The intricate world of heavy machinery encompasses a vast array of components that work in unison to achieve operational efficiency. A comprehensive grasp of these elements is crucial for anyone involved in the maintenance and operation of such equipment. By dissecting the various sections, one can better appreciate how each part contributes to the overall functionality.

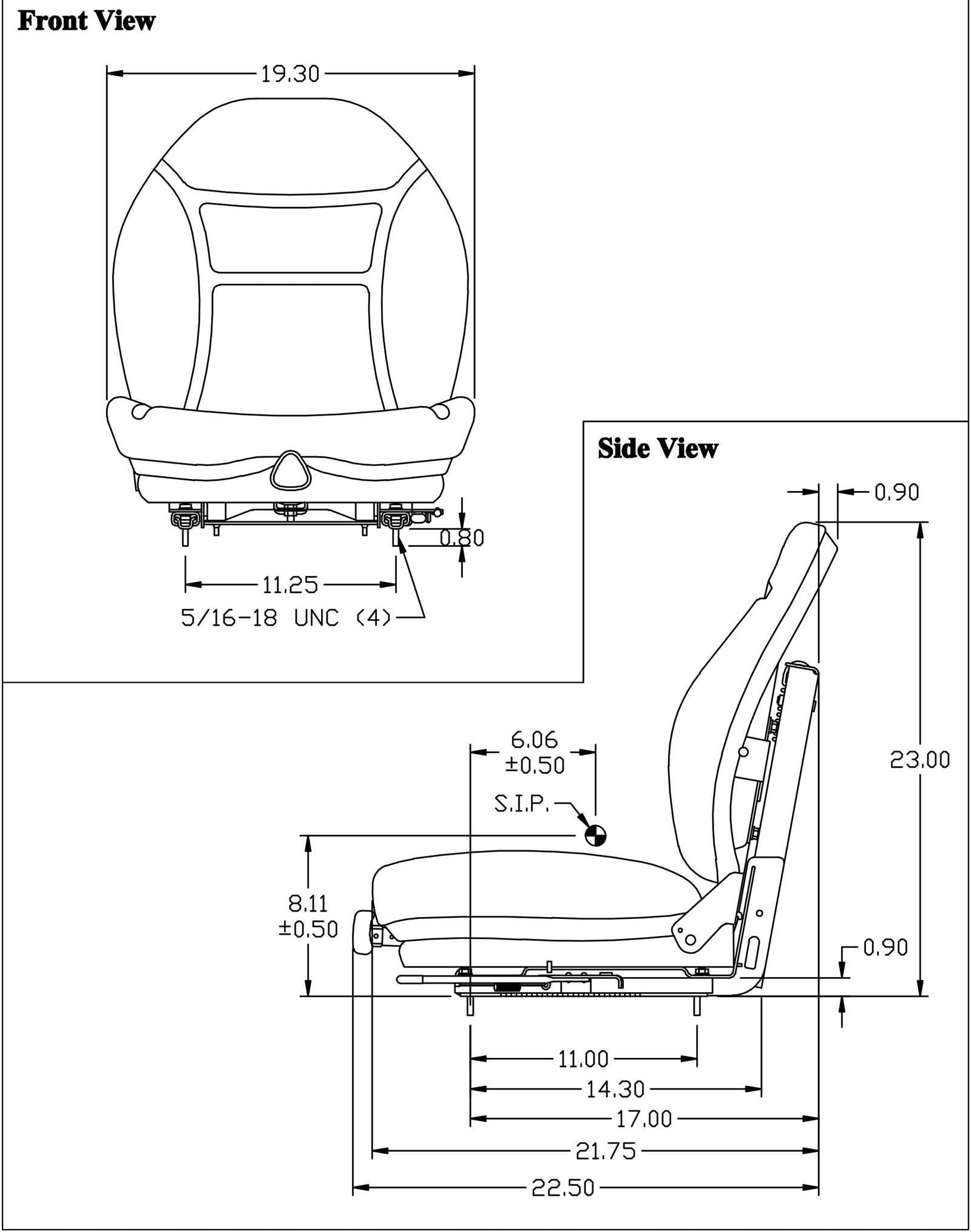

Visual representations play a vital role in comprehending the complex architecture of machinery. Detailed illustrations serve as valuable tools for technicians and operators, offering insights into the layout and interconnections of individual components. Understanding these visual aids not only enhances troubleshooting skills but also promotes effective maintenance practices.

Moreover, familiarity with the specific arrangement of parts can significantly reduce downtime during repairs. When each element is clearly outlined, it becomes easier to identify potential issues and streamline the replacement process. This knowledge empowers operators to maintain their equipment in peak condition, ultimately leading to improved productivity and safety in the workplace.

Understanding the Skytrak 8042

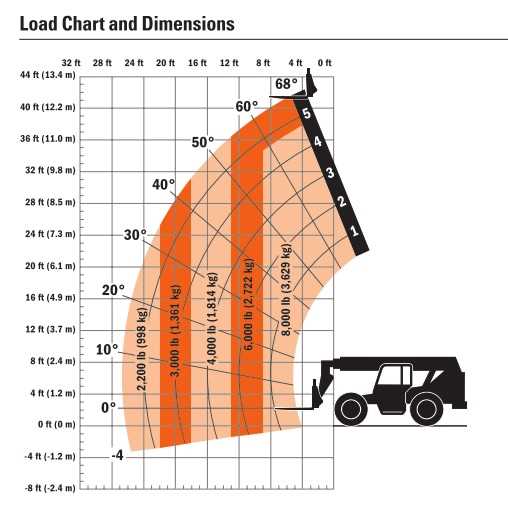

This section aims to explore the essential features and functionalities of a versatile lifting machine designed for various heavy-duty tasks. By examining its components and how they interact, we can appreciate its engineering and the efficiency it brings to construction and agricultural applications.

Key Features

The equipment is equipped with a powerful engine and a robust lifting mechanism that allows it to handle substantial loads with ease. Its adaptability makes it suitable for a range of environments, whether on construction sites or in farming operations.

Components Overview

| Component | Function |

|---|---|

| Engine | Provides power for lifting and movement. |

| Lift Arm | Facilitates elevation of heavy materials. |

| Operator’s Cabin | Ensures safety and comfort for the user. |

| Wheels | Enables mobility across different terrains. |

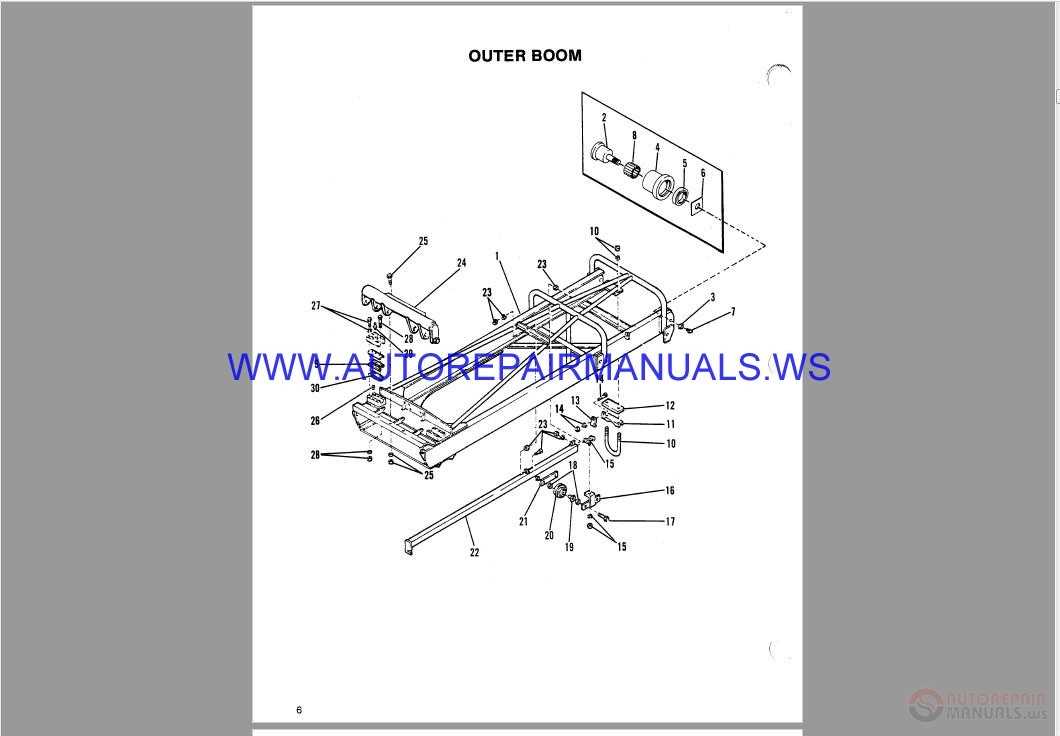

Importance of Parts Diagrams

Understanding the assembly and functionality of complex machinery is essential for maintenance and repairs. Visual representations of components play a crucial role in facilitating this knowledge, offering clarity and efficiency in the identification of individual elements. These illustrations serve as vital references, enabling technicians to locate and comprehend various sections of equipment swiftly.

Benefits of Visual References

- Enhances comprehension of machinery layout.

- Simplifies troubleshooting processes by pinpointing specific areas of concern.

- Improves communication among team members by providing a common visual language.

Efficient Repair and Maintenance

- Reduces downtime by allowing quick access to necessary components.

- Promotes accurate reassembly of equipment after maintenance tasks.

- Facilitates ordering the correct replacements without confusion.

In summary, utilizing visual aids significantly streamlines the processes of repair and upkeep, ensuring that equipment remains operational and efficient.

Key Components of the 8042 Model

The functionality of this versatile machine relies on several crucial elements that work together to enhance its performance and efficiency. Understanding these components is essential for optimal operation and maintenance.

Engine: The powerhouse of the unit, the engine provides the necessary energy to operate various functions and ensures reliable performance in diverse conditions.

Transmission: This system facilitates smooth power delivery from the engine to the wheels, allowing for seamless movement and improved maneuverability on uneven terrain.

Hydraulic System: A key feature that enables lifting and tilting operations, the hydraulic system is vital for handling heavy loads with precision and stability.

Chassis: The framework supports all other components and ensures durability and strength, which are essential for rugged applications.

Control System: This component provides the operator with the ability to manage various functions effectively, enhancing both safety and efficiency during operation.

How to Read the Diagram

Understanding technical illustrations is essential for effective maintenance and repair of machinery. These visual guides provide a detailed representation of components, their relationships, and assembly instructions. Familiarizing yourself with the structure and notations used will enhance your ability to troubleshoot and perform repairs efficiently.

Familiarizing with Symbols and Labels

The first step in interpreting the illustration is recognizing the various symbols and labels employed. Each symbol represents a specific element, and labels often indicate part numbers or functions. Take time to familiarize yourself with the legend or key, as it serves as a guide to deciphering the visual language of the schematic.

Understanding Layout and Relationships

The layout of the illustration typically reflects the physical arrangement of components. Pay attention to how parts are connected and the flow of information depicted. Lines often signify relationships, such as wiring or fluid connections. By understanding these connections, you can identify how different elements interact, facilitating a more comprehensive understanding of the system.

Common Replacement Parts

Understanding the essential components that often require replacement is crucial for maintaining equipment efficiency and longevity. Regular wear and tear can lead to the need for new elements, ensuring optimal performance and safety during operation.

Frequently Needed Components

Key items that typically need replacement include hydraulic seals, which are vital for preventing leaks, and filters, essential for maintaining clean fluids. Regular checks on these components can help identify issues before they escalate.

Upgrading Parts for Enhanced Performance

Consider investing in upgraded versions of common elements like tires and batteries. Enhanced versions can provide improved durability and efficiency, ultimately extending the lifespan of your machinery.

Maintenance Tips for Longevity

Regular upkeep is essential for maximizing the lifespan of heavy machinery. By adhering to a systematic maintenance routine, operators can ensure optimal performance and minimize the likelihood of unexpected failures. Proper care not only enhances efficiency but also contributes to the overall safety of the equipment and its users.

One fundamental aspect of maintenance is the routine inspection of critical components. Regular checks for wear and tear can help identify potential issues before they escalate into major problems. Additionally, ensuring that all moving parts are adequately lubricated can prevent friction-related damage and prolong service life.

Another crucial tip is to maintain clean equipment. Accumulation of dirt and debris can lead to overheating and increased wear on mechanical parts. Implementing a cleaning schedule, especially after heavy use, can significantly improve performance and reliability.

Proper storage also plays a vital role in the longevity of machinery. Keeping equipment in a sheltered environment protects it from harsh weather conditions that could lead to corrosion and deterioration. If possible, using covers or shelters can provide an additional layer of protection.

Finally, following the manufacturer’s guidelines for maintenance intervals and procedures is key. Adhering to recommended service schedules ensures that the machinery operates within its designed parameters, reducing the risk of costly repairs and extending its useful life.

Finding Genuine Skytrak Parts

Ensuring the longevity and efficiency of heavy machinery relies heavily on sourcing authentic components. The market is flooded with options, but identifying genuine items is crucial for maintaining optimal performance and safety. Quality parts not only enhance functionality but also protect your investment over time.

Importance of Authentic Components

Using original elements is vital for various reasons. Durability is a key factor; genuine parts are engineered to withstand the demands of rigorous tasks. Additionally, compatibility with existing systems minimizes the risk of malfunctions, which can lead to costly repairs and downtime.

Where to Find Reliable Sources

To locate trustworthy suppliers, consider authorized dealers or well-established retailers specializing in machinery. Researching reviews and seeking recommendations can guide you toward reputable sources. Always verify the legitimacy of the product by checking for certifications and warranties to ensure you receive what you expect.

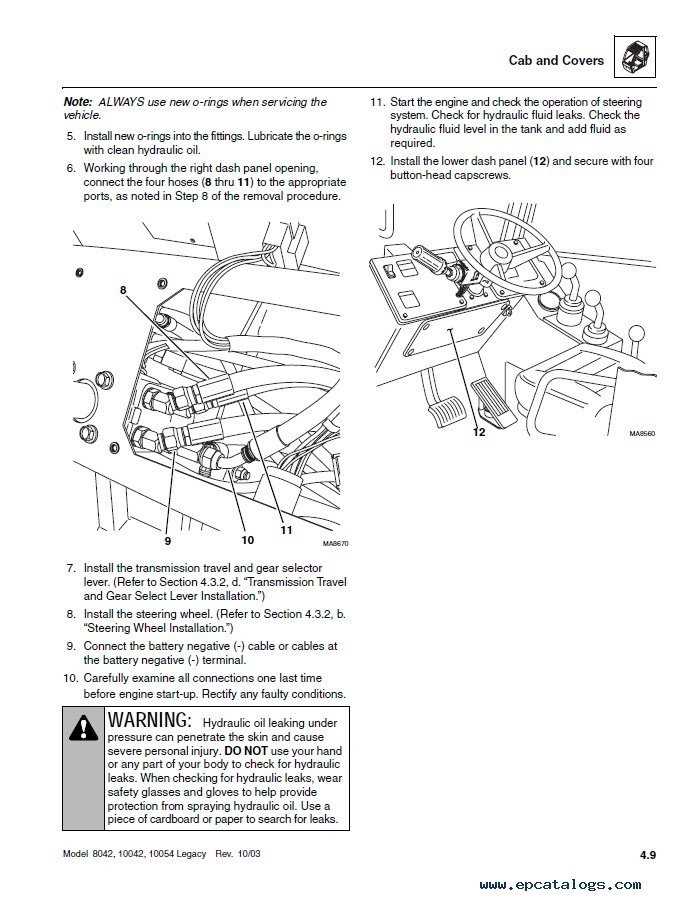

Step-by-Step Repair Process

Repairing machinery involves a systematic approach to ensure efficient restoration and optimal performance. This section outlines a comprehensive method for addressing issues effectively, focusing on essential steps and best practices that guide you through the entire procedure.

Begin by assessing the malfunction to identify specific symptoms and potential causes. Gather all necessary tools and replacement components before starting the repair to streamline the process. Ensure a clean workspace to facilitate organization and safety during the task.

Next, disconnect power sources and safely dismantle the relevant sections of the equipment, documenting each step for reference. Inspect each component for wear or damage, making notes on what requires replacement or adjustment. This meticulous examination allows for a thorough understanding of the overall condition.

Once you’ve pinpointed the problematic parts, proceed with the replacement or repair. Follow manufacturer guidelines closely to maintain integrity and safety standards. After installation, reassemble the unit carefully, ensuring that all connections are secure and properly aligned.

Finally, conduct tests to confirm the successful resolution of the issues. Regular maintenance checks post-repair are vital to prevent future complications and to extend the life of the machinery. This methodical approach not only enhances performance but also builds confidence in handling similar tasks in the future.

Tools Required for Repairs

When undertaking maintenance and restoration tasks, having the right equipment is crucial for efficiency and safety. Proper tools not only streamline the process but also ensure that repairs are executed effectively, prolonging the lifespan of the machinery.

- Wrenches: Essential for loosening and tightening bolts.

- Screwdrivers: Required for assembling and disassembling components.

- Pliers: Useful for gripping and bending materials.

- Socket Set: Ideal for working with various nut sizes.

- Jack and Stands: Necessary for safely lifting equipment for underneath access.

- Torque Wrench: Ensures bolts are tightened to specific torque settings.

- Multimeter: Helpful for electrical diagnostics.

- Safety Gear: Includes gloves, goggles, and helmets for protection.

Equipping yourself with these fundamental tools will help in effectively addressing issues, allowing for a thorough and safe repair experience.

Safety Precautions During Repairs

When undertaking maintenance on heavy machinery, ensuring safety is paramount. Proper precautions help prevent accidents and injuries, creating a secure environment for technicians. Adhering to established guidelines can significantly reduce risks associated with repairs.

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and hard hats.

- Ensure the work area is well-ventilated to avoid inhalation of harmful fumes.

- Disconnect the power supply before beginning any repair work to prevent electrical hazards.

- Use proper tools for each task, ensuring they are in good condition and suitable for the job.

- Keep the workspace organized to minimize trip hazards and maintain focus.

By following these essential precautions, technicians can delve into repairs with greater confidence, ultimately enhancing both safety and efficiency.

Where to Buy Replacement Parts

When it comes to maintaining heavy machinery, sourcing high-quality components is crucial for ensuring optimal performance and longevity. Various avenues exist for acquiring these essential items, each with its own set of advantages. Understanding where to look can save both time and money, while also guaranteeing that the equipment runs smoothly.

Authorized Dealers: One of the most reliable options is to purchase from authorized dealerships. These outlets often provide genuine components that are specifically designed for the machinery in question. Furthermore, they usually offer expert guidance, helping you choose the right items for your needs.

Online Retailers: The internet has revolutionized the shopping experience, making it easier to find what you need from the comfort of your home. Numerous online platforms specialize in equipment components, offering a vast selection and often competitive prices. Just be sure to check reviews and ratings before making a purchase to ensure quality.

Local Suppliers: Don’t overlook local suppliers who may stock the necessary components. Building a relationship with nearby vendors can provide benefits such as immediate availability and personalized service, allowing for quicker repairs and maintenance.

Salvage Yards: For those on a tighter budget, salvage yards can be a treasure trove of affordable options. Often, you can find used components in good condition that can serve as effective replacements. However, it’s important to carefully inspect these items before purchasing to avoid future issues.

In conclusion, finding suitable replacements for your equipment involves exploring multiple avenues. Whether you opt for authorized dealers, online retailers, local suppliers, or salvage yards, each option offers unique benefits that can help keep your machinery in peak condition.