When working with various machinery, having a clear representation of its components is crucial. These visual guides help users identify individual elements, facilitating easier maintenance and repairs. By comprehensively mapping out the structure, one can streamline processes and enhance efficiency.

Utilizing such visual aids enables operators to quickly locate specific sections and understand their functions within the overall system. This knowledge is vital for troubleshooting and ensuring optimal performance. A well-organized illustration not only simplifies complex assemblies but also serves as an invaluable reference for both novice and experienced users alike.

Moreover, the availability of detailed layouts contributes to informed decision-making regarding replacements and upgrades. Understanding the relationships between various components fosters a deeper comprehension of the machinery’s functionality. In essence, these representations empower users to take proactive measures in maintaining and enhancing their equipment.

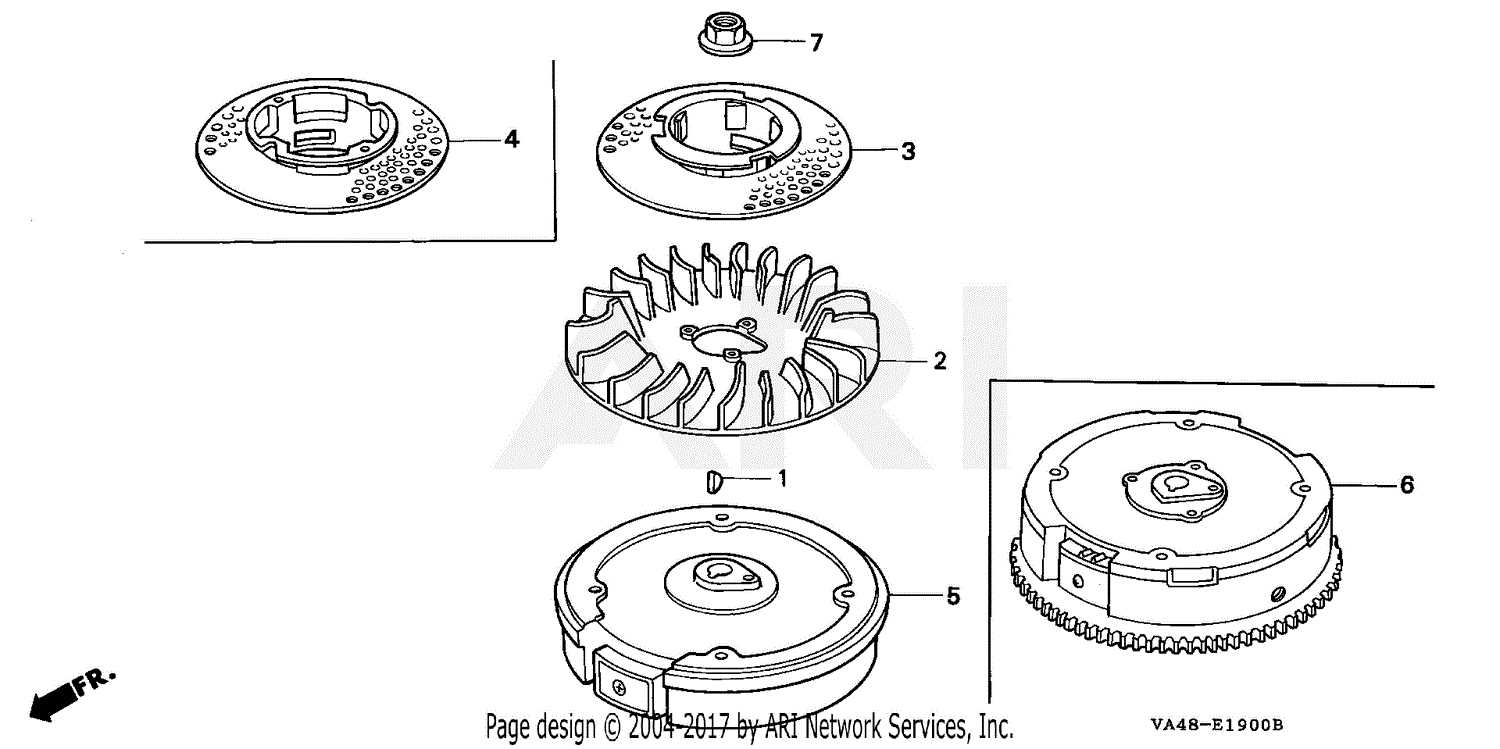

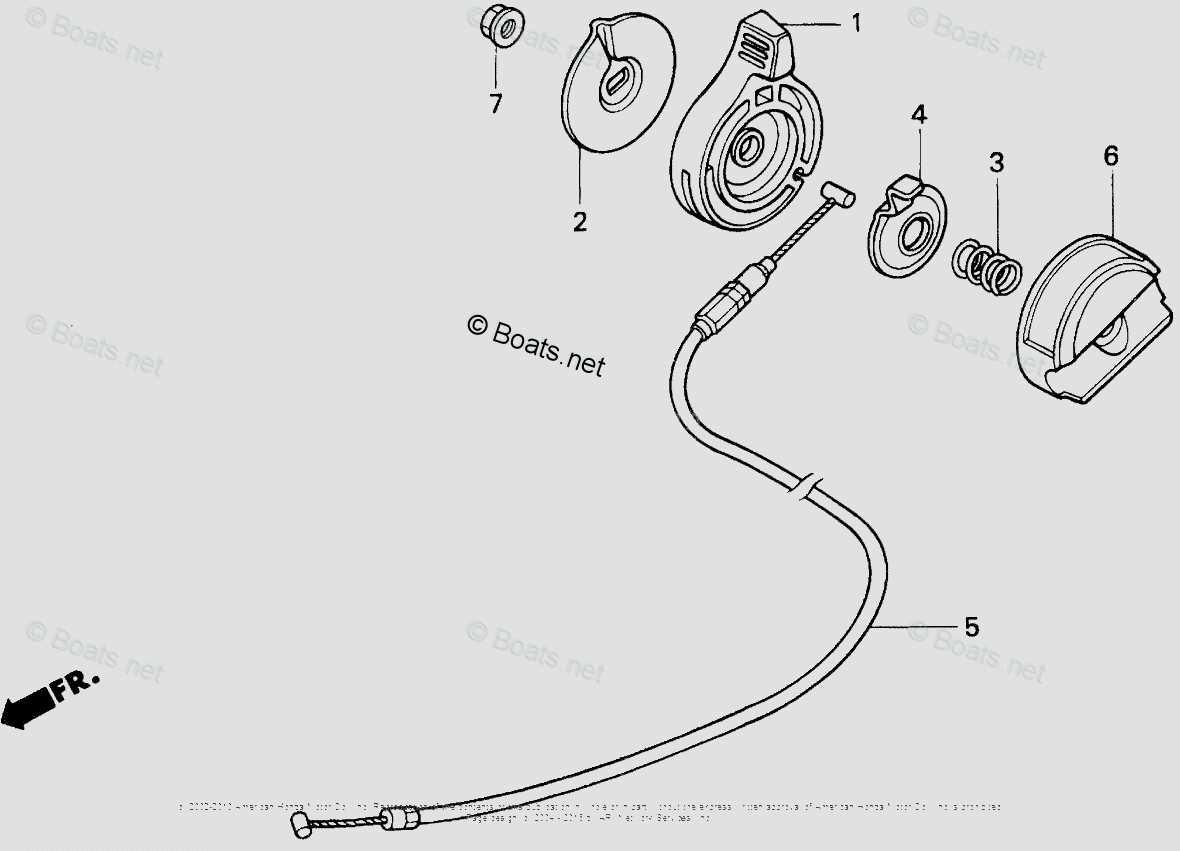

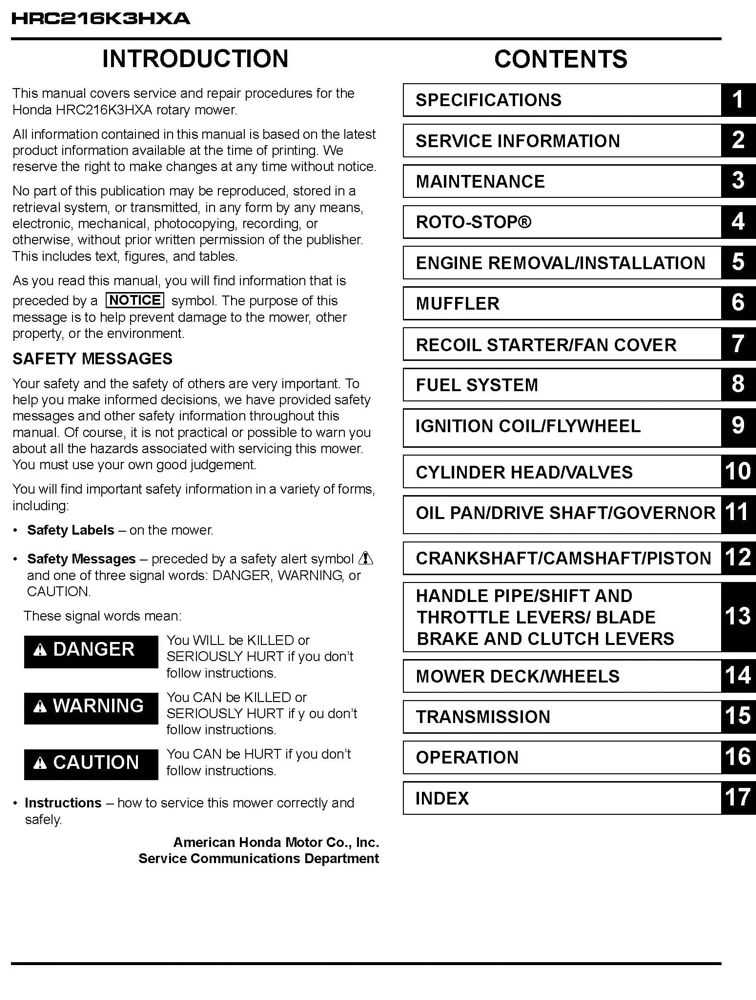

Key Components of Hrc216

Understanding the essential elements of a lawn maintenance machine is crucial for optimal performance and maintenance. Each component plays a significant role in ensuring efficiency and effectiveness during operation. Below, we delve into some of the vital parts that contribute to the functionality and reliability of this equipment.

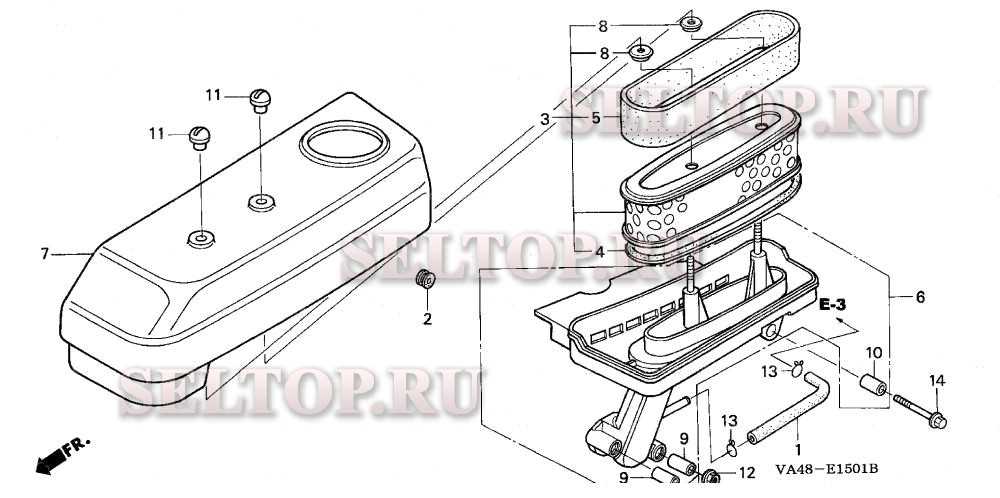

Engine and Power System

The engine serves as the heart of the machine, providing the necessary power for operation. It is typically designed for durability and efficiency, ensuring that the machine can handle various lawn conditions. Additionally, the power system encompasses components like the fuel tank and battery, which are essential for sustaining engine performance.

Cutting Mechanism

The cutting mechanism is another crucial aspect, as it directly influences the quality of the lawn finish. This system includes blades and drive components that work together to ensure a clean cut. The design and sharpness of the blades, along with their alignment, play a pivotal role in achieving a well-manicured appearance.

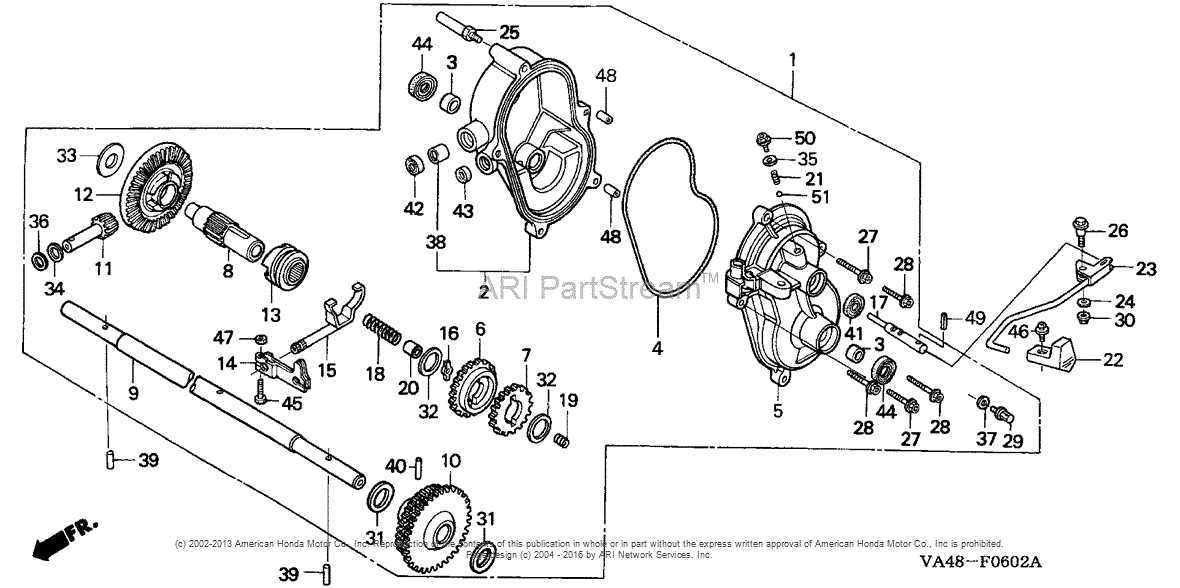

How to Read the Diagram

Understanding a schematic representation is crucial for effective maintenance and repair. These illustrations provide a visual guide, helping users identify components and their interconnections. Familiarity with these representations enhances problem-solving abilities and promotes efficient troubleshooting.

Identify Key Elements

Start by familiarizing yourself with the essential features of the illustration. Look for labels that denote specific components, as well as any symbols that indicate their functions. Understanding these symbols is key to navigating the visual effectively.

Follow the Connections

Once you recognize the components, trace the connections between them. This will give you insight into how each part interacts with others, allowing for better comprehension of the overall system. Pay attention to any notes or legends that might clarify the relationships depicted.

Common Issues with Hrc216 Parts

When dealing with lawn care machinery, users often encounter various challenges related to the individual components that contribute to the overall functionality. These difficulties can stem from wear and tear, improper maintenance, or manufacturing defects, leading to performance issues and increased downtime.

One frequent concern is the wear of belts, which can result in reduced efficiency and sluggish operation. Regular inspections and timely replacements are crucial to prevent further damage to other elements.

Another notable issue involves fuel system problems. Clogged filters or malfunctioning pumps can impede the flow of fuel, causing the engine to run inefficiently or fail to start. Proper cleaning and maintenance can mitigate these risks.

Moreover, electrical faults can arise, often manifesting as starting difficulties or erratic operation. Ensuring that all connections are secure and that components are free from corrosion can help maintain electrical integrity.

Finally, blades dulling is a common issue that can lead to poor cutting performance. Regular sharpening and replacement are essential to achieve the desired results and prolong the lifespan of the machine.

Maintenance Tips for Hrc216

Regular upkeep is essential for ensuring the longevity and efficiency of your lawn care equipment. Adopting a systematic approach to maintenance can prevent potential issues and enhance the performance of your machinery. Here are some effective strategies to consider.

Routine Inspections

Conducting regular checks on your equipment can help identify wear and tear early on. Pay attention to the following:

- Check the blades for sharpness and damage.

- Inspect the fuel and oil levels.

- Examine belts and cables for signs of fraying or looseness.

- Look for leaks in the fuel and oil systems.

Cleaning Procedures

Keeping your machine clean is vital for optimal function. Follow these cleaning tips:

- Remove grass clippings and debris after each use.

- Wash the exterior with mild soap and water.

- Clear any blockages in the air filter to ensure proper airflow.

- Inspect and clean the spark plug regularly.

Replacing Parts in Hrc216

Maintaining the functionality of your equipment is essential for ensuring its longevity and optimal performance. Over time, certain components may wear out or become less efficient, necessitating their replacement. Understanding how to effectively swap out these elements can enhance the device’s reliability and efficiency.

Identifying Worn Components

Recognizing which components need to be replaced is the first step in this process. Regular inspections can help identify signs of wear, such as unusual noises, decreased efficiency, or visible damage. By addressing these issues promptly, you can prevent further complications and maintain your device’s performance.

Replacement Process

Once you have determined which components require replacement, the next step involves gathering the necessary tools and materials. Following a detailed guide can facilitate the swapping process. Always ensure that you handle each component with care and adhere to safety guidelines to avoid any potential hazards during the replacement.

Tools Needed for Repairs

When undertaking maintenance tasks, having the right tools is essential for achieving optimal results. Proper equipment not only simplifies the process but also enhances efficiency and safety. Below, you’ll find a list of necessary tools to consider for successful repairs.

Essential Tools

The following tools are commonly required for various maintenance activities:

| Tool | Purpose |

|---|---|

| Wrench | Used for loosening or tightening bolts and nuts. |

| Screwdriver | Essential for driving screws in or out. |

| Pliers | Useful for gripping, twisting, and cutting wire or other materials. |

| Socket Set | Allows for easy fastening and loosening of nuts and bolts in tight spaces. |

| Hammer | Used for driving nails or breaking apart materials. |

Additional Equipment

In addition to the basic tools, certain projects may require specialized equipment:

| Equipment | Function |

|---|---|

| Torque Wrench | Ensures that bolts are tightened to the correct specifications. |

| Level | Used to ensure that surfaces are even and correctly aligned. |

| Utility Knife | Versatile tool for cutting various materials safely. |

| Safety Goggles | Protective eyewear to safeguard against debris and hazards. |

Identifying Worn Parts

Recognizing the signs of wear and tear is crucial for maintaining the efficiency and longevity of any machinery. Regular inspection helps ensure that components are functioning optimally and can prevent more significant issues down the line. It is essential to familiarize yourself with various elements that may exhibit deterioration over time.

Common indicators of a compromised component include unusual noises, decreased performance, and visible damage. For instance, cracks, tears, or signs of rust can signify that a part is no longer operating as intended. Additionally, keep an eye out for any looseness or excessive vibration during operation, which may indicate that a component needs to be replaced or serviced.

Periodic maintenance checks are invaluable in identifying these issues early. By staying vigilant and addressing wear promptly, you can significantly extend the lifespan of your equipment and maintain its overall performance.

Importance of Genuine Parts

Utilizing authentic components is crucial for the longevity and performance of any machine. Genuine items are designed to meet the specific requirements of the equipment, ensuring optimal functionality and reducing the risk of malfunctions. By investing in original elements, users can maintain their devices in peak condition while also safeguarding their warranty coverage.

Quality Assurance

Authentic components are manufactured under stringent quality control standards, which guarantees their reliability. These items undergo thorough testing to ensure they can withstand the demands of regular use. In contrast, imitation alternatives often lack the same level of craftsmanship, potentially leading to premature wear and failure.

Enhanced Performance

Using genuine components contributes to the overall efficiency of the equipment. These items are engineered to work seamlessly with the existing system, facilitating better performance and productivity. Opting for original elements can significantly reduce the likelihood of breakdowns, thereby minimizing downtime and maintenance costs.

Where to Find Hrc216 Diagrams

For those seeking detailed illustrations of specific machinery, there are several valuable resources available. These resources can help users understand the components and their arrangement effectively. Utilizing reliable platforms is essential for accessing accurate information and maintaining the functionality of equipment.

One of the most accessible options is the manufacturer’s official website. Often, companies provide comprehensive resources, including manuals and visual guides that outline the internal structure. Additionally, user forums and communities dedicated to machinery can be treasure troves of shared knowledge and experience, where enthusiasts exchange tips and illustrations.

Another excellent source is online marketplaces that sell machinery parts. These sites frequently include visual references alongside product listings, enabling users to view component layouts. Furthermore, dedicated repair guides and instructional videos can be found on platforms like YouTube, offering step-by-step visual assistance that simplifies understanding.

Finally, local hardware stores or specialized shops often maintain catalogs with detailed visuals. These can be useful for both new users and seasoned professionals looking for reference materials. By exploring these avenues, anyone can locate the information needed to enhance their knowledge and skills.

Hrc216 Parts Compatibility Guide

This section provides a comprehensive overview of the interchangeability and compatibility of various components used in a specific lawn care model. Understanding which elements can be used interchangeably is crucial for effective maintenance and repairs, ensuring optimal performance and longevity of the equipment.

Essential Components and Their Alternatives

When selecting replacements for essential components, it’s vital to consider alternatives that meet the same specifications. Many manufacturers provide compatible options that function similarly, helping users find suitable replacements without compromising quality. Always consult the specifications before making a decision to ensure a proper fit.

Maintenance Tips for Component Longevity

To extend the lifespan of your equipment, regular maintenance is key. Cleaning and inspecting each component for wear and tear can prevent unexpected breakdowns. Additionally, using compatible parts as needed can help maintain optimal performance, reducing the likelihood of future issues.

Benefits of Using Parts Diagrams

Utilizing visual representations of components offers numerous advantages for both maintenance and assembly processes. These illustrations provide clarity and enhance understanding, enabling users to easily identify various elements and their relationships within a system.

Enhanced Clarity: Visual aids eliminate ambiguity, making it easier for individuals to comprehend the layout and functionality of different parts. This can significantly reduce the likelihood of errors during repairs or installations.

Improved Efficiency: By referring to visual schematics, technicians can quickly locate specific elements, saving valuable time in troubleshooting and assembly tasks. This efficiency translates into quicker turnaround times and increased productivity.

Better Communication: These visuals serve as a common reference point among team members, facilitating clearer communication. Whether in a workshop or a collaborative environment, everyone can benefit from a shared understanding of the component arrangement.

Educational Tool: For newcomers, visual representations act as effective educational tools. They simplify complex concepts, making it easier for learners to grasp intricate systems and mechanics.

FAQs about Hrc216 Maintenance

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. This section addresses common inquiries related to the maintenance process, offering insights and guidance for effective care.

| Question | Answer |

|---|---|

| How often should I perform maintenance? | It is recommended to check your equipment every season or after a specific number of operating hours, depending on usage intensity. |

| What are the signs of wear? | Look for unusual noises, decreased performance, and visible damage to components, which may indicate the need for attention. |

| Can I perform maintenance myself? | Basic upkeep can often be done independently, but for complex issues, consulting a professional is advisable. |

| What tools are necessary for maintenance? | A standard toolkit, including wrenches and screwdrivers, along with specific tools for your model, is typically sufficient. |

| Is it necessary to use original components? | While original components are preferred for compatibility and performance, high-quality alternatives may also be suitable. |