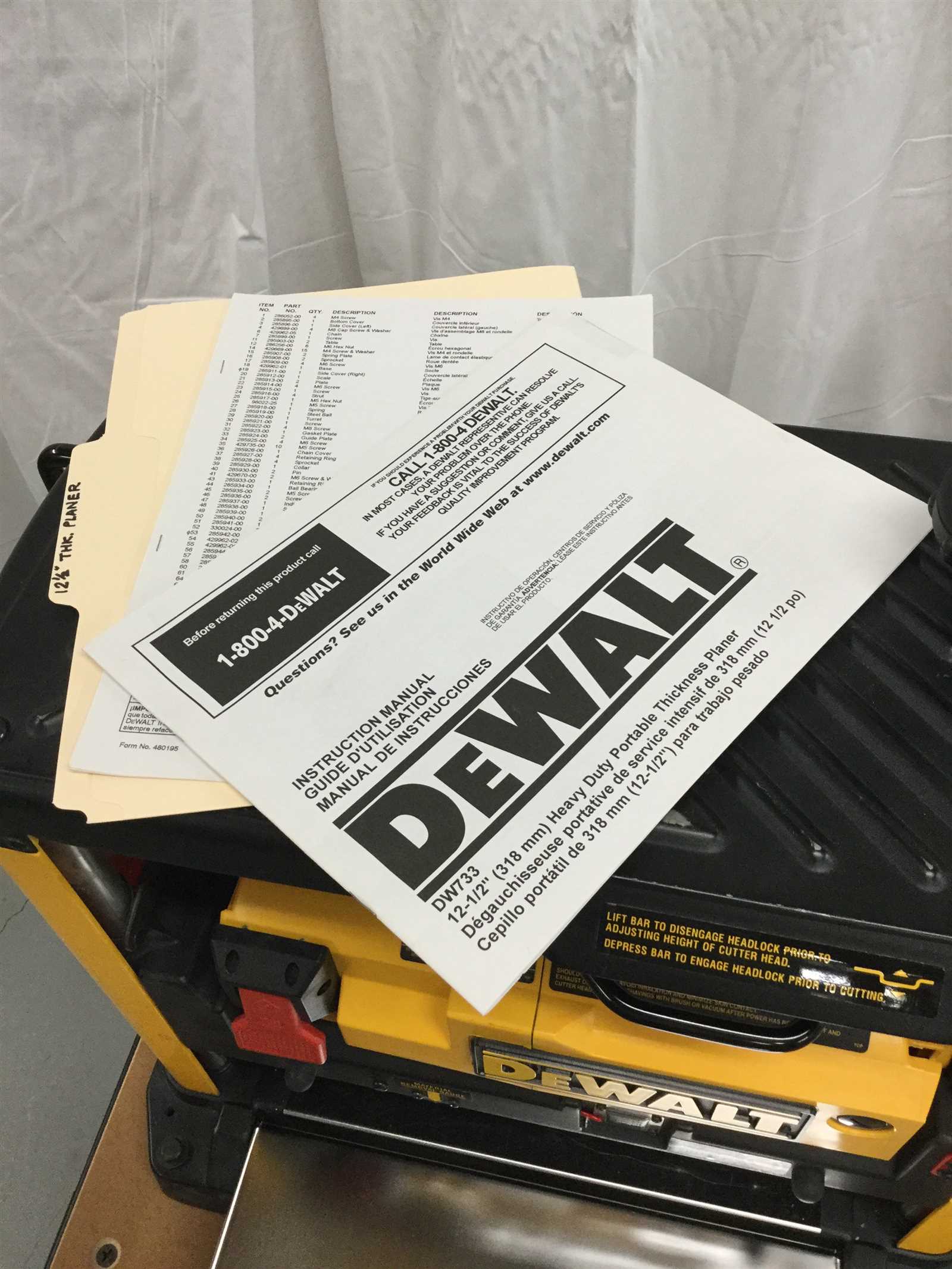

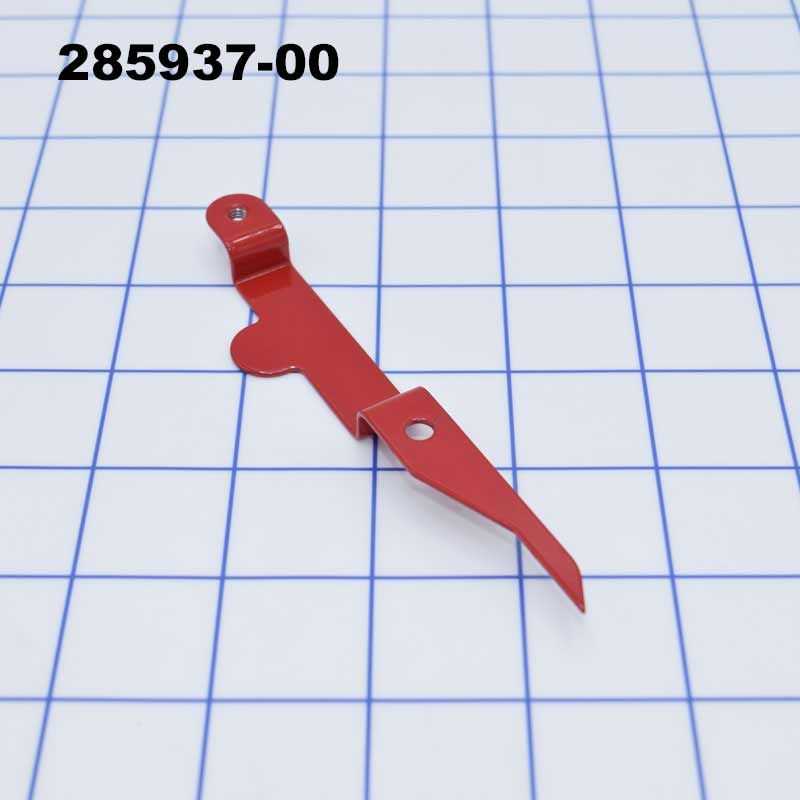

Replacement Parts for DW733

Maintaining the longevity and efficiency of your equipment often involves acquiring specific components designed for optimal performance. Identifying the necessary elements can significantly enhance functionality and ensure smooth operation. In this section, we will explore various alternatives available for your machine, highlighting essential items that can be replaced to restore its peak condition.

Blades: High-quality cutting edges are crucial for precision tasks. Consider upgrading to a durable option for improved results.

Belts: A reliable belt ensures seamless power transfer. Opt for a robust version to minimize wear and tear.

Bearings: These components are vital for smooth movement. Regular replacements can prevent friction-related issues and extend service life.

Motor Components: Replacing motor elements can rejuvenate performance. Focus on efficiency when selecting these vital parts.

Ultimately, investing in the right replacements can transform your machinery, leading to enhanced performance and reliability.

Maintenance Tips for Longevity

Ensuring the extended life of your equipment requires consistent care and attention. By following a few essential practices, you can enhance performance and minimize the likelihood of issues. Regular upkeep not only keeps your tools in optimal condition but also promotes safety during operation.

Regular Cleaning

Keeping your machinery clean is crucial. Dust and debris can accumulate and lead to malfunctions. After each use, take a moment to wipe down surfaces and remove any buildup. A clean tool not only performs better but also has a longer lifespan.

Routine Inspections

Conducting frequent assessments helps identify wear and tear early. Look for signs of damage, such as frayed cables or loose components. Addressing these issues promptly can prevent more significant problems down the line. Additionally, ensuring that all moving parts are properly lubricated can greatly enhance functionality and reduce friction.

Tools Needed for Repairs

When it comes to maintenance and troubleshooting, having the right equipment is crucial for achieving efficient results. A well-stocked toolkit can significantly streamline the repair process, ensuring you have everything necessary to tackle any issues that arise.

Essential Hand Tools

Basic hand tools such as screwdrivers, pliers, and wrenches are fundamental for most repairs. Additionally, a reliable set of hex keys can help in adjusting components with precision, while a tape measure is invaluable for ensuring correct measurements during the repair process.

Power Tools and Accessories

Incorporating power tools into your toolkit can enhance efficiency. A drill with various bits allows for quick fastening and removal, while a sander can smooth out surfaces after repairs. Always ensure you have the appropriate safety gear, such as gloves and goggles, to protect yourself during maintenance tasks.

Where to Find Replacement Parts

When it comes to maintaining your equipment, sourcing new components is crucial for ensuring optimal performance. There are several avenues you can explore to locate the necessary replacements, each offering distinct advantages depending on your needs.

Online Retailers: The internet is a treasure trove of resources for acquiring new items. Websites specializing in machinery supplies often provide a wide selection, detailed descriptions, and competitive pricing. Make sure to read reviews to gauge the reliability of the seller.

Manufacturer Websites: For authenticity and quality assurance, visiting the official site of the manufacturer can be beneficial. They typically offer original replacements and may provide useful documentation to assist in installation.

Local Hardware Stores: Don’t overlook neighborhood shops. They might stock compatible components or be able to order what you need. Building a relationship with local retailers can also lead to personalized advice and service.

Specialized Distributors: Some companies focus exclusively on specific types of machinery. These distributors can often provide expert knowledge and hard-to-find items that general retailers may not carry.

Online Marketplaces: Platforms like eBay or Amazon can be great for finding both new and used components. Be sure to verify the seller’s reputation and check for return policies to protect your purchase.

Forums and Community Groups: Engaging with communities focused on your equipment can yield valuable recommendations and leads on where to find the right components. Members often share personal experiences and might even offer parts for sale.

By exploring these various resources, you can effectively track down the components needed to keep your machinery running smoothly.

Comparison with Similar Models

In evaluating various tools within the same category, it’s essential to analyze their features, specifications, and overall performance. This comparison aims to highlight the strengths and weaknesses of similar devices, providing a clearer understanding of their functionalities and usability.

When examining alternatives, one can observe differences in motor power, cutting capacity, and design efficiency. Some models may offer enhanced durability, while others focus on user-friendly controls or compactness. Assessing these aspects allows users to choose a tool that aligns best with their specific needs and preferences.

Additionally, the availability of replacement components and support services can significantly impact the long-term value of these devices. By considering these factors, users can make informed decisions that ensure optimal performance and reliability over time.

Community Resources and Support

Accessing reliable information and assistance is crucial for anyone involved in maintenance and repair tasks. A vibrant community can offer valuable insights, practical advice, and emotional support for individuals navigating their projects. These resources often include forums, social media groups, and local workshops where enthusiasts share their knowledge and experiences.

Online Forums and Discussion Groups

Many online platforms serve as hubs for enthusiasts to connect and exchange information. Participating in these forums allows individuals to ask questions, seek advice, and share tips related to their projects. Engaging with like-minded individuals fosters a sense of belonging and can significantly enhance the learning experience.

Local Workshops and Meetups

In-person gatherings provide opportunities for hands-on learning and collaboration. Local workshops often feature expert-led sessions, where participants can gain practical skills and learn about troubleshooting techniques. These events are not only educational but also a chance to network and build friendships within the community.

Embrace the power of community as a vital resource in your journey. Whether through online platforms or local gatherings, the support and knowledge available can make all the difference in successfully achieving your goals.