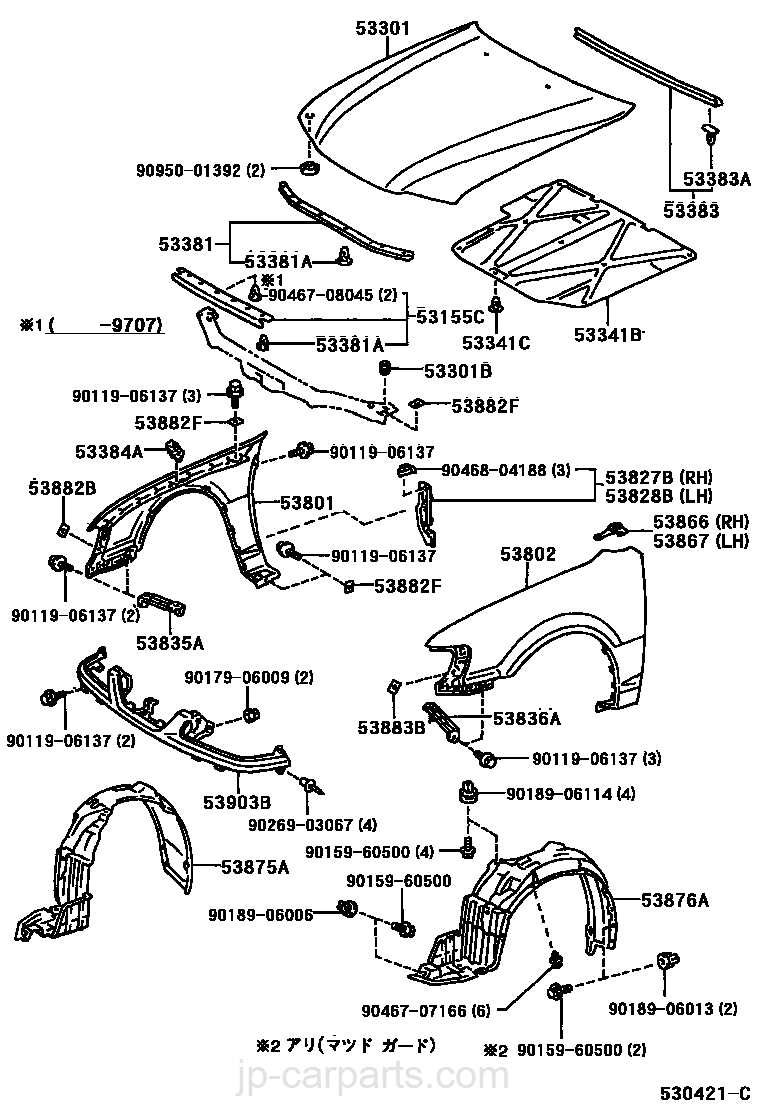

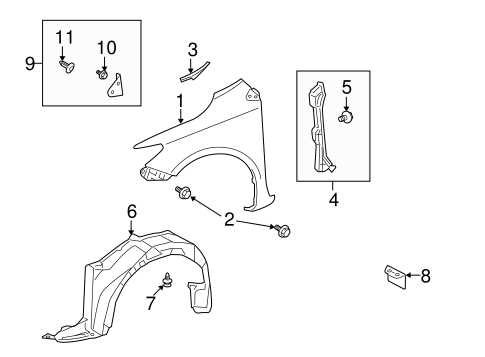

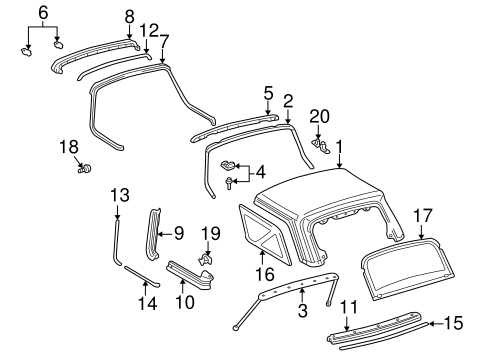

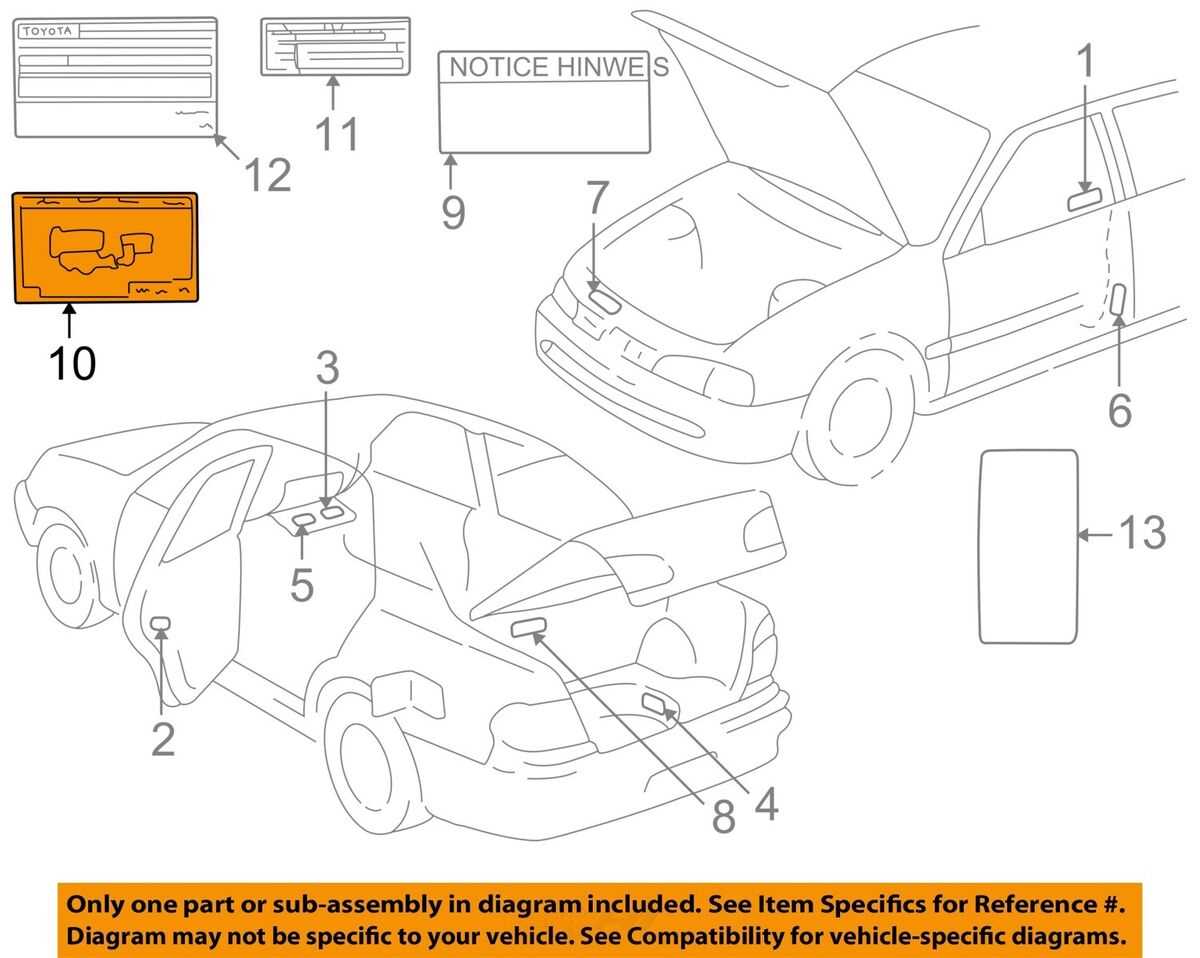

The arrangement and structure of mechanical elements play a crucial role in ensuring smooth operation and maintenance of any vehicle. A clear overview of these interconnected elements helps users effectively address issues, plan repairs, and optimize performance.

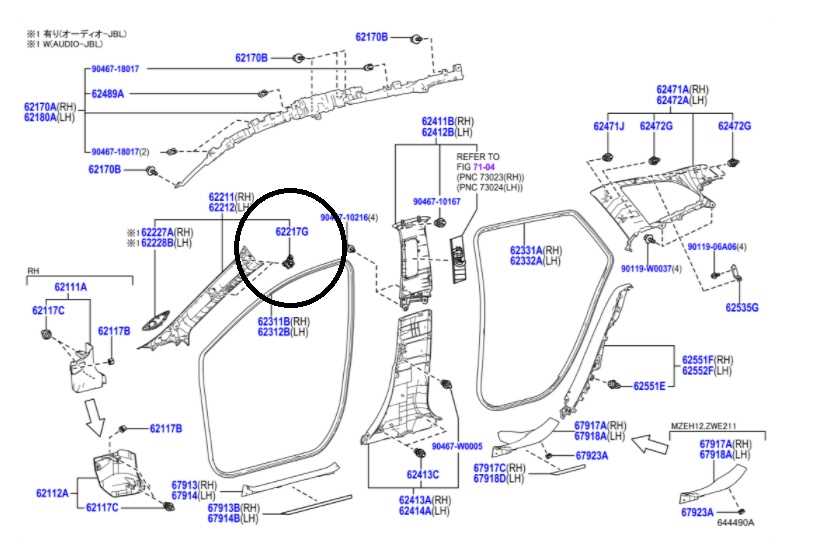

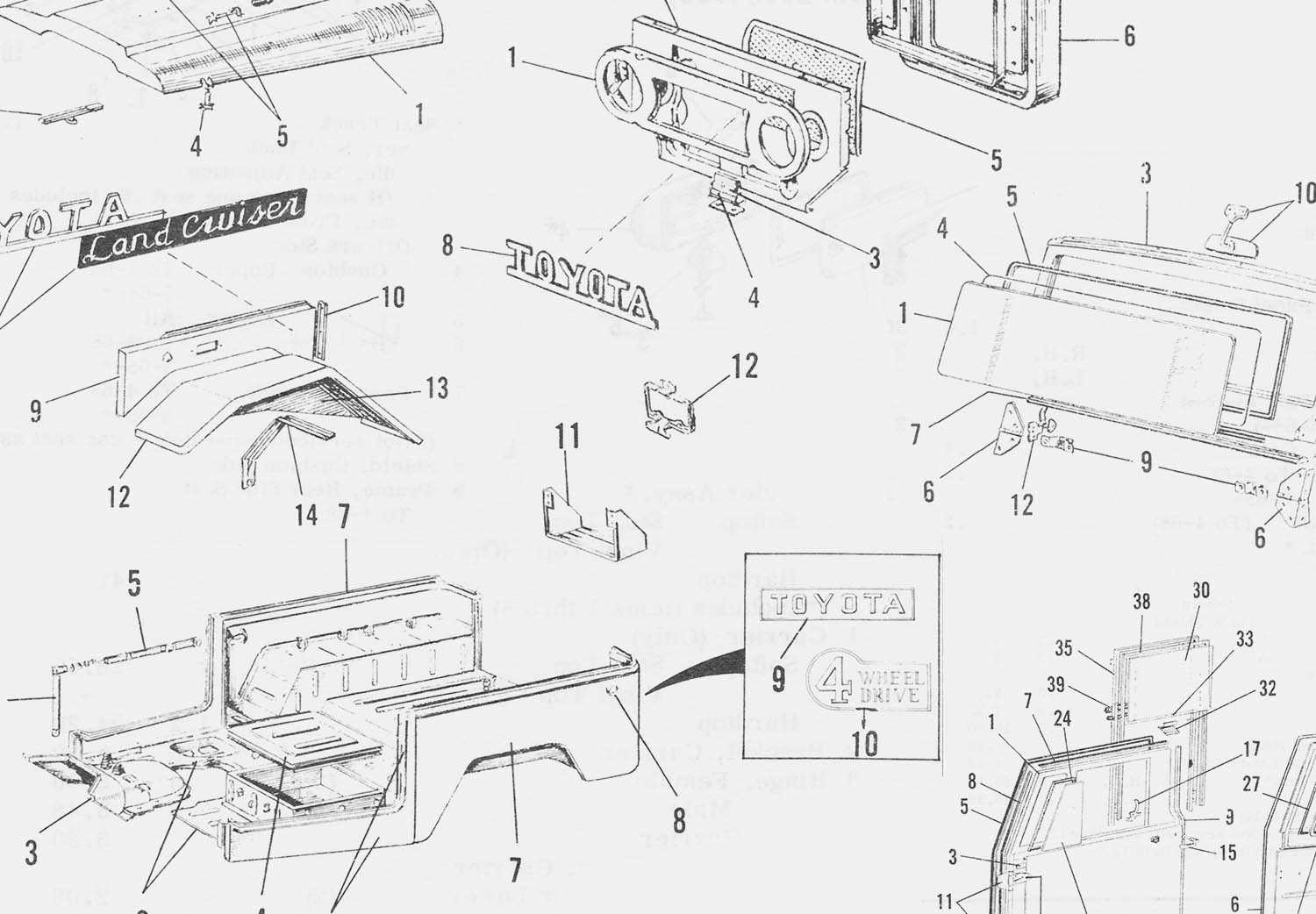

Exploring detailed illustrations of automotive assemblies enables both professionals and enthusiasts to gain valuable insights. With these layouts, it becomes easier to identify connections, understand the relationship between individual elements, and anticipate potential maintenance needs.

Whether you’re dealing with intricate systems or focusing on specific areas, these visual breakdowns provide clarity. They act as a guide for repairs, replacements, and improvements, minimizing the guesswork involved in complex mechanical tasks.

Toyota Part Diagram Overview

This section offers a comprehensive look into the structure and arrangement of various automotive components. The goal is to provide clarity on how individual elements fit together and function within a vehicle’s system, ensuring smooth operation and efficient maintenance.

| Component Category | Description | Examples | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine Assembly | Includes elements responsible for power generation and energy conversion. | Cylinder, crankshaft, fuel injectors | |||||||||||||||||||||

| Transmission System | Facilitates the transfer of power from the engine to the wheels. | Clutch, gearbox, driveshaft | |||||||||||||||||||||

| Brake Mechanism | Ensures vehicle control and safety through friction-based stopping power. | Brake pads, calipers, rotors | |||||||||||||||||||||

| Electrical Network | Manages power distribution and electronic functions across the vehicle. |

| Category | Main Features | Best Suited For | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sedan | Comfortable ride, fuel-efficient, compact design | Daily commuting, urban driving | |||||||||||||

| SUV | High ground clearance, spacious, of

Common Components in Toyota Parts

Vehicles rely on a variety of essential elements to ensure smooth operation, safety, and durability. These components work together to maintain functionality across different systems, including engine performance, braking, and interior comfort. Mechanical ElementsMechanical components are responsible for converting energy into motion and ensuring stability. This category includes moving elements within the engine, transmission systems, and braking mechanisms that help regulate speed and control. Electrical Systems and Sensors

Modern vehicles integrate electrical systems for enhanced efficiency and safety. These systems include wiring, sensors, and modules that communicate with the engine and other parts, ensuring precise control over various functions.

Avoiding Common ErrorsM How to Read Diagrams EffectivelyUnderstanding technical visuals requires attention to detail and an organized approach. By following a clear strategy, you can decode even the most complex visual schemes with ease.

Effective reading Using Diagrams for Maintenance Tasks

Visual guides play a crucial role in keeping machinery running smoothly. They simplify complex processes, making it easier to identify components, understand connections, and follow procedures step-by-step. By relying on well-organized schematics, users can reduce mistakes and ensure each part fits perfectly within the system. Advantages of Visual Aids in Repairs

How to Use Schematics Efficiently

|