The arrangement and configuration of components in a mechanical system play a crucial role in its overall functionality and efficiency. Grasping the layout of these elements enables users to maintain and optimize performance effectively. By examining the structure, one can identify critical relationships and interdependencies that contribute to seamless operation.

In this section, we will explore a specific assembly’s configuration, focusing on the intricacies that define its design. Detailed analysis will provide insights into how various segments interact, ensuring optimal functionality. Understanding these connections is essential for anyone looking to enhance their knowledge and skills in managing such systems.

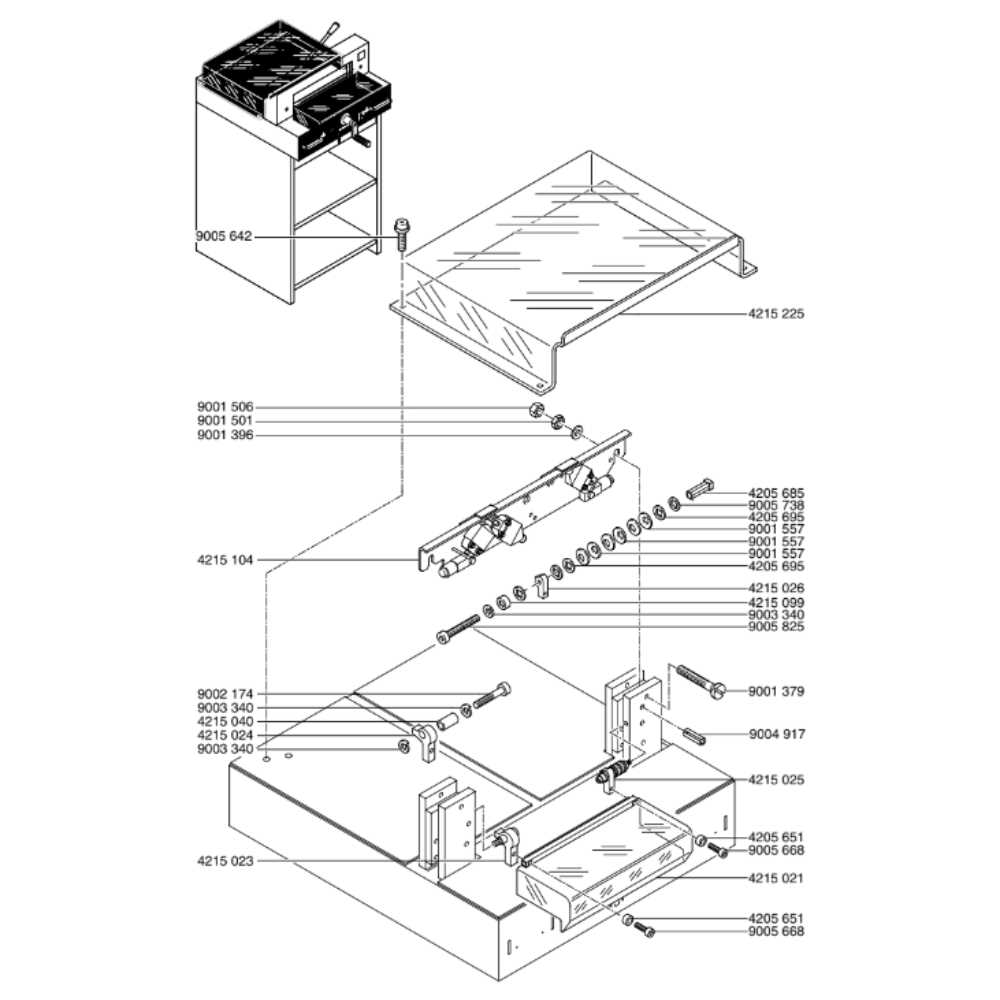

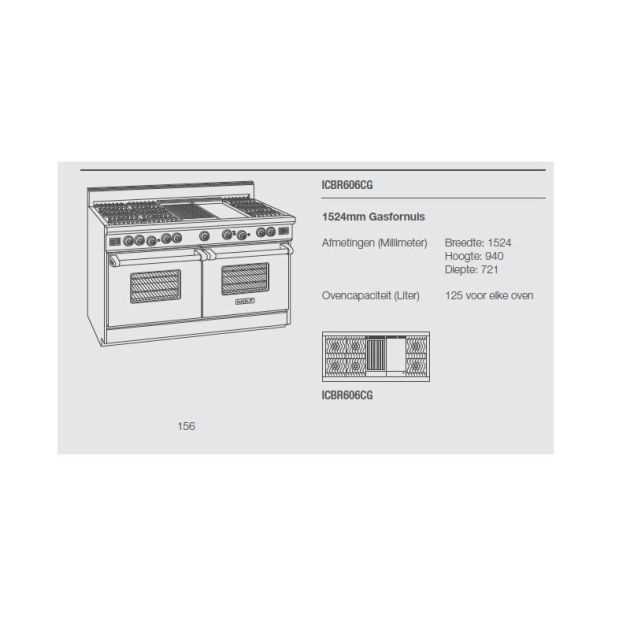

Understanding Wolf R366 Components

In any complex system, comprehending the individual elements is crucial for effective operation and maintenance. This section delves into the various components that make up the machinery, highlighting their roles and interconnections. By grasping how each piece functions, users can optimize performance and troubleshoot issues more effectively.

Key Elements of the System

The system consists of several essential units, each contributing to the overall functionality. Understanding the purpose of these units allows for better decision-making when it comes to repairs or upgrades. Familiarity with these elements can also lead to improved efficiency in usage.

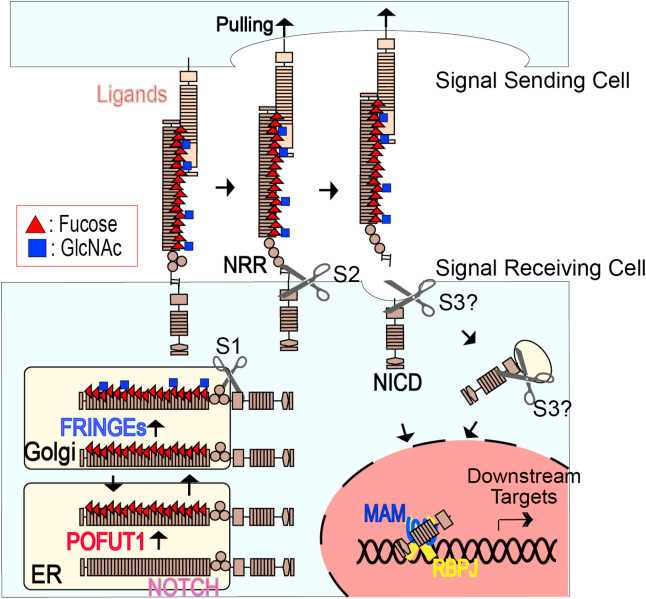

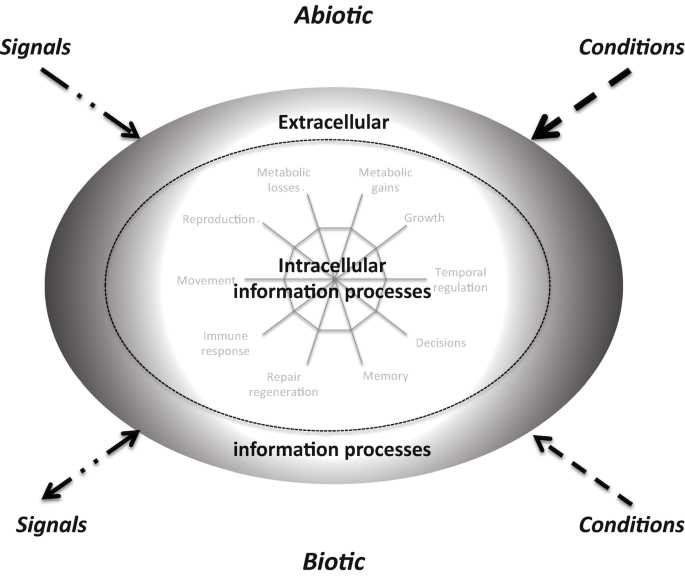

Integration and Interaction

The way components interact is equally important. Each unit relies on others for seamless operation, making knowledge of their integration vital. By examining these interactions, users can gain insights into potential bottlenecks and areas for improvement.

Essential Parts and Their Functions

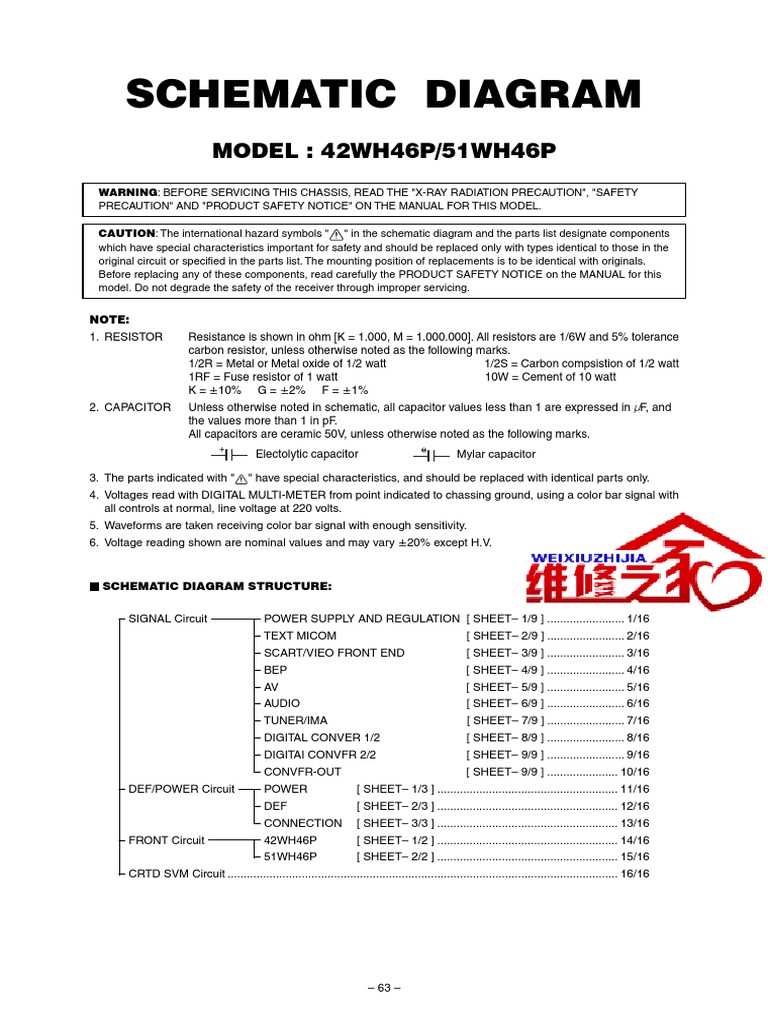

Understanding the crucial components of a system is vital for ensuring its optimal performance and longevity. Each element plays a specific role, contributing to the overall functionality and efficiency of the mechanism. In this section, we will explore the key elements that are integral to the operation of this particular model.

Heating Element: This component is responsible for generating the necessary heat to facilitate the cooking process. Its efficiency directly affects the speed and consistency of temperature control.

Control Panel: Serving as the interface for users, this part allows for the adjustment of settings and monitoring of operations. Its design and functionality can greatly enhance user experience.

Fuel System: This system supplies the energy needed for operation, whether through gas or other means. The reliability of this component is critical for safe and effective performance.

Ventilation System: Proper airflow is essential to prevent overheating and ensure safety. This system helps maintain optimal operating conditions by regulating temperature and expelling excess heat.

Insulation: This feature minimizes heat loss, enhancing energy efficiency. Effective insulation not only improves performance but also contributes to safety by preventing overheating of external surfaces.

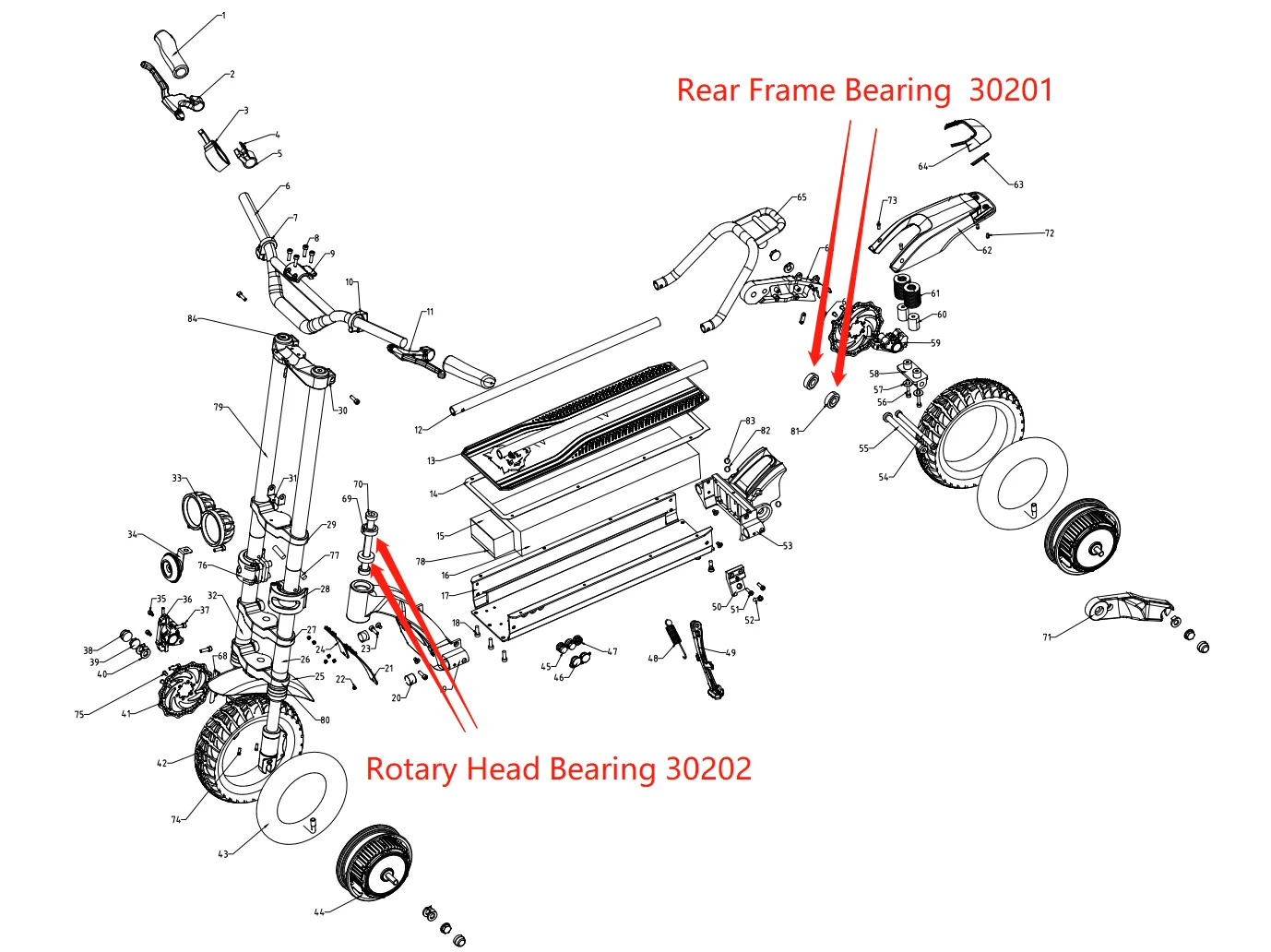

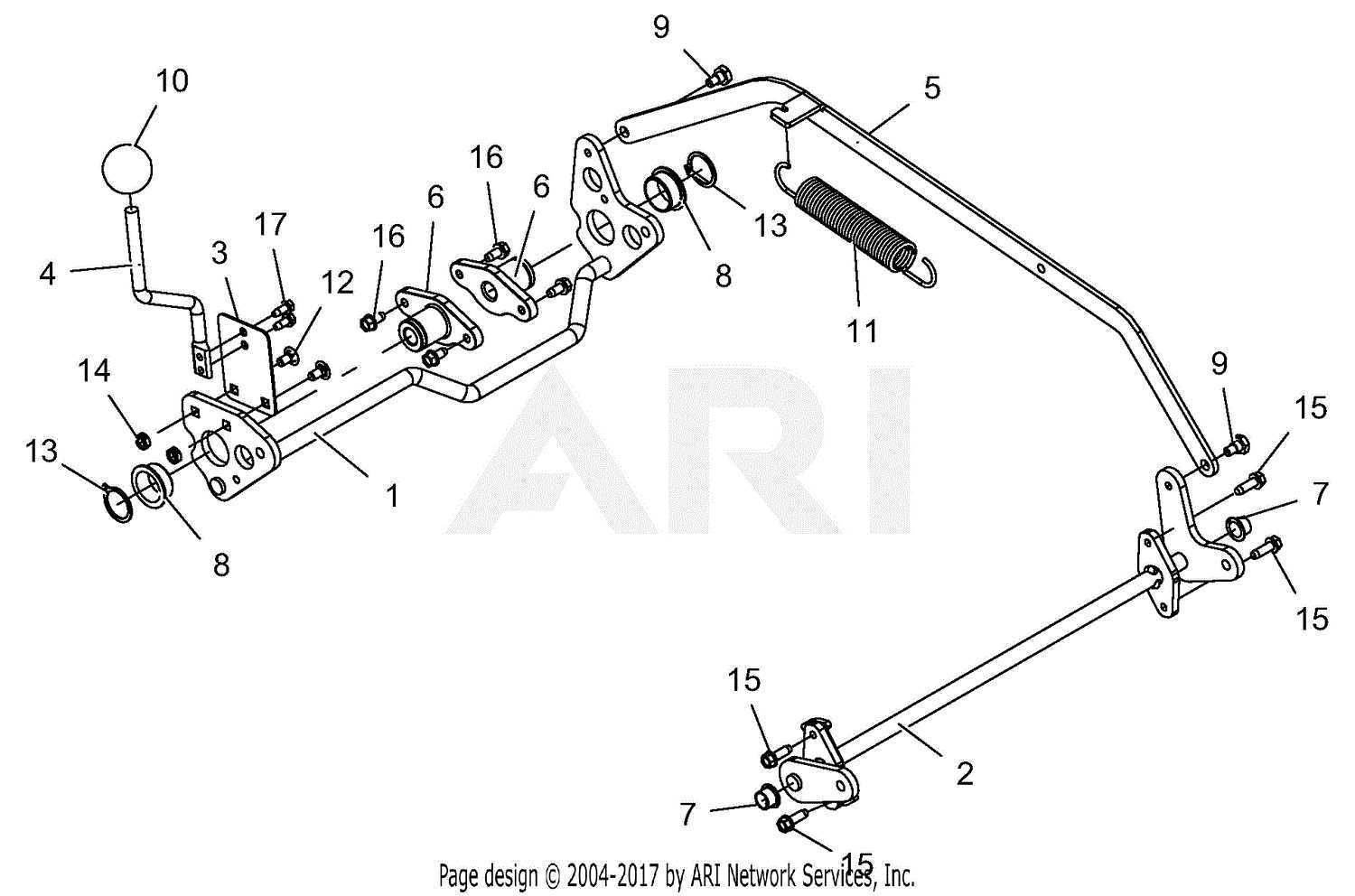

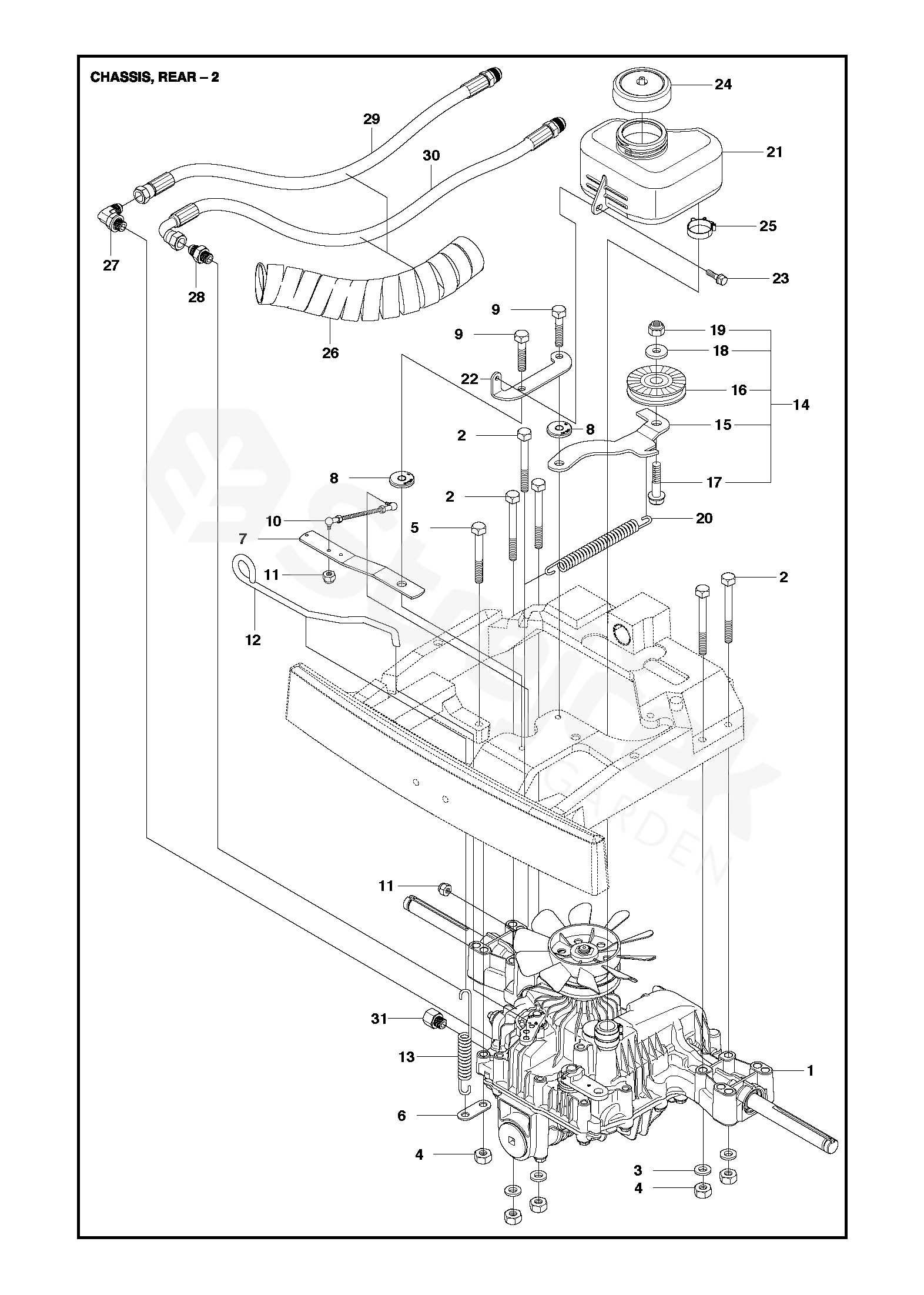

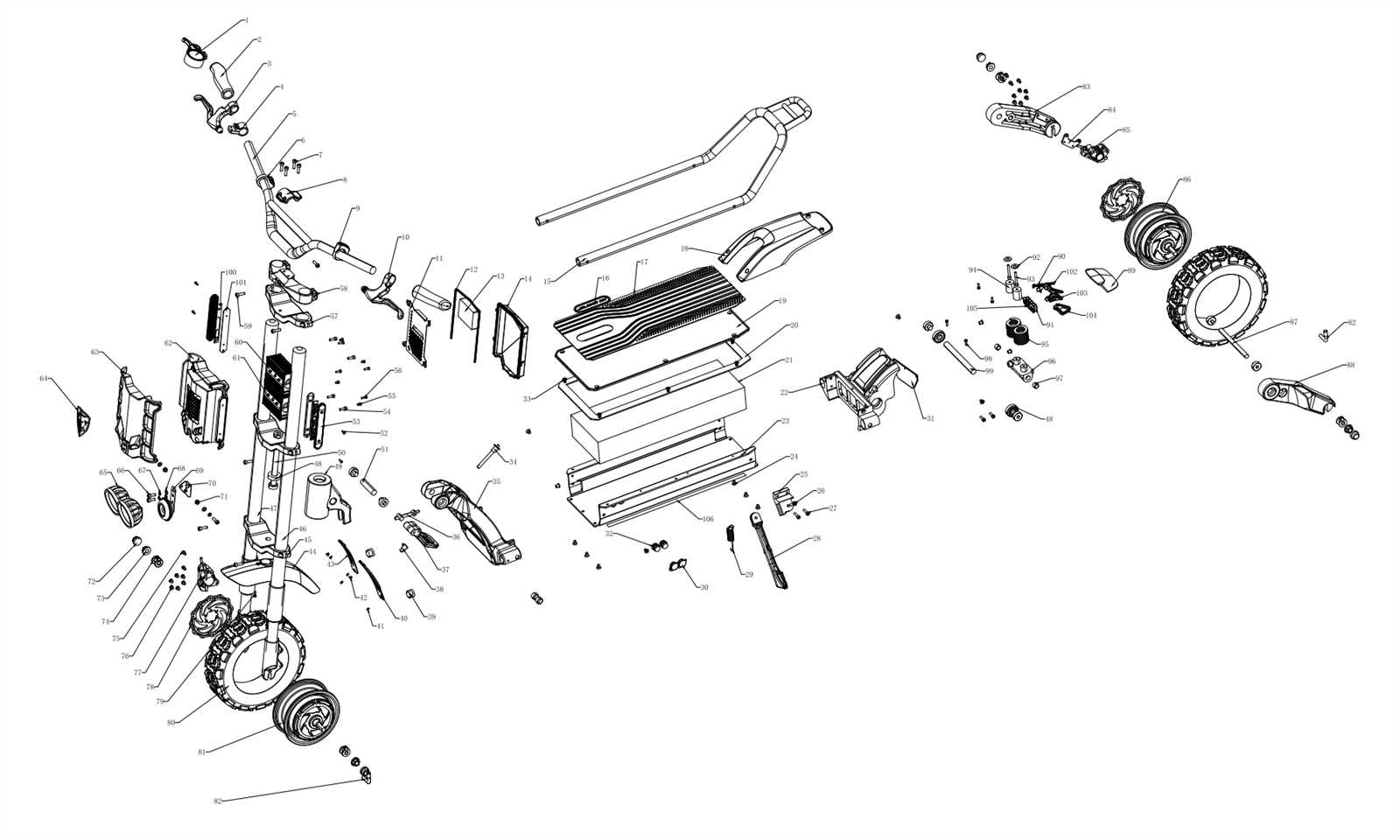

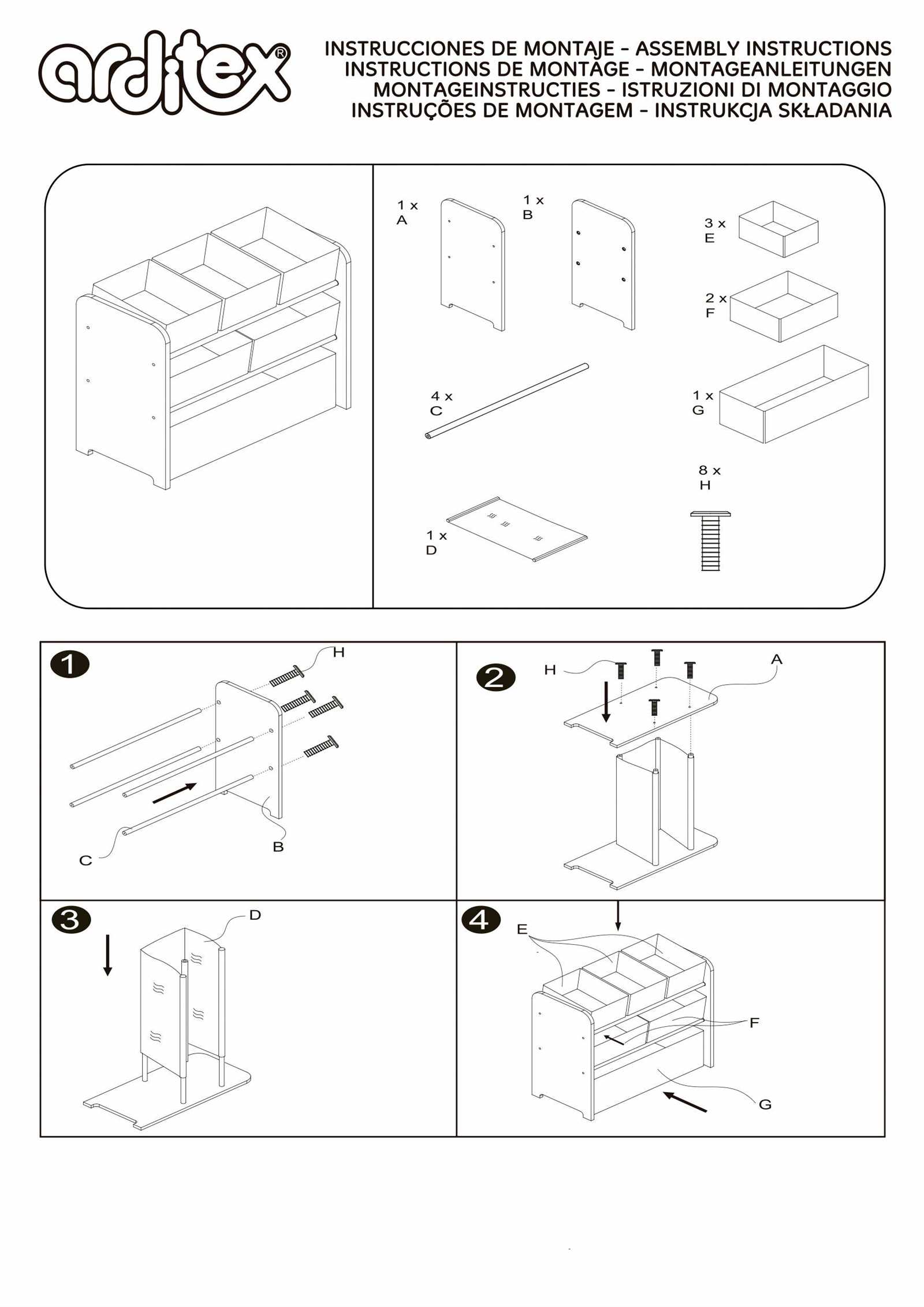

Visual Representation of Component Layout

This section aims to provide a clear and detailed illustration of the arrangement of various elements within a specific system. Understanding the spatial distribution of components is essential for effective maintenance and troubleshooting.

Importance of Component Layout

A well-organized layout aids in identifying connections and functionalities. Here are key benefits:

- Facilitates easier access to parts during servicing.

- Enhances understanding of the overall system architecture.

- Reduces the likelihood of errors during assembly or repairs.

Typical Layout Features

The arrangement usually includes several critical aspects:

- Positioning: Each element is strategically placed for optimal functionality.

- Labeling: Clear markings help in recognizing components quickly.

- Connections: Lines or pathways indicate how parts interact and communicate.

Importance of Each Component Explained

Understanding the significance of each element in a mechanical system is crucial for optimal performance and longevity. Each component plays a specific role that contributes to the overall functionality, making it essential to appreciate their individual contributions.

| Component | Function | Impact on System |

|---|---|---|

| Element A | Provides structural support | Ensures stability and durability |

| Element B | Facilitates energy transfer | Enhances efficiency and performance |

| Element C | Regulates temperature | Prevents overheating and damage |

| Element D | Controls fluid movement | Maintains proper operation |

Maintenance Tips for Key Parts

Ensuring the longevity and performance of critical components requires regular attention and care. Adopting a systematic approach to maintenance can prevent unexpected failures and enhance efficiency.

Regular Inspections

Conduct frequent assessments of essential elements to identify signs of wear or damage. Early detection can mitigate larger issues down the line.

Proper Lubrication

Applying the correct lubricants at designated intervals helps reduce friction and wear, promoting smoother operation.

| Component | Inspection Frequency | Lubrication Type |

|---|---|---|

| Motor | Monthly | Grease |

| Belts | Weekly | Dry lubricant |

| Filters | Quarterly | N/A |

Common Issues with Components

When dealing with mechanical assemblies, several common challenges can arise, impacting functionality and performance. Understanding these issues is essential for effective troubleshooting and maintenance.

- Wear and Tear: Over time, components can degrade, leading to decreased efficiency. Regular inspections can help identify signs of wear.

- Misalignment: Improper alignment can cause excessive strain, resulting in premature failure. Ensuring accurate installation is crucial.

- Corrosion: Exposure to moisture and contaminants can lead to rust and deterioration. Protective coatings can mitigate this risk.

- Loose Connections: Fasteners may loosen due to vibration, impacting stability. Periodic checks and re-tightening can prevent issues.

- Overheating: Insufficient cooling can cause components to overheat, risking failure. Monitoring temperature levels is vital for longevity.

Addressing these common issues proactively can enhance reliability and extend the lifespan of mechanical systems.

Replacing Parts: A Step-by-Step Guide

Maintaining equipment requires careful attention to detail, especially when it comes to substituting components. This section outlines a straightforward approach to ensure the process is efficient and effective, minimizing downtime and maximizing performance.

Step 1: Begin by identifying the specific element that needs replacement. Refer to your reference materials to understand its function and placement within the overall system.

Step 2: Gather the necessary tools and new components. Ensure you have everything at hand to avoid interruptions during the replacement.

Step 3: Carefully disassemble the unit, taking note of how components are arranged. This can be crucial for reassembly.

Step 4: Install the new element, ensuring it fits securely and aligns with the surrounding parts. Double-check connections to guarantee functionality.

Step 5: Reassemble the unit, following the notes taken during disassembly. Make sure all screws and fixtures are tightened appropriately.

Step 6: Finally, test the system to confirm that the replacement was successful. Monitor for any irregularities that may arise during operation.

By following these steps, you can effectively manage replacements, ensuring that your equipment remains in optimal working condition.

Where to Find Replacement Parts

Locating suitable components for your appliance can be crucial for maintaining its efficiency and performance. There are several reliable sources where one can find the necessary items to ensure proper functionality.

One of the most effective methods is to explore authorized distributors that specialize in equipment maintenance. These suppliers often carry a comprehensive inventory of essential items tailored to specific models. Additionally, online marketplaces can provide a wide selection of components, allowing you to compare prices and availability easily.

Another option is to check local repair shops, as they may have spare items in stock or can order them for you. Engaging with online forums and community groups dedicated to similar equipment can also yield valuable recommendations for sourcing specific components.

Upgrading Components for Better Performance

Enhancing the elements of a system can significantly boost its efficiency and functionality. By selecting superior components, users can achieve smoother operation and improved outcomes. This process often involves evaluating existing elements and identifying opportunities for enhancement.

First, consider the core functionalities that are crucial for optimal performance. Upgrading to higher-quality parts can lead to faster processing times and increased reliability. Second, it’s essential to ensure compatibility among the new elements and the overall architecture to prevent potential issues during integration.

Lastly, investing in advanced technologies can yield long-term benefits, providing a robust foundation for future upgrades and adaptations. By prioritizing quality and compatibility, users can enjoy a more responsive and capable system.

Safety Precautions When Handling Parts

When dealing with components, it is essential to follow specific guidelines to ensure both personal safety and the integrity of the items involved. Adhering to these practices minimizes risks and promotes a secure working environment.

Essential Safety Guidelines

- Always wear protective gear, including gloves and goggles.

- Ensure that the workspace is clean and well-lit.

- Be cautious of sharp edges and fragile materials.

Proper Handling Techniques

- Lift items using both hands to distribute weight evenly.

- Avoid placing components near heat sources or moisture.

- Store all items in a designated area to prevent damage.

FAQs About Wolf R366 Components

This section addresses common inquiries regarding various elements related to a specific model of cooking equipment. Understanding these components can enhance functionality and maintenance.

Below are some frequently asked questions:

| Question | Answer |

|---|---|

| What are the key features of these components? | The essential features include durability, compatibility, and efficiency in performance. |

| How can I identify the correct parts? | Refer to the manufacturer’s specifications and model identifiers for accurate identification. |

| What maintenance is required? | Regular cleaning and inspections are necessary to ensure optimal operation. |

| Where can I purchase replacements? | Authorized retailers and online marketplaces offer a variety of replacement options. |