The proper functioning of any agricultural equipment depends on the seamless integration of its various elements. Understanding how these elements are interconnected is crucial for efficient operation and maintenance. This section delves into the arrangement and key structures that make up the heart of these powerful machines.

Mechanical systems require precision in both design and placement. Whether it’s ensuring optimal performance or addressing potential malfunctions, familiarity with the inner workings of these machines proves invaluable for operators and technicians alike.

Identifying and locating specific mechanisms can simplify repairs and routine checks, allowing users to keep their equipment running smoothly. With this guide, you’ll gain a deeper understanding of how individual pieces come together to form a cohesive system.

Engine Components Overview

The engine of this model is a powerful and efficient system that ensures reliable performance in various applications. Each component within the system is meticulously designed to work in harmony, providing smooth and consistent power output. Understanding the structure of this system helps in maintaining and optimizing its performance over time.

Key elements of the engine include the core power unit, responsible for converting fuel into mechanical energy, along with supplementary systems that support cooling, lubrication, and fuel delivery. These elements work together to maximize efficiency and durability, ensuring the engine can operate under different workloads and conditions.

Additionally, the fuel injection mechanism plays a vital role in controlling the distribution of fuel, while the cooling system ensures that heat is effectively managed to prevent overheating. Proper maintenance and familiarity with these components are essential for keeping the system in peak operating condition.

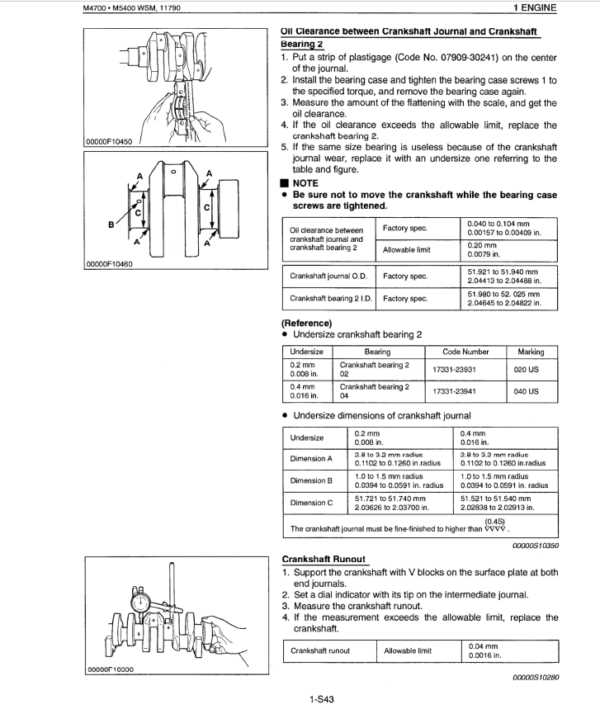

Understanding Key Parts of the Engine

The engine is a complex mechanical system composed of numerous components that work together to generate power and ensure smooth operation. Each component plays a vital role in maintaining the efficiency and performance of the machinery. By gaining a better understanding of the primary elements that make up the engine, one can improve maintenance practices and ensure the longevity of the system.

At the heart of the engine lies the cylinder block, which serves as the foundation, housing the main moving components. The crankshaft converts linear motion into rotational force, allowing the engine to produce mechanical energy. Above the cylinder block, the cylinder head contains various valves responsible for controlling airflow and fuel intake. Pistons move within the cylinders, powered by combustion, transferring energy to the crankshaft.

Another crucial component is the camshaft, which coordinates the opening and closing of the valves in precise synchronization with the

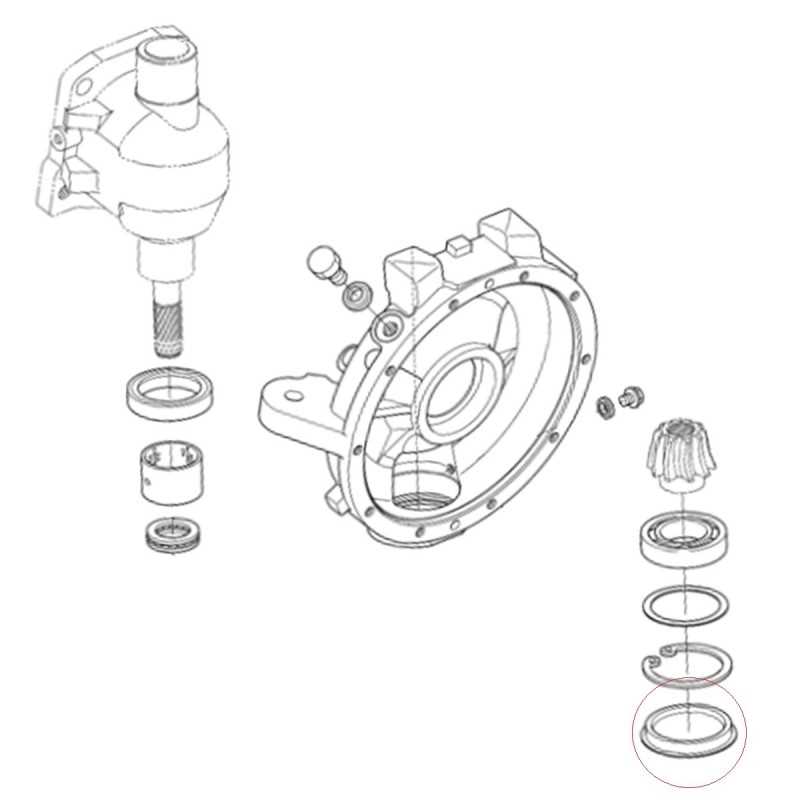

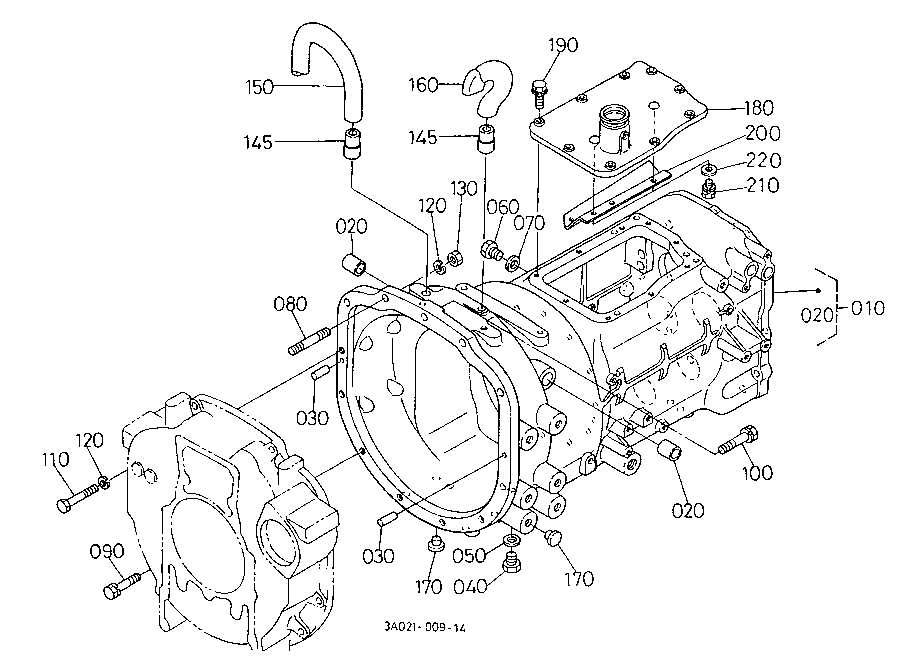

Transmission System Breakdown for Kubota M5400

The transmission mechanism is a vital component responsible for transferring power from the engine to the wheels, ensuring smooth operation and control in various field conditions. A detailed understanding of its key elements allows for efficient maintenance and troubleshooting of potential issues.

- Clutch Assembly: This part plays a crucial role in disengaging the power flow, allowing the operator to shift gears without causing damage to the internal components.

- Gearbox: Houses a series of gears that alter the speed and torque. Proper lubrication and alignment of these gears are essential for the overall functionality.

- Shift Mechanism: The lever and rods connected to the gearbox enable the selection of different gear ranges. Regular checks ensure smooth shifting and avoid unnecessary wear.

- Driveshaft: This rotating component

Insights Into Gearbox and Power Transfer

The transmission of mechanical energy within a vehicle’s machinery is a crucial aspect of ensuring efficient performance and long-term durability. Understanding the interplay between the gearbox and power transfer mechanisms provides valuable knowledge for maintaining the overall functionality of equipment. This section explores how different components work together to deliver power effectively.

Key Components of the Gearbox

At the heart of the transmission system lies the gearbox, which regulates speed and torque through various gears. These elements interact to adjust the mechanical output to match specific operating conditions. The main components include:

- Gears: Different sizes and types of gears provide control over speed and power.

- Shafts: Drive shafts facilitate the flow of power between the engine and other mechanical elements.

- Pump – The pump is responsible for moving fluid within the system, creating the necessary pressure that powers various functions. It draws fluid from the reservoir and delivers it to other components.

- Reservoir – This tank holds the hydraulic fluid, ensuring a continuous supply of liquid for the system to function. The reservoir also helps to cool and filter the fluid.

- Main Features of the Hydraulic System

The hydraulic system plays a vital role in the functionality of modern machinery, offering power and control for a variety of tasks. It operates by transmitting force through pressurized fluid, allowing the equipment to perform heavy-duty operations efficiently and smoothly.

- Fluid Power Transmission: This system utilizes pressurized fluid to transfer energy from one point to another, enabling precise control over various attachments and mechanisms.

- Integrated Pump Mechanism: A key component, the hydraulic pump, generates pressure within the system, driving the fluid to power different functions such as lifting or steering.

- Valves and Control Units: Valves manage the flow of fluid, regulating the direction and intensity of pressure, ensuring the proper functioning of actuators and cylinders.

- Cylinders and Actuators: Hydraulic cylinders convert fluid pressure into linear motion, driving mechanical parts such as lifts, arms, and other operational elements.

- Cooling and Filtration: Maintaining the system’s efficiency is crucial, and proper filtration and cooling prevent contamination and overheating, extending the life of the components.

- Safety and Maintenance Features: Built-in safety valves protect against pressure overloads, while regular maintenance ensures smooth operation and longevity of the system.

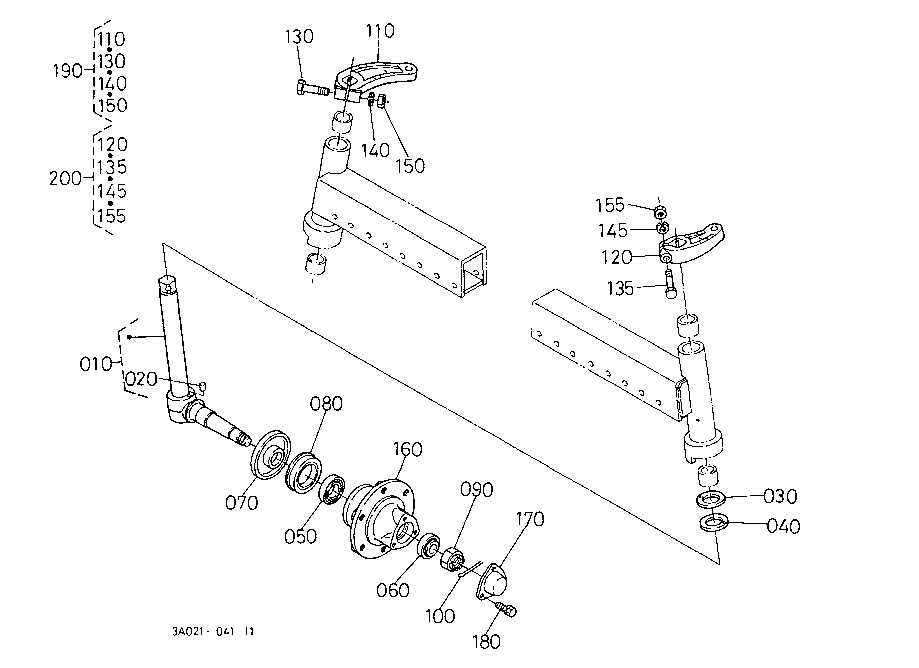

Steering System Structure

The steering system of agricultural machinery plays a vital role in ensuring smooth and precise maneuverability. It is designed to provide operators with optimal control while navigating various terrains. Understanding the key components and their functions can help maintain efficiency and longevity of the equipment.

- Steering Wheel: The primary control mechanism that allows the operator to direct the vehicle’s movement. It is connected to the steering column and offers feedback based on the terrain conditions.

- Steering Column: The vertical shaft that connects the steering wheel to the steering mechanism. It transmits the operator’s input to the rest of the system.

- Hydraulic Pump: Provides power to the steering system, enabling easier control by reducing the physical effort required by the operator.

- Steering Cylinder: A hydraulic component that converts fluid pressure into mechanical force to steer the wheels.

- Power Steering System: A system that enhances steering capability, reducing the need for manual effort, especially during tight turns or when operating under heavy load conditions.

- Linkage Mechanism: The connecting parts that transmit the motion from the steering cylinder to the wheels, allowing them to turn in response to operator input.

Regular maintenance of each component is essential to ensure smooth operation and prevent unnecessary wear and tear. Proper fluid levels, regular inspections, and timely replacements of worn-out parts are critical for maintaining the integrity of the steering system.

Detailed Look at Steering Components

Steering systems play a critical role in ensuring the smooth and responsive movement of heavy machinery. These mechanisms are designed to provide precise control and maneuverability, essential for the efficient operation of agricultural equipment. A closer examination of the key steering elements reveals how they work in unison to deliver the stability and precision required for navigating various terrains.

- Steering Wheel: The primary interface for the operator, allowing control of direction. It is connected to the steering shaft, which translates the driver’s input into mechanical movement.

- Steering Shaft: A pivotal component that connects the steering wheel to the rest of the system. This shaft is responsible for transmitting the operator’s commands to the steering box or mechanism.

- Steering Box: Often referred to as the steering gear, this component changes the rotational motion from the shaft into lateral movement to control the front wheels or tracks.

- Hydraulic System: Some vehicles utilize hydraulic assistance to reduce the effort needed to turn the steering wheel. This system uses fluid pressure to provide smoother steering under heavy loads.

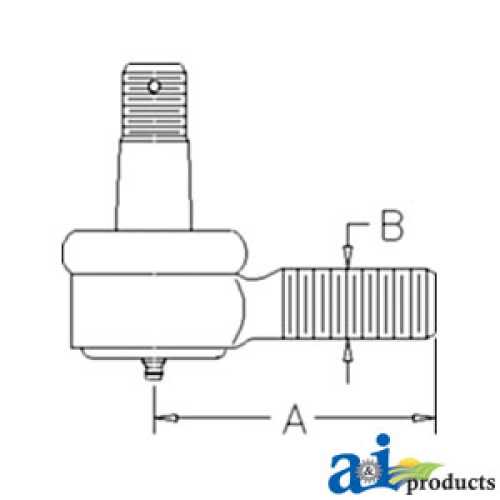

- Steering Linkage: This is a series of rods and joints that connect the steering box to the wheels. The linkage ensures the wheels move in the correct direction based on the input from the operator.

- Ball Joints: Essential for connecting the steering arms to the wheels, ball joints allow for smooth movement and flexibility as the wheels turn.

Each of these elements contributes to the overall functionality of the system, making it possible to maintain precise control and stability under a variety of conditions. Regular maintenance and inspection of these parts are vital for ensuring long-term performance and safety.

Cooling System Elements in Kubota M5400

The cooling system of a tractor plays a crucial role in maintaining optimal engine performance by regulating temperature levels. A well-functioning cooling mechanism ensures that the engine does not overheat during extended use, thus preventing potential damage and improving the longevity of the equipment. This section will explore the components involved in this vital system and their functions within the machine.

Key Components of the Cooling Mechanism

At the heart of the cooling setup is the radiator, which dissipates heat from the engine. The fluid circulating through the radiator absorbs excess heat and releases it into the surrounding air. This ensures that the engine remains at an efficient working temperature. Another essential component is the water pump, which keeps the coolant flowing throughout the engine and radiator, ensuring that the cooling fluid reaches all necessary areas.

Additional Cooling Elements

In addition to the radiator and water pump, the system includes components such as the thermostat and coolant hoses. The thermostat controls the flow of the coolant based on the engine temperature, ensuring that the system operates within an ideal range. Coolant hoses allow the liquid to move between the engine, radiator, and pump, completing the circulation process and ensuring continuous heat exchange.

Critical Components of the Cooling System

The cooling system plays a vital role in maintaining optimal performance and longevity of an engine. It ensures that the engine does not overheat by regulating the temperature through various essential elements that facilitate heat dissipation. These components work together to prevent damage to the engine and enhance its efficiency.

At the core of the system are several key elements, each serving a specific purpose in managing heat. These parts are carefully designed to channel coolant and dissipate excess heat effectively, thereby ensuring the engine operates within safe temperature limits.

Component Description Radiator Responsible for cooling the heated coolant from the engine, using air flow to dissipate heat. Water Pump Circulates coolant through the engine, ensuring continuous heat absorption and transfer. Thermostat Regulates the flow of coolant to maintain a stable engine temperature. Coolant Hoses Carry the coolant to and from the engine, connecting the radiator, water pump, and engine block. Cooling Fan Helps draw air through the radiator to enhance heat dissipation, especially when the vehicle is stationary. Fuel System Diagram for Kubota M5400

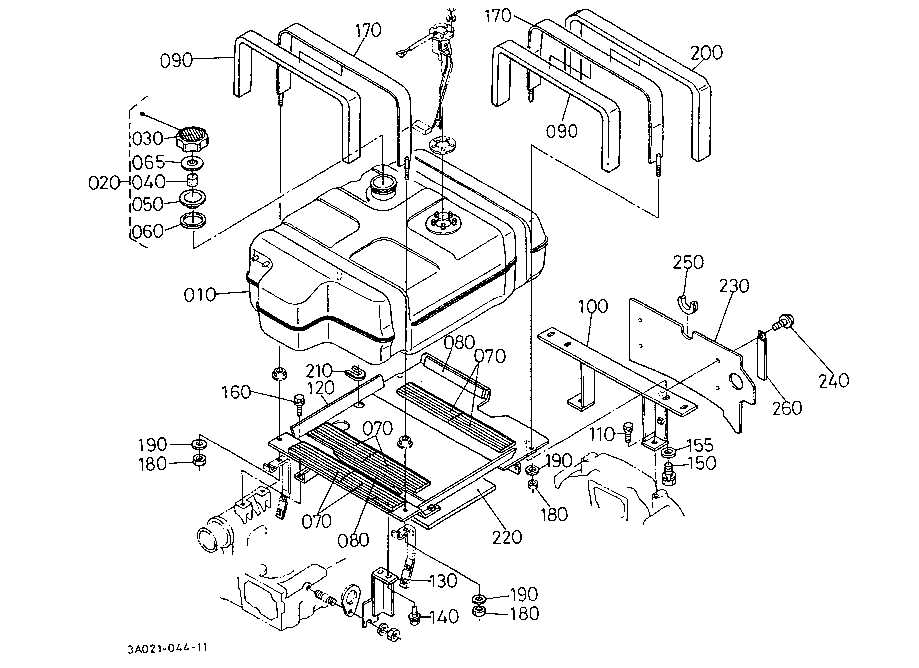

Understanding the fuel flow in agricultural machinery is crucial for maintaining optimal performance. The components responsible for fuel delivery ensure that the engine receives the correct amount of fuel for combustion. This section will explore the key elements that make up the fuel delivery system and how they interact to provide the necessary power for the equipment to operate efficiently.

Key Components of the Fuel Delivery System

- Fuel tank: Stores the fuel required for operation.

- Fuel filter: Removes impurities from the fuel before it reaches the engine.

- Fuel pump: Moves fuel from the tank through the system to the engine.

- Injection system: Delivers fuel to the engine cylinders at precise intervals.

- Fuel lines: Provide a pathway for fuel to travel between components.

System Functionality

The fuel is drawn from the tank by the pump, passing through the filter to ensure cleanliness. The fuel is then delivered through the lines to the injectors, which meter the fuel according to the engine’s needs. Proper maintenance of each component is essential for ensuring the system functions smoothly, preventing clogging or fuel starvation that can lead to reduced efficiency or engine failure.

Exploring the Fuel Delivery Process

Efficient fuel distribution is a critical component of any engine system, as it ensures optimal performance and power output. Understanding how fuel moves from the storage tank to the combustion chamber allows for better maintenance and troubleshooting. This process involves several stages, each playing a vital role in ensuring that the engine receives the correct amount of fuel at the right time.

At the core of this process is the fuel pump, which draws fuel from the tank and sends it through various filters and lines. These filters serve to remove impurities that could damage sensitive engine components. Once the fuel is properly filtered, it travels through the injector system, which precisely meters the fuel into the engine, mixing it with air to form a combustible mixture.

The proper operation of these components is essential for maintaining fuel efficiency and preventing issues such as misfires or poor engine performance. Routine inspections and maintenance of the fuel delivery system are recommended to keep the system running smoothly, ensuring that all elements work in harmony to deliver fuel in an efficient manner.

Brake System Components and Their Functions

The brake system of a heavy-duty machine plays a crucial role in ensuring safe operation and control. It consists of several key elements that work together to slow down or stop the vehicle when necessary. Understanding the function of each component can help in maintaining the system’s efficiency and preventing premature wear or failure.

- Brake Pedal: The brake pedal is the primary control that the operator uses to activate the braking mechanism. When pressed, it sends a signal to engage the brakes, ensuring the vehicle slows down or halts.

- Hydraulic Pump: This component is responsible for generating the necessary hydraulic pressure to activate the braking system. It ensures that fluid is pushed into the brake lines when the brake pedal is engaged.

- Brake Fluid Reservoir: The reservoir stores brake fluid, which is essential for the proper functioning of the hydraulic braking system. It ensures that the system has enough fluid to operate effectively.

- Brake Lines: These tubes carry the brake fluid from the reservoir to the brake cylinders. The fluid pressure in these lines activates the brakes, helping to control the vehicle’s speed.

- Brake Shoes or Pads: The brake shoes or pads are the components that press against the brake drums or rotors to create friction. This friction slows down the wheels, bringing the machine to a stop.

- Master Cylinder: The master cylinder is a critical part of the hydraulic system that receives the pressure from the brake pedal and transfers it to the brake lines. It controls the flow of brake fluid to various parts of the system.

- Brake Drums or Rotors: These are the parts that rotate with the wheels and provide a surface for the brake shoes or pads to apply friction. Depending on the system design, either a drum or rotor is used to slow down or stop the vehicle.

Each component of the braking system plays a vital role in ensuring that the vehicle can be safely controlled, particularly in emergency situations. Proper maintenance and timely replacement of these parts are essential for smooth operation and the safety of the machine and operator.

Hydraulic Mechanism and Its Components

The hydraulic system is an essential aspect of many machines, offering precise control and power transmission through fluid pressure. This section focuses on the inner workings of the hydraulic mechanism and the key elements that enable smooth and efficient operation. Understanding how each component contributes to the overall functionality will provide a deeper insight into the entire hydraulic process.