In the realm of handheld heating tools, the efficiency and precision of the flame generator are paramount. Such devices, often utilized in various applications from culinary arts to crafting, require a thorough understanding of their internal structure. A well-designed mechanism not only ensures effective operation but also enhances user safety and satisfaction.

Each element within these compact devices plays a crucial role, contributing to the overall functionality and reliability. Recognizing how these components interact allows users to optimize performance and troubleshoot any issues that may arise. A detailed overview of the individual parts provides insight into maintenance practices and potential upgrades, ensuring longevity and effectiveness.

By examining the intricate layout of these essential elements, users can appreciate the engineering behind their favorite tools. Whether for professional tasks or hobbyist projects, knowledge of the device’s composition fosters a deeper connection and promotes a more efficient workflow.

Understanding Bernzomatic Micro Torch

This section explores the essential elements and functionality of a portable heating device, focusing on its various components and their significance in achieving optimal performance. By examining the intricate design and mechanisms involved, users can better appreciate how this tool operates effectively in different applications.

Components Overview

Key elements of this device include a fuel reservoir, ignition system, and adjustable flame control. Each component plays a vital role, ensuring safety and precision during use. Understanding their functions can enhance user experience and improve results.

Application Versatility

The versatility of this heating instrument allows it to be employed in a range of tasks, from culinary uses to intricate repairs. Its ability to generate a focused flame makes it an ultimate choice for professionals and hobbyists alike, ensuring efficiency and effectiveness in every endeavor.

Key Components of Micro Torch

A small handheld flame-producing device consists of several essential elements that work together to create a precise and controlled heat source. Understanding these components can enhance the user experience and ensure safety during operation.

- Fuel Source: This is the substance that ignites to produce the flame, often found in canisters or cartridges.

- Ignition System: Responsible for initiating the combustion process, it typically involves a piezoelectric mechanism or a manual striker.

- Adjustable Flame Control: This feature allows users to modify the size and intensity of the flame, providing versatility for various tasks.

- Nozzle: The opening where the flame emerges, designed to focus the heat precisely where needed.

- Safety Mechanism: Incorporates features like a lock or child safety to prevent accidental ignition.

- Handle: Designed for comfortable grip, ensuring ease of use during prolonged periods.

Understanding these fundamental elements enhances both the functionality and safety of the device, making it a valuable tool for various applications.

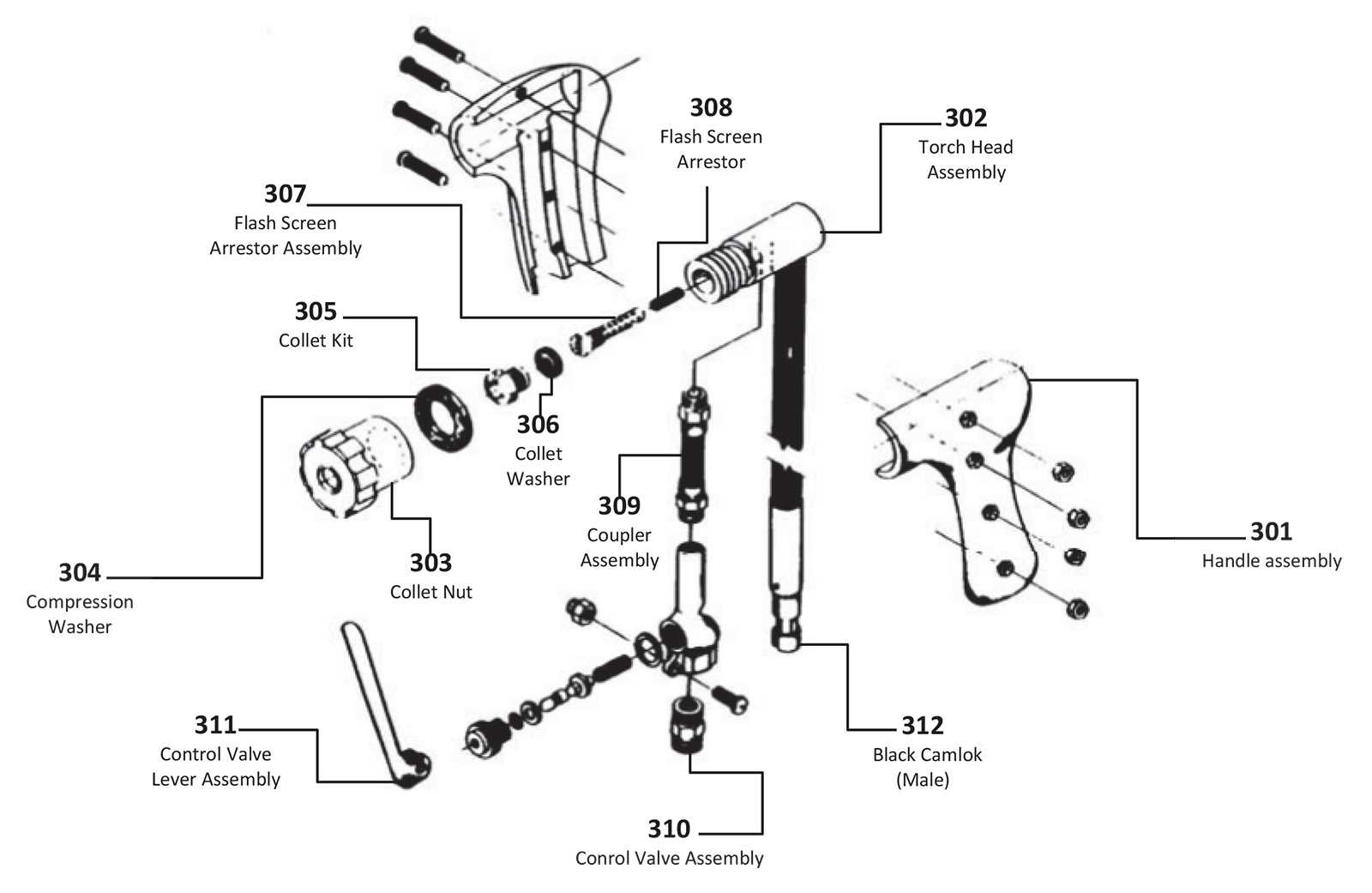

How to Read Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. These illustrations serve as a guide, helping users identify and locate individual elements within a device. Familiarity with the symbols and labels used can significantly enhance your troubleshooting and assembly skills.

Identify Key Symbols

Begin by familiarizing yourself with the common symbols depicted in the illustration. Each icon typically corresponds to a specific component, often accompanied by a reference number. These identifiers allow for easy cross-referencing with the accompanying list of parts, which may detail specifications and part numbers.

Follow the Flow

Next, observe how the elements are arranged. The layout often reflects the assembly order or functional sequence of the device. By tracing the connections between components, you can gain insight into the overall operation, which is crucial for troubleshooting issues or performing upgrades.

Importance of Each Part

Understanding the significance of individual components in a handheld heating device is crucial for optimal functionality and safety. Each element plays a unique role, contributing to the overall efficiency and performance of the unit.

The ignition mechanism serves as the initial trigger, ensuring reliable start-up for consistent use. An effective ignition ensures that users can operate the device smoothly and without hassle.

The fuel chamber is essential for storing the energy source, impacting how long the device can operate continuously. A well-designed chamber maximizes efficiency, enabling longer sessions without frequent refueling.

The nozzle directs the flame, allowing for precision during tasks. A properly shaped nozzle can enhance control, making it easier to focus heat on specific areas.

The adjustment valve regulates the intensity of the flame, which is vital for various applications. Fine-tuning the heat output ensures that users can adapt to different materials and requirements effectively.

The body casing provides protection and ensures durability. A robust casing safeguards internal components from damage and wear, extending the life of the device.

In summary, each element is indispensable, and understanding their functions allows users to maximize the device’s potential while ensuring safe operation.

Common Issues with Micro Torches

In the realm of handheld heating devices, users often encounter a range of challenges that can affect performance and reliability. Understanding these common pitfalls can enhance the overall experience and ensure efficient operation.

| Issue | Description |

|---|---|

| Inconsistent Flame | Variability in flame output can lead to difficulties in achieving desired temperatures. |

| Fuel Leaks | Improper seals may cause flammable substances to escape, posing safety risks. |

| Clogged Nozzle | Debris or residue buildup can obstruct gas flow, diminishing effectiveness. |

| Ignition Failure | Malfunctions in the ignition system may prevent the device from lighting up. |

| Overheating | Extended use without cooling can lead to overheating and potential damage. |

Replacing Worn-Out Parts

Over time, certain components of your tool may wear down, affecting performance and safety. Understanding when and how to replace these elements is crucial for maintaining efficiency and extending the lifespan of your equipment.

Identifying Damage: Regularly inspect your equipment for signs of wear, such as cracks or decreased functionality. Addressing these issues promptly can prevent further complications.

Choosing Quality Replacements: Opt for high-quality alternatives that meet or exceed manufacturer specifications. This ensures compatibility and durability, leading to ultimate performance enhancement.

Installation Tips: Follow proper procedures when replacing components to avoid damage. Refer to instructional guides for detailed steps and safety measures.

Regular maintenance and timely replacements can significantly improve the reliability and effectiveness of your tool.

Maintenance Tips for Longevity

Ensuring the durability of your equipment involves regular care and attention. By following specific guidelines, you can significantly extend its lifespan and maintain optimal performance. This proactive approach not only enhances efficiency but also reduces the likelihood of unexpected issues.

Regular Cleaning: Keep the exterior and components free from debris and residue. Use a soft cloth and appropriate cleaning agents to avoid damage.

Check Connections: Inspect all fittings and connections for signs of wear. Tighten loose components to prevent leaks and ensure proper function.

Storage Conditions: Store your equipment in a cool, dry place away from direct sunlight. This helps prevent corrosion and degradation of materials.

Routine Inspections: Schedule regular checks to identify potential problems early. Look for signs of wear, cracks, or other irregularities.

Usage Guidelines: Follow the manufacturer’s recommendations for usage. Overloading or improper use can lead to premature failure.

By incorporating these practices into your maintenance routine, you can ultimately achieve greater reliability and longevity from your tools.

Choosing Compatible Accessories

Selecting the right components for your heating tool is crucial for optimal performance and safety. Ensuring compatibility between the main device and its additional elements can enhance functionality and longevity, ultimately leading to a more satisfying user experience.

Understanding Specifications

Before purchasing any supplementary items, carefully review the specifications of your device. This includes fuel types, nozzle sizes, and temperature settings. Compatibility with these features can significantly affect efficiency and safety during use.

Quality Matters

Opt for high-quality accessories from reputable manufacturers. While it may be tempting to choose cheaper options, substandard components can lead to malfunctions or even accidents. Investing in reliable parts ensures that your equipment remains safe and effective.

Comparing Different Micro Torch Models

This section explores the various designs available in the compact flame tool market, highlighting key features that distinguish one model from another. Understanding these differences can aid in selecting the ideal device for specific tasks, whether for culinary, crafting, or repair purposes.

Key Features

When evaluating these instruments, consider aspects such as fuel capacity, ignition type, and temperature range. Fuel efficiency is critical for prolonged use, while user-friendly ignition systems can enhance overall convenience. Additionally, the maximum flame temperature can significantly influence performance in diverse applications.

Usability and Design

Ergonomics and size also play essential roles in user experience. A comfortable grip and lightweight design contribute to better handling, especially during extended tasks. Some models offer adjustable flames, allowing users to tailor the intensity based on their specific needs, making versatility a crucial factor in choosing the right tool.

Safety Precautions When Using Torch

When handling high-temperature tools, it is essential to prioritize safety to prevent accidents and injuries. Understanding the potential risks and following proper guidelines can help ensure a secure working environment.

Essential Guidelines

Before initiating any project, review and adhere to the following safety protocols:

| Precaution | Description |

|---|---|

| Protective Gear | Always wear safety goggles, gloves, and flame-resistant clothing. |

| Ventilation | Work in a well-ventilated area to avoid inhaling harmful fumes. |

| Flammable Materials | Keep flammable items away from the work area to minimize fire risk. |

| Awareness | Stay alert and focused, avoiding distractions while working. |

Emergency Preparedness

Be ready to act quickly in case of an emergency. Have a fire extinguisher nearby and know how to use it. Familiarize yourself with first aid procedures for burns or injuries.

DIY Repairs for Micro Torch

When it comes to small heating devices, minor issues can often arise that may hinder their performance. Instead of opting for professional assistance, many enthusiasts choose to tackle these challenges themselves. Engaging in DIY repairs not only saves money but also enhances your understanding of the equipment.

Common Issues and Solutions

- Flame Issues: If the flame is inconsistent or not igniting, check the fuel level. A refill may be necessary, or inspect the ignition mechanism for blockages.

- Leaking Fuel: A leak can be dangerous. Ensure that all connections are tight, and replace any damaged seals or gaskets.

- Temperature Control: If the temperature regulation is off, examine the adjustment dial and clean any debris that may interfere with its function.

Essential Tools for Repairs

- Wrench Set: For tightening or loosening connections.

- Screwdriver: To access internal components.

- Replacement Seals: Always keep extra seals on hand to address leaks promptly.

- Cleaning Tools: Brushes and compressed air can help clear any blockages.

With the right tools and a bit of patience, maintaining and repairing your heating device can be a rewarding experience. Regular upkeep ensures longevity and optimal performance.

Resources for Further Learning

Enhancing your understanding of specialized tools and their components is crucial for both enthusiasts and professionals. A variety of resources are available to deepen your knowledge and skills in this area.

- Online Tutorials: Numerous websites offer step-by-step guides and videos that cover everything from basic usage to advanced techniques.

- Manufacturer Manuals: Reviewing official manuals can provide insights into maintenance, safety procedures, and troubleshooting.

- Community Forums: Joining forums dedicated to tool enthusiasts allows you to exchange tips, ask questions, and learn from others’ experiences.

- Workshops and Classes: Local community centers or specialty stores often host hands-on workshops that focus on practical skills and safety practices.

- Books and eBooks: A range of literature is available, offering comprehensive information on tool operation, safety, and project ideas.

Utilizing these resources will not only enhance your practical skills but also build your confidence in working with specialized equipment.