Maintaining outdoor machinery requires a comprehensive understanding of its structure and functionality. Familiarity with the various elements that constitute a machine can significantly enhance its performance and longevity. This knowledge not only aids in effective repairs but also in optimizing the overall efficiency of the equipment.

In this section, we will explore the intricacies involved in identifying essential components and their relationships within the assembly. By delving into the design and arrangement of these crucial elements, users can better grasp how each part contributes to the overall operation. Recognizing these components can also simplify troubleshooting processes and ensure that any necessary replacements are made accurately.

Whether you are a seasoned technician or a casual user, understanding the layout of machinery can empower you to tackle maintenance tasks with confidence. This guide aims to provide insights that will enhance your ability to manage repairs and upkeep effectively, ensuring your equipment remains in optimal working condition.

Poulan Pro Snow Blower Parts Overview

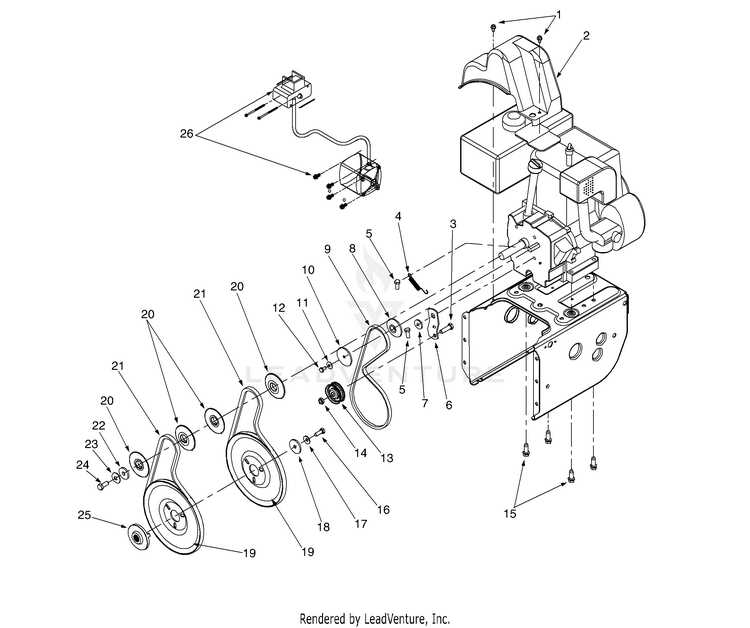

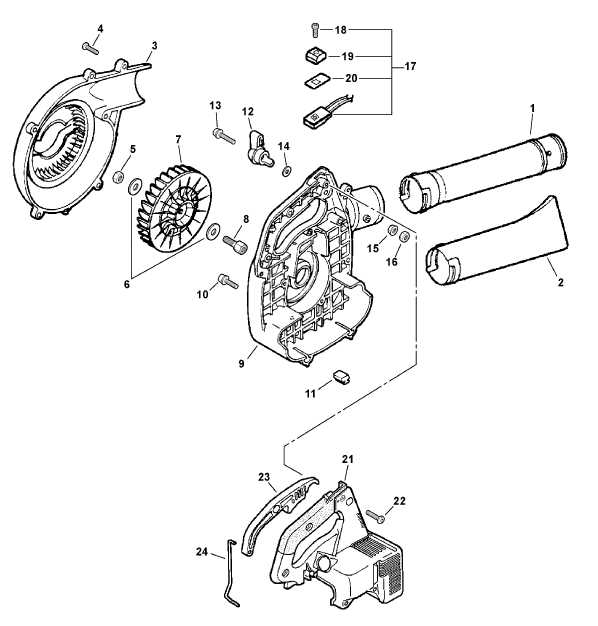

This section provides a comprehensive understanding of the essential components involved in the functioning of a snow-clearing machine. Each element plays a crucial role in ensuring effective operation and maintenance, contributing to the overall performance of the equipment.

Key Components

- Engine: Powers the entire machine, providing the necessary force for movement and operation.

- Chassis: The main structure that supports and houses various parts, ensuring durability and stability.

- Auger: Responsible for collecting and moving snow toward the discharge chute.

- Impeller: Assists in propelling the cleared snow out of the chute.

- Controls: Allow the operator to manage speed, direction, and other functions effectively.

Maintenance and Care

Regular upkeep is vital for optimal performance. Consider the following practices:

- Inspect and replace worn or damaged components promptly.

- Keep the engine well-oiled and fueled to ensure reliability.

- Clean the machine after each use to prevent build-up and corrosion.

- Check belts and cables for signs of wear and tension.

Essential Components of Snow Blowers

The efficiency of clearing heavy winter precipitation relies on several key elements that work together seamlessly. Understanding these fundamental components is crucial for effective operation and maintenance. Each part plays a vital role in ensuring optimal performance, making it easier to tackle even the most challenging conditions.

Key Elements

Recognizing the main features of these machines helps users appreciate their functionality. The essential components include the engine, auger, impeller, and chute, each contributing to the overall effectiveness in moving and directing accumulated precipitation. Proper maintenance of these elements is essential for longevity and reliability.

Component Table

| Component | Function |

|---|---|

| Engine | Powers the entire unit, providing the necessary energy for operation. |

| Auger | Collects and breaks up compacted snow, preparing it for movement. |

| Impeller | Propels the collected material through the discharge chute. |

| Chute | Directs the expelled material away from the working area. |

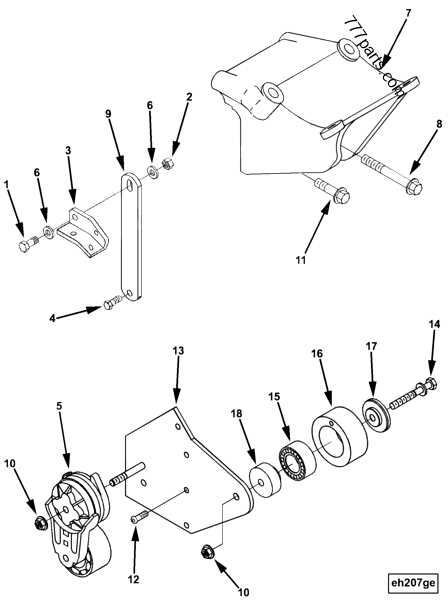

Understanding Snow Blower Diagrams

Interpreting technical illustrations is essential for effective maintenance and repair of outdoor equipment. These visual aids serve as guides, providing valuable information on the arrangement and functionality of various components. Familiarizing oneself with these illustrations enhances troubleshooting skills and aids in identifying necessary replacements or repairs.

Components Overview

Key elements depicted in these illustrations typically include:

- Power Source: Indicates the type of engine or motor utilized.

- Chassis: Shows the main frame supporting other components.

- Control Mechanisms: Details levers and switches for operation.

- Auger Assembly: Represents the component responsible for gathering and propelling material.

- Discharge Chute: Illustrates the pathway through which material is expelled.

Reading the Illustrations

To effectively utilize these visual resources, follow these steps:

- Identify each component: Start by recognizing individual parts and their locations.

- Understand the relationships: Note how components connect and interact with each other.

- Refer to the accompanying text: Look for labels or descriptions that clarify each part’s function.

- Use color coding: Pay attention to any colors used to distinguish different sections or components.

Common Issues and Solutions

In the realm of outdoor equipment, various challenges can arise that may hinder performance. Understanding these typical problems and their respective remedies is essential for maintaining optimal functionality. Below, we outline some frequent concerns users encounter and provide practical solutions to address them.

| Issue | Description | Solution |

|---|---|---|

| Engine Won’t Start | The motor fails to ignite or operate when prompted. | Check the fuel level and ensure the ignition system is functioning. Replace spark plugs if necessary. |

| Ineffective Operation | Equipment struggles to clear or move material effectively. | Inspect for clogs or damage in the auger or impeller. Clear any obstructions and ensure all components are secure. |

| Excessive Vibration | Unusual shaking or rattling occurs during operation. | Examine for loose or damaged parts. Tighten bolts and replace any broken components as needed. |

| Fuel Leaks | Visible leakage of fuel from the machine. | Inspect fuel lines and connections for cracks or damage. Replace any faulty hoses or fittings. |

Maintenance Tips for Longevity

Regular upkeep is essential to ensure the extended functionality and performance of your equipment. By adhering to some straightforward maintenance practices, you can enhance the lifespan and reliability of your machinery, reducing the likelihood of unexpected breakdowns.

Routine Inspection

Conducting periodic checks is crucial for identifying wear and tear early. Look for signs of damage or irregularities in components and ensure that all parts are securely fastened. Regular inspections can help prevent more serious issues down the line.

Cleaning and Lubrication

Keeping the machine clean from debris and dirt is vital. After each use, remove any accumulated materials, especially around critical moving parts. Additionally, applying lubricant to necessary areas will minimize friction and prolong the life of the components.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect Components | Every Use | Check for wear and secure fittings. |

| Clean Debris | After Each Use | Remove dirt to prevent buildup. |

| Lubricate Moving Parts | Every 10 Uses | Use appropriate lubricant for best results. |

| Check Fuel System | Every Season | Ensure fuel is fresh and system is clean. |

How to Identify Parts Easily

Recognizing components of your equipment can significantly enhance your maintenance experience. By familiarizing yourself with various elements, you can ensure optimal performance and make informed decisions when replacements are necessary. This guide will help you navigate the identification process with ease.

Here are some practical steps to simplify the identification of components:

- Refer to the Manual: Always start with the owner’s guide. It typically includes a comprehensive list of elements, complete with descriptions and images.

- Use Online Resources: Websites dedicated to equipment servicing often provide detailed descriptions and visuals. These can assist you in locating specific items.

- Label Components: As you disassemble any unit, use labels to tag parts. This practice will help you remember their locations and functions for future reference.

- Seek Professional Assistance: When in doubt, consult with a specialist or a knowledgeable retailer. They can offer insights and help identify any unfamiliar items.

By following these steps, you can enhance your ability to recognize and understand the various components of your equipment effectively.

Tools Required for Repairs

Proper maintenance and repair of outdoor machinery necessitate a selection of essential implements. These tools not only facilitate effective servicing but also ensure the longevity and optimal performance of the equipment. Having the right set of tools on hand can significantly streamline the repair process, allowing for quicker troubleshooting and fixes.

Basic Hand Tools: A collection of fundamental hand tools is crucial for any repair task. Wrenches, screwdrivers, and pliers are among the primary implements needed to address various issues that may arise during maintenance. These items provide the necessary leverage and precision to tackle routine adjustments and repairs.

Specialized Equipment: In addition to standard tools, certain specialized equipment may be required depending on the specific repairs needed. Items such as torque wrenches or socket sets can be invaluable for tasks requiring specific torque settings or the removal of hard-to-reach fasteners.

Safety Gear: Safety should always be a priority when undertaking any repair work. Protective gloves, goggles, and hearing protection are essential to safeguard against potential hazards. Using appropriate safety gear minimizes the risk of injury and ensures a safer working environment.

Equipping yourself with the right tools and safety measures will enhance your repair experience, making it efficient and effective.

Ordering Replacement Parts Online

In today’s digital age, acquiring necessary components for your equipment has never been more convenient. Online platforms provide a wide array of options, making it easier to find the specific items needed for repairs or upgrades. Understanding how to navigate these resources effectively can save both time and money.

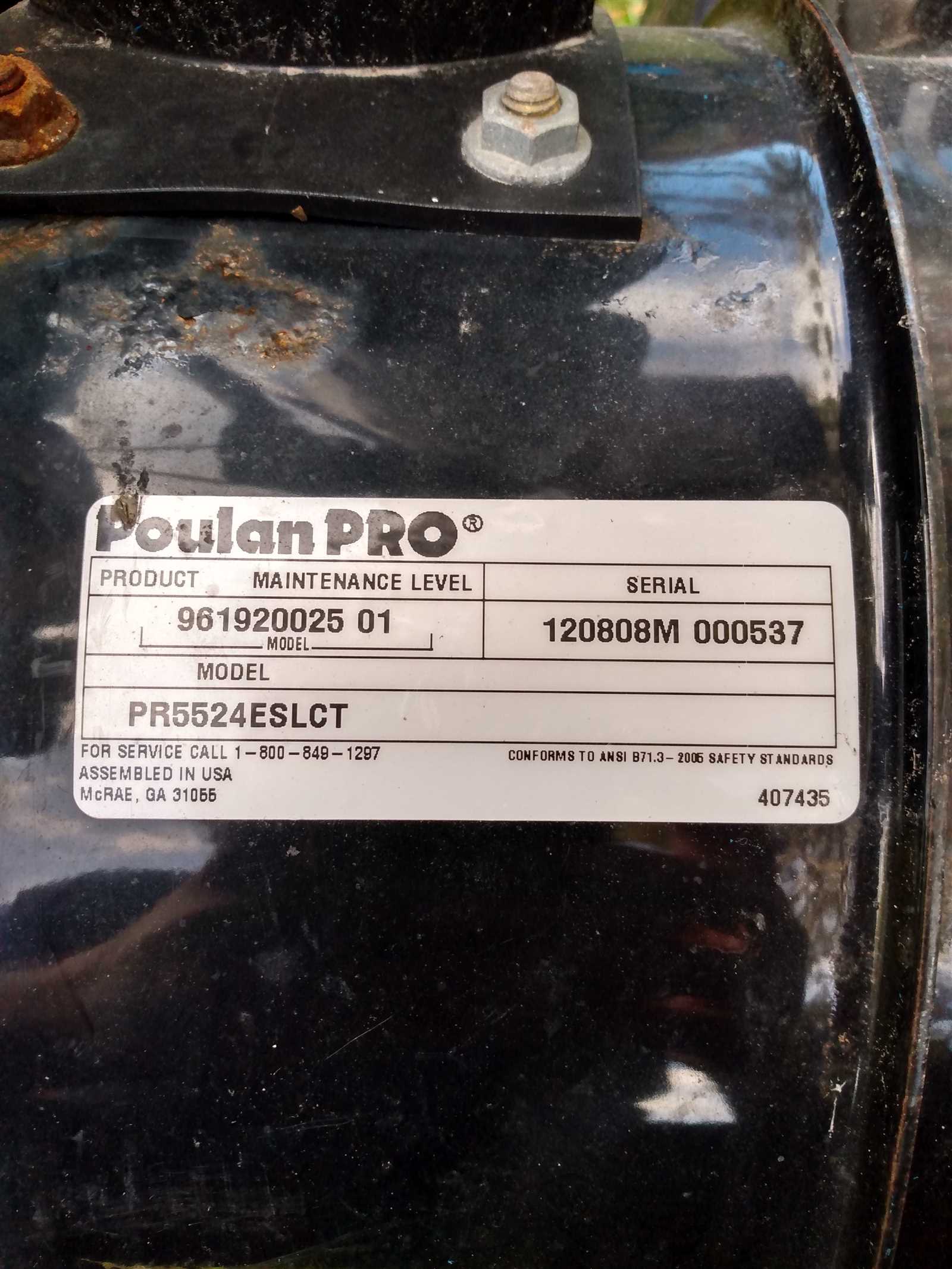

When seeking components, it’s crucial to have the correct model information on hand. This ensures that the chosen items will be compatible with your equipment. Many online retailers offer detailed descriptions and specifications, helping you to make informed decisions. Take advantage of search filters to narrow down your choices based on your requirements.

Additionally, consider checking customer reviews and ratings before finalizing a purchase. This feedback can provide insights into the quality and reliability of the components. Many platforms also offer customer support to assist with any inquiries, ensuring you receive the best possible service.

Lastly, be mindful of shipping options and return policies. Understanding these factors can help avoid complications should the items not meet your expectations. With a little diligence, online ordering can streamline the process of sourcing essential components for your equipment.

Upgrading Your Snow Blower

Improving the efficiency and performance of your equipment can significantly enhance your winter experience. By investing in better components and features, you can ensure reliable operation during harsh conditions. This section explores various ways to enhance your machinery, making it more effective in tackling challenging snow accumulation.

Choosing Advanced Components

One of the most impactful upgrades involves selecting high-quality components. Opting for enhanced augers and impellers can boost your device’s ability to clear snow efficiently. Additionally, consider upgrading the engine for more power and reliability, which will ensure better performance in heavy snowfall.

Adding Useful Accessories

Integrating accessories such as heated handles or LED lights can greatly improve comfort and visibility. These enhancements not only make the operation more enjoyable but also allow for safer use during nighttime or adverse weather. Evaluate your current setup and identify areas where additional features could provide more convenience and efficiency.

Frequently Asked Questions

This section aims to address common inquiries related to the maintenance and functionality of winter machinery. Understanding these aspects can enhance user experience and ensure optimal performance.

What should I do if my equipment won’t start?

If the machinery fails to ignite, check the fuel levels and ensure that the ignition system is functioning correctly. It’s also advisable to inspect the spark plug for any signs of wear.

How can I improve the efficiency of my device?

Where can I find replacement components?

How often should I perform maintenance?

Customer Reviews and Experiences

This section delves into the feedback and insights shared by users regarding their experiences with the equipment. Customers often provide valuable information about its efficiency, reliability, and ease of use. Understanding these firsthand accounts can assist potential buyers in making informed decisions.

Many users have praised the machine’s performance in clearing various types of snow and debris, highlighting its power and effectiveness in harsh winter conditions. They noted that the design facilitates maneuverability, allowing for efficient operation in tight spaces.

Additionally, several reviews mention the durability of the components, emphasizing that they withstand regular use without significant wear. Customers appreciate the straightforward maintenance procedures, which contribute to a hassle-free ownership experience.

However, some users expressed concerns regarding specific aspects, such as weight and storage. While many found the equipment manageable, a few suggested that a more compact design could enhance usability. Overall, user feedback serves as a useful resource for those considering this machinery.

Comparing Poulan Pro Models

When considering different models of outdoor equipment, it’s essential to evaluate their unique features, performance capabilities, and suitability for specific tasks. Each model brings distinct advantages and may cater to various user needs, making a comprehensive comparison invaluable for making informed decisions.

Key Features

Examining the primary characteristics of various models can help users identify which equipment aligns with their requirements. Factors such as engine power, operational width, and ease of use play crucial roles in determining the efficiency and effectiveness of these machines.

Performance Comparison

Understanding how different models perform in various conditions can aid users in selecting the right equipment for their needs. Performance metrics like clearing efficiency, maneuverability, and durability should be assessed to ensure optimal functionality.

| Model | Engine Power (HP) | Clearing Width (inches) | Weight (lbs) | Recommended Use |

|---|---|---|---|---|

| Model A | 6.5 | 21 | 80 | Light to Medium Tasks |

| Model B | 8.0 | 24 | 100 | Medium to Heavy Tasks |

| Model C | 9.5 | 30 | 120 | Heavy Duty Tasks |