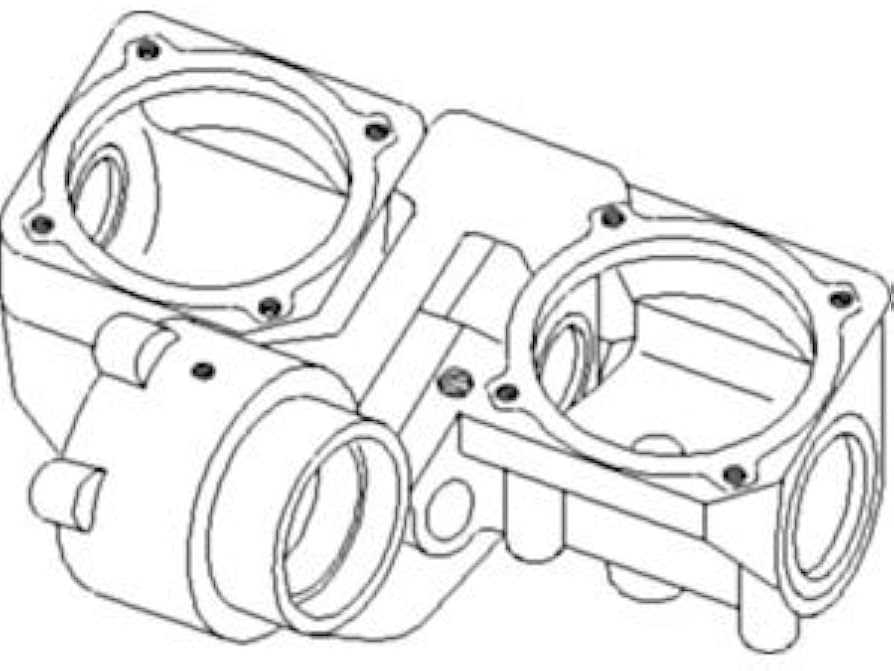

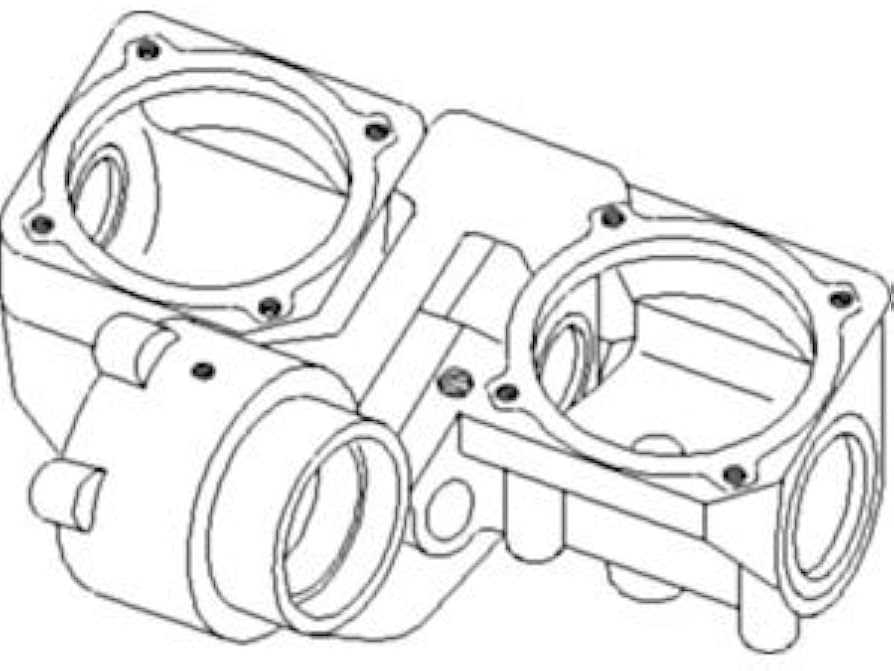

In this section, we delve into the intricate anatomy of machinery components, shedding light on their internal configuration and functional aspects.

Understanding the inner workings of these elements provides valuable insights into their operational efficiency and maintenance requirements.

Examining the detailed breakdown of these parts facilitates a comprehensive grasp of their roles within the broader machinery framework.

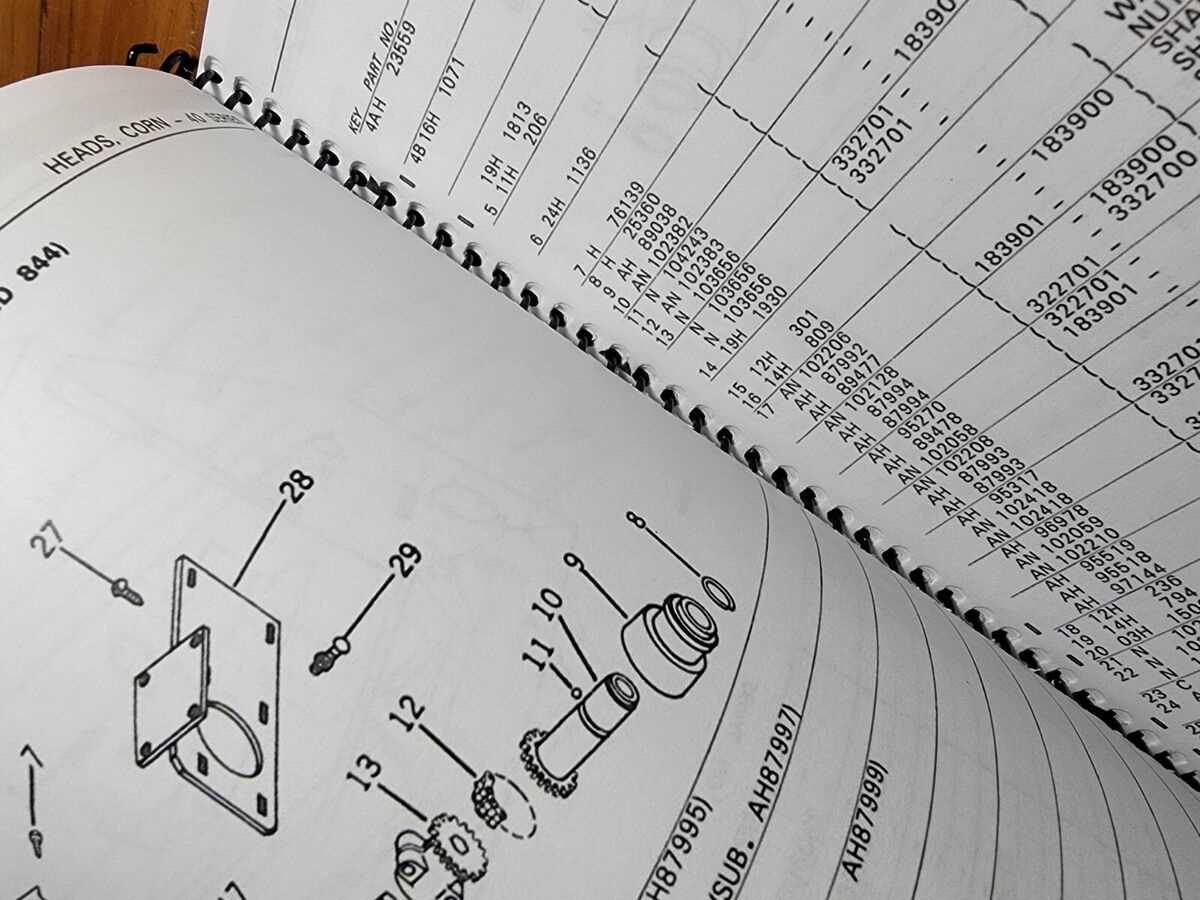

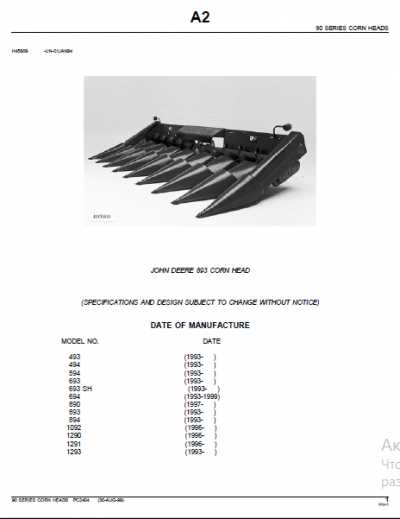

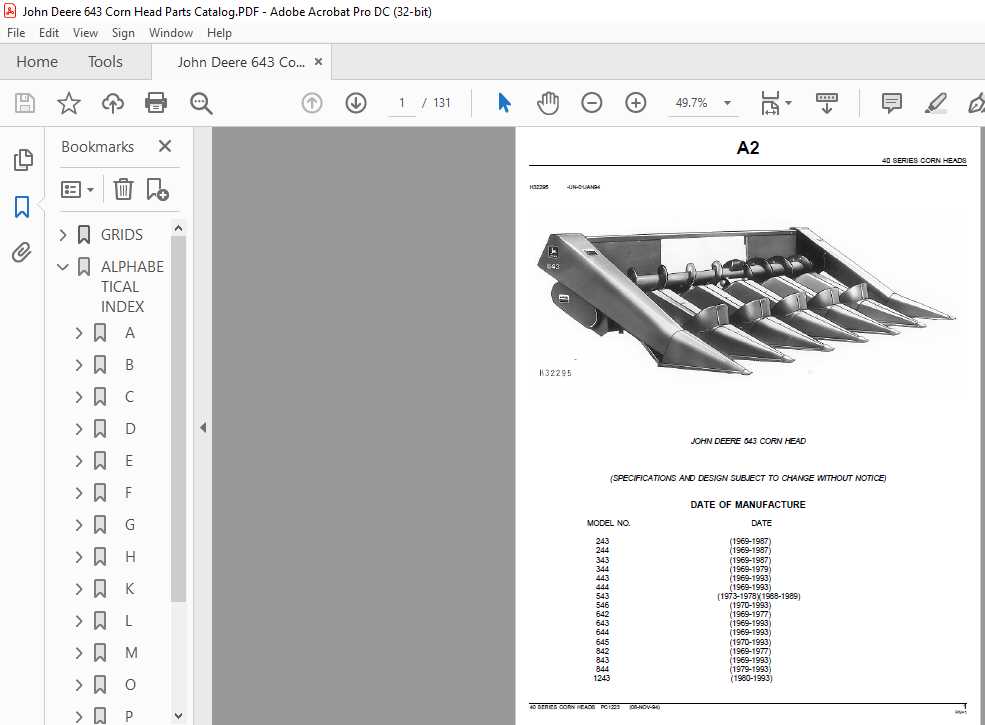

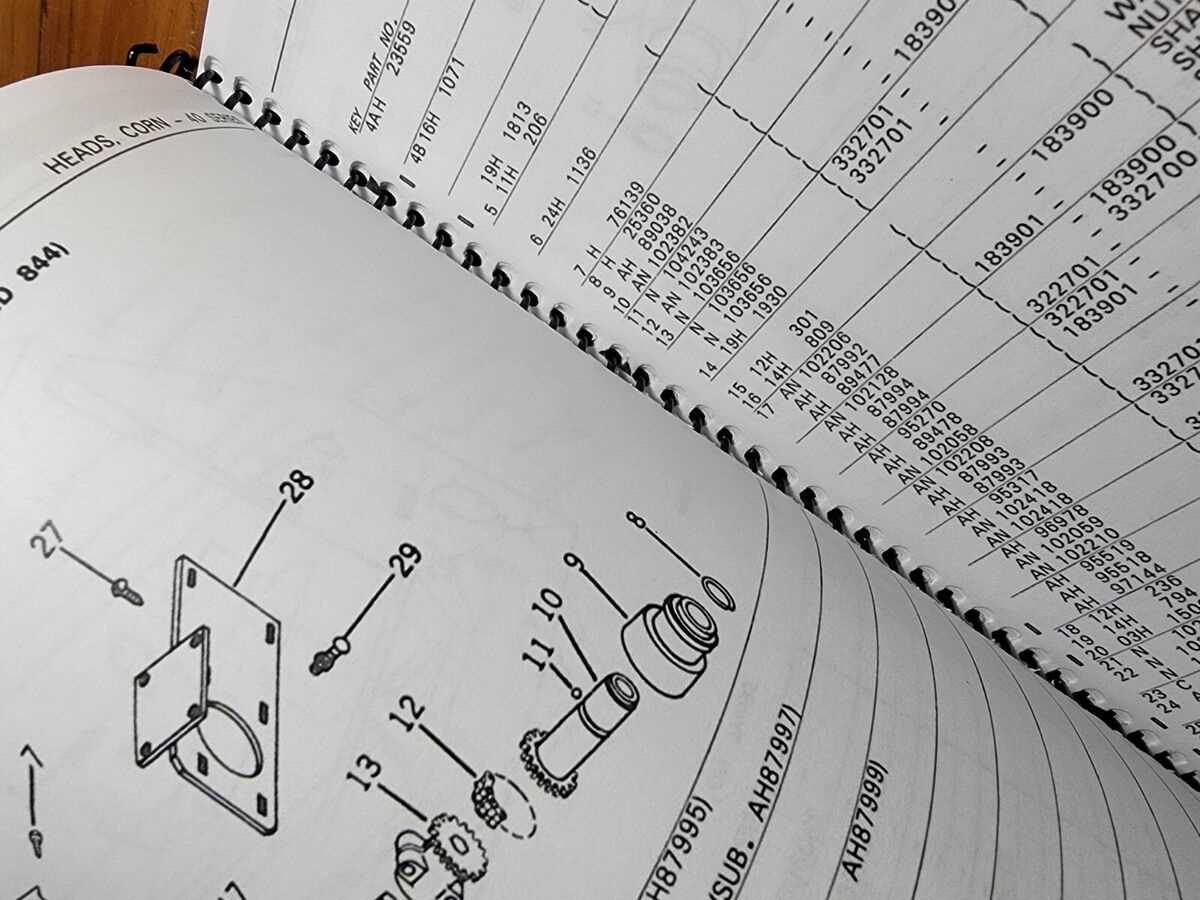

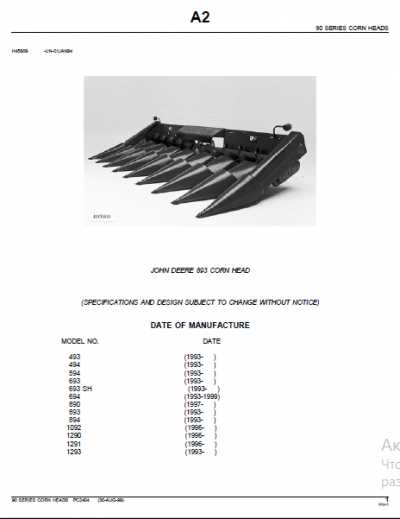

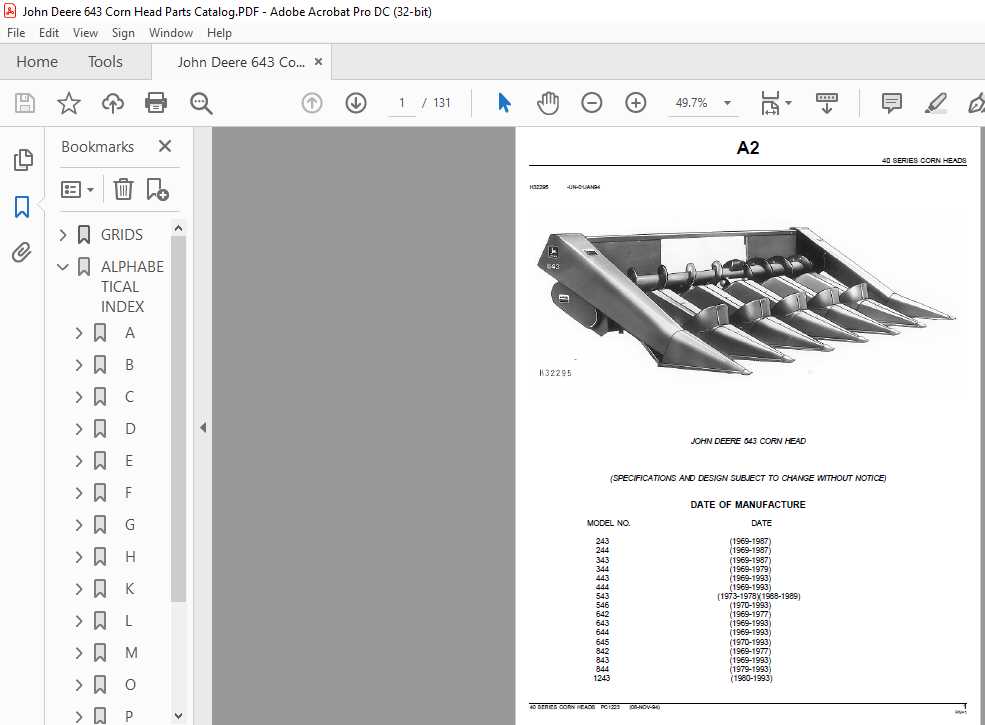

Components Overview of a Corn Head

In this section, we will explore the fundamental elements that make up a corn head, highlighting its essential components and their roles in the harvesting process. Understanding these parts is crucial for efficient operation and maintenance.

Cutting Mechanism

The cutting mechanism of a corn head includes the blades or knives that are responsible for cleanly severing the corn stalks during harvesting. It ensures a precise cut to facilitate smooth feeding into the harvesting equipment.

Gathering System

The gathering system comprises various components such as gathering chains, augers, or belts that work together to gather the corn stalks from the field and guide them towards the cutting mechanism. This system plays a vital role in ensuring continuous and uniform feeding of corn into the harvester.

Main Structural Elements of the Harvester

The key structural components of a harvester are designed to ensure effective field operations, providing optimal crop gathering and processing. These elements work in tandem to deliver reliable performance during harvesting, regardless of the terrain or crop type.

Frame and Body

The frame forms the backbone of the harvester, supporting all other components. It is constructed to endure the rigors of fieldwork, maintaining durability and stability. The body encases the internal mechanisms, offering protection and streamlined operation.

Cutting and Feeding Mechanisms

The cutting system plays a crucial role in separating crops from the field. This mechanism is designed for precision, minimizing waste while ensuring a smooth cut. The feeding mechanism then efficiently

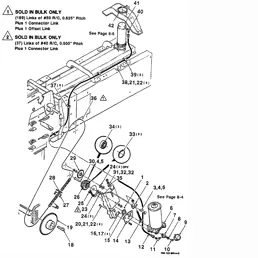

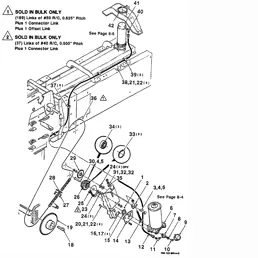

Functionality of Gathering Chains

Gathering chains play a crucial role in the operation of harvesting equipment, facilitating the smooth and efficient transport of material through the system. These chains are specifically designed to capture and move the plant stalks towards the processing mechanism, ensuring continuous flow and preventing jams. The correct alignment and synchronization of the chains directly affect the productivity of the machinery, reducing material loss and improving the overall yield.

Key components of gathering chains include durable links, precision-engineered sprockets, and tension mechanisms. Together, these elements ensure reliable performance, even under challenging working conditions. Regular maintenance, including adjustments and lubrication, is necessary to prevent wear and tear, ensuring the chains operate at peak efficiency throughout the harvesting season.

| Component |

Function |

Maintenance Tips |

| Links |

Capture and transport stalks |

Inspect for damage, lubricate regularly |

Role of Deck Plates in Harvesting

Deck plates play a crucial role in the efficient separation and collection of crops during harvesting. Their primary function is to guide plants through the machinery while ensuring that only the desired parts are processed, reducing loss and maximizing yield. Proper alignment and adjustment of these components are essential to maintain optimal performance and minimize damage to the plants.

How Deck Plates Work

The deck plates create a controlled gap through which the stalks are fed, allowing for selective removal of the valuable portions. The width of this gap must be carefully set according to the size of the plants being harvested, ensuring smooth passage while preventing excess material from being pulled through.

- Selective harvesting:

Auger Mechanism and Its Importance

The auger mechanism plays a crucial role in modern agricultural equipment, contributing to the efficient processing and transport of materials. This system ensures a continuous and uniform flow of material, which is essential for maintaining productivity and reducing potential bottlenecks during operations. Understanding its structure and function is key to maximizing the efficiency of the entire machinery.

How the Auger Works

The auger consists of a rotating helical screw blade, which moves material along its shaft. This spiral motion is designed to gather and transport material efficiently, whether it is being directed towards a processing unit or collected for further handling. The continuous rotation ensures a steady flow, preventing blockages or interruptions.

- Helical design for smooth material transport

- Efficient in moving both small and large quantities

- Reduces manual intervention by automating material movement

Benefits of a Well-Maintained Auger

Inspection Tips for Stalk Rollers

Regular maintenance and inspection of key mechanical components is essential for ensuring optimal performance during harvest. Stalk rollers play a crucial role in processing plant materials efficiently, and their condition directly impacts the overall effectiveness of the machine.

First, visually inspect the rollers for signs of wear or damage. Look for cracks, uneven surfaces, or signs of excessive friction that could indicate issues with alignment or lubrication. Any significant wear could reduce the rollers’ ability to handle materials smoothly, leading to reduced productivity.

Next, check the spacing and rotation of the rollers. Misalignment or irregular movement may indicate the need for adjustment or replacement of certain parts. Ensure that all fasteners are secure and that no debris is obstructing the system, as this could hinder performance.

Lastly, evaluate the condition of the bearings and other moving elements. Proper lubrication is key to reducing wear and tear, so inspect for any signs of insufficient lubrication, such as

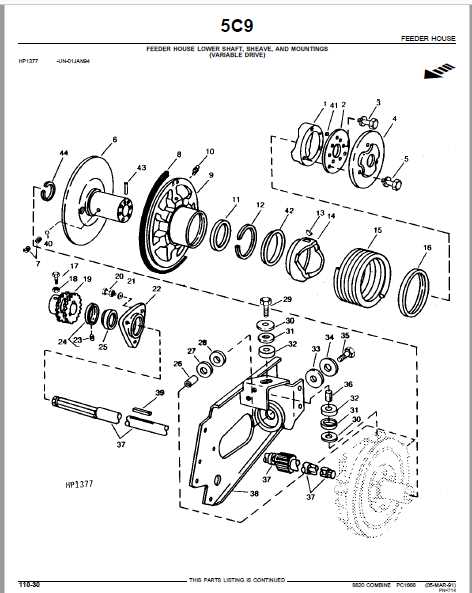

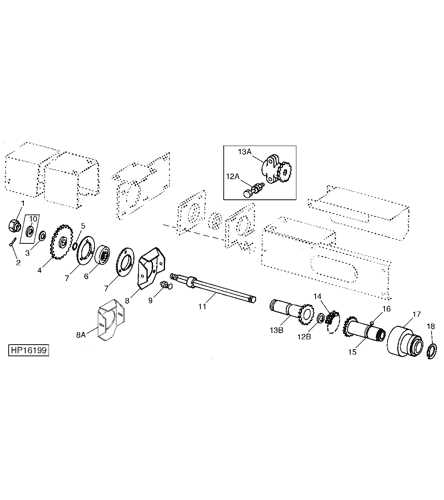

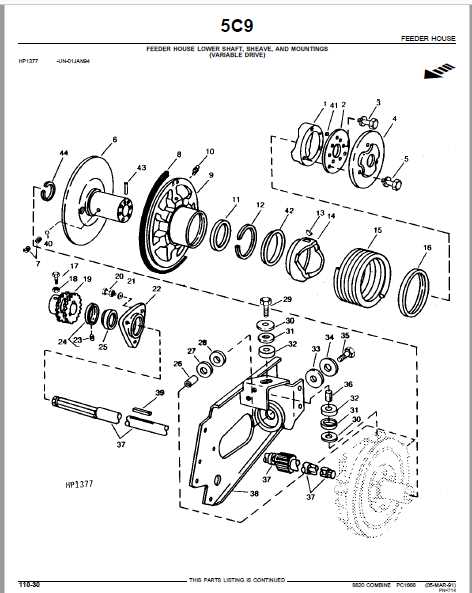

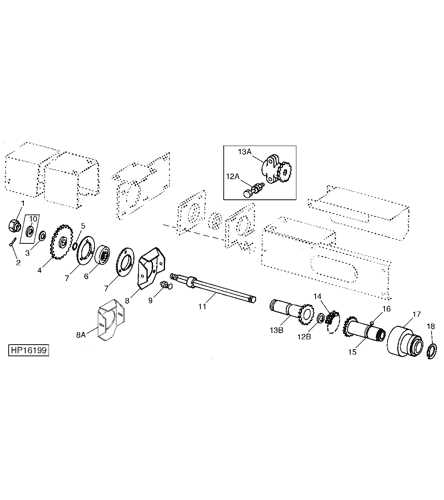

Drive System and Its Key Parts

The drive system plays a crucial role in ensuring the efficiency and smooth operation of agricultural machinery. It is responsible for transferring power from the engine to various functional components, allowing for effective performance during fieldwork. Understanding the structure and key elements of the drive system is essential for maintaining optimal functionality and preventing potential breakdowns.

Power Transmission Mechanism: The core of the drive system is the power transmission mechanism, which channels energy to the working units. This includes belts, chains, and gear assemblies that ensure synchronized movement of the components.

Gearbox: The gearbox is a critical component that regulates speed and torque. By adjusting the power distribution, it helps adapt the machinery’s output to different field conditions and tasks, optimizing performance.

Drive Shafts: Drive shafts connect the engine with other mechanical parts, transmitting rotational energy

Maintaining the Corn Harvester’s Gearbox

Proper upkeep of the gearbox is crucial to ensure smooth operation and longevity of your harvesting equipment. Regular maintenance not only prevents breakdowns but also maximizes efficiency during the harvesting season. The gearbox, as a key component, requires attention to detail when inspecting for wear or potential issues.

Here are essential steps to maintain the gearbox effectively:

- Inspect for Leaks: Regularly check the gearbox for any signs of oil leaks, as these can indicate worn seals or damaged components.

- Monitor Fluid Levels: Ensure that the oil level in the gearbox is within the recommended range. Low fluid levels can lead to overheating and wear.

- Check for Unusual Noises

Blade Adjustments for Optimal Performance

Maintaining the sharpness and alignment of cutting elements is crucial for ensuring efficient and smooth operation. Properly adjusted blades reduce wear, increase productivity, and minimize the risk of damage to the equipment. By following a few key guidelines, you can keep the cutting system in peak condition, extending its lifespan and maximizing efficiency.

Steps for Proper Blade Alignment

- Ensure the cutting edges are sharp. Dull blades can cause uneven cutting and put additional strain on the machinery.

- Check the distance between blades and the ground. This should be consistent across the entire unit to avoid uneven cutting results.

- Use a leveling tool to confirm that all blades are aligned correctly. Misalignment can lead to damage or inefficient cutting.

- Adjust the tension to the manufacturer’s re

Hydraulic System Components Breakdown

The hydraulic system is essential for powering various mechanical functions, ensuring smooth and efficient operation. Understanding the individual components of this system is crucial for maintaining its performance and troubleshooting potential issues. Below is a detailed breakdown of the main elements involved in the hydraulic setup.

- Pump: The heart of the hydraulic system, responsible for generating the flow of fluid that powers other components.

- Valves: These control the direction and pressure of the fluid, allowing precise control over the machinery’s movements.

- Cylinders: Convert hydraulic energy into mechanical force, creating linear motion crucial for lifting or adjusting various parts.

- Hoses and Lines: These transport the hydraulic fluid throughout the system, connecting the pump, valves, and cylinders.

- Reservoir: Stores the hydraulic fluid and helps

Common Issues and Replacement Parts

In agricultural machinery, regular maintenance and addressing common problems are essential for ensuring peak performance during harvesting. Over time, various components may wear out or malfunction, affecting the overall efficiency of the equipment. This section outlines frequent issues that users encounter and provides guidance on suitable replacement solutions.

Frequent Mechanical Problems

One of the typical challenges is the wear and tear of moving parts, which can lead to reduced performance. Bearings, gears, and chains are particularly susceptible to damage from prolonged use. Additionally, issues with alignment can cause inefficiencies in the operation, often requiring adjustments or part replacements.

Recommended Replacement Solutions

When it comes to finding replacement components, ensuring compatibility is crucial. Always select parts that match the original specifications for the best results. Below is a list of commonly replaced components and their respective alternatives: