In modern climate control systems, the arrangement and structure of internal elements play a crucial role in delivering efficient and reliable performance. The way these units are assembled directly affects their ability to regulate temperature, manage airflow, and ensure long-term durability. By exploring the key elements and their positioning, one can gain valuable insight into how cooling solutions function.

Each piece of equipment within these systems serves a specific purpose, from managing airflow to distributing cooled air throughout the environment. Knowing the individual components and how they interconnect can help users troubleshoot issues, maintain optimal performance, and make informed decisions when repairs or replacements are needed.

This guide will walk through the essential components and their configurations, providing a comprehensive overview of the system’s mechanics and highlighting how these elements work together to create a balanced and effective cooling process.

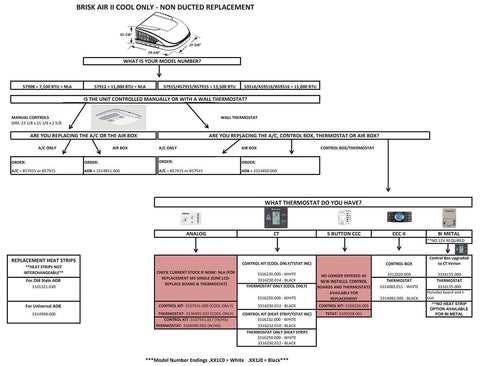

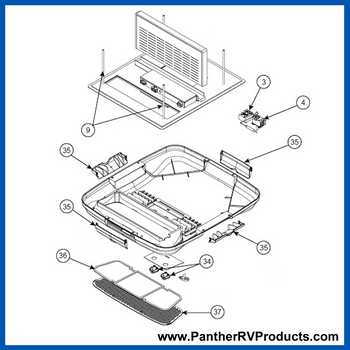

Dometic Brisk Air 2 Parts Overview

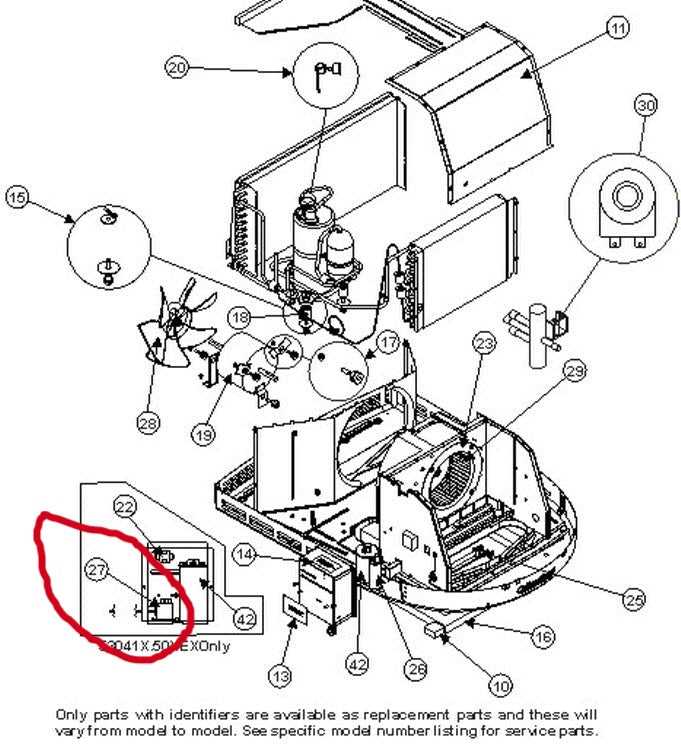

The cooling system discussed in this section consists of various essential components that ensure efficient operation and comfort. Each element plays a crucial role in maintaining temperature control, air circulation, and energy efficiency, contributing to the overall performance of the unit.

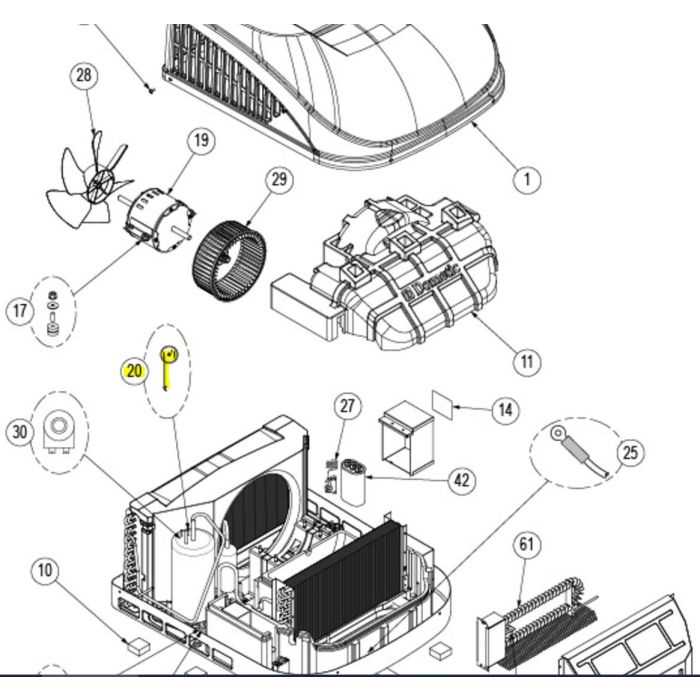

Main Components of the Cooling Unit

The cooling setup includes several integral parts that work together to provide effective cooling. These elements are designed to interact seamlessly, ensuring that the system performs optimally under different conditions.

| Component | Description | ||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Compressor | The core element responsible for circulating refrigerant through the system, aiding in heat exchange and cooling. | ||||||||||||||||||||||||||||||||||||

| Evaporator Coil | This component absorbs heat from the surrounding environment, cooling the air that passes through it. | ||||||||||||||||||||||||||||||||||||

| Condenser Coil | Facilitates the release of absorbed heat, allowing the refrigerant to return to its initial state. | ||||||||||||||||||||||||||||||||||||

| Fan Assembly | Ensures consistent airflow by pushing air through

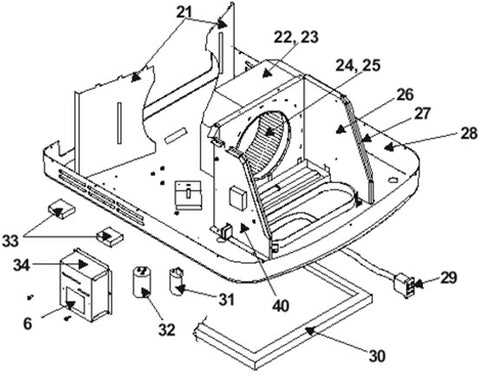

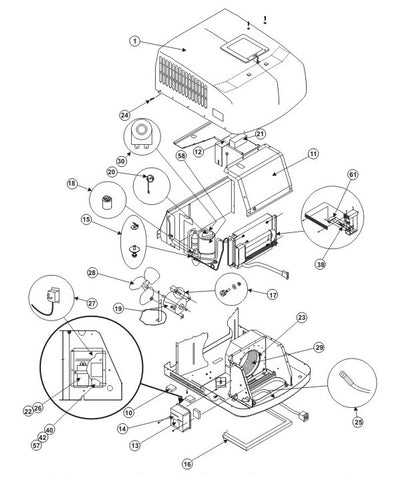

Understanding the Main ComponentsTo efficiently manage the cooling system, it’s essential to be familiar with its key elements. Each part plays a crucial role in ensuring optimal performance and longevity. Gaining knowledge about the primary components can help with troubleshooting and maintenance, allowing for more effective use of the system.

By understanding how these core elements interact, users can ensure better performance and detect potential issues early, preventing costly repairs. Cooling System BreakdownThe cooling system is essential for maintaining a comfortable environment by regulating temperature. Understanding the core components and how they work together is crucial for diagnosing any issues and ensuring smooth operation. This section provides a detailed overview of the various elements that contribute to the cooling process, including key mechanisms that enable temperature control and airflow. Core ComponentsThe system relies on several critical elements that work in unison to cool down the environment. One of the main components is the compressor, which circulates the refrigerant through the system. The evaporator and condenser coils also play vital roles in absorbing and releasing heat, while the fan circulates air over these coils to enhance the cooling effect. Each of these parts must function properly to achieve optimal performance. Functionality and Operation

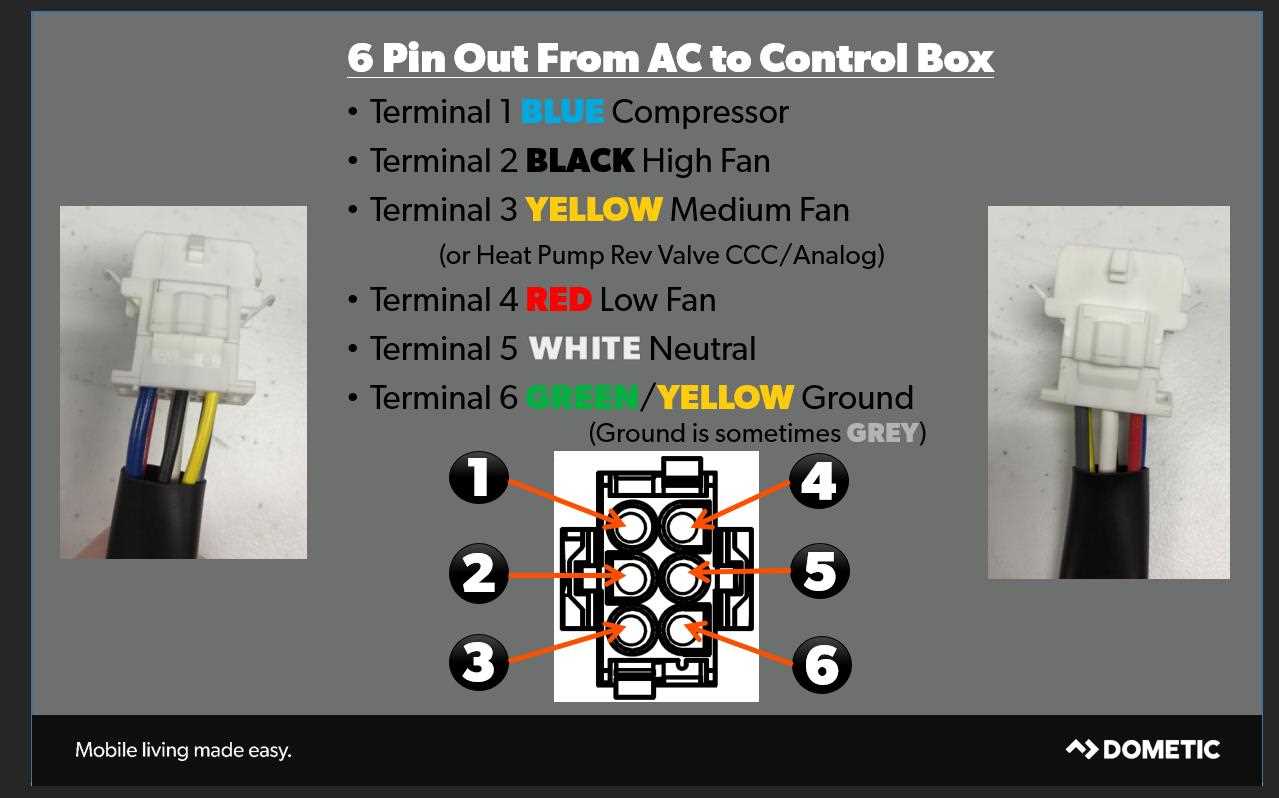

At the heart of the cooling process is the refrigerant, a chemical that changes from liquid to gas as it absorbs heat. The compressor pumps the refrigerant through the coils, where it cools down and condenses, Electrical Connections and Wiring Diagram

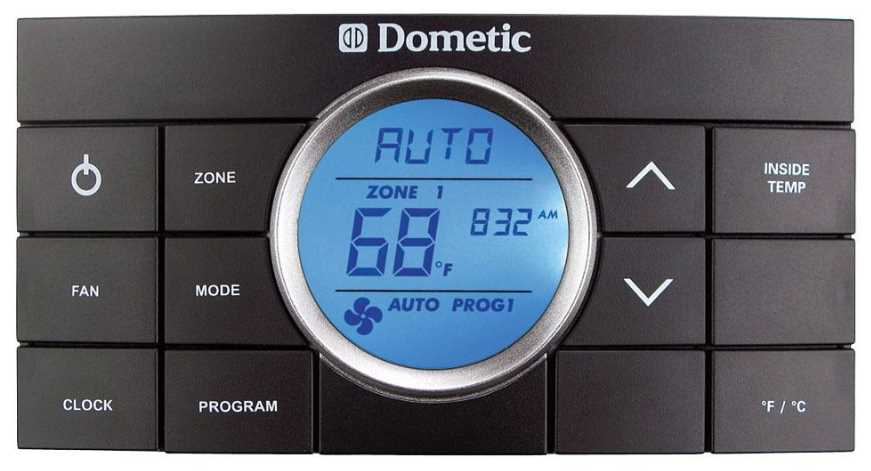

The proper setup of electrical connections is crucial for the safe and efficient functioning of any system. This section provides an overview of the recommended procedures for wiring, ensuring that all components are correctly linked and powered. A clear and organized wiring plan can prevent malfunctions, reduce the risk of electrical hazards, and optimize performance. Wiring Layout Overview

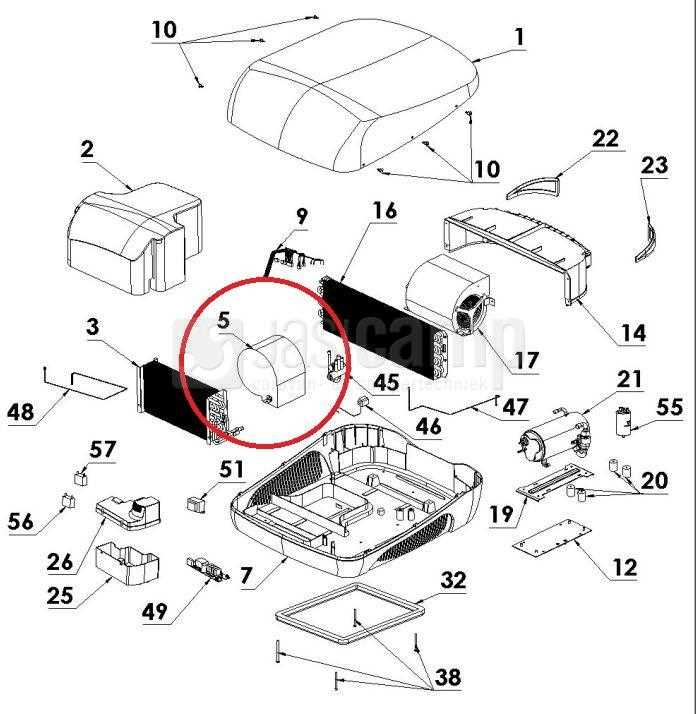

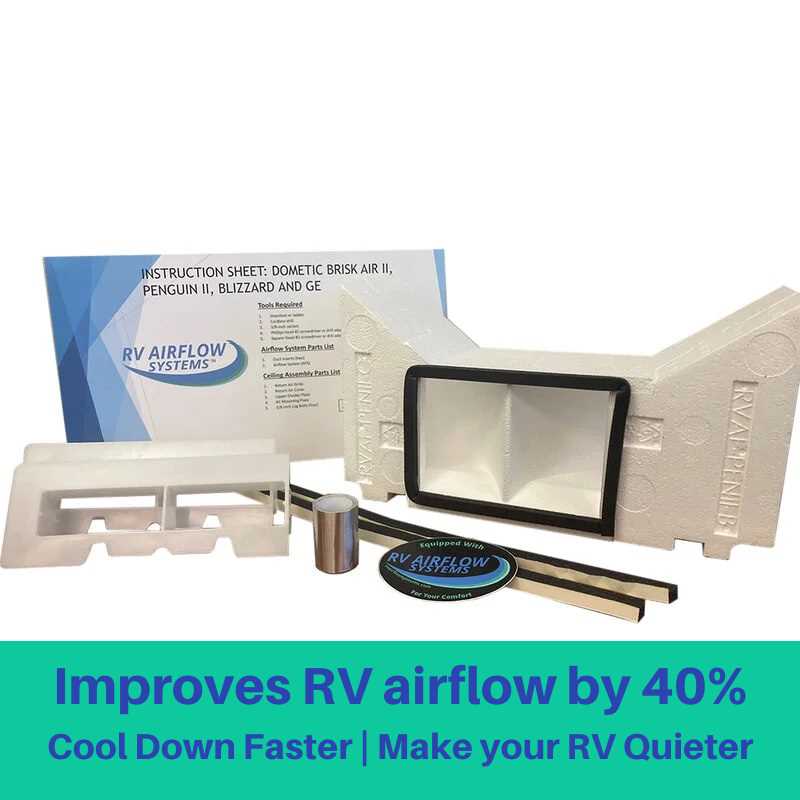

A comprehensive wiring layout is essential to understand how each component interacts within the system. The layout illustrates the flow of electricity, connecting power sources, controls, and other elements. Each wire plays a specific role, guiding power through the system to maintain operation. Proper insulation, labeling, and routing are vital to avoid short circuits and ensure easy troubleshooting. Key Considerations for Safe InstallationWhen handling the wiring, it’s important to follow industry standards and safety protocols. Always double-check connections, use the appropriate wire gauge, and ensure grounding is properly executed. Failing to adhere to these standards can lead to performance issues, overheating, or damage to the system. For enhanced safety, consider the use of circuit breakers and fuses to protect the electrical network from overloads. Airflow and Ventilation Mechanism

Efficient ventilation is key to maintaining a comfortable and well-regulated indoor environment. The movement of air through a cooling system ensures the circulation of fresh air while removing excess heat. This process helps create a balanced and comfortable atmosphere within enclosed spaces, preventing overheating and maintaining an optimal climate. Key Components of the Ventilation System

Air Circulation Process

|