In the realm of heavy machinery, having a clear grasp of the various elements that contribute to optimal performance is essential. Each component plays a critical role in ensuring the reliability and efficiency of the equipment, enabling operators to achieve their goals with ease. Knowledge of these integral parts not only aids in maintenance but also enhances overall operational safety.

For enthusiasts and professionals alike, exploring the intricate relationships between different sections of the machinery can lead to improved functionality. By familiarizing yourself with these crucial elements, you can make informed decisions regarding repairs and upgrades. This understanding serves as the foundation for any successful machinery operation.

As we delve into the specifics, you will uncover how each segment interacts within the system, allowing for a comprehensive appreciation of your equipment’s design. Ultimately, this insight can empower you to optimize performance and prolong the lifespan of your machinery.

Ditch Witch 1820 Overview

This section provides a comprehensive examination of a specialized piece of machinery designed for efficient trenching and underground operations. Renowned for its robust construction and innovative features, this equipment is essential for various construction and utility projects.

Key Features

Engineered to tackle tough terrains, this machine combines power with versatility. Its compact design allows for easy maneuverability in confined spaces while maintaining exceptional digging capabilities. Additionally, the intuitive controls enhance user experience, making operation straightforward.

Specifications

| Specification | Detail |

|---|---|

| Engine Power | Various options available |

| Digging Depth | Up to 48 inches |

| Weight | Approximately 4,200 lbs |

| Width | 30 inches |

| Hydraulic System | High-efficiency hydraulic pump |

This machinery is not only a significant investment for contractors but also a reliable tool that enhances productivity and efficiency on job sites.

Key Features of the 1820 Model

This section highlights the standout characteristics of a specific excavation machine designed for efficiency and versatility in various applications. Understanding these features can enhance user experience and operational effectiveness.

Performance Advantages

- Robust engine providing exceptional power and torque.

- Enhanced maneuverability for navigating tight spaces.

- Efficient fuel consumption for longer operational hours.

Design Innovations

- Ergonomic controls for user-friendly operation.

- Durable construction to withstand rigorous tasks.

- Compact design allowing for easy transport and storage.

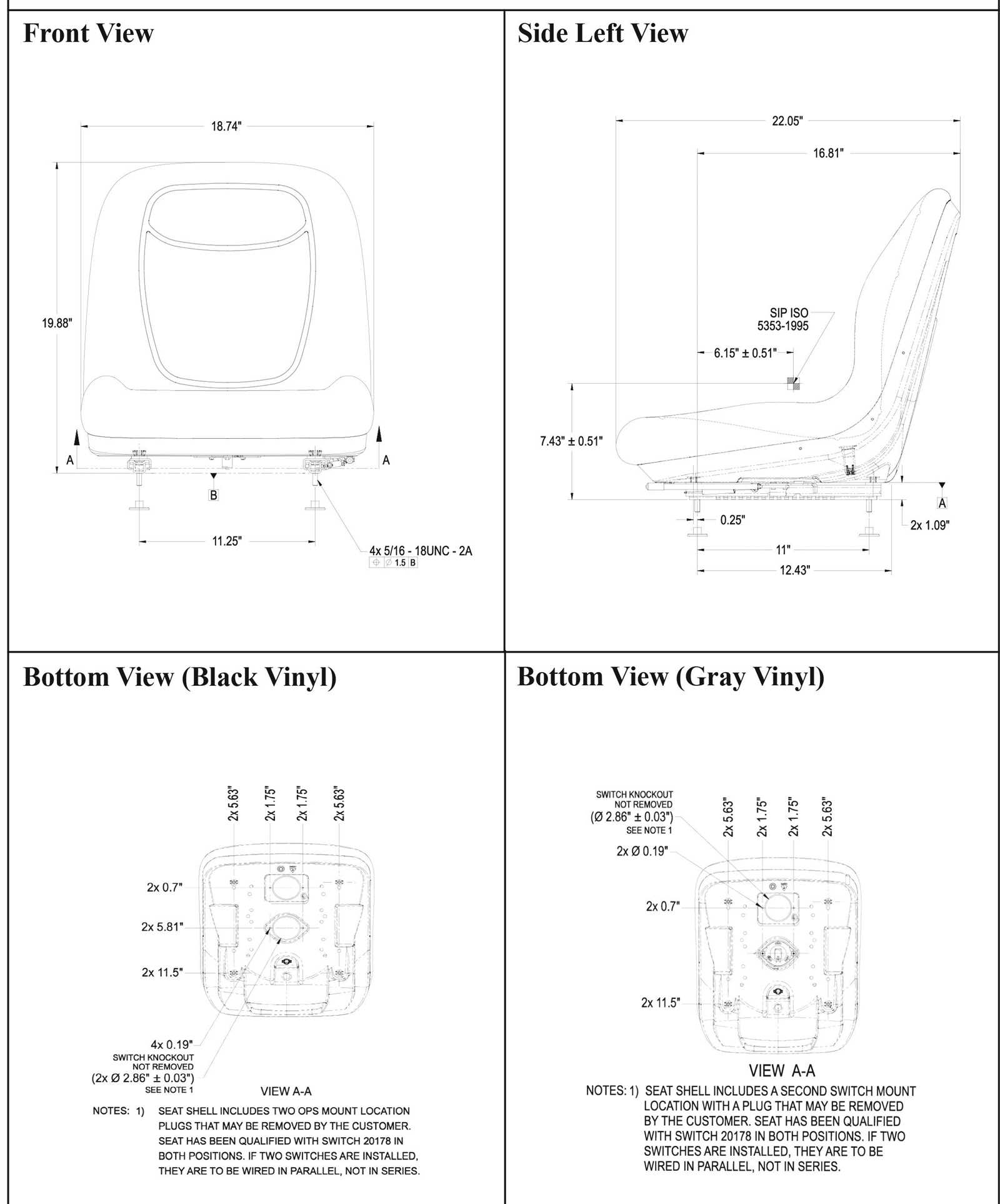

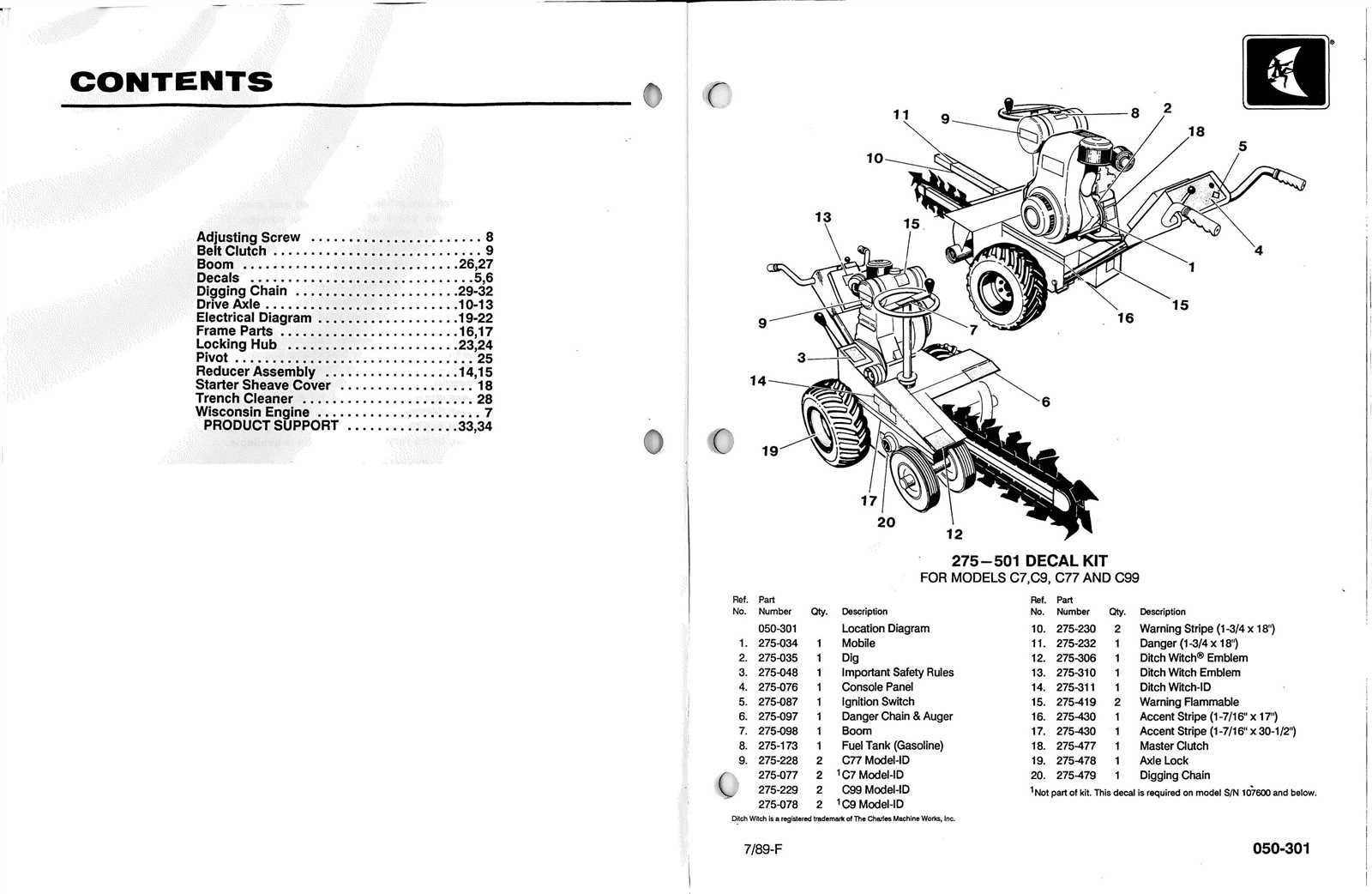

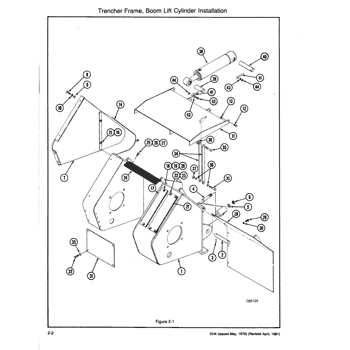

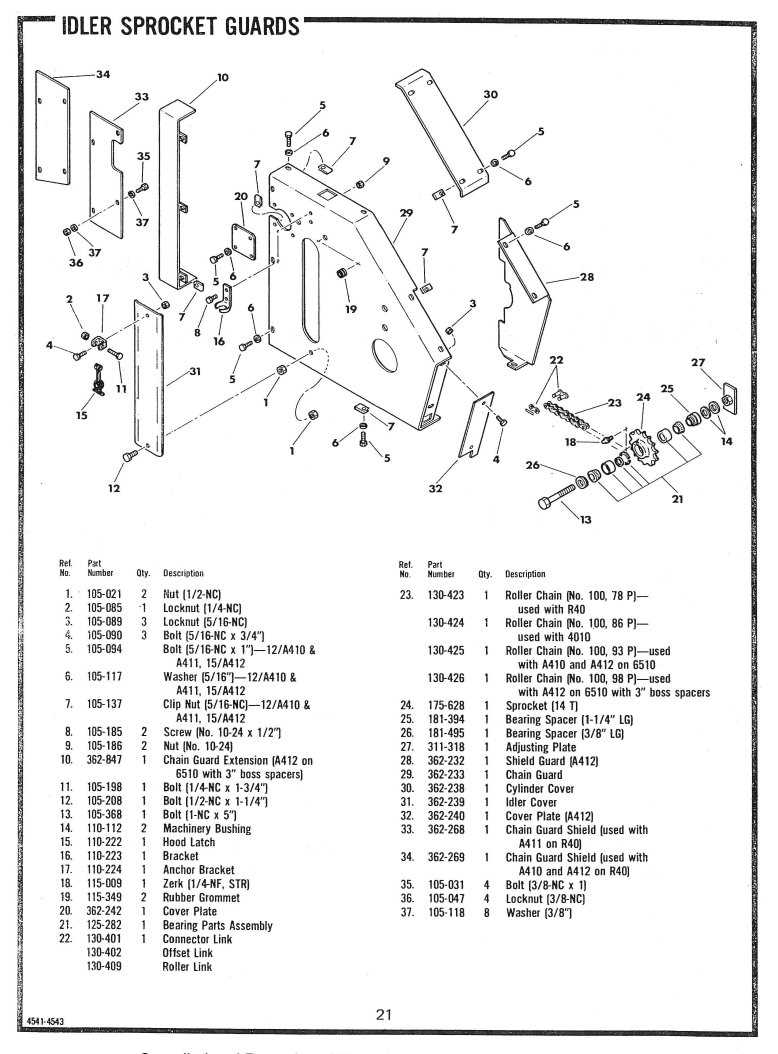

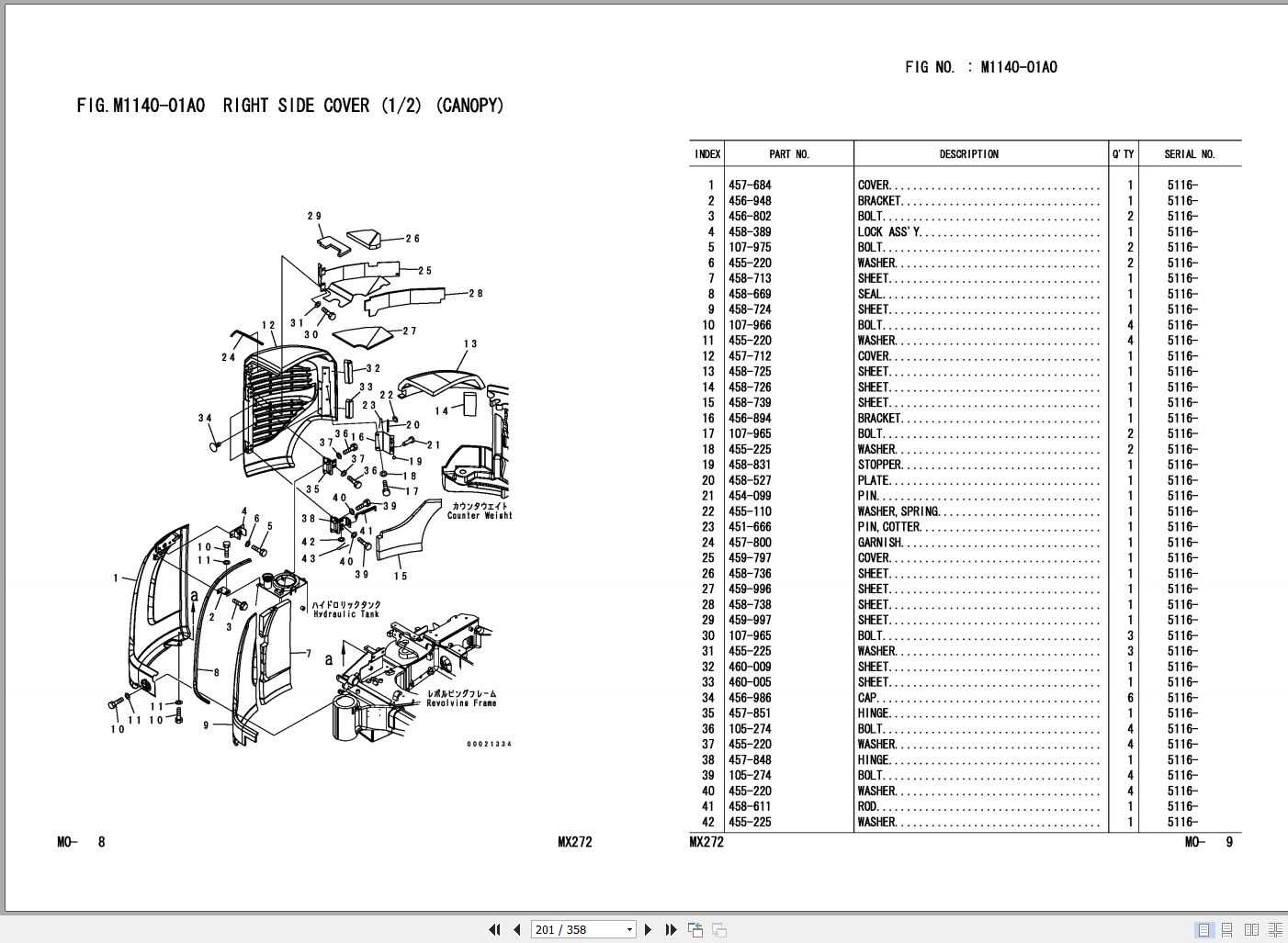

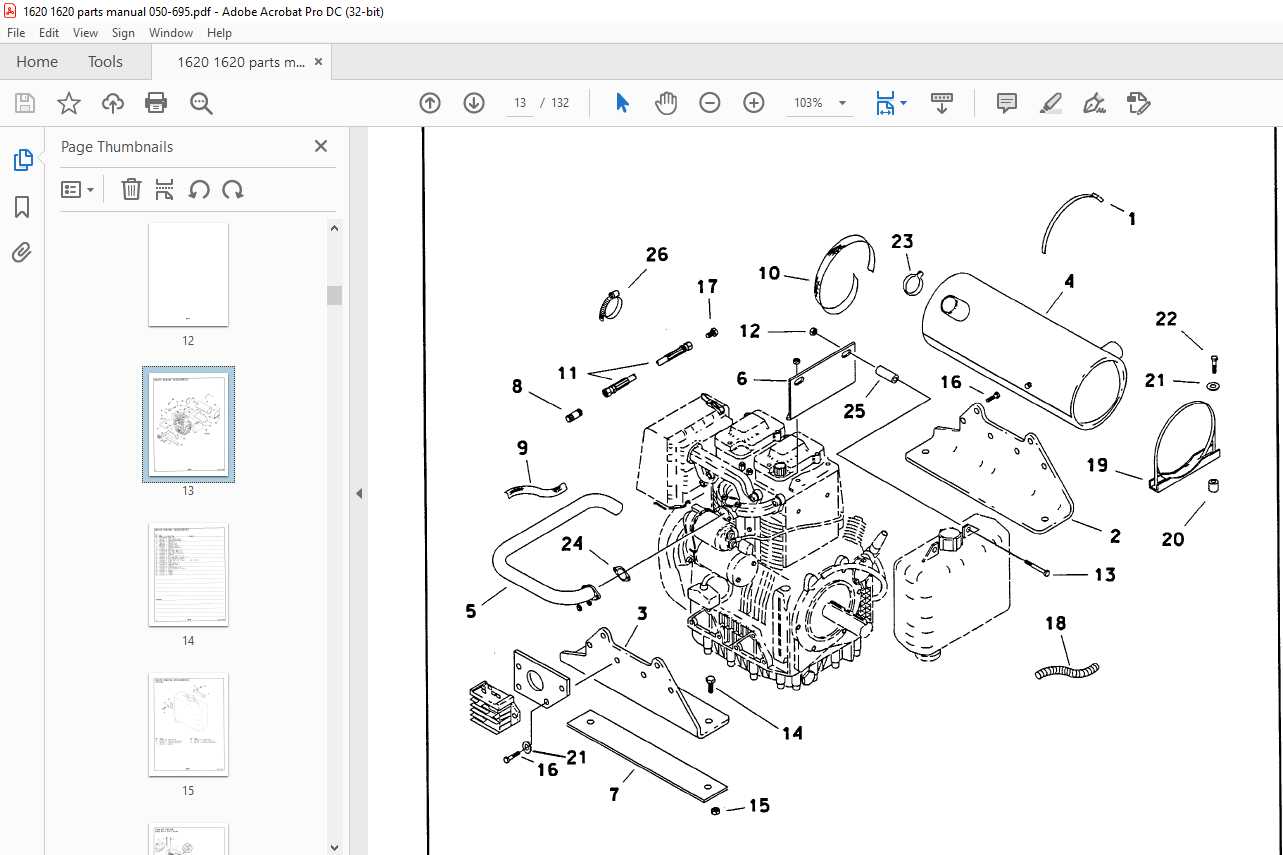

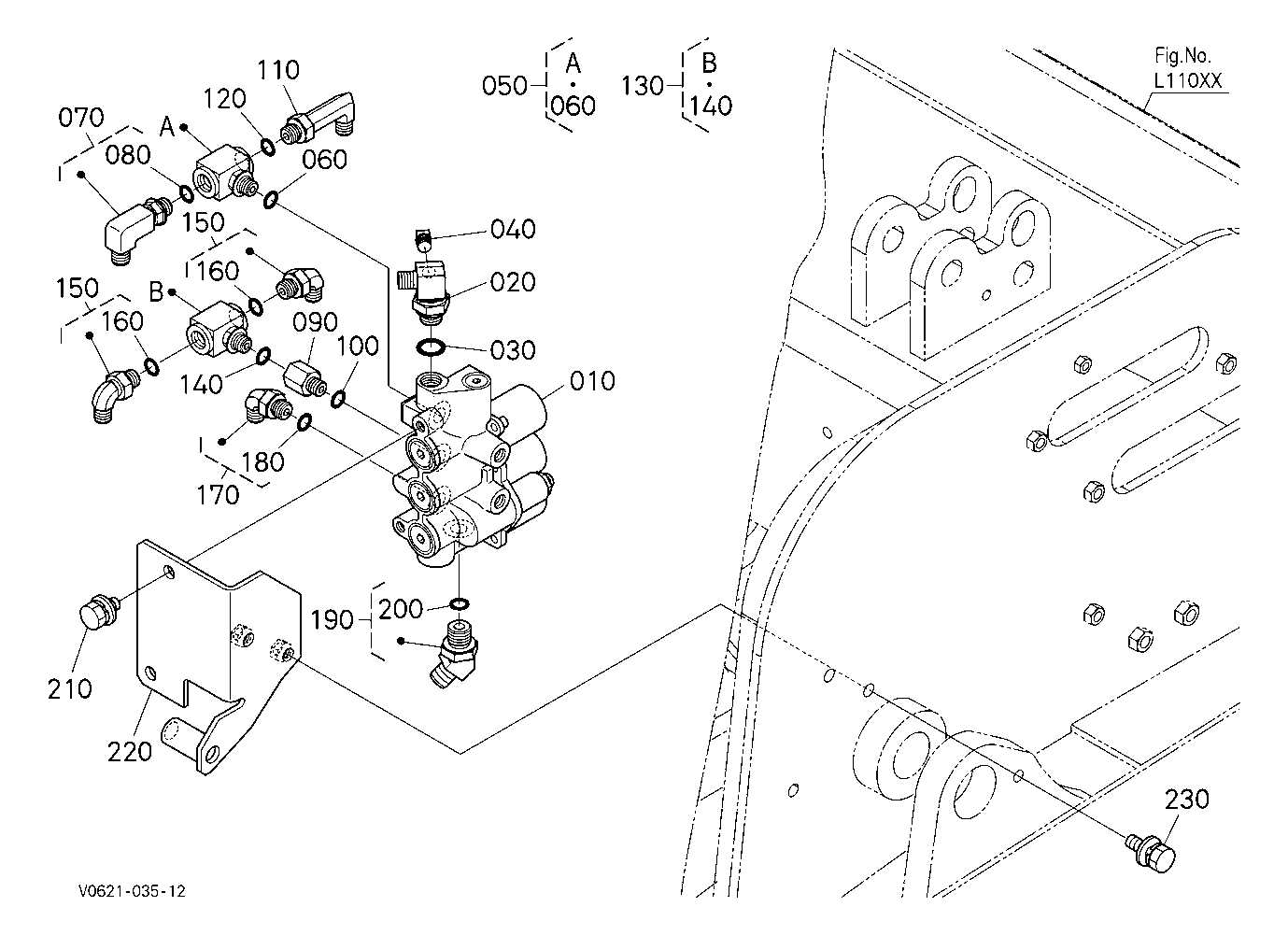

Importance of Parts Diagrams

Understanding the intricate layout of machinery components is crucial for effective maintenance and repair. Clear illustrations provide technicians with essential visual aids, ensuring that each element is easily identifiable and comprehensible. This facilitates quicker troubleshooting and enhances the overall efficiency of service processes.

| Benefits | Description |

|---|---|

| Enhanced Clarity | Visual representations make complex systems easier to understand. |

| Streamlined Maintenance | Quick reference for identifying and replacing specific components. |

| Reduced Downtime | Efficient troubleshooting leads to faster repairs. |

| Improved Training | Helps new technicians grasp system layouts more effectively. |

Common Issues with Ditch Witch 1820

Every piece of heavy machinery can encounter problems over time, leading to inefficiencies and potential downtime. Understanding the frequent challenges can help operators maintain optimal performance and extend the lifespan of their equipment.

Hydraulic Problems: One of the most prevalent issues involves hydraulic systems. Leaks or low fluid levels can significantly reduce efficiency, causing slow or unresponsive movements.

Engine Performance: Operators often report issues related to engine performance, including overheating or difficulty starting. Regular maintenance is crucial to prevent these situations from escalating.

Track Wear: Tracks may experience excessive wear, leading to compromised stability and traction. Regular inspections and timely replacements are essential to ensure safety.

Electrical Failures: Electrical components can be prone to failure, affecting various functions. Routine checks can identify problems early, preventing more extensive repairs.

Addressing these common challenges proactively can help maintain the equipment’s reliability and performance.

Where to Find Parts Diagrams

Locating visual representations of components is essential for efficient maintenance and repairs. Numerous resources are available to assist users in this endeavor, ensuring they can effectively identify and procure the necessary items for their machinery.

Online Retailers: Many e-commerce platforms specialize in construction equipment. These sites often provide detailed illustrations alongside descriptions, enabling users to navigate through the options easily.

Manufacturer Websites: Official company sites typically offer a wealth of resources, including catalogs and technical guides. Accessing these can provide the most accurate and up-to-date information.

Forums and Community Groups: Engaging with online communities can yield valuable insights. Experienced users often share resources, including visual guides, enhancing collective knowledge.

Local Dealers: Authorized distributors can be an excellent source for printed materials and direct assistance. They often possess comprehensive knowledge about the products they sell.

By utilizing these avenues, individuals can delve into the specifics of their equipment, ensuring they have the ultimate tools at their disposal for successful upkeep.

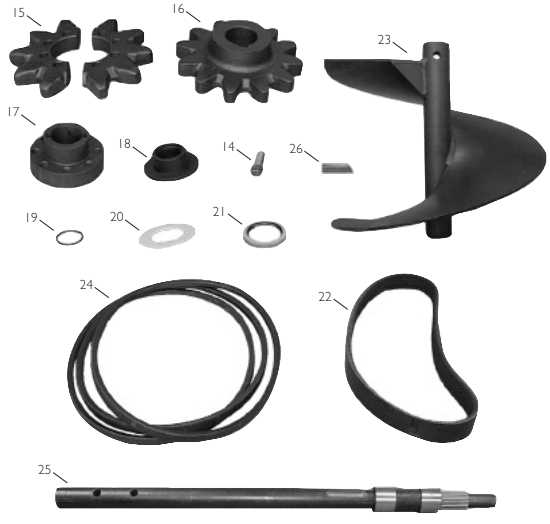

Understanding Each Component’s Role

Every machine comprises various elements that work in harmony to achieve optimal performance. Recognizing the function of each piece is crucial for maintenance and efficient operation. By delving into the specific roles, users can enhance their understanding and ensure longevity of the equipment.

- Power Source: Provides the necessary energy to operate the machine, influencing overall efficiency.

- Transmission System: Transfers power from the engine to the working components, crucial for effective movement.

- Cutting Mechanism: Engages with the terrain, designed for precise excavation and cutting.

- Control Panel: The interface for the operator, allowing for monitoring and adjustment of settings.

- Support Structure: Offers stability and balance during operation, essential for safety.

Understanding these components helps users troubleshoot issues and make informed decisions regarding repairs and upgrades. Each part plays a vital role in the seamless functioning of the machinery.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your machinery requires consistent care and attention. By implementing effective maintenance strategies, you can significantly extend the lifespan of your equipment, minimizing downtime and costly repairs.

Regular Inspections

- Conduct visual checks for wear and tear.

- Inspect fluid levels and replace as necessary.

- Look for loose connections and fasteners.

Proper Lubrication

- Use manufacturer-recommended lubricants.

- Apply oil to moving parts to reduce friction.

- Check lubrication points regularly to avoid dryness.

By following these essential practices, you can ensure that your equipment remains in peak condition, ready for any challenge that arises.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repairs. These illustrations serve as valuable guides, showing the relationships and arrangements of various elements within a machine. Mastering this skill allows for efficient troubleshooting and identification of required components, ultimately leading to more successful repairs.

Key Elements to Identify

Start by familiarizing yourself with the different sections of the illustration. Each area typically contains labels or codes that correspond to specific elements. Look for a legend or key, which provides definitions for symbols and numbers used in the visual. This will help you connect the graphical representations with the actual items you may need to replace or inspect.

Interpreting Connections and Assembly

Pay attention to how components are linked or assembled. Lines or arrows often indicate how parts fit together or interact with each other. Understanding these connections is crucial for disassembly and reassembly processes. By recognizing the flow and order of components, you can approach repairs methodically and minimize the risk of errors.

Replacement Parts and Compatibility

Finding suitable components for your machinery is crucial for maintaining optimal performance. Understanding compatibility ensures that replacements fit seamlessly and function as intended, minimizing downtime and enhancing efficiency.

Understanding Compatibility

When selecting components, it is vital to consider factors such as size, material, and design specifications. This knowledge can help users avoid mismatches that could hinder operation.

Commonly Used Components

| Component Type | Description | Compatibility Notes |

|---|---|---|

| Engine Parts | Essential for performance and efficiency. | Ensure specifications match original settings. |

| Hydraulic Components | Crucial for proper fluid operation. | Check for pressure ratings and fit. |

| Transmission Parts | Facilitates power transfer. | Must align with manufacturer guidelines. |

Tools Needed for Repairs

When undertaking maintenance or fixing machinery, having the right instruments is crucial for efficiency and effectiveness. Various implements will assist in diagnosing issues, executing repairs, and ensuring the equipment functions optimally. A well-equipped toolkit not only streamlines the repair process but also enhances safety and precision.

Essential tools include wrenches, screwdrivers, and pliers, which are fundamental for various tasks. Additionally, a multimeter can be invaluable for electrical troubleshooting, while a jack may be necessary for lifting heavy components. Depending on the specific job, replacement parts and maintenance supplies will also be essential to complete the task effectively.

By assembling a comprehensive toolkit, you can confidently address any challenges that arise during repairs, ultimately prolonging the lifespan of your equipment.

Frequently Asked Questions

This section addresses common inquiries related to maintenance and repair of specific machinery. Here, you’ll find useful information to assist with your understanding and troubleshooting needs.

General Queries

- What should I check regularly to ensure optimal performance?

- How can I identify worn components that need replacement?

- What are the signs of potential issues?

Maintenance Tips

- Regularly inspect hydraulic systems for leaks.

- Keep all moving parts lubricated as per manufacturer guidelines.

- Ensure that all fasteners are tightened to prevent vibrations.

Cost Considerations for Replacement Parts

When it comes to maintaining machinery, understanding the financial aspects of acquiring new components is crucial. Factors such as quality, sourcing options, and long-term benefits play a significant role in determining overall expenses. An informed approach can help in making decisions that ensure both performance and budget efficiency.

| Factor | Impact on Cost |

|---|---|

| Quality | Higher quality often means a greater initial investment but can reduce future replacement needs. |

| Source | Original equipment manufacturers may charge more than aftermarket suppliers, influencing budget choices. |

| Availability | Readily available components can lower shipping costs and downtime, affecting total expenditure. |

| Compatibility | Choosing the right fit can prevent additional repairs, which contributes to overall savings. |

Online Resources for Ditch Witch Owners

For those who operate specialized machinery, having access to reliable online resources is essential. Whether you’re looking for maintenance tips, community support, or technical specifications, various platforms can enhance your ownership experience.

Websites and Forums

- Manufacturer’s Official Site: Access manuals, troubleshooting guides, and updates.

- Online Communities: Join forums for advice and shared experiences from fellow operators.

- Parts Retailers: Find authorized dealers for quality replacement components.

Videos and Tutorials

- YouTube Channels: Discover helpful tutorials for repairs and maintenance.

- Webinars: Participate in online sessions hosted by experts for in-depth knowledge.