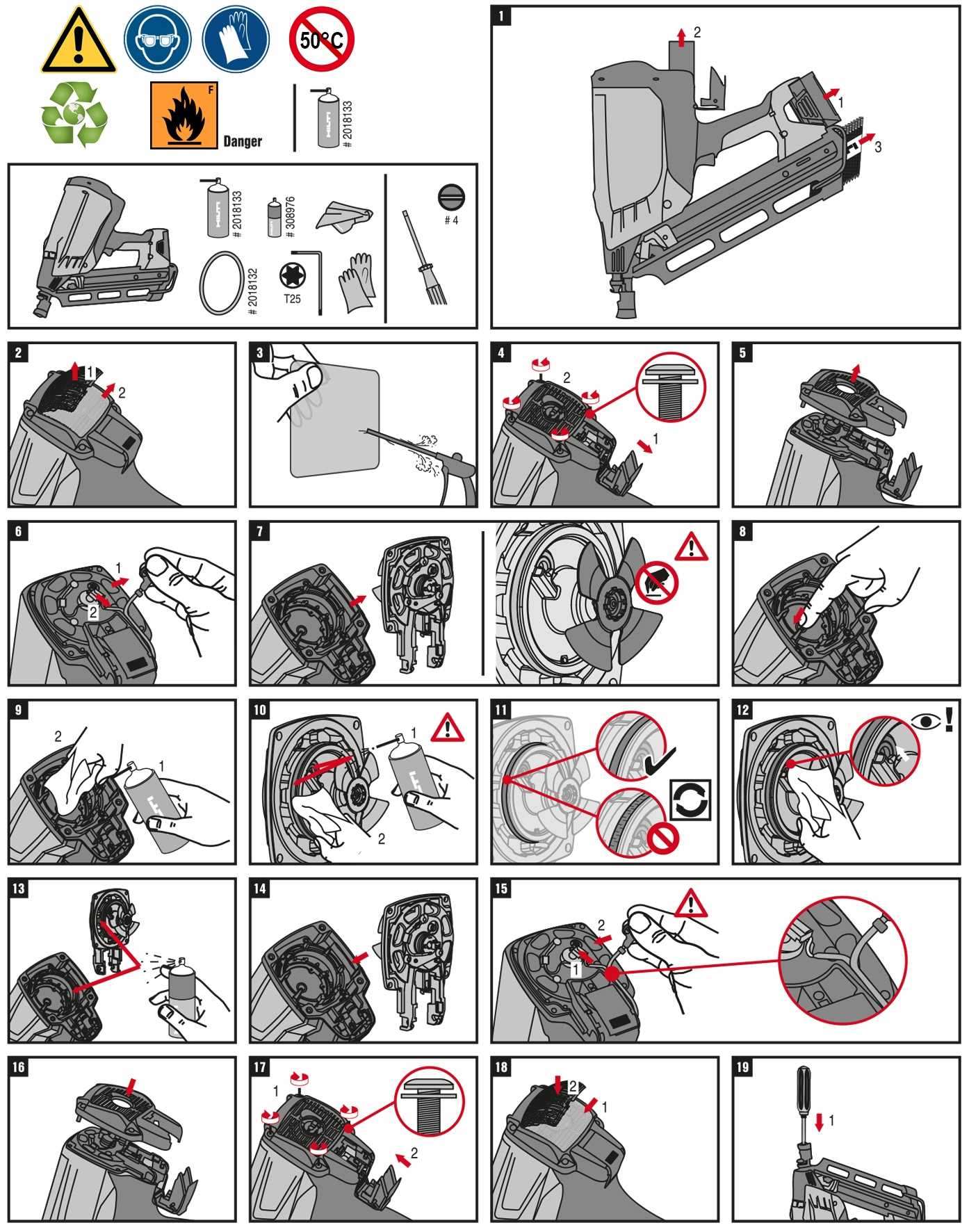

The exploration of intricate mechanical designs often requires a clear and detailed visualization of each individual element involved. Such visual aids not only enhance understanding but also ensure that each segment can be identified with precision. A well-structured blueprint serves as an invaluable resource, enabling users to quickly pinpoint and analyze specific areas of interest.

When working with complex systems, it becomes essential to have access to reliable representations of their internal structures. By utilizing these visual guides, users can navigate through intricate assemblies with ease, ensuring that each component is properly accounted for. These detailed illustrations play a crucial role in maintenance, repair, and customization tasks, offering a clear path forward.

In the context of technical work, having a reliable reference for all structural elements can make a significant difference in efficiency. Whether for professional use or personal projects, understanding the layout of mechanical systems allows for smoother workflows and a deeper grasp of how each part contributes to the overall functionality.

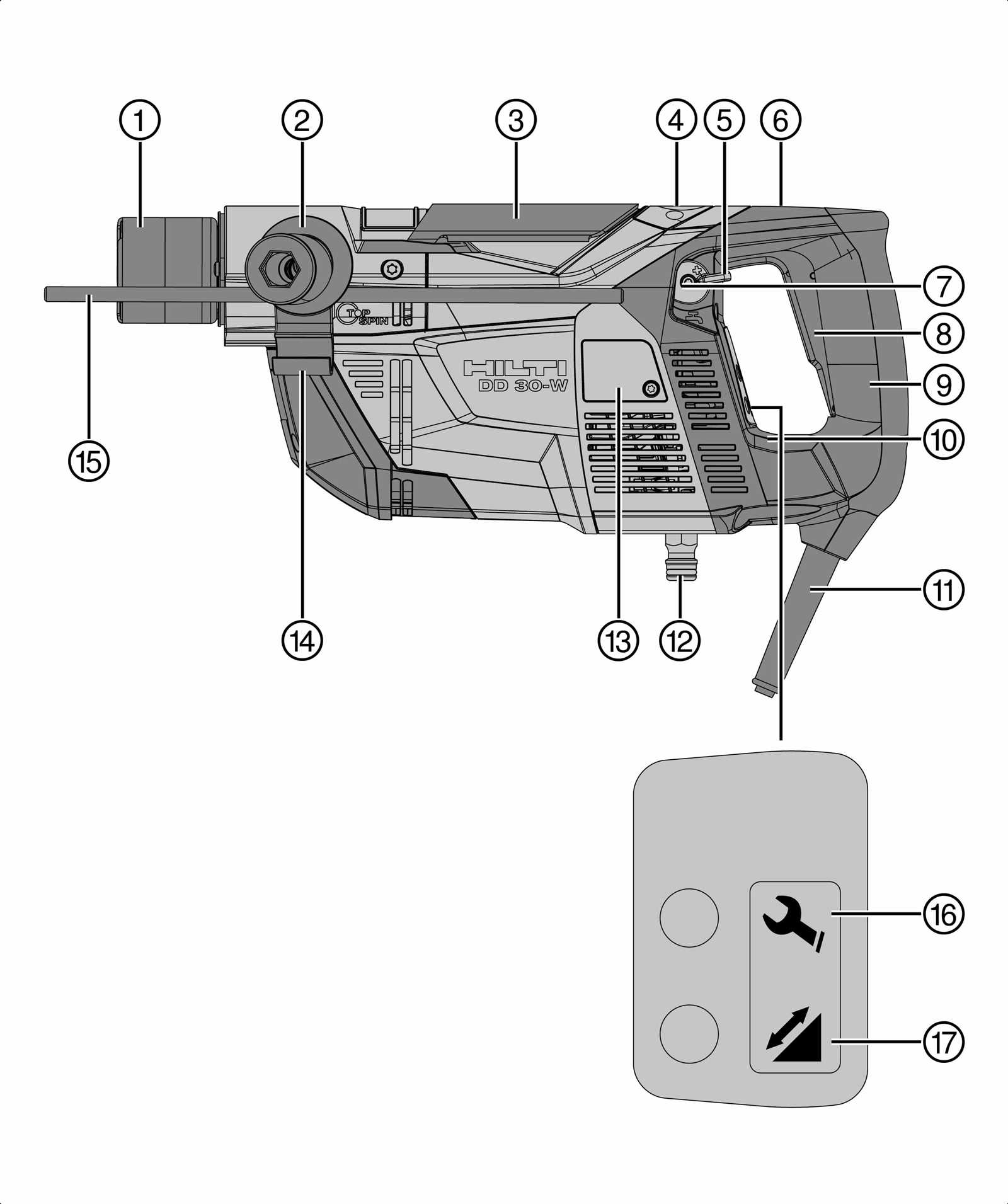

Hilti Parts Diagram Overview

This section provides a comprehensive look at the structural representation of various components and their assembly. It serves as a guide to understand how individual elements are interconnected, offering clarity on the mechanical layout of devices.

Key Component Breakdown

Understanding the layout of the essential elements is crucial for effective maintenance and repair. Below is a detailed breakdown of the main segments:

- Core assembly and alignment

- Fixing mechanisms and connectors

- Power transmission sections

Usage and Interpretation

The layout can be interpreted to assist in identifying specific elements, understanding their functions, and locating them for maintenance or replacement purposes.

- Start by analyzing the primary structural segments.

- Focus on the interconnections between different modules.

- Ensure that all components are in alignment with the overall system layout.

Key Components of Hilti Tools

Understanding the structure of professional-grade tools helps to ensure their optimal performance and longevity. Each element plays a crucial role in how these devices function, allowing for precision, durability, and efficiency across a wide range of tasks. Below, we’ll explore some of the most important elements that contribute to the functionality of these robust devices.

| Component | Description | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Motor Assembly | The powerhouse of the device, responsible for converting electrical energy into mechanical motion, driving the tool’s operation. | ||||||||||||

| Gear System | This mechanism controls the speed and torque, ensuring smooth transitions between power levels and adapting to various materials. | ||||||||||||

| Chuck Mechanism | A fastening component that holds and secures bits or attachments in place, allowing for versatile application across different tasks. | ||||||||||||

| Cooling Vents | Strategically placed openings that help dissipate heat generated during use, protecting the internal components from overheating. | ||||||||||||

| Grip and Housing |

How to Read a Hilti DiagramUnderstanding technical schematics is crucial for ensuring correct assembly, maintenance, and troubleshooting. These detailed visual guides provide clear insights into the structure and functionality of complex tools and devices. Mastering how to interpret these visuals is key to efficient usage and repair. Key Components OverviewDiagrams often include several important sections that you should familiarize yourself with. Each section represents a different aspect of the tool, allowing you to break down the information step by step.

Steps for Accurate Interpretation

Common Parts Found in Hilti ToolsVarious components are essential to the operation of power equipment used in construction and drilling tasks. These elements ensure durability, precision, and performance in daily use, allowing the tool to function smoothly across a wide range of applications. Understanding these key components can help with maintenance, repair, and optimal usage of your device. Motors and Power MechanismsThe core of any power tool is the engine or motor, responsible for converting electrical energy into mechanical movement. These power mechanisms are often designed to withstand heavy loads and provide consistent energy transfer for efficient operation. Gears and Transmission SystemsAnother crucial element is the transmission system, which allows for controlled rotation and torque. Gears work together to manage speed and force, ensuring the tool can handle different materials and tasks without compromising efficiency or safety. Understanding Hilti Tool AssemblyComprehending the structure and assembly of power tools is essential for both maintenance and effective use. By familiarizing oneself with the different components and how they fit together, one can ensure longevity and optimal performance. This section will provide an overview of how the assembly process works and what to consider when working with these tools. Key Components of the Tool

Steps for Assembling the Tool

|