When working with agricultural machinery, it is crucial to comprehend how various mechanical components interact with each other. Each part plays a specific role in ensuring that the equipment functions smoothly and efficiently. By having a clear visual reference, users can easily identify different elements and maintain the machinery effectively.

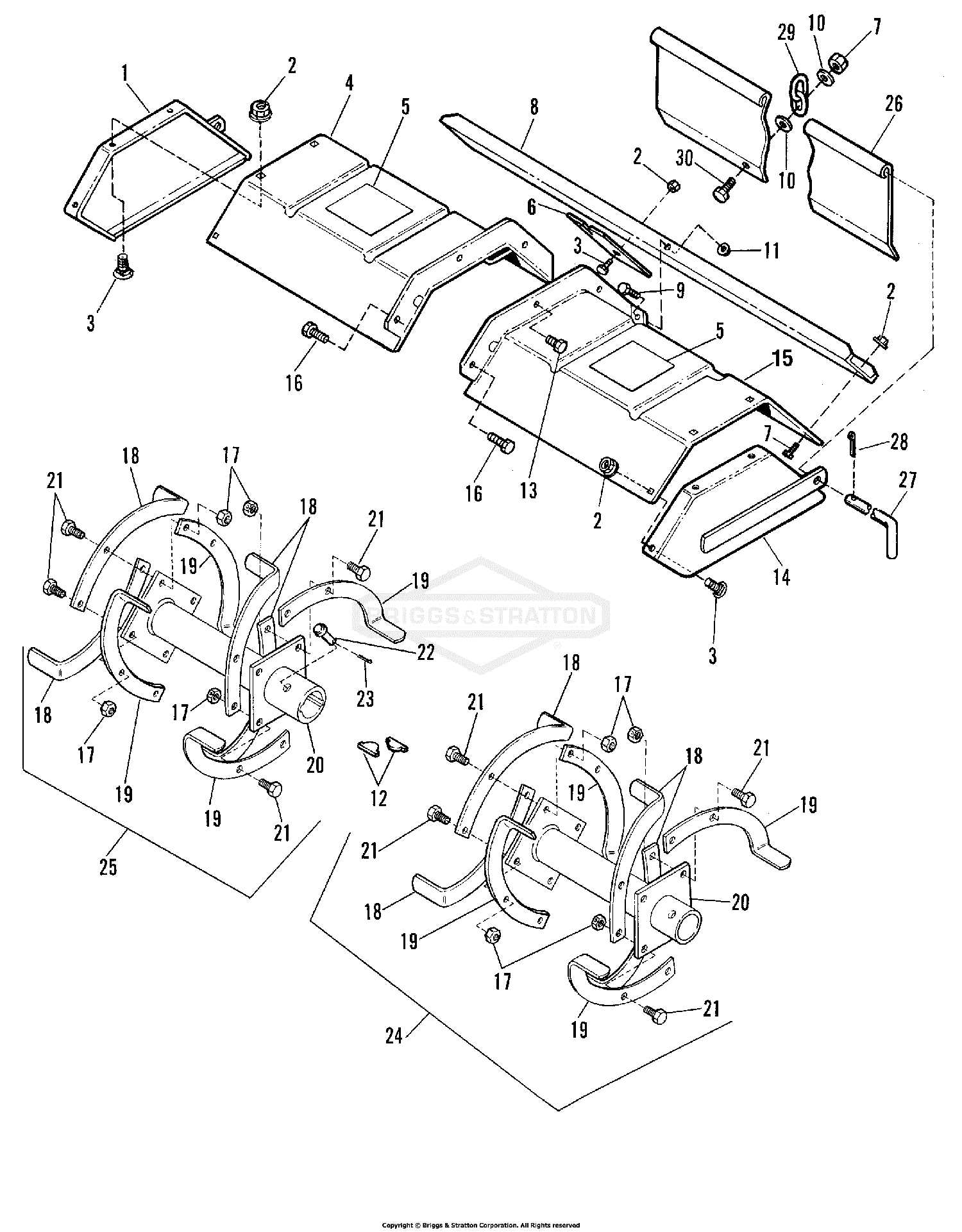

In this section, we will explore a schematic representation of key components found in soil cultivation equipment. Such diagrams help to locate and understand the role of each element, simplifying the repair and replacement process. Whether you’re a professional or a hobbyist, knowing how to read these illustrations can significantly aid in equipment upkeep.

Component schematics provide a visual guide to the arrangement and connections between various mechanical parts. These illustrations offer insights into how each part functions within the system, making troubleshooting and maintenance more accessible for users.

County Line Tiller Components Overview

The essential mechanisms of agricultural equipment include various elements that ensure its efficient operation in the field. These units work together to cultivate the soil, break it up, and prepare it for planting. Understanding how these components interact is key to maintaining high performance and reliability.

Core Mechanical Elements

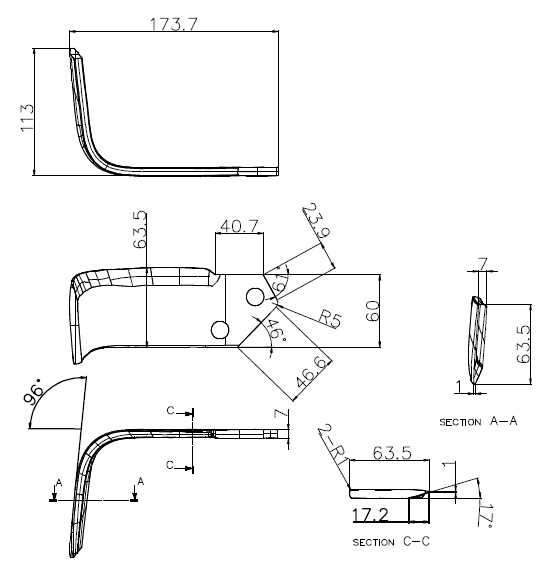

The main driving force comes from the rotary blades, which churn the soil, breaking it into smaller clumps. These rotating blades are driven by a robust power source, ensuring the equipment can handle tough terrain. The depth control mechanism is another critical part, regulating how deep the blades dig into the soil, providing precision in operation.

Support Structures and Safety Features

Supportive frameworks hold all elements together, providing durability during extensive use. Safety guards are also essential, preventing debris from being thrown during operation and ensuring that the equipment runs smoothly without endangering the operator.

Key Parts of a County Line Tiller

Understanding the essential components of this agricultural tool is crucial for efficient operation and maintenance. These machines consist of several critical elements that work together to break up soil and prepare the ground for planting. Each element plays a role in ensuring smooth functionality and durability over time.

Core Elements

The machine is composed of various moving and stationary elements, all of which contribute to its soil-working efficiency. Some of these include blades that penetrate the soil, shafts that transfer power, and guards that protect both the operator and the mechanism from debris.

Component Overview

| Component | Function |

|---|---|

| Rotary Blades | Break and turn the soil for aeration and mixing. |

| Drive Shaft | Transfers engine power to the working mechanism. |

| Frame | Holds the entire structure together and supports all parts. |

| Shielding |

How to Identify Worn Tiller BladesOver time, the cutting components of garden machinery can degrade due to consistent use. Recognizing when these parts need replacement is essential for maintaining efficient performance and preventing damage to the machine or soil. Regular inspection ensures that you catch signs of wear before they lead to bigger issues. First, look at the edges of the blades. If they appear dull or rounded, it could indicate they are no longer cutting the soil effectively. Additionally, any visible cracks or bends are signs that the metal is weakened, potentially affecting the overall function. Another sign to watch for is uneven ground coverage. Worn-out blades often result in inconsistent digging depth, leaving areas of the soil untouched or improperly turned. This can reduce the quality of the work and require more passes to achieve the desired result. Finally, strange vibrations or noises during operation could also signal that the blades are no longer balanced or have become damaged. Addressing these issues promptly can help extend the life of your equipment and ensure continued productivity. Understanding the Gearbox in Your TillerThe gearbox is a critical component in any agricultural machine, responsible for transferring power from the engine to the blades. This mechanism ensures smooth operation and allows the equipment to function at its optimal performance level. Understanding how this system works can help in troubleshooting, maintaining, and extending the lifespan of the equipment. The gearbox functions by converting engine speed into torque, which is then applied to the cutting blades. This conversion allows the blades to cut through soil efficiently, making the machine an essential tool for preparing land. Regular inspection and proper lubrication of the gearbox can prevent costly repairs and ensure the tool operates smoothly in the long run. To maintain the gearbox, check for any unusual noises, vibrations, or oil leaks, as these can be signs of wear or damage. Promptly addressing these issues will prevent further complications and keep the equipment running efficiently. Always refer to the manufacturer’s guidelines for maintenance procedures to ensure correct care of the gearbox. Tiller Shaft Assembly and FunctionThe core of any soil cultivation equipment relies on the proper assembly and function of the drive shaft. This crucial component is responsible for transferring power from the engine to the blades, ensuring smooth operation and effective ground penetration. Understanding how this mechanism works is key to maintaining optimal performance. The shaft assembly consists of several interconnected elements that ensure the power is distributed efficiently. Each part of the assembly is designed to withstand high levels of stress, working together to maintain the device’s stability during use. Proper alignment and maintenance of these elements are vital for ensuring long-lasting service and avoiding unnecessary wear. Functionally, the shaft acts as a central hub, channeling energy to the rotating blades that engage with the soil. By delivering consistent torque, it allows for the seamless breakdown of tough ground surfaces, making the task of soil preparation more efficient and less labor-intensive. How to Replace Tiller BearingsReplacing the components that support the rotational movement of agricultural equipment is essential for maintaining optimal performance. These elements ensure smooth operation, reduce friction, and enhance the overall longevity of the machinery. This guide outlines the steps necessary to effectively replace these crucial components. Tools and Materials NeededBefore starting the replacement process, gather the necessary tools and materials. You will need a wrench set, a bearing puller, grease, and replacement components. Ensuring you have everything at hand will make the procedure more efficient. Steps to Replace BearingsBegin by disconnecting the equipment from its power source to ensure safety. Next, remove any outer coverings or shields that may obstruct access to the components. Use the bearing puller to carefully detach the old units, taking care not to damage surrounding areas. Clean the housing thoroughly before installing the new bearings, ensuring a snug fit. Finally, apply a suitable grease to minimize friction and reassemble the equipment, testing its functionality once complete. Types of Tiller Tines and Their UsesTines play a crucial role in soil cultivation, impacting the efficiency and effectiveness of ground preparation. Different shapes and materials of tines are designed to achieve various tasks, from breaking up hard ground to mixing soil with organic matter. Understanding these variations allows for optimal performance and results in gardening and farming endeavors. Standard TinesStandard tines are commonly used for general cultivation and are effective in loosening and aerating the soil. Their design typically features a straight or slightly curved shape, making them ideal for breaking up compacted earth. These tines are suitable for a wide range of tasks, including preparing seedbeds and incorporating fertilizers. Twisted TinesTwisted tines offer enhanced soil penetration and mixing capabilities. The spiral shape helps to pull the tine deeper into the earth, effectively breaking up clods and aerating the soil more thoroughly. This type is particularly beneficial for working in tougher soil conditions or when the goal is to mix soil with compost or mulch. Clutch Maintenance for County Line TillersRegular upkeep of the engagement mechanism is crucial for optimal performance and longevity of your gardening equipment. Ensuring this component operates smoothly can significantly enhance efficiency during usage, allowing for a seamless experience in maintaining your land. Proper attention to this aspect not only prevents premature wear but also avoids costly repairs in the future. Signs of Wear and Necessary AdjustmentsIdentifying issues early can save you time and money. Common indicators of a malfunctioning engagement system include unusual noises, difficulty in operation, or slippage during use. If you notice any of these symptoms, it is essential to conduct a thorough inspection. Adjustments may be needed to restore proper functionality and prevent further damage. Maintenance TipsTo keep the engagement system in top shape, consider the following tips:

By implementing these practices, you can ensure the reliability and efficiency of your machinery, promoting a successful gardening experience. Importance of the PTO Shaft in TillersThe power take-off shaft plays a crucial role in the functioning of agricultural machinery, facilitating the transfer of energy from the engine to various implements. This vital component enables effective operation, ensuring that attachments perform their designated tasks efficiently. Understanding its significance helps users appreciate the overall functionality of their equipment. Functionality and EfficiencyThe PTO shaft serves as a link between the engine and the implement, allowing the machine to harness power for tasks such as soil cultivation and ground preparation. By converting the rotational energy generated by the engine, it ensures that the attachment operates smoothly, maximizing productivity during agricultural activities. Maintenance and Longevity

Proper maintenance of the power take-off shaft is essential for the longevity of both the shaft and the machinery it supports. Regular inspection and lubrication can prevent wear and tear, ensuring consistent performance. Neglecting this component may lead to operational issues, affecting the efficiency of the entire system. How to Adjust the Tiller Depth Settings

Adjusting the depth settings of your gardening implement is essential for optimizing its performance and achieving the desired soil condition. Proper depth adjustment ensures efficient operation and can enhance your cultivation results. Here’s a guide to help you make the necessary adjustments effectively. Follow these steps to adjust the depth settings:

Regularly checking and adjusting the depth settings will help you maintain optimal soil health and improve the efficiency of your gardening tasks. Safety Shields and Their Role in TillersSafety shields play a crucial role in agricultural machinery by providing essential protection for operators and bystanders. These barriers are designed to prevent accidental contact with moving components, which can pose significant hazards during operation. Proper implementation of safety features is vital for ensuring a secure working environment while using tilling equipment. These protective elements help minimize the risk of injuries caused by debris or unintended contact with the machine’s moving parts. By creating a physical barrier, safety shields enhance the overall safety of the equipment and encourage responsible usage. Operators should regularly inspect and maintain these shields to ensure they remain effective and in good condition, thereby fostering a culture of safety in agricultural practices. Furthermore, safety shields contribute to compliance with regulatory standards and promote safe working habits among users. Familiarizing oneself with the operational guidelines and the importance of these protective features is essential for maximizing safety and efficiency while using tilling machinery. Troubleshooting Common Tiller Part IssuesMaintaining optimal performance of garden machinery is essential for effective soil preparation. Various components can experience problems that hinder efficiency and functionality. Identifying these issues early can prevent costly repairs and ensure a smoother operation during gardening tasks. One common issue is difficulty starting the machine. This could stem from a faulty spark plug or a clogged air filter. Regular checks and cleanings can help ensure that the ignition system is working correctly. If the engine starts but runs poorly, it may indicate issues with fuel delivery or a blocked carburetor. Another frequent concern involves the equipment not tilling properly. This can occur if the blades are dull or damaged. Inspecting the cutting implements regularly for wear and tear is crucial. Replacing them as needed can restore the effectiveness of the machinery. Furthermore, operators may notice unusual vibrations or noises during use. These symptoms can point to loose or worn components within the machinery. It is advisable to inspect all bolts and screws to ensure they are tightened adequately. Additionally, checking for any obstructions in the mechanism can prevent further damage. |