In the world of machinery and tools, having a clear grasp of the individual elements that make up your device is crucial for optimal performance and maintenance. Each component plays a specific role, contributing to the overall functionality and efficiency of the system. Familiarity with these elements can significantly enhance your ability to troubleshoot issues and carry out necessary repairs.

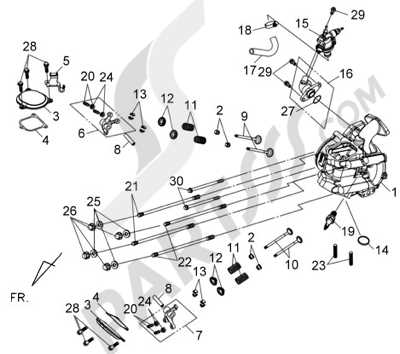

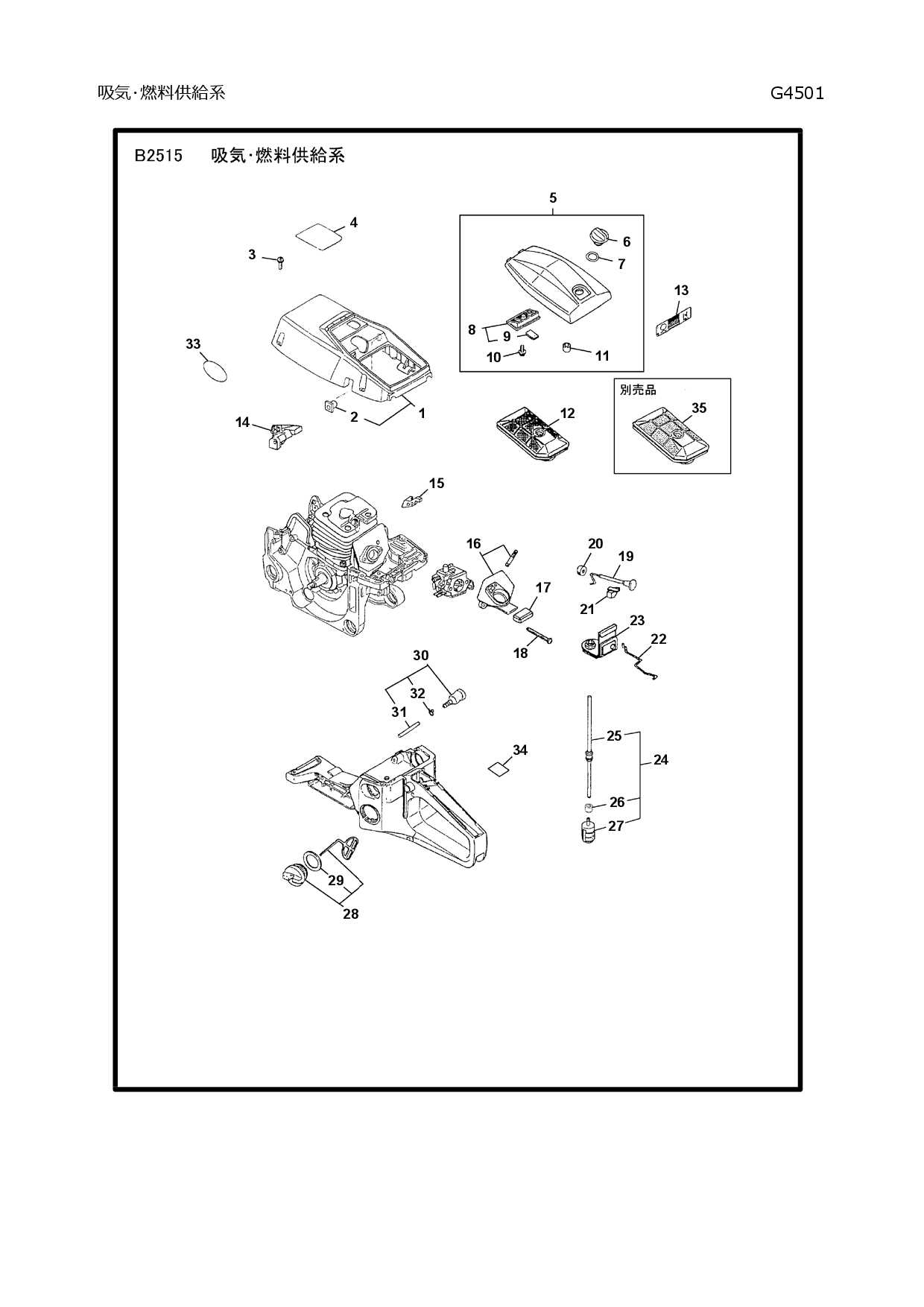

Visual representations of these components serve as invaluable resources for users, allowing for quick identification and understanding of how each part interacts with others. Whether you are a novice or an experienced user, these visual guides can simplify complex assemblies and provide clarity in maintenance procedures.

By exploring the intricate layout of your machinery, you can gain insights into its operation and longevity. This knowledge not only empowers you to perform routine checks but also prepares you for unexpected challenges, ensuring that your equipment remains in top working condition.

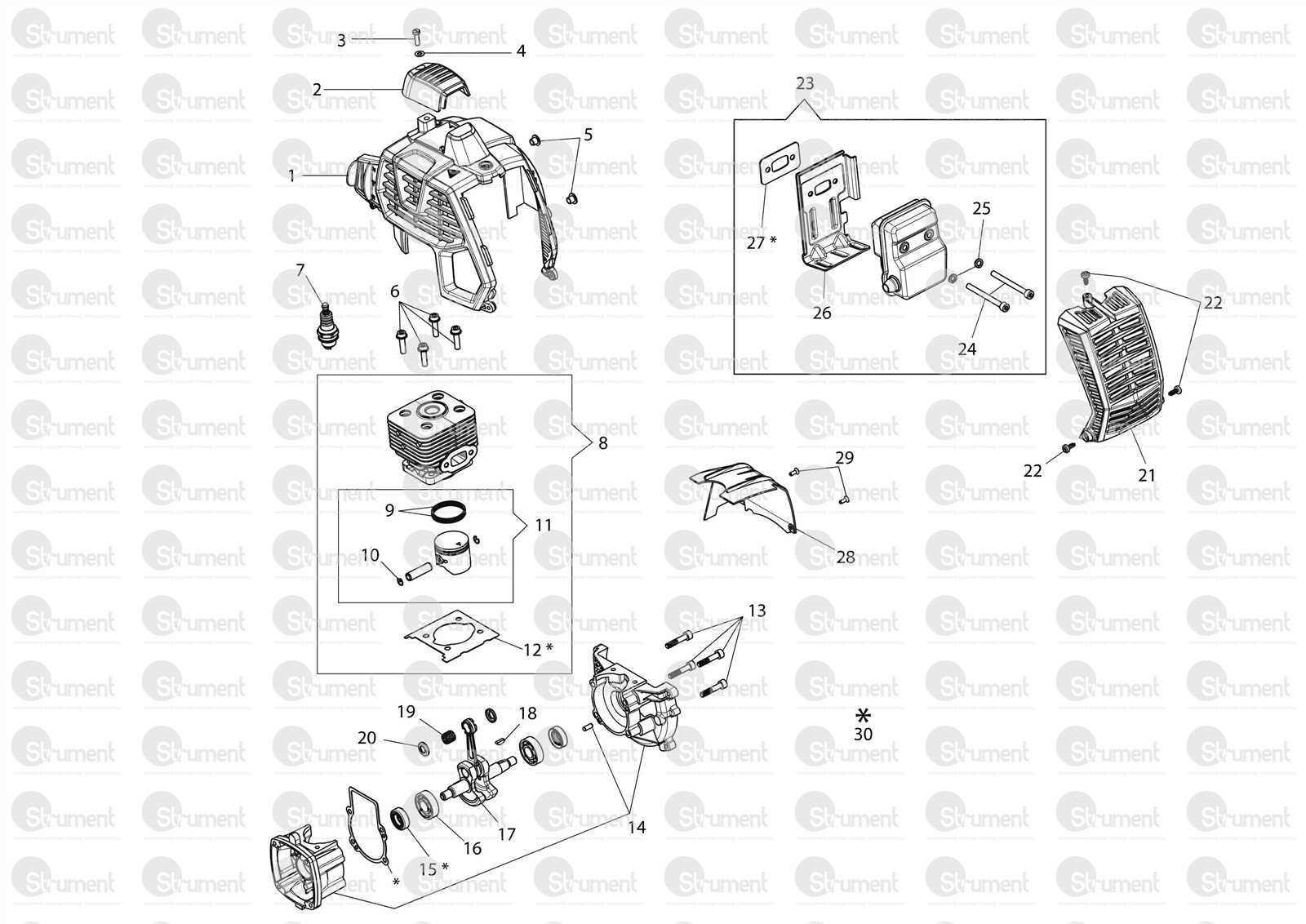

Pp5020av Parts Overview

This section offers a comprehensive look at the components essential for the functioning of the model. Each element plays a crucial role, contributing to overall performance and efficiency. Understanding these elements can enhance maintenance and troubleshooting efforts.

Key Components: The primary sections include the engine assembly, fuel system, and electrical setup. Each category contains various individual items that are vital for seamless operation.

Maintenance Tips: Regular inspection and timely replacement of worn-out elements can prevent major issues and extend the lifespan of the equipment. Familiarity with the essential components will enable users to manage upkeep more effectively.

Understanding the Pp5020av Model

This section delves into the intricacies of a specific equipment model, emphasizing its design and functionality. By exploring its various components and their interrelations, one can gain a comprehensive understanding of how this machinery operates effectively within its intended applications.

Key Features

The model is distinguished by several notable characteristics that enhance its performance and user experience. Each feature contributes to its overall efficiency, making it suitable for various tasks.

| Feature | Description |

|---|---|

| Robust Construction | Designed for durability, ensuring longevity even under demanding conditions. |

| Advanced Technology | Incorporates modern innovations that improve functionality and ease of use. |

| Versatile Applications | Suitable for a wide range of tasks, making it adaptable to different environments. |

Maintenance Considerations

Regular upkeep is essential to maintain optimal performance. Understanding the maintenance requirements helps in prolonging the equipment’s lifespan and ensuring reliable operation.

Importance of Accurate Parts Diagrams

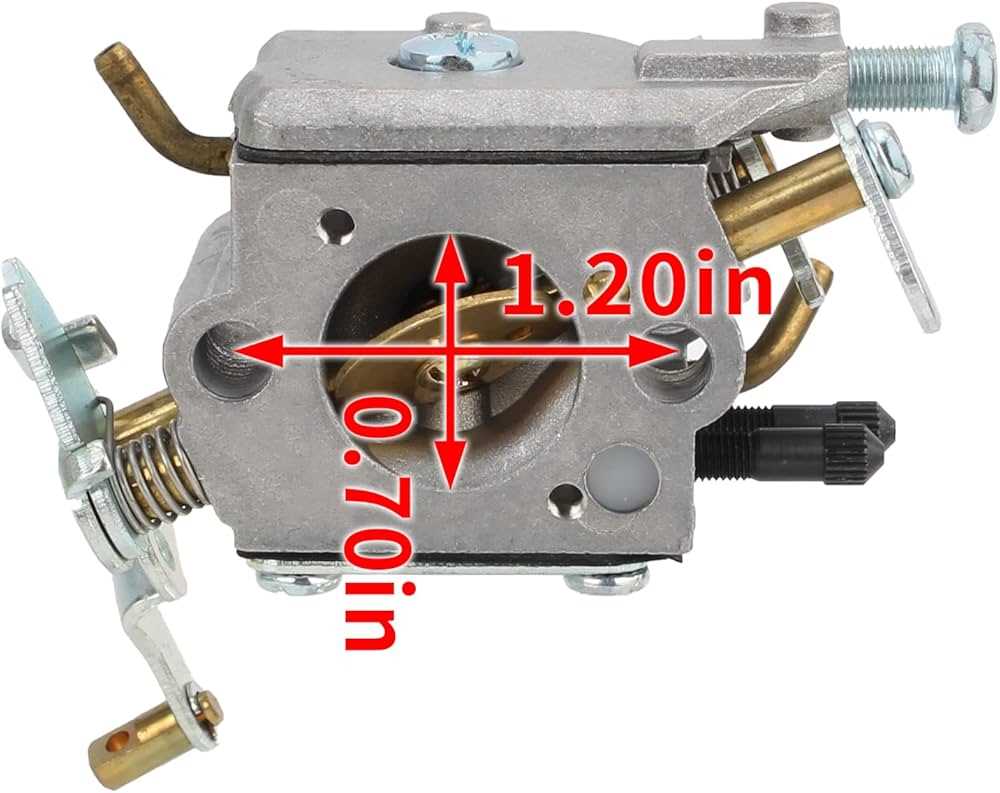

Precise representations of components play a crucial role in the maintenance and repair of machinery. They serve as essential tools that facilitate understanding, enabling technicians to identify each piece effectively. Without clarity in these visual aids, the risk of errors during assembly or disassembly increases significantly.

Having a well-detailed visual reference helps streamline the repair process, ensuring that all necessary elements are accounted for. This reduces downtime and enhances efficiency, as technicians can quickly locate and replace faulty items. Furthermore, accurate representations contribute to improved communication among team members, allowing for better collaboration and knowledge sharing.

| Benefits | Description |

|---|---|

| Efficiency | Speeds up repair and maintenance tasks by providing clear guidance. |

| Accuracy | Minimizes mistakes during assembly, reducing the likelihood of malfunction. |

| Collaboration | Enhances teamwork by ensuring everyone has the same reference for repairs. |

| Training | Serves as an educational tool for new technicians, helping them understand component functions. |

Main Components of Pp5020av

This section explores the essential elements that contribute to the functionality and efficiency of the machine. Each component plays a critical role, ensuring that the device operates smoothly and effectively.

Engine: The heart of the system, responsible for powering all operations and ensuring reliable performance.

Fuel Tank: This reservoir stores the necessary fuel, enabling prolonged usage without frequent refills.

Air Filter: Vital for maintaining optimal airflow, it prevents debris from entering the engine, enhancing longevity and efficiency.

Exhaust System: This assembly directs emissions away from the engine, contributing to better performance and reduced environmental impact.

Blade Assembly: The cutting mechanism that ensures precision and effectiveness in various tasks, crucial for achieving desired results.

Control Handle: Provides the user with the ultimate command over the device, allowing for adjustments and maneuverability during operation.

How to Read Parts Diagrams

Understanding visual representations of components is crucial for effective assembly and maintenance. These illustrations simplify complex structures, allowing users to identify and locate individual elements with ease. Mastering the reading of these graphics enhances efficiency and accuracy in various tasks.

Key Elements to Identify

- Labels: Look for names and numbers associated with each component.

- Connections: Observe lines indicating how parts interact or connect.

- Legend: Refer to a key that explains symbols used in the illustration.

Steps to Interpret Effectively

- Start by familiarizing yourself with the overall layout.

- Identify key components by following labels.

- Trace connections to understand the relationship between elements.

- Cross-reference with manuals for detailed descriptions.

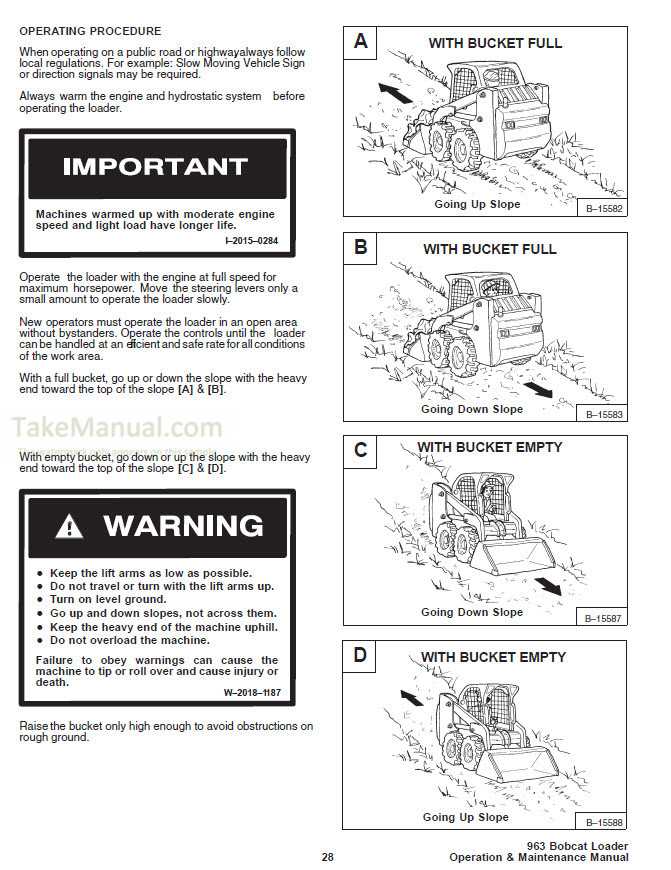

Common Issues and Solutions

In any mechanical system, users often encounter a variety of challenges that can hinder performance. Understanding these common problems, along with their solutions, is crucial for maintaining efficiency and prolonging the lifespan of the equipment.

Overheating is a frequent concern that can arise due to insufficient cooling or clogged air filters. To address this issue, regularly clean or replace filters and ensure proper airflow around the unit. Additionally, checking coolant levels can prevent overheating in engines.

Starting difficulties are another common issue, often linked to battery problems or fuel delivery failures. Regularly inspect battery connections for corrosion and ensure the fuel system is free of blockages. If the ignition system shows signs of wear, replacing spark plugs may also resolve the issue.

Unusual noises can indicate internal wear or damage. Listening for grinding or rattling sounds is essential. Regular maintenance, including lubrication of moving parts and tightening loose components, can significantly reduce these noises and improve overall functionality.

Vibrations during operation can signal an imbalance or misalignment. Check for loose mounts and ensure all components are securely fastened. Balancing rotating parts and realigning shafts can also help eliminate excessive vibrations.

By identifying these typical issues and applying the suggested solutions, users can enhance the reliability and performance of their equipment, ensuring it operates smoothly for years to come.

Where to Find Replacement Parts

Locating suitable components for your equipment can be a straightforward process if you know where to look. There are various resources available that can help you find exactly what you need to keep your machine in optimal condition.

- Manufacturer’s Website: The official site often provides a comprehensive catalog of available components along with detailed descriptions.

- Authorized Dealers: Contacting local dealers can be beneficial. They typically have access to a wide range of items and can offer expert advice.

- Online Retailers: Websites dedicated to selling equipment components often have user-friendly search functions. Look for customer reviews to gauge the quality of the products.

- Repair Shops: Local repair professionals often stock or can order components for you. They might also provide installation services.

- Forums and Online Communities: Engaging with fellow users in online forums can yield useful insights and recommendations for sourcing components.

Exploring these avenues will increase your chances of finding the right items efficiently. Always verify the compatibility of components with your specific model before making a purchase.

Tools Required for Assembly

To successfully bring together components of your equipment, having the right tools on hand is essential. Utilizing the appropriate instruments not only streamlines the process but also ensures that each piece is securely and correctly installed. Below is a list of recommended tools that will aid in the assembly procedure.

Essential Tools

- Flathead screwdriver

- Phillips screwdriver

- Socket wrench set

- Allen wrench set

- Pliers

- Tape measure

Additional Supplies

- Lubricant for moving parts

- Cleaning cloths

- Protective gloves

- Safety goggles

Having these tools ready will significantly enhance your assembly experience and help achieve a more efficient and effective outcome.

Maintenance Tips for Longevity

Ensuring the extended life of your equipment requires consistent care and attention. Implementing effective maintenance practices can significantly enhance performance and reduce the likelihood of costly repairs. Understanding the intricacies of your machinery is essential for achieving optimal functionality.

Regular Cleaning

Keep your tools clean to prevent dirt and debris from affecting performance. Regularly remove any build-up to maintain efficiency. A clean environment also contributes to safer operation.

Periodic Inspections

Conduct frequent checks on key components to identify wear or damage early. Look for signs of corrosion or loosening parts. Addressing issues promptly can avert more significant problems down the line.

Upgrading Your Pp5020av

Enhancing your equipment can significantly improve its performance and longevity. By integrating superior components and innovative technologies, you can achieve optimal functionality and efficiency. This section will explore the best practices for elevating your device.

Choosing Quality Components

Investing in high-quality elements is crucial. Look for durable materials and reliable manufacturers that ensure longevity. Research customer reviews and expert opinions to guide your selection, and consider the ultimate compatibility with your current setup.

Implementing Modern Technologies

Incorporating the latest technologies can provide enhanced features. Consider upgrades that improve usability and performance, such as advanced controls or better power management. Always ensure that these advancements align with your specific needs for the best results.

Comparing Pp5020av with Similar Models

In the world of outdoor power equipment, understanding the nuances between different models is essential for making informed decisions. This section delves into how a specific tool compares with its contemporaries, focusing on features, performance, and usability that cater to various user needs.

When assessing comparable tools, one can notice that many share similar specifications but differ in design and functionality. For instance, while some models emphasize lightweight construction for ease of handling, others prioritize robust power output for more demanding tasks. Performance metrics, such as engine capacity and fuel efficiency, play a crucial role in determining suitability for specific applications.

Another critical aspect to consider is ergonomics. Some devices are designed with user comfort in mind, featuring adjustable handles and reduced vibration, while others might not offer the same level of user-friendliness. Durability also varies among models, with certain brands employing higher-quality materials that enhance longevity and reduce maintenance needs.

Ultimately, the choice between these options depends on individual requirements and preferences. By examining the strengths and weaknesses of each model, users can better align their selection with the tasks at hand, ensuring a more satisfying and efficient experience.

Expert Recommendations for Users

For individuals seeking to optimize their experience with equipment maintenance, following expert guidance is essential. Understanding the intricacies of components can greatly enhance functionality and longevity. Here are some tailored suggestions to ensure effective management and performance of your device.

| Recommendation | Description |

|---|---|

| Regular Inspections | Conduct routine checks to identify wear and tear early on. |

| Quality Replacement | Always opt for high-quality substitutes when necessary to maintain efficiency. |

| Consult the Manual | Refer to the user guide for specific details on assembly and care. |

| Professional Assistance | Seek help from qualified technicians for complex repairs. |