The intricate design of high-performance machinery often involves a variety of elements working in unison. Gaining insight into these components is crucial for effective operation and maintenance. This section will explore the various parts that contribute to the functionality of a specific power tool, emphasizing their roles and interconnections.

Detailed examination of individual sections allows users to appreciate the engineering behind efficient performance. Each element serves a unique purpose, and understanding their arrangement can enhance repair efforts and ensure optimal usage. The clarity provided by an organized representation of these elements aids in troubleshooting and fosters a deeper knowledge of the tool’s design.

By delving into the specifics of this equipment, users can cultivate a more informed approach to their projects. Whether for routine maintenance or intricate repairs, familiarizing oneself with the configuration of these components is invaluable for achieving lasting results and maximizing productivity.

Overview of Hilti TE 3000

This section provides a comprehensive understanding of a powerful tool designed for heavy-duty applications. Its robust construction and innovative features make it an essential choice for professionals in various industries.

Key characteristics include:

- Exceptional durability for demanding tasks

- Enhanced efficiency through advanced technology

- User-friendly interface for easy operation

Applications typically encompass:

- Concrete demolition

- Heavy material breaking

- Construction site preparation

By integrating high-performance components, this tool stands out in its category, ensuring reliability and effectiveness in challenging environments.

Key Features and Specifications

This section highlights the essential characteristics and technical details of the tool, providing insights into its performance and usability. Understanding these features is crucial for users looking to maximize efficiency and effectiveness in their tasks.

Power and Efficiency: The tool boasts a robust motor that ensures high performance, enabling users to tackle demanding projects with ease. Its design emphasizes energy efficiency, allowing for extended use without frequent recharges.

Durability: Constructed with high-quality materials, this equipment is engineered to withstand harsh conditions. Its rugged build ensures longevity, making it a reliable choice for professionals in various industries.

Ergonomics: Designed with user comfort in mind, the tool features an ergonomic handle that reduces fatigue during prolonged use. This thoughtful design enhances control and precision, contributing to overall productivity.

Versatility: Equipped with interchangeable components, the device can adapt to a wide range of applications, from light-duty tasks to heavy-duty operations. This flexibility makes it an invaluable addition to any toolkit.

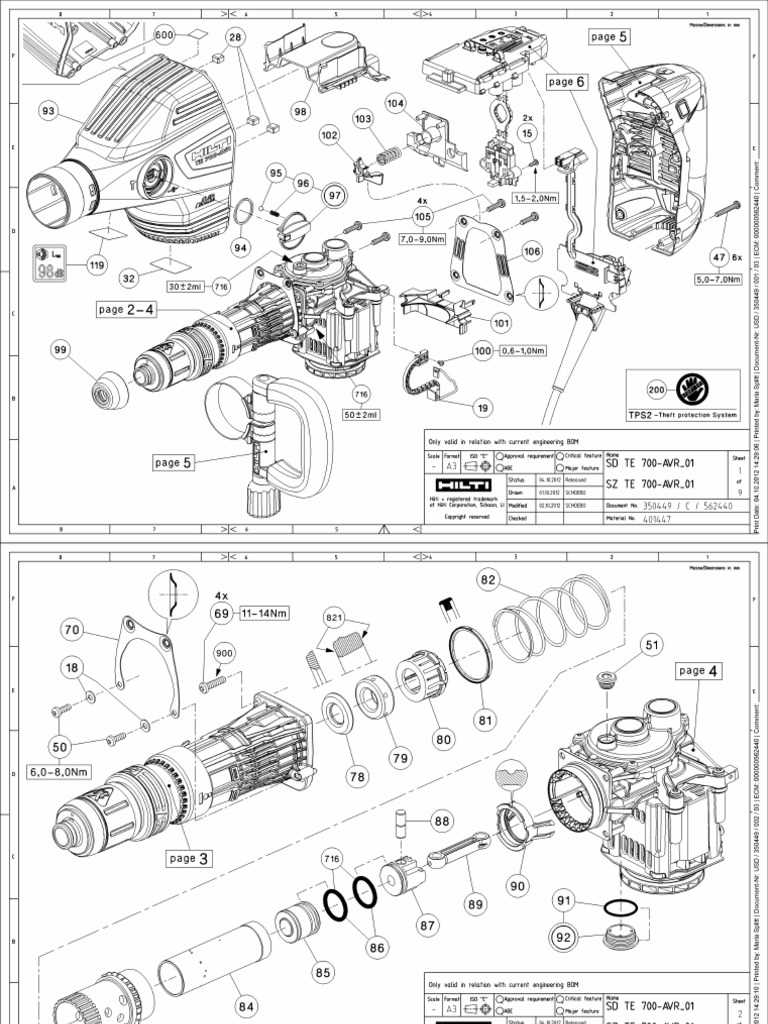

Understanding the Parts List

When working with complex tools, having a comprehensive inventory of components is crucial for maintenance and repairs. This section will guide you through the essential elements that comprise these intricate devices, enhancing your ability to identify and manage each item effectively.

A thorough inventory provides insights into the function and importance of each element. Here are some key aspects to consider:

- Identification: Each component is labeled, often with a unique number or code, to facilitate easy reference.

- Functionality: Understanding what each item does can help in diagnosing issues and performing repairs.

- Compatibility: Knowing which components work together is essential for ensuring the optimal performance of the equipment.

To effectively navigate the inventory, consider the following steps:

- Familiarize yourself with the terminology used to describe each component.

- Refer to the inventory regularly during maintenance to ensure all elements are accounted for.

- Consult additional resources or manuals for detailed explanations of specific components.

By understanding the various elements and their roles, you will be better equipped to manage the tool and ensure its longevity.

Common Components Explained

This section aims to elucidate the essential elements found in powerful tools designed for construction and renovation tasks. Understanding these components is crucial for effective operation and maintenance, ensuring optimal performance and longevity of the equipment.

Power Mechanism

The power mechanism serves as the heart of the tool, converting electrical energy into mechanical action. This vital component determines the efficiency and effectiveness of the tool, making it indispensable for high-demand applications.

Attachment System

An attachment system allows users to interchange various accessories tailored for specific tasks. This versatility enhances functionality, enabling the tool to adapt to different materials and work conditions, thus expanding its usability in diverse projects.

Maintenance Recommendations for Longevity

Ensuring the durability and optimal performance of any tool requires regular upkeep and careful handling. Following specific guidelines can greatly enhance the lifespan of your equipment and prevent unexpected failures.

- Regular Cleaning: Keep the exterior and interior free from dust and debris.

- Lubrication: Apply appropriate lubricants to moving parts to reduce friction.

- Inspection: Frequently check for wear and tear, replacing any worn components promptly.

- Storage: Store in a dry, cool place away from direct sunlight to prevent damage.

By adhering to these practices, you can maximize the efficiency and reliability of your equipment over time.

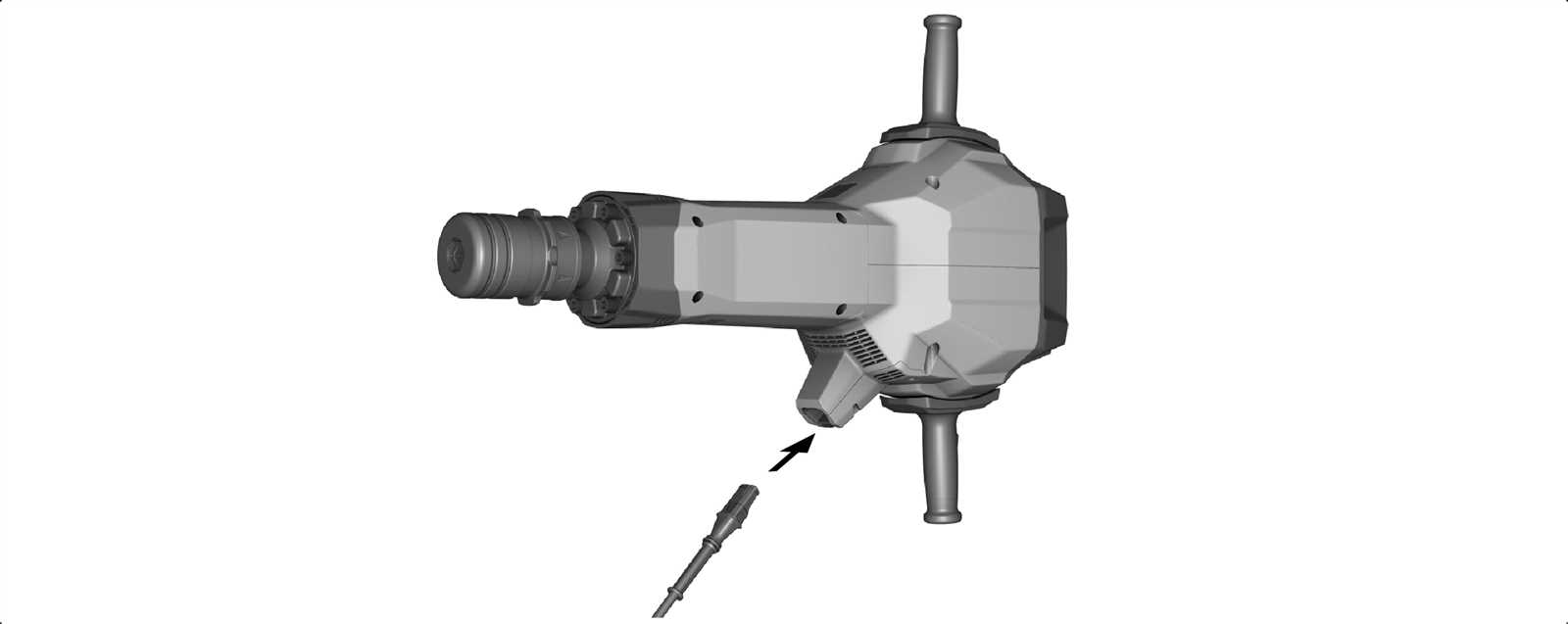

Replacement Procedures for Major Parts

When it comes to maintaining heavy-duty equipment, understanding how to replace essential components is crucial for optimal performance and longevity. This section outlines the steps necessary to successfully swap out key elements, ensuring that the machinery operates smoothly and efficiently.

- Preparation:

- Gather the necessary tools, including wrenches, screwdrivers, and pliers.

- Ensure that you have the correct replacement components on hand.

- Consult the manufacturer’s manual for any specific instructions related to the equipment.

- Power Down:

- Disconnect the power source to prevent any accidents during the replacement process.

- Allow the machine to cool down if it has been in use recently.

- Access the Component:

- Remove any covers or housing that obstruct access to the part that needs replacement.

- Keep track of screws and fasteners to ensure everything can be reassembled correctly.

- Remove the Old Component:

- Carefully disconnect any wiring or connections attached to the component.

- Unscrew or unbolt the component from its mount.

- Install the New Component:

- Position the new part into place, ensuring a secure fit.

- Reconnect any wiring or connections as per the guidelines.

- Reassemble the Equipment:

- Replace any covers or housing that were removed earlier.

- Double-check that all fasteners are tightened appropriately.

- Test the Equipment:

- Reconnect the power source and test the equipment to ensure everything operates correctly.

- Monitor for any unusual sounds or malfunctions during initial operation.

By following these steps, users can efficiently replace vital components, enhancing the machine’s functionality and extending its operational life.

Diagnosing Common Issues

Identifying and resolving typical problems in power tools requires a systematic approach. By understanding common symptoms and their possible causes, users can effectively troubleshoot and restore functionality to their equipment.

Common Symptoms

- Tool not starting or losing power during operation

- Excessive vibration or unusual noises

- Inconsistent performance or overheating

- Electrical issues, such as sparks or burning smells

Troubleshooting Steps

- Check the power source for reliability and proper connections.

- Inspect the tool for visible damage or wear, focusing on cables and connectors.

- Clean any debris from ventilation areas to ensure adequate airflow.

- Test key components like switches and motors for functionality.

- Refer to the manufacturer’s guidelines for specific diagnostic procedures.

Upgrading Your Hilti Tool

Enhancing the functionality of your power equipment can significantly improve its performance and longevity. By integrating advanced components and accessories, you can tailor your tool to meet specific needs, ensuring optimal efficiency in various tasks.

Consider the benefits of upgrading: Enhanced capabilities, improved safety features, and increased productivity. Whether it’s for heavy-duty applications or precise tasks, modernizing your equipment can make a remarkable difference.

One effective approach is to evaluate available enhancements that can complement your existing setup. Look for compatible attachments, improved power sources, and ergonomic upgrades. Each of these modifications can contribute to a more seamless and enjoyable user experience.

Additionally, regular maintenance and timely replacements of essential components are crucial. Keeping your equipment in top condition not only extends its lifespan but also ensures that you consistently achieve the best results.

Safety Precautions During Use

Ensuring safety during the operation of power tools is crucial to prevent accidents and injuries. Adhering to recommended guidelines not only protects the user but also enhances the longevity of the equipment. Proper understanding and implementation of safety measures create a secure working environment.

General Safety Guidelines

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and ear protection.

- Maintain a clean and organized workspace to reduce the risk of tripping and other hazards.

- Inspect the tool before each use to ensure it is in good working condition and free from defects.

- Ensure that all components are properly secured and attached before starting the operation.

- Follow the manufacturer’s instructions for operation and maintenance.

Operational Safety Tips

- Keep hands and body away from moving parts during operation.

- Use the tool only for its intended purpose to avoid misuse.

- Never disable safety features or guards that are provided with the equipment.

- Disconnect the power supply when changing accessories or performing maintenance.

- Be mindful of your surroundings and ensure that bystanders are at a safe distance.

Accessories to Enhance Performance

To optimize the efficiency and effectiveness of your tools, integrating supplementary equipment can make a significant difference. These enhancements not only improve functionality but also extend the lifespan of your devices, ensuring they operate at peak performance during demanding tasks.

Key Accessories

- Precision Attachments: These components allow for more accurate work, making intricate tasks easier and more efficient.

- Enhanced Grips: Comfortable handles provide better control and reduce fatigue during extended use.

- Durable Cases: Protective cases safeguard tools from damage, ensuring longevity and reliability.

Additional Tools

- Dust Extraction Systems

- Specialized Blades and Bits

- Rechargeable Battery Packs

Incorporating these accessories can greatly enhance your tool’s versatility, making it easier to tackle a variety of projects with confidence and precision.

Comparative Analysis with Similar Models

This section provides a detailed examination of how one particular tool aligns with and differs from comparable devices in its category. By exploring various features, functionalities, and performance metrics, users can gain insight into the strengths and weaknesses of the options available on the market.

Key Features Comparison

- Power Output: Analyze the energy capacity of each device, noting how it affects performance in various applications.

- Durability: Assess the materials used in construction, focusing on longevity and resistance to wear and tear.

- Weight and Portability: Consider the ease of transportation and handling, which can impact user convenience.

User Experience and Feedback

- Ease of Use: Compare user interfaces and control mechanisms for accessibility and functionality.

- Maintenance Requirements: Discuss the upkeep needed for each model, including parts replacement and servicing.

- Customer Satisfaction: Summarize feedback from users regarding their overall experiences and outcomes achieved with each tool.

Expert Tips for Optimal Operation

Achieving peak performance from your equipment requires a thorough understanding of its components and how they interact. By following a few best practices, users can enhance efficiency, prolong lifespan, and ensure reliable operation. Here are some key recommendations to consider.

| Tip | Description |

|---|---|

| Regular Maintenance | Consistently inspect and clean all components to prevent buildup of debris and ensure smooth functionality. |

| Proper Lubrication | Use the appropriate lubricants for moving parts to reduce friction and wear, thereby improving efficiency. |

| Follow Operating Guidelines | Adhere to manufacturer instructions for usage and load limits to avoid damage and enhance performance. |

| Use Quality Accessories | Invest in high-quality attachments and accessories that are compatible to optimize overall performance. |

| Monitor Performance | Keep track of performance metrics to identify any issues early and address them before they escalate. |