The intricate design of specialized machinery often requires a deep understanding of its various elements. Each component plays a critical role in the overall functionality, ensuring that operations run smoothly and efficiently. This article aims to illuminate the essential aspects of a particular piece of equipment, focusing on how each segment contributes to its performance.

In exploring the structure and layout of this model, we will delve into the intricacies of its assembly. By breaking down the mechanisms involved, we can gain insight into how these individual parts interact and function harmoniously. This knowledge is invaluable for maintenance, repair, and optimization of the equipment.

Ultimately, having access to a comprehensive overview of the machinery’s components allows operators and technicians to address issues proactively. Understanding these connections fosters better decision-making, enhancing both productivity and longevity in the field.

Ditch Witch 1330 Overview

This section provides an in-depth look at a versatile piece of machinery widely used in construction and utility projects. Designed for efficiency and durability, it excels in various applications, making it a valuable asset on job sites.

Key Features: The equipment boasts advanced technology that enhances performance while ensuring ease of operation. Its robust build allows it to tackle tough terrains, while ergonomic design principles prioritize user comfort.

Applications: This machine is particularly effective in tasks such as trenching, digging, and utility installation. Its adaptability to different environments makes it suitable for both residential and commercial projects.

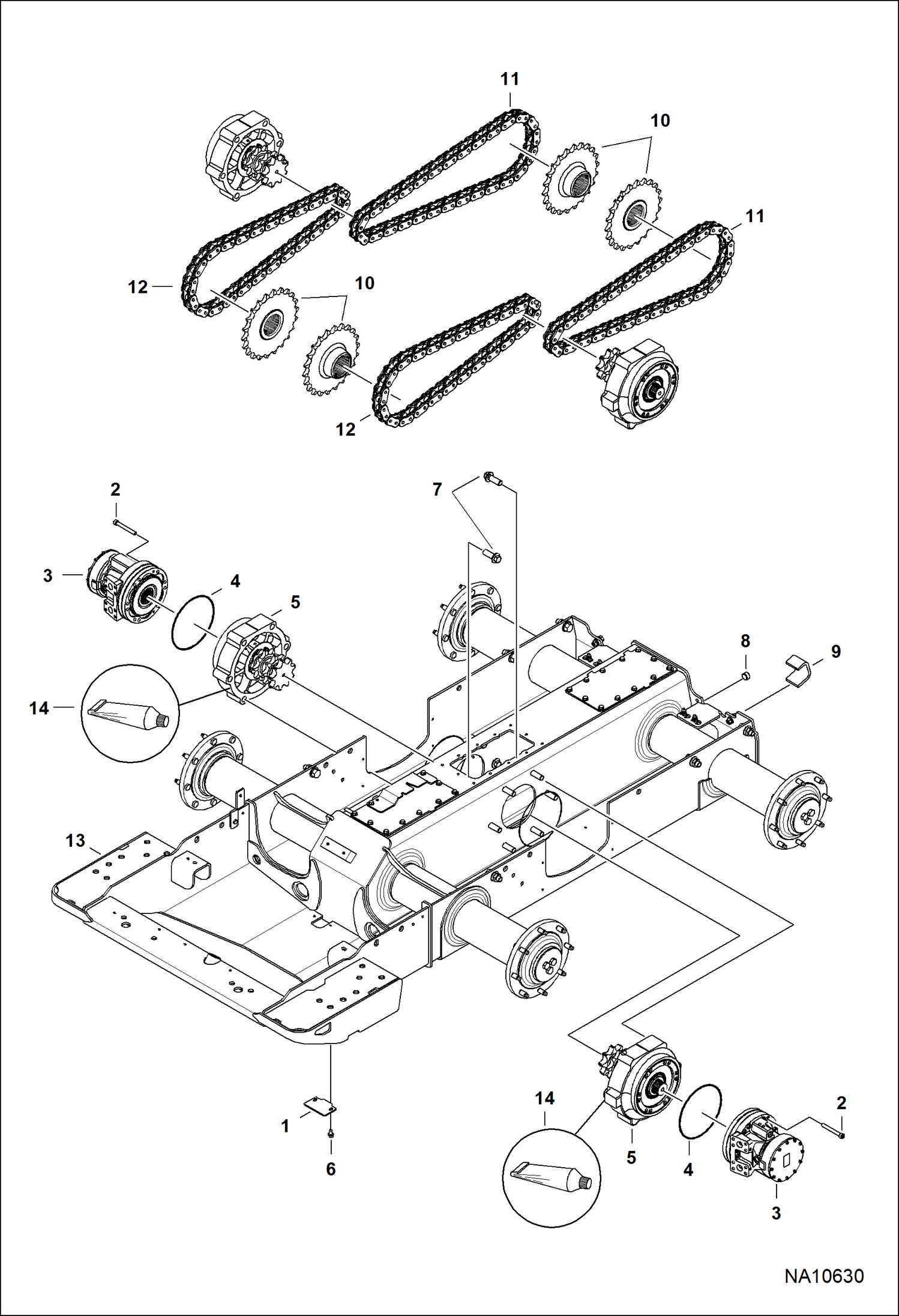

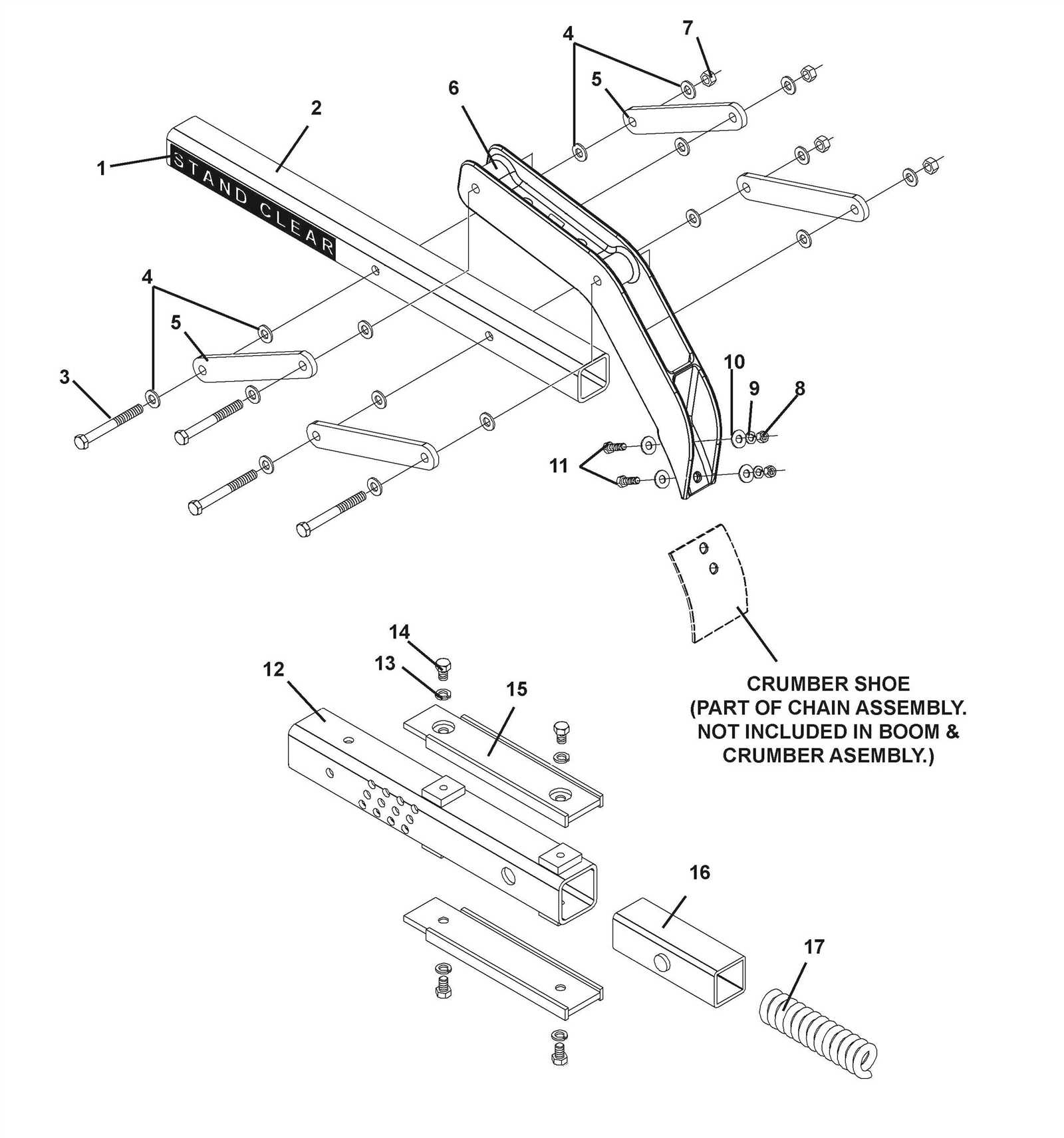

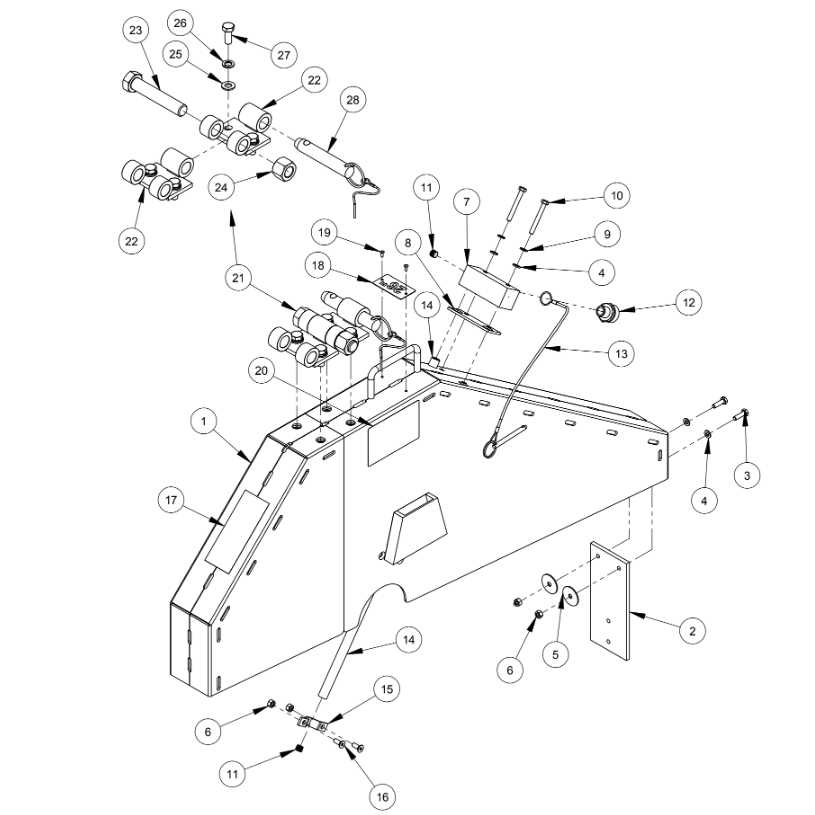

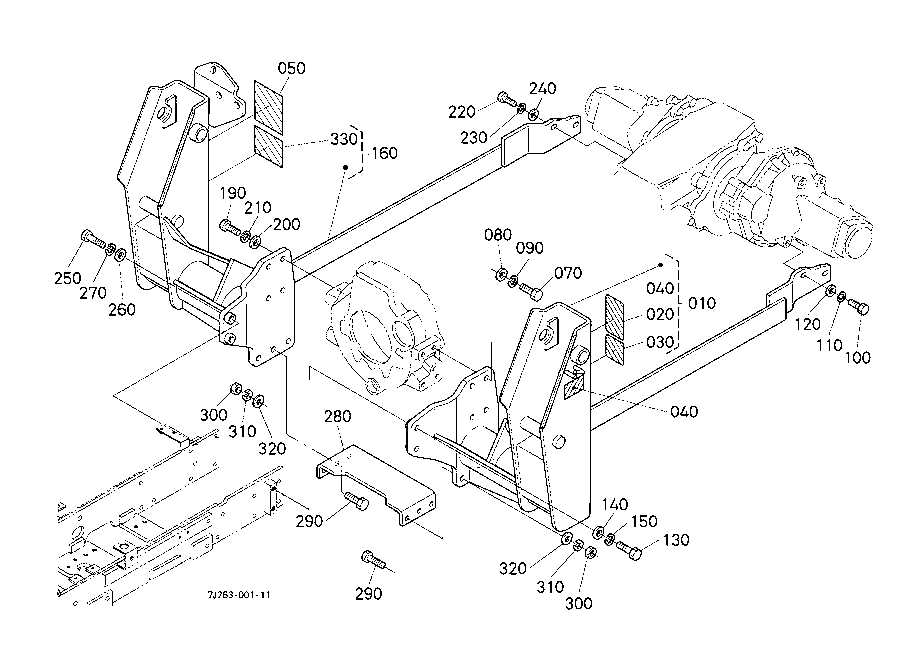

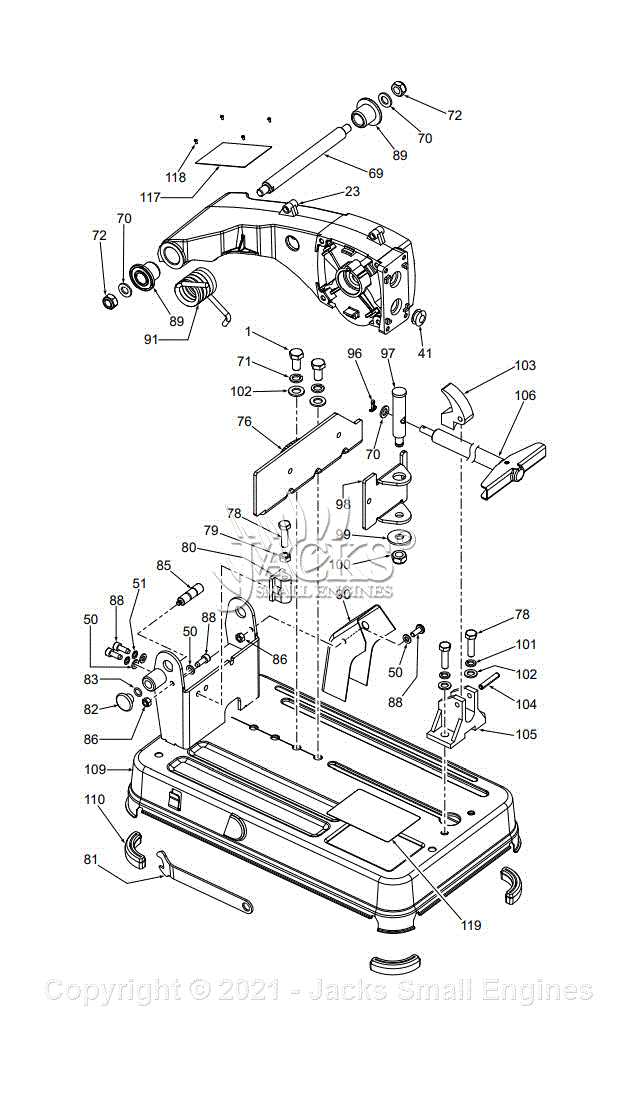

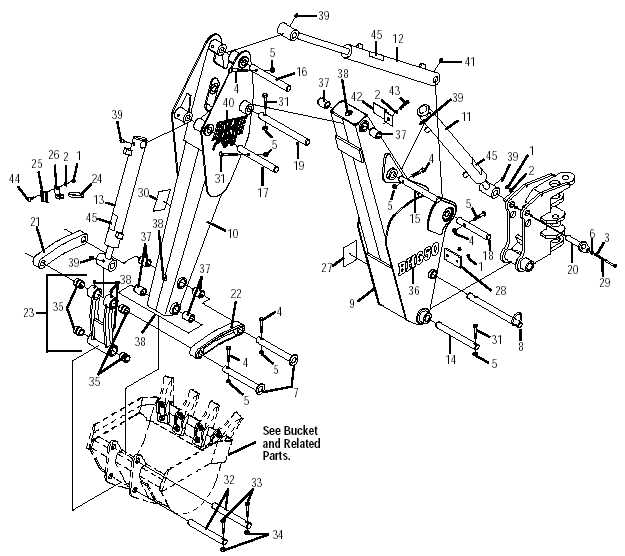

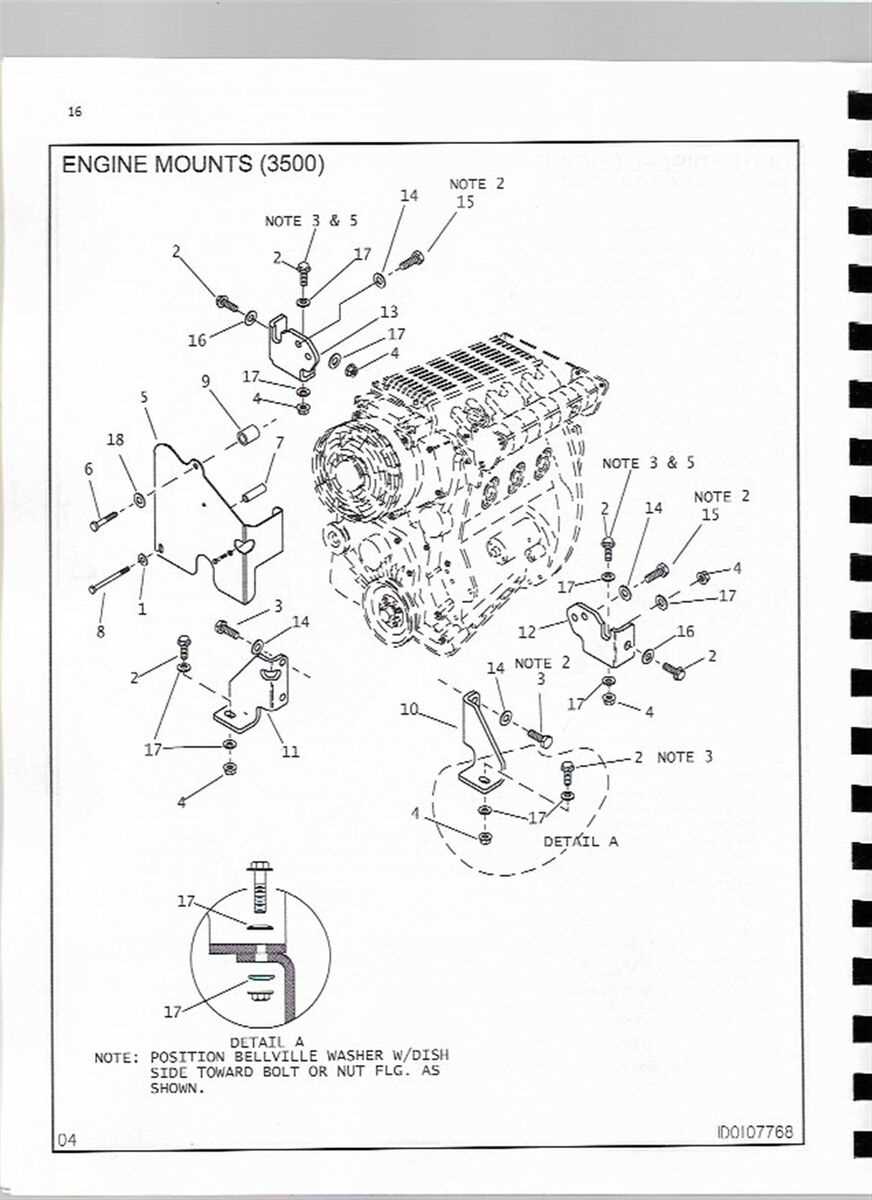

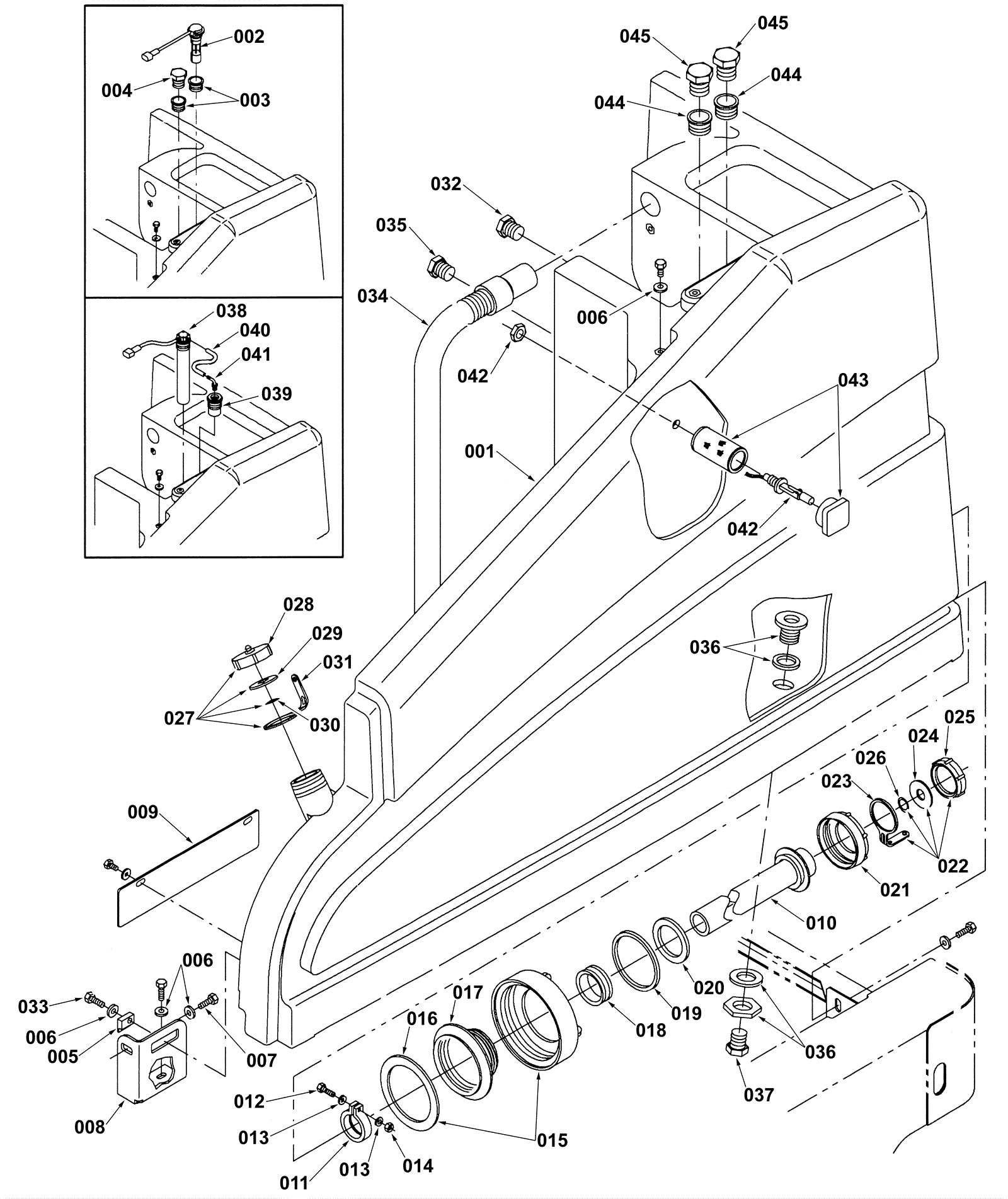

Understanding the Parts Diagram

Exploring the visual representation of components in machinery is essential for effective maintenance and repair. These illustrations serve as a guide, allowing users to identify various elements and comprehend their functions within the overall system. A thorough understanding enables technicians to troubleshoot issues more efficiently and ensures the longevity of the equipment.

Key Components

Every illustration typically highlights crucial elements such as the engine, transmission, and hydraulic systems. Recognizing these parts and their interconnections can significantly impact operational efficiency and safety during usage.

Benefits of Familiarity

Being well-versed in these visuals aids in streamlining repair processes and reducing downtime. Familiarity with each component fosters confidence in handling machinery, ultimately leading to improved performance and reduced operational costs.

Key Components of the Ditch Witch

The effectiveness of this underground excavation machine relies on several essential elements that work harmoniously to ensure optimal performance. Understanding these components can enhance maintenance practices and improve operational efficiency.

Drive System

The drive system is pivotal for the movement and maneuverability of the equipment. It consists of a powerful engine that generates the necessary torque, allowing for seamless transitions across various terrains.

Cutting Tools

Equipped with specialized cutting implements, this machinery can efficiently bore through diverse soil types. These tools are designed for durability, ensuring they withstand rigorous use while delivering ultimate precision.

Common Issues with Ditch Witch 1330

Operating machinery can lead to a variety of complications that users must address to maintain efficiency and safety. Understanding the typical challenges can help in troubleshooting and preventing significant downtime.

Hydraulic System Failures: One frequent problem is related to the hydraulic components, which can cause reduced performance. Regular checks on fluid levels and seals can prevent major breakdowns.

Engine Troubles: Issues such as overheating or poor starting can stem from inadequate maintenance or fuel system problems. Regular servicing is essential to avoid these scenarios.

Track Wear: Excessive wear on tracks can result from rough terrain or improper use. Routine inspections and timely replacements are crucial for optimal performance.

Electrical Failures: Malfunctions in the electrical system can hinder operation. Ensuring all connections are secure and components are functioning can mitigate these risks.

By being aware of these common challenges, operators can delve into solutions more effectively, leading to a smoother experience with their equipment.

Maintenance Tips for Optimal Performance

Ensuring peak functionality of your equipment requires regular attention and care. By implementing a consistent maintenance routine, you can enhance durability, improve efficiency, and minimize the risk of unexpected breakdowns. The following guidelines will help you maintain your machinery in top condition.

Regular Inspections

Lubrication and Cleaning

Keeping moving parts well-lubricated is crucial for reducing friction and wear. Regularly clean debris from the machinery to prevent clogs and overheating. Pay particular attention to filters, which should be replaced according to the manufacturer’s recommendations.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect hydraulic systems | Monthly | Check for leaks and performance issues. |

| Change oil and filters | Every 100 hours | Use high-quality fluids as recommended. |

| Clean air filters | Every 50 hours | Replace if heavily soiled. |

| Check belts and hoses | Every 200 hours | Look for cracks or signs of wear. |

How to Read the Parts Diagram

Understanding a visual representation of components is essential for efficient maintenance and repairs. This guide will help you navigate the layout and symbols typically found in such illustrations, allowing for quick identification of items and their functions.

Key Components and Symbols

Familiarize yourself with the various elements depicted in the illustration. Each icon or label corresponds to a specific component, often accompanied by a reference number. Pay close attention to any legend provided, as it explains the meaning behind the symbols used.

Locating Specific Items

To find a particular element, start by identifying its reference number. Cross-referencing this number with the accompanying list will provide you with the ultimate information needed for sourcing replacements or performing repairs. A methodical approach ensures you don’t miss crucial details.

Identifying Replacement Parts Easily

Understanding how to locate and identify necessary components is crucial for efficient maintenance and repair. With the right resources and knowledge, you can streamline the process and ensure your equipment functions optimally. This section will guide you through effective strategies to recognize and source the elements you need.

Utilize Online Resources: The internet is a treasure trove of information. Manufacturer websites often provide detailed manuals and catalogs that can help you pinpoint specific components. Take advantage of these tools to enhance your search.

Visual References: Having clear visual guides can significantly ease the identification process. High-quality images or diagrams can help you match the needed items accurately, reducing the chances of error.

Community Support: Engaging with forums or communities dedicated to similar equipment can provide invaluable insights. Experienced users often share tips and recommendations that can simplify your quest for the right components.

Professional Assistance: If you’re ever in doubt, don’t hesitate to seek help from professionals. Their expertise can save you time and ensure you get the correct items, enhancing the longevity and performance of your machinery.

Comparing Ditch Witch Models

In the realm of underground construction equipment, various models cater to diverse project requirements and operator preferences. Understanding the distinctions among these machines can greatly enhance the decision-making process for professionals seeking the ideal fit for their tasks. This section delves into the notable features and specifications of different models, enabling a comprehensive comparison.

| Model | Engine Power (HP) | Operating Weight (lbs) | Maximum Depth (in) | Width (in) |

|---|---|---|---|---|

| Model A | 30 | 4000 | 48 | 36 |

| Model B | 40 | 5000 | 60 | 40 |

| Model C | 50 | 6000 | 72 | 42 |

| Model D | 60 | 7000 | 84 | 44 |

Each variant presents unique advantages, making it essential for operators to assess their specific needs before selection. Factors such as power output, weight, depth capability, and width play critical roles in determining the best choice for any given job.

Finding Genuine Parts Suppliers

Acquiring authentic components for your machinery is essential for maintaining performance and ensuring longevity. Choosing the right suppliers can make a significant difference in the quality of the items you receive, as well as the efficiency of your operations. It’s crucial to identify vendors who prioritize reliability and trustworthiness, thereby guaranteeing that your equipment runs smoothly.

Researching Reputable Vendors

Start by investigating suppliers with a strong industry presence. Look for reviews, testimonials, and ratings from other customers to gauge their reputation. Engaging in online forums or communities can also provide valuable insights and recommendations from experienced users who have faced similar needs.

Assessing Quality and Authenticity

When evaluating potential suppliers, focus on their commitment to quality assurance. Request documentation or certification to verify that the components meet industry standards. Direct communication with the supplier can help clarify any concerns regarding the origin and authenticity of the items, ensuring that you make informed decisions.

Benefits of Regular Maintenance

Consistent upkeep of machinery significantly enhances its longevity and performance. By adhering to a routine schedule, operators can prevent minor issues from escalating into major problems, ensuring efficient operation and reducing downtime.

Improved Efficiency

Regular checks and adjustments can lead to optimized performance, enabling equipment to operate at its peak potential. This not only boosts productivity but also conserves energy and resources.

Cost Savings

Investing time in maintenance can lead to substantial savings over time. Addressing wear and tear early can prevent costly repairs and replacements in the future.

| Maintenance Task | Frequency | Benefit |

|---|---|---|

| Lubrication | Monthly | Reduces friction and wear |

| Inspection | Quarterly | Identifies potential issues |

| Parts Replacement | Annually | Prevents breakdowns |

Upgrades for Enhanced Efficiency

Improving the performance and productivity of your equipment is essential for maximizing operational success. By incorporating specific enhancements, operators can experience significant benefits, including reduced downtime, increased power output, and improved fuel efficiency. This section explores various upgrades that can lead to enhanced functionality and overall effectiveness in the field.

Powertrain Improvements

One of the most impactful areas for upgrading involves the powertrain system. Consider the following enhancements:

- Advanced Transmission: Upgrading to a more efficient transmission system can optimize power delivery and enhance torque.

- High-Performance Engines: Implementing a more powerful engine can lead to better performance under heavy loads.

- Enhanced Cooling Systems: Improved cooling mechanisms help maintain optimal operating temperatures, reducing the risk of overheating during prolonged use.

Operational Accessories

In addition to powertrain upgrades, various accessories can significantly boost efficiency:

- Smart Controls: Integrating advanced control systems allows for better management of operations and precision tasks.

- Improved Tires: Investing in specialized tires designed for specific terrains can enhance traction and maneuverability.

- Quality Attachments: Utilizing high-quality tools and attachments can streamline workflows and enhance productivity.

Incorporating these upgrades not only elevates performance but also contributes to the longevity of your machinery, making them a wise investment for any operator looking to achieve greater efficiency in their projects.

Safety Precautions While Operating

Ensuring safety during operation is paramount to prevent accidents and injuries. Adhering to established guidelines can significantly mitigate risks associated with machinery use. Proper training and awareness of your environment are essential for a secure working experience.

- Personal Protective Equipment (PPE): Always wear appropriate gear, including helmets, gloves, and safety glasses.

- Pre-Operation Inspection: Conduct a thorough check of the equipment before use. Look for any signs of wear or damage.

- Clear Work Area: Ensure the surrounding area is free from obstacles and personnel. Mark off the operational zone if necessary.

- Operator Training: Only trained and authorized personnel should operate the machinery. Ensure all operators are familiar with safety protocols.

- Emergency Procedures: Be aware of emergency stop mechanisms and procedures. Know the location of first aid kits and emergency contact numbers.

- Proper Handling Techniques: Use correct lifting and maneuvering techniques to avoid strain and injury.

By following these guidelines, operators can enhance safety and efficiency, leading to a more productive working environment.

Frequently Asked Questions about Ditch Witch

This section addresses common inquiries related to specialized equipment and its components, providing clarity for users and potential buyers. Understanding these elements can enhance user experience and ensure informed decisions.

General Questions

- What types of machinery are available?

- How do I maintain my equipment?

- Where can I find replacement components?

Technical Support

- What should I do if my equipment malfunctions?

- Are there warranty options available?

- How can I contact customer support?