When maintaining outdoor equipment, it’s essential to have a clear understanding of the internal structures and individual elements that keep the machine running smoothly. The ability to identify and access detailed layouts of each piece of the mechanism greatly simplifies the repair process, ensuring that every part is in top working order.

For those seeking to extend the lifespan of their tools, visual references can provide invaluable guidance. By closely examining the assembly and positioning of each component, users can more effectively address maintenance issues or replacement needs without unnecessary guesswork. This careful attention to detail can help prevent costly mistakes and improve overall performance.

Comprehensive Overview of the BR500 Components

Understanding the various elements that make up this equipment is crucial for maintaining its functionality and ensuring efficient operation. This section provides a detailed examination of the key units and their roles in the overall system.

- Engine Unit: The powerhouse responsible for driving the system, ensuring consistent and reliable performance under various conditions.

- Air Filtration System: Designed to protect internal components from dust and debris, this system plays a vital role in prolonging the life of the device.

- Fuel System: This component ensures proper fuel delivery and regulation, optimizing the machine’s performance while maintaining fuel efficiency.

- Control Mechanisms: Includes the various switches and levers used to operate and adjust the functionality of the device, providing users with the necessary control for different tasks.

- Exhaust System: Helps manage emissions and reduce noise, contributing to a more environmentally friendly and user-comfortable experience.

- Fan and Housing: Responsible for generating airflow, this component ensures that the machine performs its primary task effectively.

This breakdown highlights the critical systems and their importance, providing insight into how each component contributes to the overall performance.

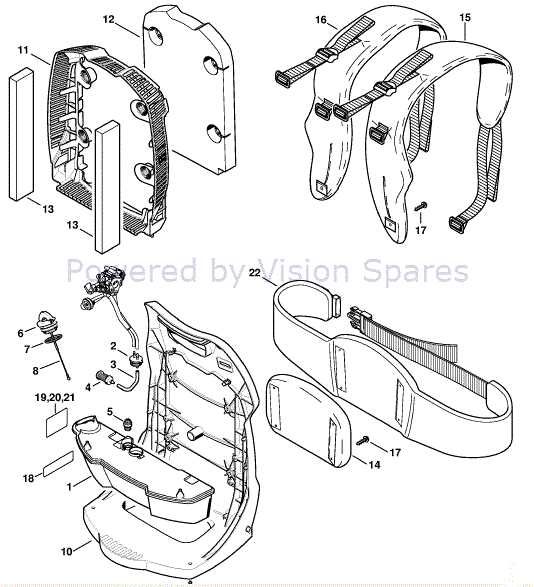

Understanding the Main Housing Structure

The external framework plays a critical role in ensuring the durability and overall protection of internal components. This outer shell is designed not only to encase various functional elements but also to withstand the rigors of extended use in demanding environments. Crafted from robust materials, it provides stability while allowing for ease of access during maintenance or repairs.

Within this structure, the integration of various panels and fasteners ensures that all internal parts remain securely in place. The design allows for airflow, preventing overheating, and incorporates ergonomic features to enhance comfort during prolonged operation. Proper understanding of this housing setup is essential for efficient maintenance and optimal performance.

Exploring the Engine Assembly Layout

The internal configuration of a powerful outdoor tool’s motor is a carefully designed system. Each component has a specific role in ensuring the overall performance and durability of the equipment. Understanding how these elements are arranged and how they interact can significantly aid in maintenance, troubleshooting, and upgrades.

Below is a detailed table showcasing the core elements involved in the motor’s structure, offering a closer look at how each section contributes to the device’s functionality.

| Component | Function | ||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cylinder | Provides the chamber where combustion occurs, generating the necessary power. | ||||||||||||||||||||||||

| Piston | Moves within the cylinder to transfer the force from combustion to mechanical energy. | ||||||||||||||||||||||||

| Crankshaft | Converts the piston’s linear motion into rotational motion to drive the output. | ||||||||||||||||||||||||

| Carburetor | Mixes air and fuel in the correct ratio for combustion within the engine. | ||||||||||||||||||||||||

Ignition System

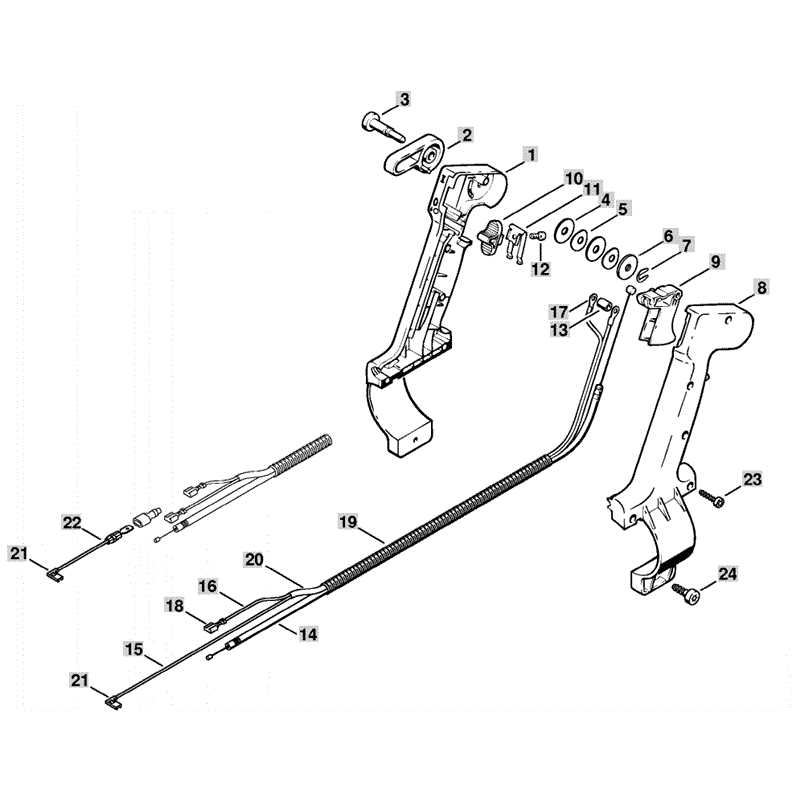

Key Elements of the Air Filtration SystemThe air filtration system is essential for maintaining optimal performance and longevity of outdoor equipment. It ensures that the engine receives clean air, free from debris and dust, which can otherwise cause damage and reduce efficiency. Understanding the core components of this system helps users ensure that their machines continue to function smoothly over time. One of the critical parts is the pre-filter, which acts as the first line of defense, trapping larger particles before they reach the main filter. This layer prevents early clogging and extends the lifespan of the primary filter. The main filter is responsible for capturing finer particles, providing an additional layer of protection to the engine. This filtration process is crucial for maintaining consistent air flow, directly impacting the overall performance of the equipment. Additionally, proper housing and sealing of the system are vital for ensuring no unfiltered air bypasses the filters. The integrity of these seals guarantees that only properly filtered air enters the combustion chamber. Regular maintenance, including cleaning or replacing the filters, ensures long-term reliability and optimal performance. Throttle Mechanism and Its Role

The throttle system is a crucial component in controlling engine performance, directly affecting speed and efficiency. Its primary function is to regulate the flow of air and fuel mixture, ensuring optimal operation under varying conditions. Understanding how this system works can provide valuable insights into maintaining peak engine performance. Below is a breakdown of the main elements involved in the throttle system:

By understanding each of these Fuel Tank and Line Connections

The proper setup and maintenance of the fuel reservoir and associated lines are crucial for ensuring optimal performance and reliability of outdoor power equipment. Understanding the layout and functionality of these components helps in troubleshooting issues and facilitating effective repairs. Fuel Reservoir Structure

The fuel reservoir typically consists of a durable plastic or composite material designed to withstand various environmental conditions. It features an opening for refueling and is equipped with a secure cap to prevent leaks. An integrated fuel filter may also be present, ensuring that impurities do not enter the engine, which can lead to performance issues. Connecting Fuel LinesFuel lines serve as the conduits that transport gasoline from the reservoir to the engine. These lines should be checked regularly for signs of wear or damage. Proper connections are vital; each line must be securely fastened to prevent fuel leaks and ensure efficient flow. Utilizing quality materials for replacement lines enhances the overall system’s durability and functionality. How the Ignition System WorksThe ignition system plays a crucial role in the operation of small engines, enabling them to start and run efficiently. It is responsible for generating the spark necessary to ignite the air-fuel mixture within the combustion chamber. This process involves several key components that work in harmony to ensure reliable performance and optimal engine function. At its core, the ignition system consists of the ignition coil, spark plug, and various electronic control elements. The ignition coil transforms the battery’s low voltage into a high voltage needed to create a spark. When the engine is cranked, the coil receives a signal from the control module, which triggers the coil to release a burst of electricity. This high-voltage pulse travels through the ignition wire to the spark plug. Once the spark plug receives the electrical pulse, it creates a spark that ignites the compressed air-fuel mixture in the engine’s combustion chamber. This ignition creates a rapid expansion of gases, pushing the piston down and generating power. Additionally, the ignition system must operate at precise timing to ensure that the spark occurs at the right moment for maximum efficiency and power output. Proper functioning of the ignition components is essential for smooth engine operation and overall performance. Analyzing the Fan and Blower ConfigurationUnderstanding the intricacies of the air circulation system is crucial for optimal performance. The interaction between the fan and blower elements significantly influences airflow dynamics, contributing to the overall efficiency of the equipment. Analyzing these components helps in identifying potential areas for improvement and maintenance, ensuring reliable operation. The fan serves as a primary mechanism for drawing air, while the blower is designed to enhance the airflow direction and pressure. Their configuration should allow for smooth airflow with minimal resistance, facilitating effective cooling and debris management. Regular inspections and adjustments can optimize their performance, leading to enhanced functionality and longevity. Attention to detail in the assembly and alignment of these components is essential. Misalignment can lead to vibrations and increased wear, affecting the overall system’s performance. Proper maintenance routines, including cleaning and lubrication, should be established to sustain the efficiency of the airflow system. This proactive approach not only improves operation but also extends the lifespan of critical components. Details of the Exhaust System ComponentsThe exhaust system plays a crucial role in managing the emissions and noise produced by internal combustion engines. Understanding its individual components is essential for proper maintenance and optimization of performance. This section delves into the various elements that constitute this vital system, highlighting their functions and importance in the overall operation. Key Components of the Exhaust SystemAmong the primary parts of the exhaust assembly are the muffler, exhaust pipe, and catalytic converter. The muffler is designed to minimize noise produced during operation, ensuring a quieter experience. The exhaust pipe directs harmful gases away from the engine and out of the vehicle, while the catalytic converter serves to reduce toxic emissions, transforming harmful substances into less harmful ones before they exit into the atmosphere. Maintenance ConsiderationsRegular inspection of the exhaust system is essential to prevent leaks and ensure efficient operation. Checking for corrosion, blockages, or damage can help identify potential issues before they escalate. Proper maintenance not only enhances performance but also contributes to environmental compliance by ensuring that emissions are kept within acceptable limits. Replacing Worn-out Belts and PulleysMaintenance of equipment is crucial for optimal performance, and one of the key aspects is ensuring that belts and pulleys are in good condition. Over time, these components can wear out, leading to decreased efficiency and potential operational failures. Regularly checking and replacing worn parts is essential to keep your machinery running smoothly. Signs of Wear and TearIdentifying when belts and pulleys need replacement can prevent further damage. Look for the following indicators:

Replacement StepsFollow these steps to replace worn belts and pulleys effectively:

Regular inspection and timely replacement of belts and pulleys can significantly extend the lifespan of your equipment and maintain its performance. Maintaining the Harness and StrapsProper upkeep of the support system and straps is essential for ensuring comfort and safety during usage. Regular inspections and maintenance can prolong their lifespan and enhance user experience. It is important to address any signs of wear or damage promptly to avoid potential accidents. Follow these guidelines to maintain the harness and straps effectively:

By adhering to these maintenance practices, users can ensure their support system remains in optimal condition, facilitating safe and comfortable operation. Electrical System Components Breakdown

The electrical system in outdoor power equipment plays a crucial role in ensuring optimal performance and reliability. Understanding the various components involved is essential for proper maintenance and troubleshooting. Each element contributes to the overall functionality, from ignition to operational controls. Below is a detailed overview of the key components commonly found in the electrical system:

Maintaining these components in good condition is vital for ensuring reliable operation. Regular inspections and timely replacements can prevent malfunctions and extend the life of the equipment. |