The functionality and efficiency of heavy machinery rely heavily on the meticulous arrangement of their various components. A comprehensive understanding of these assemblies not only enhances operational capabilities but also aids in effective maintenance and troubleshooting. Each element plays a critical role in the overall performance, necessitating an in-depth exploration of their interrelations.

By examining the layout of these mechanical assemblies, operators and technicians can identify specific locations of key features, allowing for more informed decisions during repairs and modifications. This knowledge empowers users to optimize machine performance and extend its lifespan, ensuring that it remains a valuable asset in any operation.

Moreover, a clear representation of these arrangements can serve as a valuable reference for training new personnel. Familiarity with the configuration of essential components fosters confidence and competence in handling the machinery, leading to safer and more efficient work environments.

Overview of Cat 287B Components

This section delves into the various elements that comprise the machine, highlighting their functions and importance in overall operation. Understanding these components can enhance maintenance practices and ensure optimal performance.

- Engine: The powerhouse that drives all operations, providing the necessary torque and horsepower for heavy tasks.

- Hydraulic System: This system facilitates lifting and maneuvering capabilities, allowing for precise control over attachments.

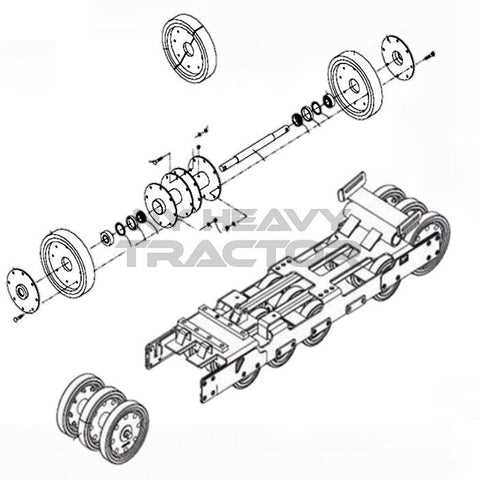

- Chassis: The sturdy frame that supports all other components, ensuring stability and durability during use.

- Tracks: The continuous bands that provide traction and support, enabling the machine to navigate various terrains.

- Cab: The operator’s workspace, designed for comfort and visibility, housing essential controls for operation.

By familiarizing oneself with these crucial parts, operators can effectively troubleshoot issues and implement maintenance strategies to prolong the lifespan of the equipment.

Essential Features of the Cat 287B

The equipment in focus is renowned for its robust design and exceptional performance, making it a preferred choice for various heavy-duty applications. Its advanced engineering ensures reliability and efficiency, meeting the demands of operators across different industries. From enhanced power to superior maneuverability, this machine is equipped with features that optimize productivity and ease of use.

Powerful Performance

One of the standout characteristics of this machinery is its powerful engine, which provides impressive horsepower and torque. This ensures that it can handle demanding tasks with ease, making it suitable for construction, landscaping, and material handling. The efficient hydraulic system further enhances its lifting capabilities, allowing for smooth operation even under heavy loads.

User-Friendly Design

The intuitive control system and ergonomic layout significantly improve user experience. Operators can easily navigate and control the machine, reducing the learning curve and enhancing productivity. Additionally, the compact size allows for excellent visibility and accessibility in tight spaces, making it versatile for various job sites.

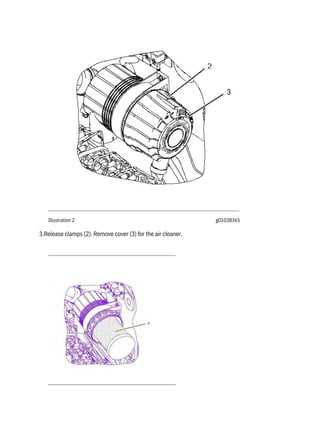

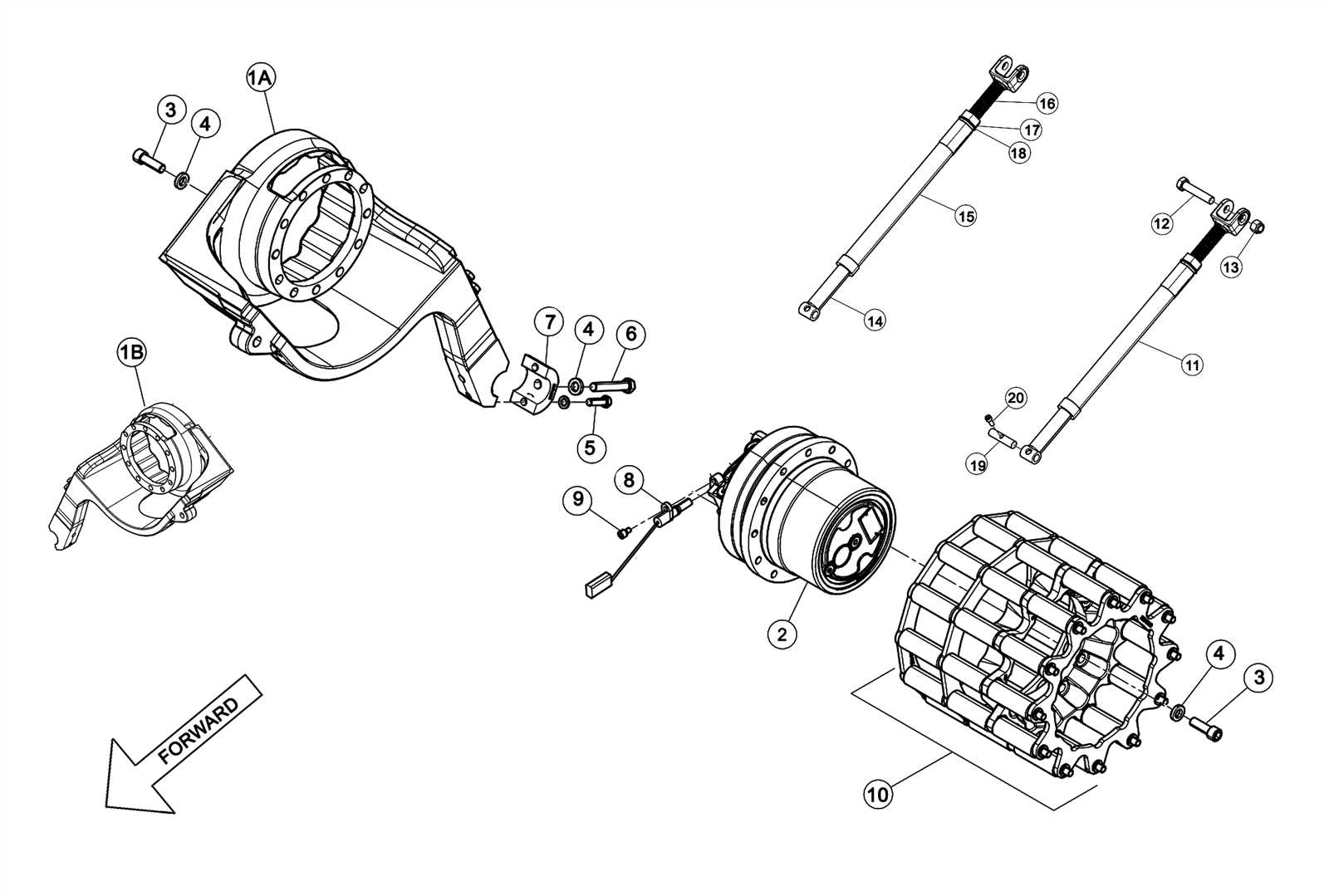

Understanding the Parts Layout

Grasping the arrangement of components is essential for effective maintenance and repair of machinery. A clear visualization of how various elements interact can greatly enhance troubleshooting and optimization efforts. By comprehending the configuration, operators and technicians can identify potential issues and streamline service procedures.

This layout typically includes a comprehensive overview of each element’s position and function within the system. Recognizing the relationship between different components allows for quicker assessments during inspections. Familiarity with the arrangement not only aids in pinpointing faults but also contributes to improved efficiency in both operation and upkeep.

In addition, understanding the configuration helps in sourcing appropriate replacements and modifications when necessary. A well-organized representation serves as a valuable reference, ensuring that all necessary tools and parts are readily accessible for any maintenance task. Ultimately, a thorough knowledge of the setup fosters a more proficient approach to machine handling.

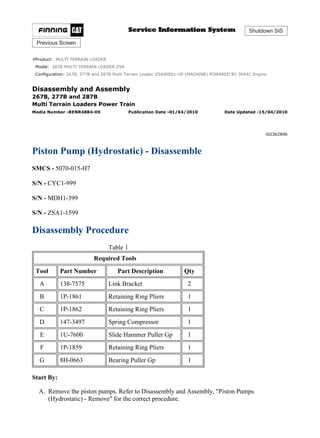

Key Assembly and Disassembly Steps

Understanding the procedures for assembling and disassembling machinery components is crucial for maintenance and repair. Proper handling of each part ensures the longevity of the equipment and prevents damage during the process. This section outlines essential steps that should be followed for effective management of these mechanical assemblies.

Preparation and Safety Measures

Before beginning the assembly or disassembly process, it is vital to prepare the workspace and gather the necessary tools. Ensure that the area is clean and free from obstructions. Additionally, wearing appropriate safety gear, such as gloves and goggles, will protect against potential hazards. Always consult the manufacturer’s guidelines for specific instructions related to the components being handled.

Step-by-Step Assembly Procedure

Start by organizing all components and verifying their condition. Begin the assembly by positioning the main parts together in accordance with the alignment features. Secure each part using the recommended fasteners, ensuring they are tightened to the specified torque settings. As you proceed, regularly check for proper alignment and functionality. Following these steps will lead to a reliable assembly that performs effectively.

Maintenance Guidelines for Cat 287B

Proper upkeep is essential for ensuring optimal performance and longevity of your machinery. Regular inspections and servicing play a crucial role in identifying potential issues before they escalate into significant problems. Adhering to a systematic maintenance schedule can help maintain efficiency and reduce the risk of unexpected breakdowns.

Routine Inspections: Conducting frequent evaluations of various components is vital. Check fluid levels, including hydraulic and engine oils, and ensure they are within the recommended ranges. Examine filters for dirt and clogs, replacing them as necessary to maintain cleanliness and efficiency.

Component Care: Pay close attention to moving parts, ensuring they are well-lubricated. Look for signs of wear or damage, especially in critical areas such as the undercarriage and attachment points. Promptly replace any worn or damaged components to avoid compromising functionality.

Cleaning Procedures: Keep the machinery clean to prevent dirt and debris from causing damage. Regularly wash exterior surfaces and inspect for leaks. A clean machine not only operates better but also makes it easier to spot issues that require attention.

Documentation and Record Keeping: Maintain a detailed log of all maintenance activities, including inspections, repairs, and parts replacements. This record can serve as a valuable reference for future service and helps in tracking performance trends over time.

By following these maintenance recommendations, you can ensure that your equipment remains in top condition, ultimately enhancing its reliability and performance throughout its operational life.

Common Repairs and Solutions

When operating heavy machinery, encountering mechanical issues is a frequent occurrence. Understanding typical repairs and their respective solutions can significantly enhance the efficiency and longevity of the equipment. This section aims to outline common malfunctions, their causes, and practical approaches to resolve these challenges effectively.

Hydraulic System Failures

Hydraulic system issues often manifest as reduced power or sluggish movement. These problems can stem from leaks in hoses, damaged seals, or low fluid levels. Regular maintenance checks can identify these issues early. If a leak is detected, promptly replacing damaged hoses or seals is crucial. Additionally, ensuring that the hydraulic fluid is at the correct level can prevent further complications.

Engine Overheating

Overheating engines can lead to severe damage if not addressed quickly. This issue may arise from a malfunctioning cooling system, low coolant levels, or a blocked radiator. It is vital to regularly inspect the cooling system for any blockages and to maintain proper coolant levels. Flushing the cooling system can also improve efficiency and prevent overheating.

Comparative Analysis of Cat Models

This section delves into the intricacies of various machinery models, highlighting their similarities and differences. Understanding these distinctions is crucial for potential buyers and users, as each version offers unique features tailored to specific operational needs. By examining these models closely, one can make informed decisions based on performance, functionality, and application suitability.

Key Features and Specifications

Different machinery variations present a range of specifications that cater to various applications. While some versions are designed for enhanced lifting capabilities, others focus on improved fuel efficiency. Understanding these key attributes allows users to select the most appropriate machine for their tasks, ensuring optimal performance.

Performance and Efficiency

Performance metrics often vary significantly among different models, affecting productivity and operational costs. Comparative analysis reveals that while some machines excel in speed, others may provide better torque or lifting capacity. This information is vital for operators who prioritize efficiency and effectiveness in their daily tasks.

Importance of Genuine Replacement Parts

Utilizing authentic components for machinery maintenance is crucial for ensuring optimal performance and longevity. These original elements are designed specifically to fit and function correctly within the system, providing reliability and peace of mind.

Choosing genuine replacements comes with several advantages:

- Quality Assurance: Original components undergo rigorous testing to meet industry standards, guaranteeing their durability and effectiveness.

- Perfect Fit: These elements are crafted to exact specifications, ensuring seamless integration and minimizing the risk of malfunction.

- Enhanced Performance: Authentic parts contribute to the overall efficiency of the machinery, helping to maintain its operational capabilities.

- Manufacturer Support: When using original components, users often receive better support and warranty options from the manufacturer, offering added protection.

In contrast, opting for generic alternatives may lead to complications, including:

- Increased Risk of Failure: Substandard components can lead to system failures, resulting in costly repairs and downtime.

- Compatibility Issues: Non-genuine parts may not fit properly, causing misalignments that affect performance.

- Warranty Voids: Many manufacturers will not honor warranties if non-original elements are used, potentially leading to unexpected expenses.

Investing in authentic replacements ultimately protects the investment in machinery and ensures it continues to operate at peak efficiency.

Parts Availability and Sourcing

Access to replacement components and accessories is crucial for maintaining machinery efficiency and performance. Understanding where to find these items can significantly impact operational continuity. Various suppliers and platforms offer an array of options, catering to different needs and budgets.

Numerous online retailers specialize in heavy equipment components, providing detailed catalogs for easy browsing. These platforms often feature user reviews and ratings, assisting buyers in making informed decisions. In addition to online resources, local distributors can offer valuable support and timely availability of essential items.

Furthermore, considering used or refurbished components can present cost-effective alternatives. Many businesses provide warranties and guarantees on such items, ensuring reliability without compromising quality. Engaging with forums and community groups dedicated to machinery enthusiasts can also yield insights into sourcing hard-to-find components and best practices in procurement.

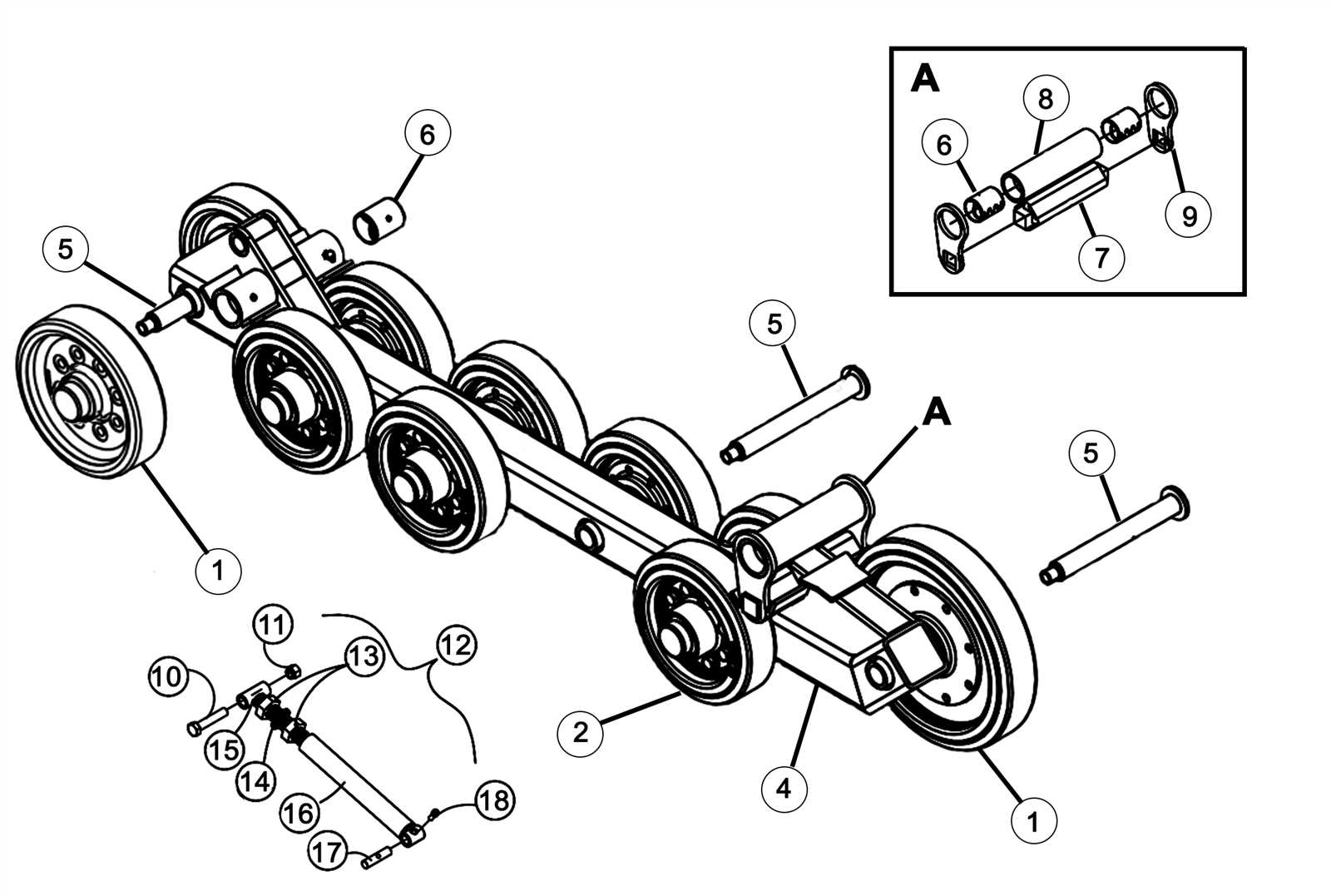

Visual Identification of Components

Understanding the layout and features of essential machine elements is crucial for effective maintenance and repair. Proper visual recognition allows operators to quickly assess the condition and functionality of various components, facilitating timely interventions and enhancing overall equipment efficiency.

Key Components to Recognize

- Hydraulic Cylinders

- Engine Assembly

- Transmission System

- Cooling System

- Chassis Structure

Benefits of Component Identification

- Improved Maintenance: Early detection of issues can lead to more efficient repairs.

- Enhanced Safety: Recognizing critical parts can prevent accidents and ensure safe operations.

- Increased Lifespan: Proper care and timely replacement of worn components can extend the overall life of the equipment.