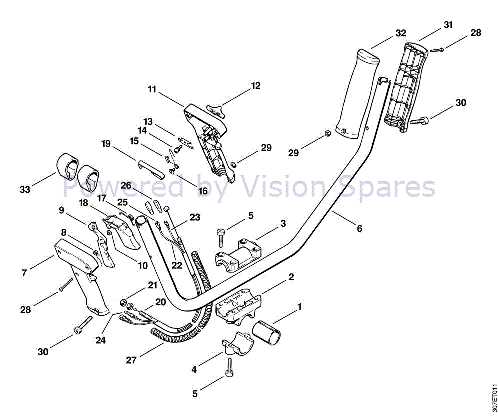

The effective functioning of any gardening tool relies on its individual components working in harmony. This section delves into the intricate arrangement of elements within a specific model of brushcutter, illustrating how each piece contributes to the overall performance. By examining this layout, users can gain insight into maintenance and repair, enhancing the longevity and efficiency of their equipment.

Detailed visual representations provide clarity on the interconnections between various components. Recognizing how these elements are organized allows for easier troubleshooting and informed decision-making when replacing or upgrading parts. Moreover, understanding the structure of this device empowers users to perform regular maintenance tasks, ensuring their tool operates at peak performance for years to come.

Whether you are a seasoned professional or a gardening enthusiast, familiarizing yourself with the arrangement of this specific brushcutter can significantly improve your experience. A comprehensive knowledge of its internal makeup not only aids in addressing issues as they arise but also fosters a deeper appreciation for the engineering behind such essential outdoor equipment.

This section aims to provide a comprehensive overview of the essential elements of the equipment, highlighting their roles and interconnections. Understanding these components is crucial for effective maintenance and optimal performance of the machinery.

Key Elements of the Equipment

- Engine Assembly

- Drive Shaft

- Fuel System

- Air Filter

- Cutting Head

- Handle Assembly

- Throttle Control

- Ignition System

- Starter Mechanism

- Protection Guard

- Fuel Tank

- Support Frame

Importance of Each Component

Each part plays a vital role in ensuring the functionality and efficiency of the equipment. The engine assembly provides the necessary power, while the drive shaft transmits this power to the cutting head. A well-maintained fuel system ensures optimal combustion, while a clean air filter protects the engine from debris.

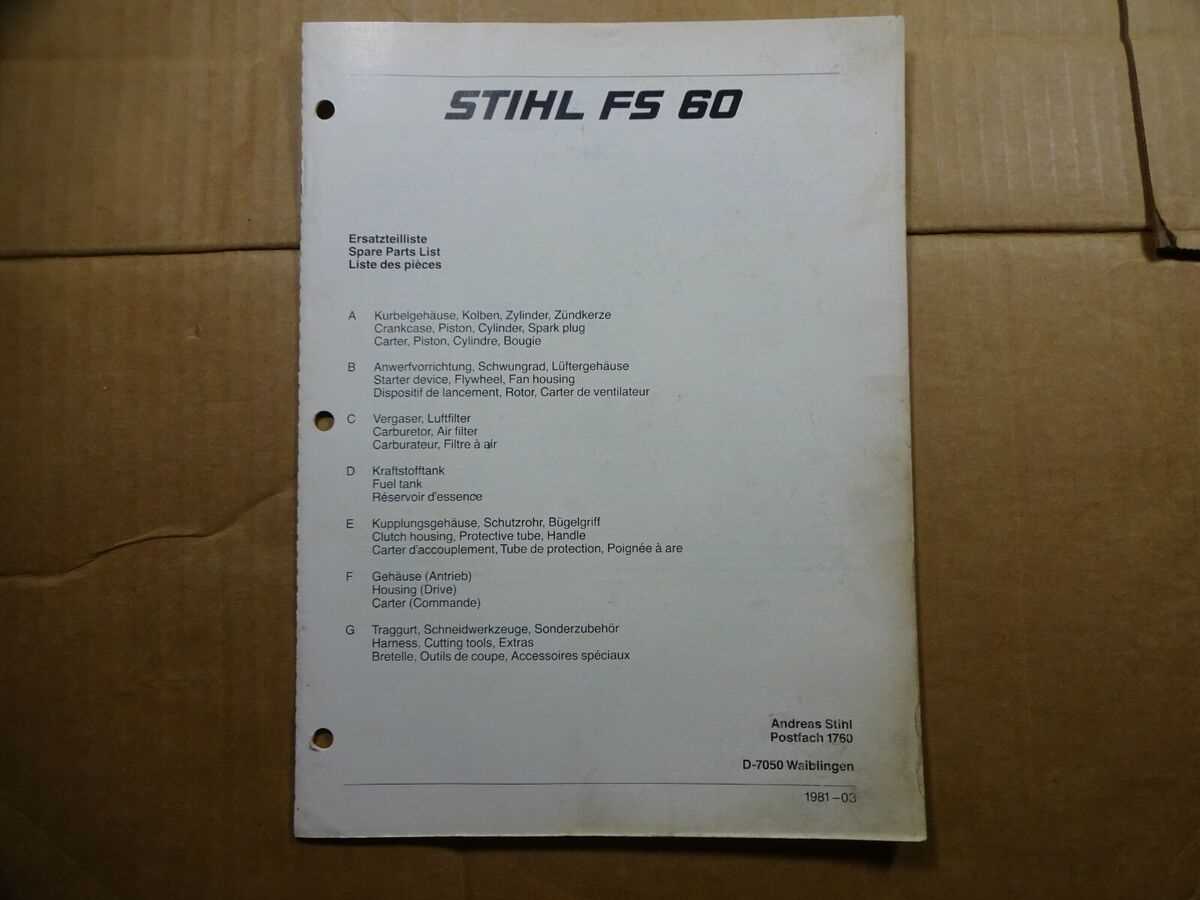

Identifying Key Parts of the FS81

Understanding the essential components of this particular outdoor power equipment is crucial for effective maintenance and operation. Recognizing each element and its function helps ensure optimal performance and longevity. Below, we outline the main components and their roles.

Main Components

- Engine: The powerhouse that drives the entire mechanism, providing the necessary energy for cutting tasks.

- Fuel Tank: Stores the mixture required for combustion, crucial for engine operation.

- Cutting Head: The section responsible for actual cutting, equipped with a line or blade, depending on the intended use.

- Handle: Offers control and maneuverability, allowing the user to operate the device comfortably.

- Throttle Trigger: Regulates the engine speed, enabling the user to adjust power according to the task.

Additional Parts

- Gearbox: Converts engine power into rotational force for the cutting head.

- Air Filter: Prevents dirt and debris from entering the engine, ensuring efficient operation.

- Spark Plug: Ignites the fuel-air mixture, initiating the combustion process within the engine.

- Vibration Dampening System: Reduces vibrations transmitted to the user, enhancing comfort during extended use.

- Safety Guard: Protects the user from debris and enhances safety during operation.

Understanding the Parts Diagram Layout

The layout of an assembly schematic is essential for anyone looking to grasp the structure and function of equipment components. By examining the arrangement, users can better comprehend how various elements interact within the system. A clear visualization allows for easier identification of each part’s role and its contribution to overall performance.

Components Overview

The schematic typically features a variety of components, each labeled for easy reference. These labels help users quickly locate specific elements and understand their respective functions. Familiarity with the symbols and numbering used in these layouts is crucial for effective navigation through the assembly.

Interconnections and Relationships

In addition to identifying individual components, the layout also illustrates how these elements connect and interact. Understanding these relationships is vital for diagnosing issues and performing maintenance. A well-organized schematic serves as a valuable tool for ensuring optimal operation and troubleshooting when necessary.

Commonly Replaced Components Explained

Understanding frequently swapped elements in outdoor power equipment can enhance maintenance efforts and prolong the lifespan of your tools. Regular replacements ensure optimal performance and reliability, addressing wear and tear from everyday usage. Below, we discuss key components that often require attention and replacement in such machinery.

| Component | Description | Symptoms of Failure |

|---|---|---|

| Fuel Filter | Filters impurities from the fuel, preventing damage to the engine. | Difficulty starting, reduced power, or stalling. |

| Air Filter | Prevents dust and debris from entering the engine, maintaining air quality. | Decreased power, rough idling, or increased fuel consumption. |

| Spark Plug | Ignites the air-fuel mixture in the engine for combustion. | Hard starting, misfires, or reduced engine performance. |

| Cutting Blade | The primary tool for cutting grass and vegetation. | Uneven cuts, excessive vibration, or visible damage. |

| Starter Rope | Used to manually start the engine by pulling. | Difficulty starting, frayed or broken rope. |

Maintenance Tips for Stihl FS81 Parts

Regular upkeep of your equipment is essential for optimal performance and longevity. By adhering to a few fundamental practices, you can ensure that all components function smoothly and efficiently, ultimately enhancing your overall experience.

-

Regular Cleaning: Keep all surfaces clean to prevent dirt and debris accumulation. This practice not only promotes better performance but also helps to identify wear and tear early.

-

Inspect Components: Routinely examine all elements for signs of damage or wear. Look for cracks, corrosion, or looseness that could affect operation.

-

Lubrication: Apply appropriate lubricants to moving parts as specified in the manufacturer’s guidelines. This minimizes friction and reduces wear.

-

Replace Worn Parts: Identify and replace any components that show significant wear. This includes filters, blades, and other consumables that impact performance.

-

Check Fuel and Oil Levels: Ensure that fuel and oil levels are adequate and that the fluids are clean. Contaminated fuel can lead to poor operation and damage.

-

Follow Maintenance Schedule: Adhere to the recommended maintenance schedule provided by the manufacturer. This will help prevent unexpected issues and prolong the life of your equipment.

By incorporating these essential practices into your routine, you can maintain the functionality and reliability of your machine, ensuring it operates at peak efficiency whenever you need it.

Tools Required for Disassembly

To successfully take apart your equipment for maintenance or repair, having the right tools is essential. The proper instruments will not only make the process smoother but also help avoid damage to components. Below is a list of the necessary tools to ensure an efficient disassembly.

Essential Tools

- Screwdrivers: A set of screwdrivers, including flathead and Phillips, will be required to remove screws from various parts.

- Wrenches: A combination of metric and standard wrenches will assist in loosening nuts and bolts.

- Plier Set: Needle-nose and standard pliers will be useful for gripping and pulling components.

- Socket Set: A socket set can speed up the process of removing bolts, especially in tight spaces.

Additional Tools

- Torque Wrench: Ensures that components are tightened to the correct specifications when reassembling.

- Cleaning Brush: A brush helps to remove dirt and debris from parts, ensuring optimal performance.

- Container for Small Parts: Keeping screws and small components organized will prevent loss during disassembly.

How to Order Replacement Parts

When it comes to maintaining your equipment, getting the right components is essential for ensuring proper function. Knowing how to efficiently order the necessary replacements can save time and effort in keeping your tool in top condition. Understanding where to find the correct items and how to ensure compatibility is crucial.

Step 1: Begin by identifying the exact model of your tool. Each product may require specific components that vary depending on its design and year of production.

Step 2: Search for trusted suppliers or authorized dealers. Purchasing from reputable sources guarantees that you receive quality items, ensuring

Installing New Components Safely

When replacing or adding components, it’s essential to follow the correct procedures to ensure both efficiency and safety. Proper installation minimizes the risk of malfunction and helps extend the equipment’s lifespan. By taking a few key precautions, you can avoid damage and ensure the optimal performance of your tools.

Preparation Before Installation

Before starting the process, ensure you have the necessary tools and that the equipment is properly powered down. Double-check that the new component matches the specifications of the device you’re working with. This step prevents potential mismatches that could lead to performance issues or damage.

Handling and Fitting the Components

Troubleshooting Common Issues

When maintaining outdoor equipment, it’s essential to know how to identify and resolve typical challenges that may arise during usage. Understanding the signs of malfunction and knowing where to begin troubleshooting can prevent further complications and help restore functionality efficiently.

Engine Performance Problems

If the engine shows signs of decreased power or irregular operation, it could indicate several underlying factors. Start by checking for blockages in air filters or fuel lines, as debris can reduce airflow and fuel supply. Additionally, worn-out components may require replacement to restore proper performance.

Handling Starting Failures

One of the most frequent

Exploring Upgrades for Enhanced Performance

Maximizing the efficiency of your equipment often involves considering various improvements that can significantly boost functionality. By upgrading key components, you can achieve smoother operation and extend the lifespan of your device, ensuring it remains reliable during demanding tasks.

Optimizing Engine Efficiency

One effective way to improve performance is by focusing on the engine. Adjustments or replacements aimed at increasing power output can lead to faster and more consistent operation. Additionally, upgrading certain internal parts may contribute to better fuel consumption, which is crucial for long-term efficiency.

Enhancing Durability and Longevity

For those looking to reduce wear and tear

Comparative Analysis with Other Models

When examining similar equipment, it is essential to highlight the key distinctions between various models. These differences often determine the performance, durability, and usability of each tool, offering insights into which may be more suitable for specific tasks.

Performance and Power

One of the primary factors to consider when comparing different models is the level of power output and overall performance. Some variants provide higher efficiency, making them ideal for demanding environments, while others are more suited for lighter tasks due to their compact design and ease of use.

Durability and Maintenance

Durability is another crucial aspect, especially for those looking for long-term reliability. Some models are constructed with

Customer Reviews on Parts Quality

Feedback from users often highlights the importance of reliable components in ensuring the long-term performance of equipment. Many individuals share their experiences with different replacements and how these elements have impacted their overall satisfaction.

- Durability: A common theme in reviews is the longevity of the materials, with many customers praising the resilience of the components used in their devices.

- Fitment: Proper alignment and seamless integration are frequently noted as key factors contributing to smooth operation, with buyers appreciating precise compatibility.

- Performance: Customers often describe how replacements have restored or even improved the efficiency of their machines, emphasizing the importance of high-quality materials.

- Value for

Resources for Further Information

For those seeking additional guidance and detailed insights, there are numerous avenues to explore. Whether you’re aiming to expand your understanding or require technical advice, various sources can provide valuable information to help with maintenance, repair, and upgrades.

- Official product manuals – These guides often contain in-depth explanations and step-by-step instructions for different tasks.

- Online forums – Community-driven platforms where users share personal experiences and tips for resolving common issues.

- Video tutorials – Visual aids that can walk you