Mechanical systems, especially those found in complex machinery, rely on a well-organized structure of various elements. Each component plays a crucial role in maintaining the overall performance and ensuring smooth operation. Recognizing the layout of these systems can be vital for effective maintenance and troubleshooting.

In order to achieve long-term reliability, it’s essential to comprehend how different elements are arranged and interact with each other. By gaining insight into the specific positioning and connections within a system, one can approach repairs and upgrades with greater precision.

Whether you’re maintaining a piece of equipment or seeking to understand the relationships between individual components, familiarizing yourself with the structure will enhance your efficiency and technical expertise. Exploring the inner framework of these systems is key to keeping everything running at optimal

Understanding the GT235 Engine Components

Machines rely on a complex system of mechanical parts to function efficiently. These systems are meticulously designed to work in harmony, ensuring smooth operation and durability over time. Every component plays a critical role in maintaining the overall performance, from providing power to ensuring the smooth running of the machinery.

Key Functional Elements

Within the system, there are several vital elements that contribute to its proper functioning. Some components manage the distribution of energy, while others focus on maintaining stability and ensuring the safety of the entire setup. Proper care and regular maintenance of these elements can significantly extend the operational life of the equipment.

Maintaining Optimal

Essential Parts of John Deere GT235

In every machine, several components work together to ensure smooth and efficient performance. These elements, when functioning harmoniously, contribute to the overall reliability and durability of the vehicle. Understanding the key elements can help maintain and troubleshoot the system more effectively.

- Power Supply Unit – The central force behind movement, driving the mechanical functions.

- Cooling Mechanism – Ensures the temperature remains optimal, preventing overheating during extended use.

- Transmission System – Regulates the flow of power from the core to the wheels, controlling speed and maneuverability.

- Fuel System

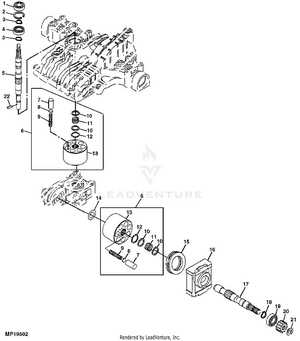

How to Read Engine Diagrams

Understanding mechanical layouts is essential for anyone working with machinery. These visual representations simplify complex systems, allowing users to follow the flow of components and connections without needing to see the actual machinery. With practice, reading these layouts becomes an intuitive process, helping users diagnose issues and plan repairs efficiently.

Breaking Down the Components

When looking at a mechanical layout, it’s important to first identify the key elements. These often include symbols representing different parts and pathways. Knowing how these symbols are used to represent real-world components helps in making sense of the entire system.

- Maintenance Tips for GT235 Engines

Regular upkeep is essential to ensure that your machinery runs smoothly and efficiently. By following a consistent care routine, you can extend its lifespan and avoid costly repairs. The following steps will guide you through some basic but critical aspects of maintaining your equipment.

- Lubrication: Make sure to regularly check and change the lubrication fluids. Fresh oil is crucial for reducing friction and preventing wear.

- Filter checks: Ensure air and fuel filters are clean and functional. Replace them as necessary to avoid blockages that could harm performance.

- Cooling system: Inspect the cooling system to prevent overheating. Regularly flush and refill coolant to keep the temperature regulated.

- Common Issues with Engine Components

Mechanical systems often encounter various challenges during their operation, especially when exposed to long periods of use or extreme conditions. These issues can arise due to wear and tear, improper maintenance, or even external factors such as environmental conditions. Understanding these common problems can help prolong the lifespan of machinery and ensure optimal performance.

Symptoms of Malfunction

Typical signs of trouble can range from unusual noises to reduced efficiency. Operators might notice fluctuations in power output, increased fuel consumption, or difficulties in starting the machine. These indicators usually signal underlying mechanical problems that need to be addressed swiftly to prevent further damage.

Frequent Causes

Many issues stem from the degradation of essential components over time. Lubric

Finding Replacement Parts Easily

Locating the right components for your machine can seem challenging, but with the right approach, it becomes a straightforward task. Knowing where to look and what to consider can save you time and ensure your equipment runs smoothly for years to come.

- Online Resources: Many websites specialize in providing specific components for various models, offering a wide range of selections. Searching by model number or description often yields fast results.

- Local Dealers: Visiting a trusted dealer can offer the advantage of expert advice and quick access to hard-to-find items, along with the possibility of in-person troubleshooting.

Upgrades for Improved Performance

Optimizing a machine for enhanced efficiency often involves making key modifications that boost its overall capabilities. By fine-tuning certain components and introducing advanced technology, one can achieve smoother operation and greater reliability, especially under demanding conditions. These adjustments allow the equipment to operate more effectively, extending its lifespan and ensuring consistent output.

Power Enhancements: Adjusting the fuel system and incorporating updated control systems can significantly enhance the power output. With proper calibration, the machine can achieve better performance across various terrains, making it more versatile.

Durability and Longevity: Upgrading cooling systems and reinforcing critical components helps protect the machine from wear and tear. This not only increases durability but also minimizes the need for freque

Comparing GT235 with Other Models

When evaluating different riding mowers, it’s important to consider various features that can significantly influence performance and user experience. Each model brings its own strengths, suited for specific needs, whether it’s efficiency, ease of use, or versatility. Understanding the nuances between machines helps in choosing the right option for both residential and professional applications.

Some options in the market may offer advanced technology, while others prioritize simplicity and durability. In comparing similar models, aspects like engine power, maneuverability, and cutting width often come to the forefront. These characteristics can vary greatly, making one model better suited for larger areas, while others

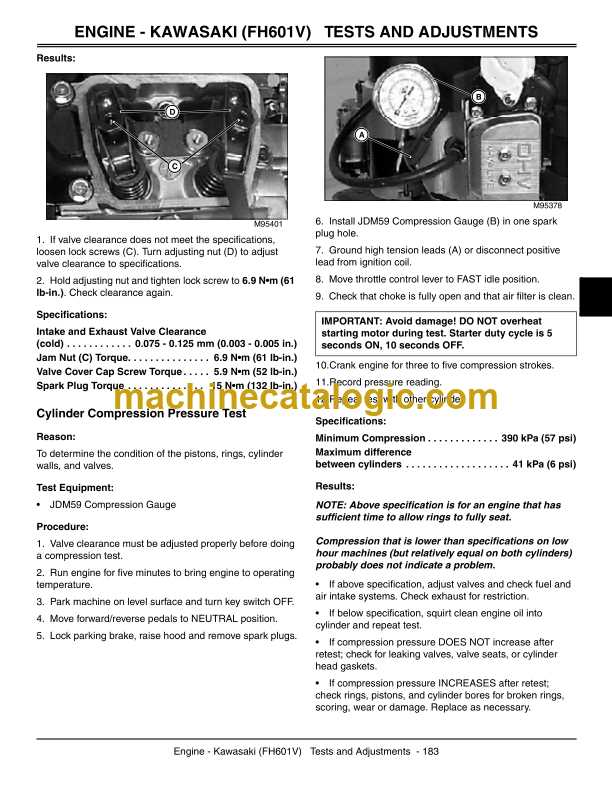

Tools Needed for Engine Repairs

When undertaking repairs for mechanical systems, having the right tools at hand can significantly improve both efficiency and safety. The appropriate selection of equipment ensures that each task is done with precision and minimizes the risk of damage to components.

Basic Hand Tools

Standard hand tools such as screwdrivers, wrenches, and pliers are essential for a wide range of mechanical fixes. A reliable set of sockets and spanners will also be useful, as they allow for easy manipulation of nuts and bolts. Additionally, a torque wrench ensures that fasteners are tightened to the correct specifications.

Specialized Instruments

Safety Precautions During Maintenance

When performing upkeep on machinery, it is essential to prioritize safety to prevent accidents and ensure a smooth process. Adhering to specific guidelines can significantly reduce the risk of injury and equipment damage.

Always wear appropriate personal protective equipment, such as gloves, goggles, and sturdy footwear, to shield yourself from potential hazards. This gear is crucial in mitigating risks associated with sharp edges and heavy components.

Before beginning any task, ensure that the power source is disconnected. This step is vital in preventing unintentional activation, which could lead to severe injuries. Additionally, allow the machinery to cool down after operation to avoid burns or other heat-related injuries.

Keep the workspace organized and free of clutter. A tidy environment reduces the chance of accidents caused by slipping or tripping over tools and materials. Always have a first aid kit accessible in case of minor injuries.

Lastly, consult the maintenance manual for any specific safety instructions relevant to the equipment being serviced. Understanding the unique characteristics of the machinery will enhance safety measures and operational efficiency.

Resources for Parts and Diagrams

Accessing reliable information regarding components and their layouts is crucial for effective maintenance and repairs. Various sources provide valuable insights, making it easier for users to identify what they need for their machinery. These resources can assist both novice and experienced individuals in obtaining the correct items.

Resource Type Description Examples Online Retailers Websites that sell components directly to consumers, often featuring detailed descriptions and images. Amazon, eBay, specialized machinery suppliers Manufacturer Websites Official sites that offer technical specifications, schematics, and additional resources for users. Brand websites, official parts stores Forums and Community Groups Online platforms where users share experiences, advice, and sometimes diagrams. Reddit, dedicated machinery forums, Facebook groups Repair Manuals Publications that provide comprehensive instructions, including illustrations of various components. Printed manuals, PDF guides

- Maintenance Tips for GT235 Engines