In the realm of precision engineering, mastering the intricacies of essential machinery is crucial for optimal performance. This segment explores the various elements that contribute to the functionality and efficiency of a specific type of milling apparatus, highlighting their roles and interconnections.

Each individual component plays a pivotal role, influencing not only the overall operation but also the quality of the output produced. By examining the specific roles and arrangements of these mechanisms, users can enhance their understanding and maintenance practices.

Whether you are a seasoned professional or a newcomer, familiarizing yourself with these integral components is the ultimate key to unlocking enhanced capabilities and ensuring longevity in your machining endeavors. A thorough grasp of how these elements interact will facilitate more effective troubleshooting and upgrades in the future.

Overview of Bridgeport 2J Head

This section provides a comprehensive insight into a renowned milling machine assembly that is essential for precision engineering. The design and functionality of this mechanism enable efficient machining operations, making it a favorite among machinists.

Key features include robust construction and versatility, which allow it to handle a variety of tasks with accuracy. The mechanism is often praised for its ease of use and adaptability to different tools and attachments.

Understanding the components that make up this assembly is crucial for effective maintenance and operation. Each element plays a significant role in the overall performance, contributing to the machine’s reliability and efficiency.

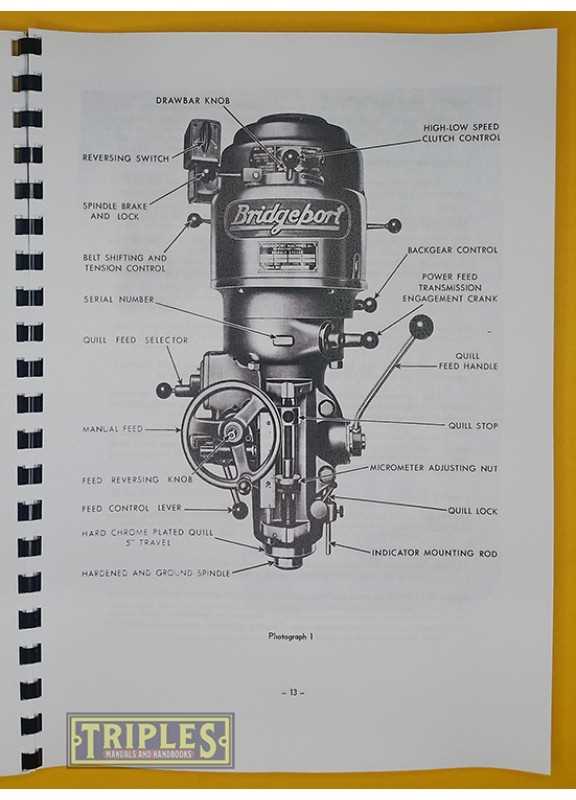

Key Components of the 2J Head

Understanding the essential elements of the 2J mechanism is crucial for anyone looking to optimize their machining capabilities. Each component plays a vital role in ensuring precision, efficiency, and overall performance. This section will explore the fundamental parts that contribute to the functionality and effectiveness of this machinery.

Functional Elements

The primary functional components include the spindle assembly, which facilitates rotation and cutting, and the feed mechanisms, responsible for movement along various axes. These parts work together seamlessly to achieve the desired machining outcomes.

Support Structures

Support structures such as the housing and base provide stability and alignment, ensuring that all moving elements operate smoothly. These foundational components are critical in maintaining the integrity and longevity of the entire system.

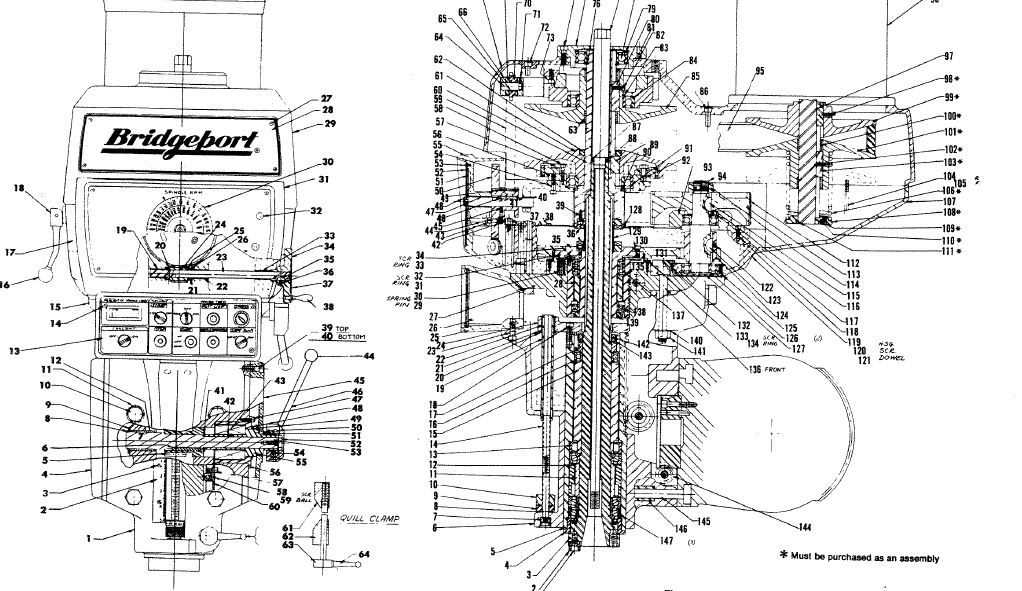

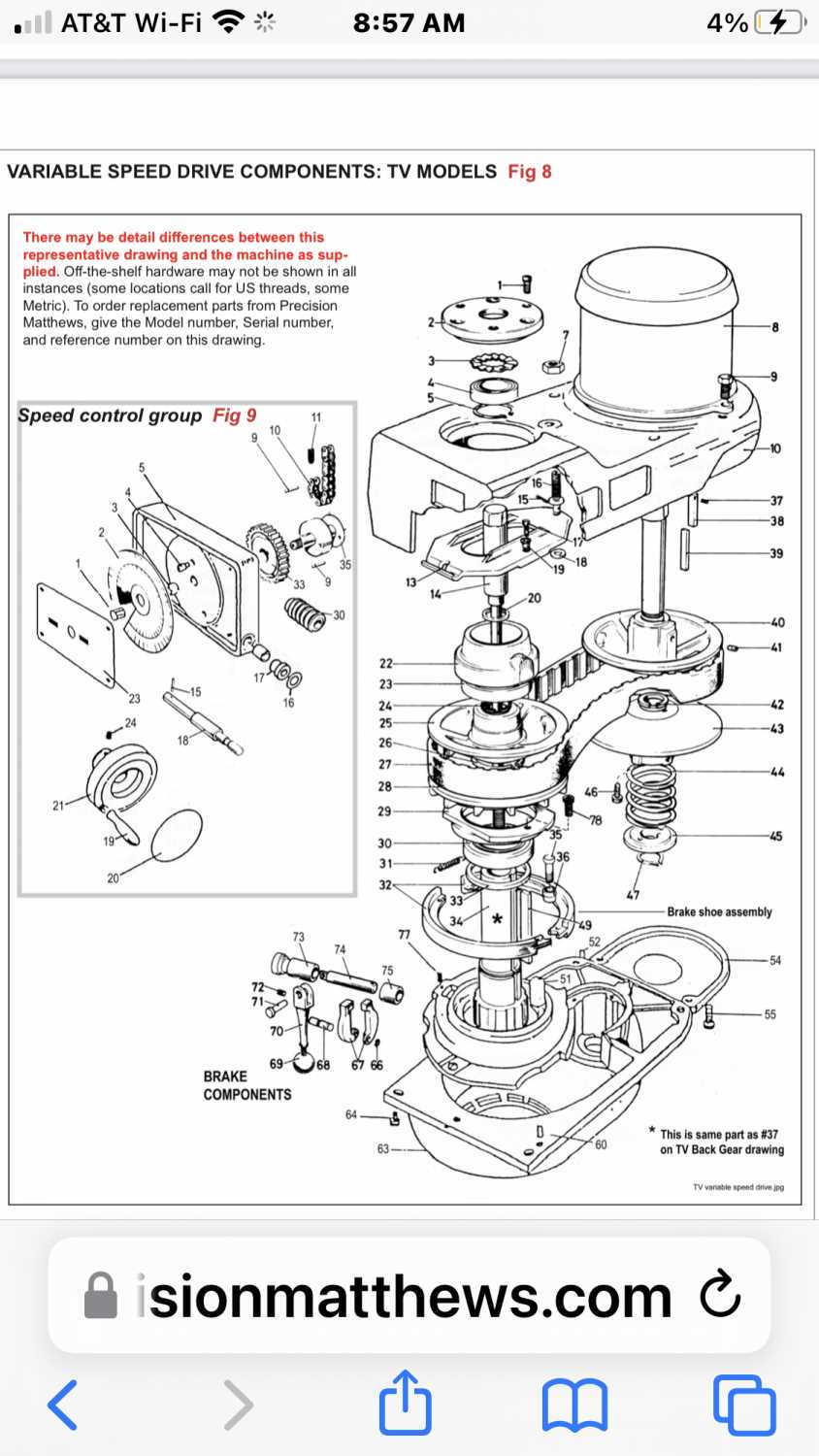

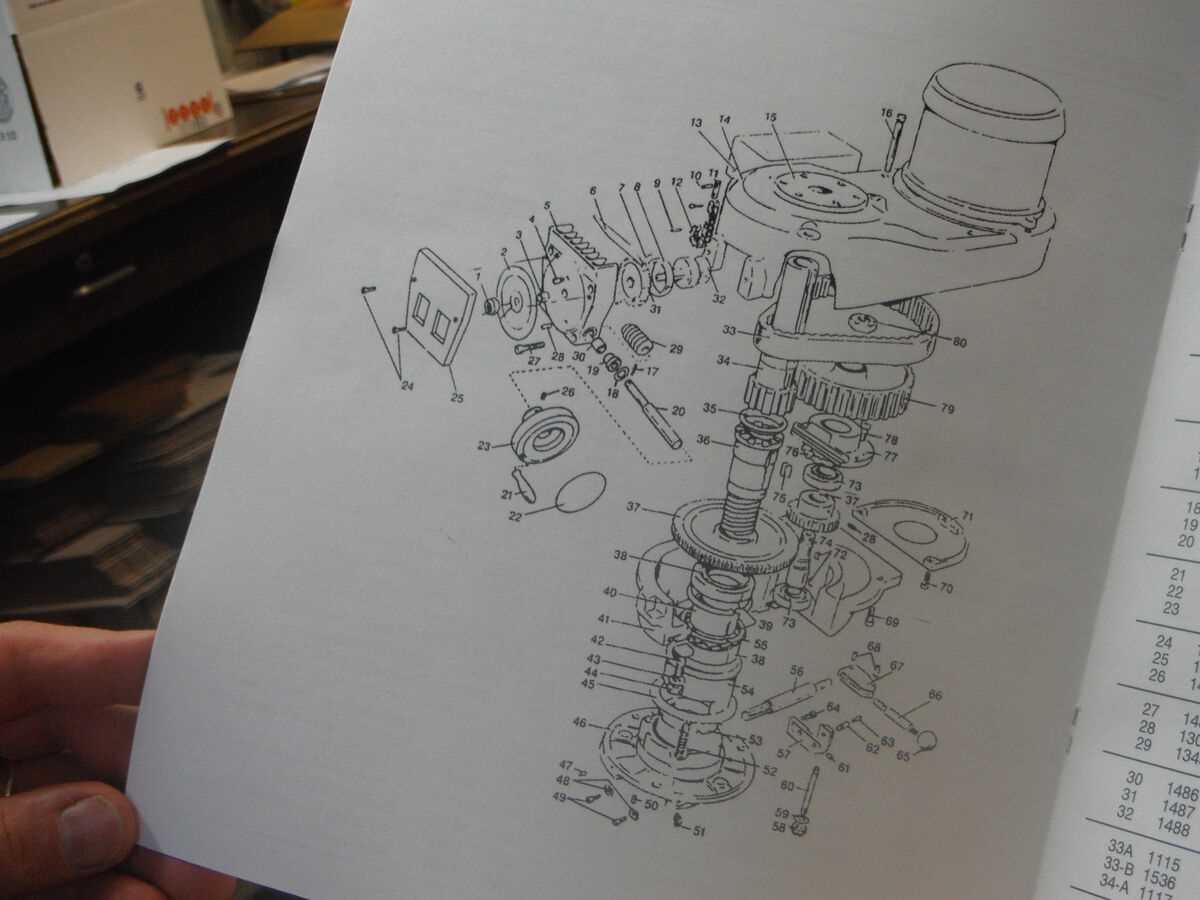

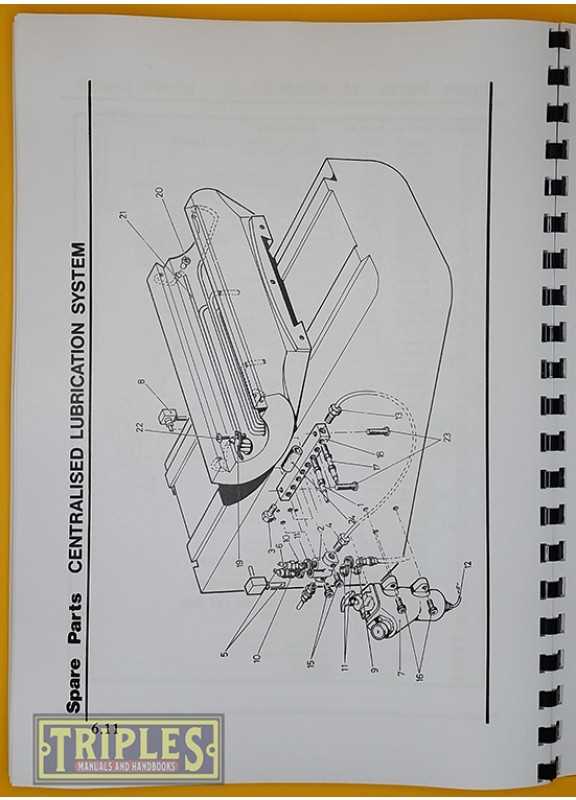

Understanding the Parts Diagram

Comprehending the visual representation of a mechanical assembly is crucial for effective maintenance and repair. It serves as a roadmap, guiding users through the intricate components and their interconnections. By familiarizing oneself with this schematic, individuals can troubleshoot issues, perform upgrades, and ensure optimal functionality.

Each element depicted in the illustration plays a vital role in the overall operation. Recognizing how these pieces fit together enhances both the understanding of the system’s mechanics and the ability to execute necessary adjustments. Attention to detail in this visual guide allows for informed decision-making when it comes to repairs or replacements.

Moreover, the layout often indicates the sequence of assembly, highlighting which components require removal before accessing others. This structured approach minimizes the risk of damage and streamlines the process, making it essential for both novice and experienced users alike. Mastery of this visual tool is an investment in efficiency and longevity of the machinery.

Common Issues with 2J Head Parts

When dealing with machining components, several challenges frequently arise that can hinder performance and efficiency. Identifying these common problems early can lead to more effective maintenance and prolong the lifespan of the machinery.

Common Problems

| Issue | Description |

|---|---|

| Wear and Tear | Over time, moving components may experience significant degradation, impacting accuracy. |

| Alignment Issues | Improper alignment can lead to uneven wear and operational inefficiencies. |

| Overheating | Excessive heat can warp components, causing further mechanical failure. |

Maintenance Tips

Regular inspections and timely servicing can mitigate many of these issues. Ensuring proper lubrication and adjusting tensions can significantly enhance the functionality of the machine.

Maintenance Tips for Longevity

Ensuring the extended lifespan of machinery involves consistent care and attention to detail. Regular maintenance not only enhances performance but also prevents unexpected breakdowns, ultimately saving time and resources.

Routine Inspection

Conduct frequent assessments to identify wear and tear. This proactive approach allows for timely repairs and minimizes the risk of larger issues.

Lubrication Practices

Proper lubrication is essential for smooth operation. Utilize appropriate lubricants and apply them according to the manufacturer’s recommendations to reduce friction and prevent corrosion.

| Task | Frequency |

|---|---|

| Visual Inspection | Weekly |

| Lubrication | Monthly |

| Parts Replacement | As Needed |

Repairing Worn or Damaged Parts

Over time, components in any machinery can suffer from wear and tear, leading to decreased performance and potential failure. Addressing these issues promptly is crucial to maintain efficiency and prolong the lifespan of the equipment. Understanding the common problems and effective repair techniques can save both time and resources.

Common Issues and Solutions

Various factors contribute to the degradation of machinery elements, including friction, environmental conditions, and improper usage. Identifying the specific issue is the first step in implementing an effective repair strategy.

| Common Issue | Potential Solution |

|---|---|

| Excessive wear | Regrind or replace affected surfaces |

| Cracks or fractures | Welding or using epoxy fillers |

| Loose connections | Tightening or replacing fasteners |

| Corrosion | Sandblasting and applying protective coatings |

Preventative Measures

To minimize future wear and damage, regular maintenance and inspections are essential. Keeping components clean, lubricated, and properly aligned can significantly enhance their durability and performance. Implementing a proactive maintenance schedule will help identify potential issues before they escalate, ensuring the equipment remains in optimal working condition.

Tools Required for Parts Replacement

Replacing components in a milling machine requires a specific set of instruments to ensure efficiency and accuracy. Using the correct tools minimizes the risk of damage and enhances the overall performance of the equipment.

- Wrenches: Essential for loosening and tightening bolts.

- Screwdrivers: Necessary for removing screws of various sizes.

- Torque Wrench: Ensures that fasteners are tightened to the correct specifications.

- Allen Keys: Required for hexagonal bolts and screws.

- Pliers: Useful for gripping and manipulating small parts.

- Measuring Tools: Calipers and micrometers are crucial for precision measurements.

Having these tools readily available streamlines the process, allowing for a smoother workflow during maintenance tasks.

Upgrading Your Bridgeport 2J Head

Enhancing the performance and functionality of your milling apparatus can lead to improved efficiency and precision. Upgrades can involve various components that contribute to better machining capabilities and overall operational effectiveness.

First and foremost, consider replacing the existing motor with a more powerful option. This upgrade can provide increased torque and speed, allowing for more demanding tasks. Additionally, exploring different spindle configurations can significantly affect the range of tooling you can use, enhancing versatility.

Another critical aspect involves upgrading the control system. Implementing a modern digital readout or CNC conversion can transform the way you interact with your machine, making it easier to achieve the ultimate accuracy. Furthermore, investing in high-quality tooling can yield superior finishes and prolong tool life.

Lastly, ensure that maintenance practices are up to date. Regularly checking and replacing worn components can prevent costly downtime and keep your equipment running smoothly. With these improvements, you’ll be well on your way to maximizing your machine’s potential.

Comparing 2J Head to Other Models

This section explores the nuances between the 2J variant and its contemporaries, highlighting their strengths and weaknesses. Understanding these differences can guide users in selecting the most suitable option for their specific machining needs.

Performance Characteristics

The 2J model is recognized for its robust performance, but how does it stand against other designs? While some models prioritize speed, others excel in precision. A comprehensive comparison reveals various aspects such as durability, adaptability, and efficiency.

Cost Analysis

When considering investment, evaluating the financial implications of different models is crucial. The 2J may come at a premium, but its long-term benefits often justify the expense compared to alternatives.

| Model | Performance | Cost | Durability |

|---|---|---|---|

| 2J | High | $$$ | Excellent |

| Model A | Medium | $$ | Good |

| Model B | High | $$$ | Very Good |

Finding Replacement Parts Online

When it comes to maintaining and repairing machinery, locating the right components can be a daunting task. The internet has become an invaluable resource for enthusiasts and professionals alike, providing access to a vast array of options. Whether you’re seeking specific items or general supplies, understanding how to navigate online marketplaces can streamline the process and save both time and money.

Utilizing Reliable Sources

Begin your search by identifying trustworthy vendors. Established online retailers often offer a wider selection and reliable customer service. Look for platforms that specialize in industrial equipment or tools, as they typically have a more comprehensive inventory. Additionally, reading reviews and checking ratings can help ensure that you’re purchasing from a reputable source.

Searching Effectively

Use precise terminology when searching for the components you need. Familiarize yourself with alternative names or model numbers, as this can broaden your search results. Utilizing filters and sorting options on websites can also help refine your choices, making it easier to find exactly what you are looking for. Don’t hesitate to reach out to sellers for further information about compatibility and specifications.

In summary, leveraging online resources effectively can greatly enhance your chances of finding the right components for your machinery. By focusing on reliable sources and employing strategic search methods, you can ensure a smoother and more successful procurement process.

Expert Recommendations for Users

When working with intricate machinery, understanding essential components is crucial for optimal performance and longevity. Users are encouraged to familiarize themselves with specific features and best practices to ensure smooth operation and maintenance.

Regular Maintenance

Consistent upkeep is vital. Regularly inspect for wear and tear, and replace components as needed to prevent larger issues. Establish a routine that includes cleaning and lubrication to enhance efficiency.

Consult Technical Resources

Utilize technical manuals and online forums for guidance. Engaging with experienced users can provide valuable insights and troubleshooting techniques, helping to maximize the effectiveness of your equipment.

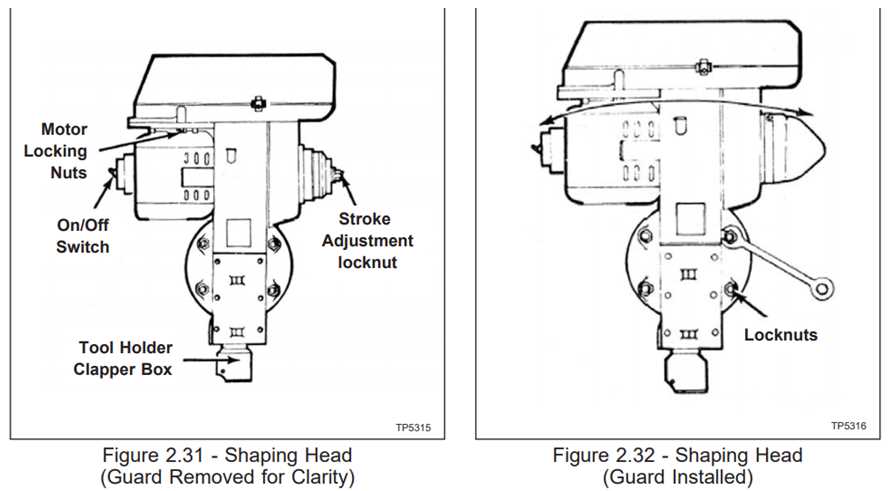

Visual Guides to Assembly

This section aims to provide clear and detailed visual representations to facilitate the assembly process of various mechanical components. By using diagrams and illustrations, users can easily understand each step, ensuring precision and efficiency in their work.

Step-by-Step Visual Instructions

Utilizing a series of images, each phase of the assembly is broken down into manageable steps. These guides highlight essential elements, allowing for better comprehension and fewer errors during the construction process.

Key Components Overview

A comprehensive visual overview of critical elements involved in assembly helps users recognize and differentiate between various pieces. This knowledge is vital for achieving the ultimate functionality and performance of the machinery.

Frequently Asked Questions About 2J Head

This section addresses common inquiries regarding a specific component utilized in various machinery. Understanding these aspects can greatly enhance performance and maintenance efficiency, making it essential for users and enthusiasts alike.

What are the key features of the 2J component?

The 2J component is renowned for its durability and precision engineering. Users appreciate its compatibility with various setups, allowing for optimal customization and efficiency in operation.

How can I maintain my 2J component effectively?

Regular inspections and proper lubrication are crucial for the longevity of the 2J component. Ensure to follow the manufacturer’s guidelines for maintenance to avoid any potential issues.