Exploring the intricacies of a highly regarded crafting instrument offers valuable insights into its functionality and maintenance. Each element within this complex mechanism plays a crucial role in ensuring optimal performance and precision during operation. By delving into the various components, users can better appreciate the design and engineering that enhance the crafting experience.

For enthusiasts and professionals alike, familiarizing oneself with the specific features and functions of this device can lead to improved outcomes in their projects. Recognizing how each segment contributes to the overall efficiency not only aids in troubleshooting but also encourages informed decision-making when it comes to upgrades and repairs. Understanding the assembly of these intricate parts is essential for achieving mastery in the craft.

Whether you are embarking on a new venture or seeking to refine your skills, knowledge of the inner workings of this apparatus is indispensable. Armed with this understanding, you will be better equipped to harness the full potential of the tool, enabling you to create with confidence and expertise.

Understanding the mechanisms of specialized cutting tools is crucial for both novice and experienced users. These tools are designed to provide precision and versatility, making them essential in various crafting and woodworking applications. This section offers insight into the essential components and functionalities that contribute to the effective operation of these machines.

The following elements are fundamental to the performance and efficiency of these cutting devices:

- Frame: The robust structure that supports the entire assembly, providing stability during operation.

- Motor: The power source that drives the blade, influencing speed and cutting capabilities.

- Blade holder: The mechanism that securely grips the cutting blade, allowing for easy changes and adjustments.

- Table: The flat surface where materials are placed for cutting, often adjustable for different angles and heights.

- Foot pedal: An optional feature that allows hands-free control of the cutting action, enhancing user convenience.

Each of these elements plays a vital role in the overall functionality of the tool, contributing to its effectiveness in executing intricate cuts and designs. Familiarity with these components can enhance the user experience and ensure proper maintenance.

Key Components of the Machine

The intricate design of this machinery incorporates various essential elements that work in harmony to achieve precise cutting and craftsmanship. Understanding these components is crucial for maintenance and effective operation, ensuring optimal performance throughout its lifespan.

Core Elements

- Frame: The robust structure that provides stability and support, allowing for accurate movements.

- Motor: The power source that drives the cutting mechanism, influencing speed and efficiency.

- Blade Holder: This component securely grips the cutting tool, enabling quick changes and adjustments.

Operational Features

- Table: A flat surface designed to support the material being worked on, often adjustable for different angles.

- Foot Pedal: Provides convenient control over the machine’s operation, allowing for hands-free use.

- Dust Collection System: Maintains a clean workspace by efficiently removing debris generated during cutting.

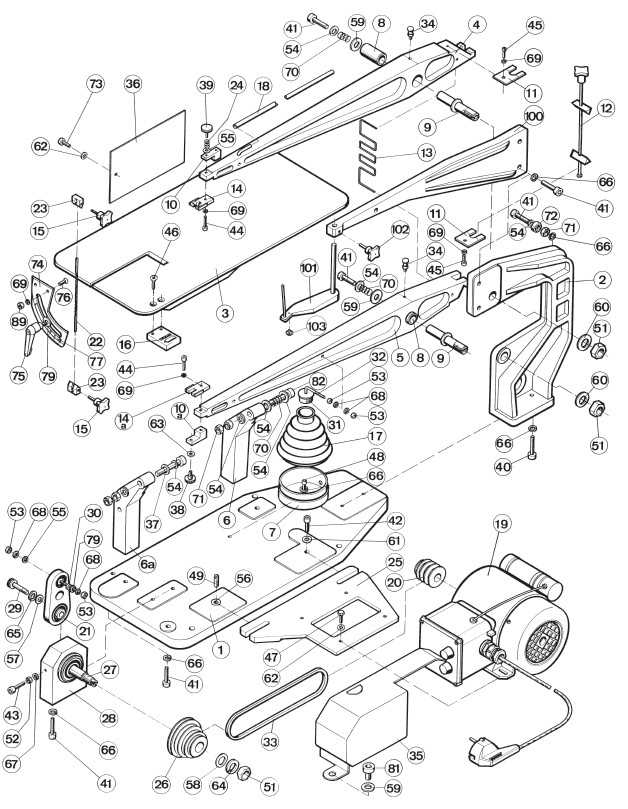

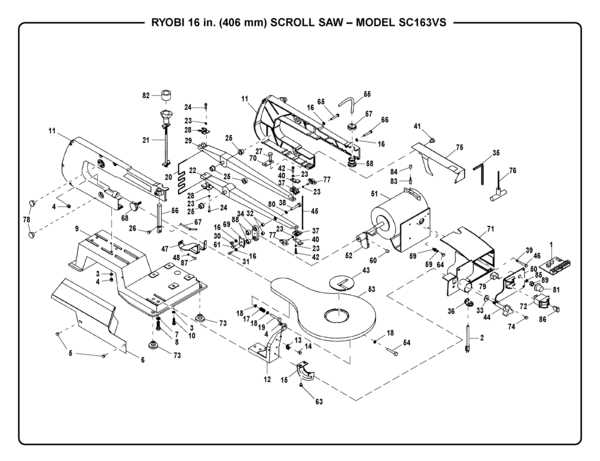

Understanding the Parts Layout

Grasping the configuration of components is essential for effective operation and maintenance of any intricate tool. Familiarity with each element’s position and function enhances overall usability and can simplify troubleshooting processes.

This layout typically includes various sections that serve specific roles, contributing to the smooth performance of the machine. By comprehending how each segment interacts, users can optimize their experience and extend the longevity of their equipment.

| Component Name | Description |

|---|---|

| Base | Supports the entire structure, ensuring stability during operation. |

| Arm | Holds the blade and facilitates movement for cutting actions. |

| Table | Provides a surface for the material, adjustable for different angles. |

| Motor | Powers the cutting mechanism, driving the blade for effective operation. |

| Blade Holder | Secures the blade in place, allowing for quick changes and adjustments. |

Importance of Accurate Diagrams

Precise visual representations play a crucial role in the effective assembly and maintenance of complex machinery. They serve as essential guides for users, helping to illustrate the correct arrangement of components and ensuring that each element functions harmoniously within the system. Such illustrations facilitate a deeper understanding of intricate designs, making it easier for operators and technicians to troubleshoot issues and perform repairs.

Without reliable visuals, users may encounter difficulties in recognizing how various elements interact. This can lead to misalignment, improper assembly, and ultimately, equipment failure. Therefore, having well-crafted illustrations is vital for both novice and experienced users alike, as they enhance clarity and reduce the likelihood of errors.

| Key Benefits | Description |

|---|---|

| Enhanced Understanding | Clear visuals help users grasp complex arrangements and functions quickly. |

| Reduced Errors | Accurate guides minimize the chances of incorrect assembly or maintenance. |

| Time Efficiency | Well-designed illustrations save time by streamlining the repair or setup process. |

| Improved Safety | Understanding the layout can help prevent accidents related to improper use or handling. |

Common Issues with Scroll Saw Parts

Various challenges can arise during the operation of intricate cutting machines, often leading to decreased performance and frustration. Understanding these common problems is crucial for maintaining efficiency and prolonging the lifespan of the equipment.

Frequent Complications

- Misalignment of components, affecting the accuracy of cuts.

- Worn or damaged blades causing uneven results.

- Excessive vibration leading to operator discomfort and reduced control.

- Clogging from debris or dust obstructing the mechanism.

- Electrical issues impacting power supply and operational consistency.

Maintenance Recommendations

- Regularly check and align all movable elements for precision.

- Replace worn blades promptly to maintain cutting quality.

- Inspect and clean components frequently to prevent build-up.

- Ensure proper electrical connections and troubleshoot any power issues.

- Consider using vibration-dampening mats to enhance stability.

How to Identify Each Component

Understanding the various elements of your cutting tool is essential for effective operation and maintenance. Each section plays a crucial role in the overall functionality, and recognizing them can significantly enhance your crafting experience.

To begin with, familiarize yourself with the base, which provides stability and support. This foundational piece is vital for ensuring that the entire apparatus remains steady during use. Next, focus on the arm, a key component that connects to the blade and allows for movement. This section often has a pivot point, enabling it to adjust angles for various cutting tasks.

Additionally, identify the motor, which powers the mechanism. This element is usually located at the rear and is crucial for generating the necessary speed and force for cutting. Pay attention to the blade holder, designed to secure the cutting tool in place. A proper fit here is essential for achieving precise cuts.

Lastly, examine the control panel, where you will find switches and settings that allow you to adjust the speed and operation mode. Understanding each of these components will not only improve your skills but also help in troubleshooting and maintaining your equipment effectively.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the extended functionality of your equipment. Proper care not only enhances performance but also prolongs the life of components. By adopting a few straightforward practices, users can avoid premature wear and maintain optimal efficiency.

Here are some valuable suggestions to keep in mind:

- Clean Regularly: Dust and debris can accumulate over time, leading to inefficiencies. Use a soft cloth to wipe down surfaces and a vacuum to remove particles from hard-to-reach areas.

- Lubricate Moving Parts: Ensure that all moving components are properly lubricated. This helps reduce friction and wear, enhancing the smooth operation of the machinery.

- Check for Wear: Regularly inspect all components for signs of wear and tear. Early detection of potential issues can prevent costly repairs in the future.

- Use Appropriate Accessories: Utilizing the right attachments and accessories is crucial. Ensure they are compatible to avoid unnecessary strain on the machinery.

- Follow Manufacturer Guidelines: Adhere to the maintenance schedule and recommendations provided by the manufacturer to ensure your equipment operates as intended.

Implementing these practices will not only enhance the performance of your equipment but also ensure that it serves you well for years to come.

Replacement Parts and Upgrades

When it comes to enhancing the functionality and longevity of your cutting tool, considering alternative components and enhancements is essential. Upgrading certain features can lead to improved performance, greater precision, and a more enjoyable user experience. This section explores various options for replacements and enhancements to ensure your equipment remains in optimal condition.

Common Replacement Options

- Blades: Choosing high-quality blades tailored for specific materials can significantly impact cutting efficiency and accuracy.

- Motor Upgrades: Increasing motor power can enhance cutting speed and performance, especially when working with tougher materials.

- Table Inserts: Replacing worn-out table inserts with new ones can improve stability and reduce vibration during operation.

Performance Enhancements

- Installing a dust collection system to maintain a clean workspace and improve visibility.

- Adding a variable speed control for greater flexibility in cutting different materials.

- Utilizing precision alignment tools to ensure perfect cuts every time.

Exploring these alternatives can lead to a more efficient and enjoyable cutting experience, making it worthwhile to consider investing in quality replacements and upgrades.

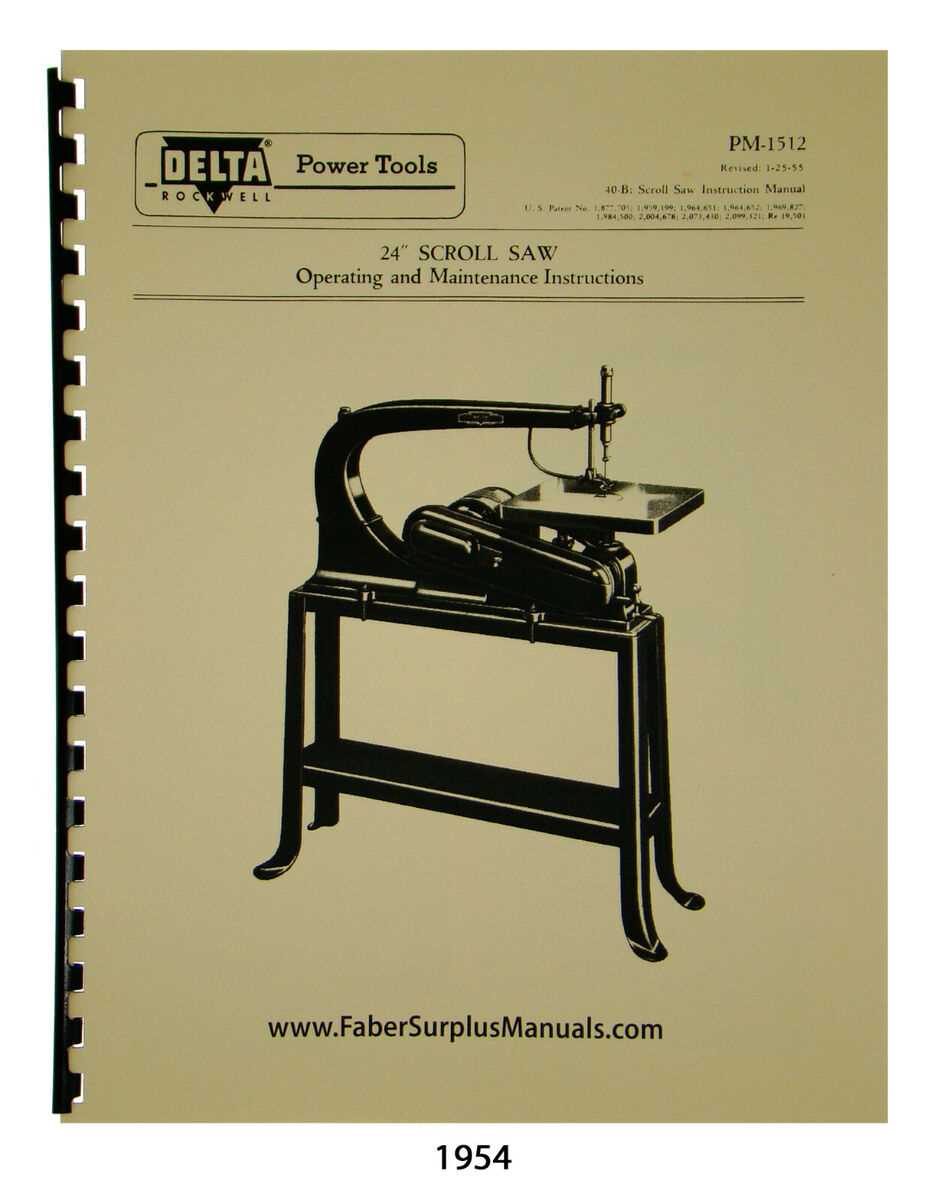

Resources for Parts Diagrams

Accessing accurate schematics and illustrations for tool components is essential for maintenance and repair. A variety of resources exist that can assist enthusiasts and professionals alike in locating detailed visual references for their equipment. These resources range from online platforms to printed manuals, ensuring users have multiple options for finding the information they need.

Online Platforms

- Manufacturer Websites: Many tool manufacturers provide downloadable manuals and detailed visuals on their official sites, offering reliable information directly from the source.

- Online Retailers: Websites that specialize in tool sales often include diagrams in product listings, making it easier to identify parts and components for various models.

- Community Forums: User-driven platforms frequently share experiences and resources, including links to diagrams and troubleshooting guides.

Printed Resources

- User Manuals: Hard copies of manuals typically contain visual aids, offering insights into component arrangement and functionality.

- Technical Books: Specialized literature on tool maintenance often features comprehensive illustrations, aiding in understanding complex machinery.

- Trade Magazines: Periodicals focused on woodworking and craftsmanship frequently publish articles that include diagrams and repair tips.

Finding Quality Repair Manuals

When it comes to maintaining or restoring machinery, having access to reliable instructional guides is essential. These resources provide detailed information on troubleshooting, assembly, and disassembly, ensuring that users can efficiently carry out repairs. The availability of high-quality manuals significantly enhances the repair process and minimizes the risk of errors.

To locate the best resources, consider several approaches. Online platforms often host a variety of technical documents, including user-created content. Furthermore, specialized forums and communities can offer valuable recommendations and even direct links to trusted manuals. It’s important to prioritize sources known for their accuracy and comprehensiveness.

| Source Type | Description | Example |

|---|---|---|

| Manufacturer Websites | Official resources providing original manuals and updates. | Company’s support page |

| Online Marketplaces | Platforms that allow users to purchase or download manuals. | eBay, Amazon |

| Community Forums | Discussion boards where enthusiasts share knowledge and resources. | Reddit, specialized hobbyist sites |

| Library Archives | Local or online libraries offering access to technical books and manuals. | Public library, Google Books |