Modern appliances rely on various interconnected elements to function smoothly. Each of these elements plays a specific role, contributing to the overall efficiency and performance. Identifying the layout and relationships between these elements can help maintain optimal functionality and extend the lifespan of the equipment.

Exploring essential mechanisms and the arrangement of components allows users to address issues more efficiently. Whether troubleshooting minor malfunctions or planning regular upkeep, having a clear understanding of the internal structure can simplify many tasks. Familiarity with key elements ensures smoother operation and quicker problem resolution.

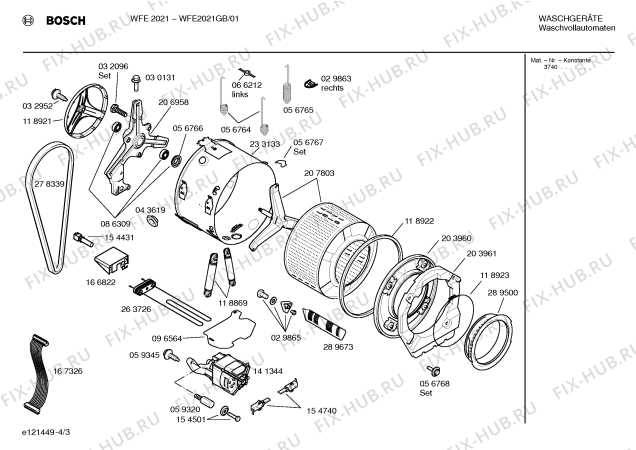

A well-organized schematic can serve as a vital reference tool. It provides a detailed look at how individual units fit together, helping users navigate repairs or replacements with ease. Knowing how the different

Overview of Appliance Component Layout

Understanding the internal structure of household equipment helps with maintenance, repairs, and upgrades. A well-organized layout of essential modules ensures efficient troubleshooting and easy access to key elements during servicing. Familiarity with such configurations can significantly extend the operational life of the device.

Main Functional Elements

The appliance is built with several interconnected units that work together to provide optimal performance. The heating element, sensors, and control board are among the core components responsible for functionality. Each element has a specific role, from temperature regulation to moisture detection, ensuring smooth operation.

Supporting Mechanisms and Accessories

Apart from primary modules, secondary elements like belts

Key Components Inside a Dryer

A modern appliance for drying fabrics contains various essential elements that work together to ensure efficient moisture removal and optimal performance. Understanding the inner structure can help with maintenance and troubleshooting.

- Heating Element: Responsible for generating the required heat to dry the clothes effectively.

- Blower Fan: Circulates warm air through the drum, accelerating the drying process.

- Drum: Rotates the load to ensure even air exposure and prevent wrinkles.

- Thermostat: Monitors and regulates the internal temperature to avoid overheating.

- Lint Filter: Captures fibers and debris, preventing blockages in the ventilation system.

- Moisture Sensor:

Identifying Wiring and Electrical Layouts

Understanding the organization of wiring and electrical connections is essential for troubleshooting and maintaining appliances. A clear layout helps locate potential faults and ensures safe interaction with the system, minimizing risks of incorrect handling.

Wiring Configuration Overview

Electrical systems often follow standardized color codes and schematics, indicating power flow, grounding points, and connection types. Recognizing these elements ensures proper identification and alignment during maintenance or repair activities.

Key Components and Their Connections

Component Function Connection Type How the Heating Element Works

The heating element plays a crucial role in transforming electrical energy into heat, ensuring warm airflow during operation. Its function is fundamental in maintaining efficient performance and delivering the necessary warmth to facilitate the intended process.

- The element receives electrical power, which flows through its conductive coils.

- As current moves through the coils, resistance generates heat, raising the temperature.

- Air passes over the heated coils, absorbing the warmth and distributing it evenly throughout the system.

- Temperature control components, such as thermostats, regulate the heat to prevent overheating.

- Once the desired temperature is reached, the power supply is interrupted to maintain balance.

This regulated heating mechanism ensures a consistent and controlled temperature, optimizing both performance and energy consumption.

Airflow Path and Venting Structure

The movement of air inside the appliance plays a crucial role in ensuring efficient operation. The system directs warm air through designated channels, allowing moisture to be extracted effectively, while guiding the residual air safely out of the system.

Air Circulation Process

The air enters the system, passes through a heating element, and flows into the main chamber. As it circulates, it collects moisture, which is then expelled through a network of exhaust ducts. Proper circulation minimizes moisture buildup and promotes faster operation.

Exhaust Configuration

The venting system is designed to release humid air outside or into a designated outlet. This structure prevents heat accumulation within the device and ensures smooth airflow. Regular cleaning of these channels ensures optimal performance and reduces the risk of

Control Panel Connections Overview

This section provides an insight into the connections found on the control interface of the appliance. Understanding these linkages is crucial for effective troubleshooting and maintenance. The connections enable communication between various components, ensuring that the device operates smoothly and efficiently.

Key Components

The control panel consists of several essential elements that facilitate user interaction and operational control. Each connection serves a specific purpose, from powering the unit to sending signals for specific functions.

Connection Types

Here is a summary of the various connection types typically found in the control interface:

Connection Type Description Power Supply Provides the necessary electrical power for the control functions. Signal Wires Transmits operational commands between the control panel and other components. Ground Connections Ensures safety by preventing electrical surges and potential hazards. Feedback Lines Allows for communication of status updates back to the control interface. Understanding the Drum and Belt Mechanism

The functionality of a clothing drying appliance relies heavily on the interaction between its main components. Among these, the cylinder and its connecting belt play crucial roles in ensuring efficient operation. Grasping how these elements work together enhances the understanding of the appliance’s performance and maintenance needs.

The Role of the Cylinder

The cylinder serves as the central chamber where garments are placed for drying. Its rotation facilitates even heat distribution and airflow, which are essential for removing moisture. Proper functioning of the cylinder is vital; any obstruction or imbalance can significantly hinder the drying process.

Importance of the Connecting Belt

The connecting belt is responsible for transmitting power from the motor to the cylinder. It ensures that the cylinder rotates smoothly at the required speed. If the belt becomes worn or damaged, it may slip or break, leading to a complete halt in the drying cycle. Regular checks on the belt’s condition are advisable to prevent unexpected malfunctions.

Exploring the Lint Filter Assembly

The lint filter assembly is a crucial component in ensuring optimal performance and efficiency in clothing care appliances. This assembly plays a significant role in trapping fibers and debris that are released during the drying process, preventing them from obstructing airflow and maintaining the appliance’s functionality.

Understanding the structure and operation of this assembly can greatly enhance user experience and prolong the lifespan of the equipment. Below is a detailed overview of the components that typically make up the lint filter assembly.

Component Description Lint Filter A mesh screen designed to capture lint and prevent it from entering the exhaust system. Frame The structure that holds the lint filter in place, ensuring a secure fit during operation. Seal A rubber or foam material that creates an airtight barrier, preventing lint from bypassing the filter. Indicator Light A visual cue that alerts users when the lint filter needs cleaning. Location of Thermostats and Sensors

This section provides an overview of the positioning of temperature regulation devices and monitoring elements within the appliance. Understanding their locations is essential for troubleshooting and maintenance, ensuring optimal functionality.

Temperature Regulation Components

Temperature regulation components play a crucial role in maintaining the appropriate heat levels during operation. These devices are strategically placed to effectively monitor and adjust the heating process. Typically, they are found in areas exposed to airflow, allowing them to accurately gauge the temperature of the air circulating within the unit.

Monitoring Elements

Monitoring elements are essential for detecting various operational parameters. Their placement is critical for providing accurate readings and ensuring safety. Generally, these components are located near the heating element and in the exhaust pathway, which helps in assessing the appliance’s performance and preventing overheating.

Component Type Location Function Thermostat Near heating element Regulates temperature Thermal Fuse Exhaust pathway Prevents overheating Humidity Sensor Drum area Monitors moisture levels Mounting and Frame Structure Details

The assembly and structural framework of household appliances play a crucial role in ensuring stability and durability during operation. Understanding the intricate design and arrangement of these components can significantly enhance maintenance and repair processes.

Typically, the mounting components include brackets and supports that secure the main unit to its surrounding structure. These elements are engineered to withstand vibrations and forces generated during use. Additionally, the frame provides essential support, contributing to the overall integrity of the appliance. Various materials, such as steel or composite materials, are utilized in construction to optimize both strength and weight.

Furthermore, the configuration of the frame is designed to facilitate ease of access for servicing. Proper alignment of mounting holes and support brackets ensures a seamless assembly process, which is vital for maintaining the appliance’s functionality and safety. Understanding these details is essential for effective repairs and prolonging the lifespan of the unit.

Replacing Door Switch and Hinges

Replacing the door mechanism and its associated components is a vital task for ensuring proper functionality. This section outlines the steps involved in the removal and installation of these essential elements, which play a crucial role in the overall operation of the appliance.

Tools and Materials Needed

- Screwdriver (Philips and flathead)

- Replacement door switch

- New hinges

- Utility knife

- Safety gloves

Step-by-Step Instructions

- Ensure the appliance is unplugged for safety.

- Open the door and locate the screws securing the existing hinges.

- Remove the screws using the appropriate screwdriver and detach the door.

- Take out the old door switch by unscrewing it from its mounting bracket.

- Install the new door switch, ensuring it fits securely.

- Attach the new hinges to the door frame.

- Reattach the door by aligning it with the hinges and securing it with screws.

- Test the door switch by closing the door and observing if the appliance responds correctly.

Pump and Drain System Overview

The effective removal of moisture from appliances is essential for optimal functionality. This section delves into the components involved in the fluid removal mechanism, focusing on how they work together to ensure efficient operation.

Components of the Pump and Drain Mechanism

The mechanism primarily consists of a pump and a drainage pathway that facilitates the expulsion of water. Each element plays a crucial role in maintaining performance and preventing malfunctions.

Component Function Pump Circulates and discharges moisture from the unit. Drain Hose Provides a pathway for the expelled fluid to exit. Drain Filter Prevents debris from obstructing the drainage system. Importance of Maintenance

Regular upkeep of the fluid removal system is vital for longevity and efficiency. Neglecting maintenance can lead to clogs and potential failures, affecting overall performance.