The intricacies of machinery often require a detailed exploration of their constituent elements. A comprehensive overview of these parts not only enhances operational efficiency but also aids in effective maintenance and troubleshooting. Familiarizing oneself with the arrangement and functionality of each section is crucial for anyone working with complex equipment.

In this guide, we delve into the essential features of a specific model, shedding light on the various components and their interconnections. This knowledge empowers operators to make informed decisions and optimize performance, ensuring that every element works in harmony.

Whether you’re a seasoned technician or a newcomer, grasping the layout of these essential mechanisms will enhance your understanding and proficiency. With clear illustrations and descriptions, this resource aims to clarify the roles of each individual part, fostering a deeper appreciation for the equipment’s design and functionality.

Understanding the Vermeer BC600XL Parts

When it comes to the maintenance and operation of specialized machinery, comprehending the individual components is crucial. Each element plays a significant role in ensuring the equipment runs smoothly and efficiently. A thorough grasp of these elements not only aids in troubleshooting but also enhances overall performance.

Key components of such machines include the engine, hydraulic systems, and cutting mechanisms. These parts work in harmony to provide optimal functionality. Regular inspections and an awareness of how these elements interact can prevent costly breakdowns and extend the lifespan of the equipment.

Familiarizing oneself with the layout and function of these components can significantly improve maintenance routines. Understanding the specific role of each piece allows operators to make informed decisions regarding repairs and upgrades. This knowledge is essential for anyone involved in the care or operation of the machinery.

Overview of the BC600XL Model

This section provides a comprehensive look at a specialized equipment model designed for efficiency and versatility in various tasks. This machine is known for its robust construction and user-friendly features, making it a popular choice among professionals in the field.

Key Features

- Powerful engine for optimal performance

- Compact design for ease of maneuverability

- Advanced safety mechanisms to protect users

- Innovative technology for enhanced functionality

Applications

- Tree care and maintenance

- Landscaping and gardening projects

- Utility line clearance

- General outdoor work requiring heavy-duty equipment

The combination of these features and applications makes this model an essential tool for those seeking reliability and performance in their operations.

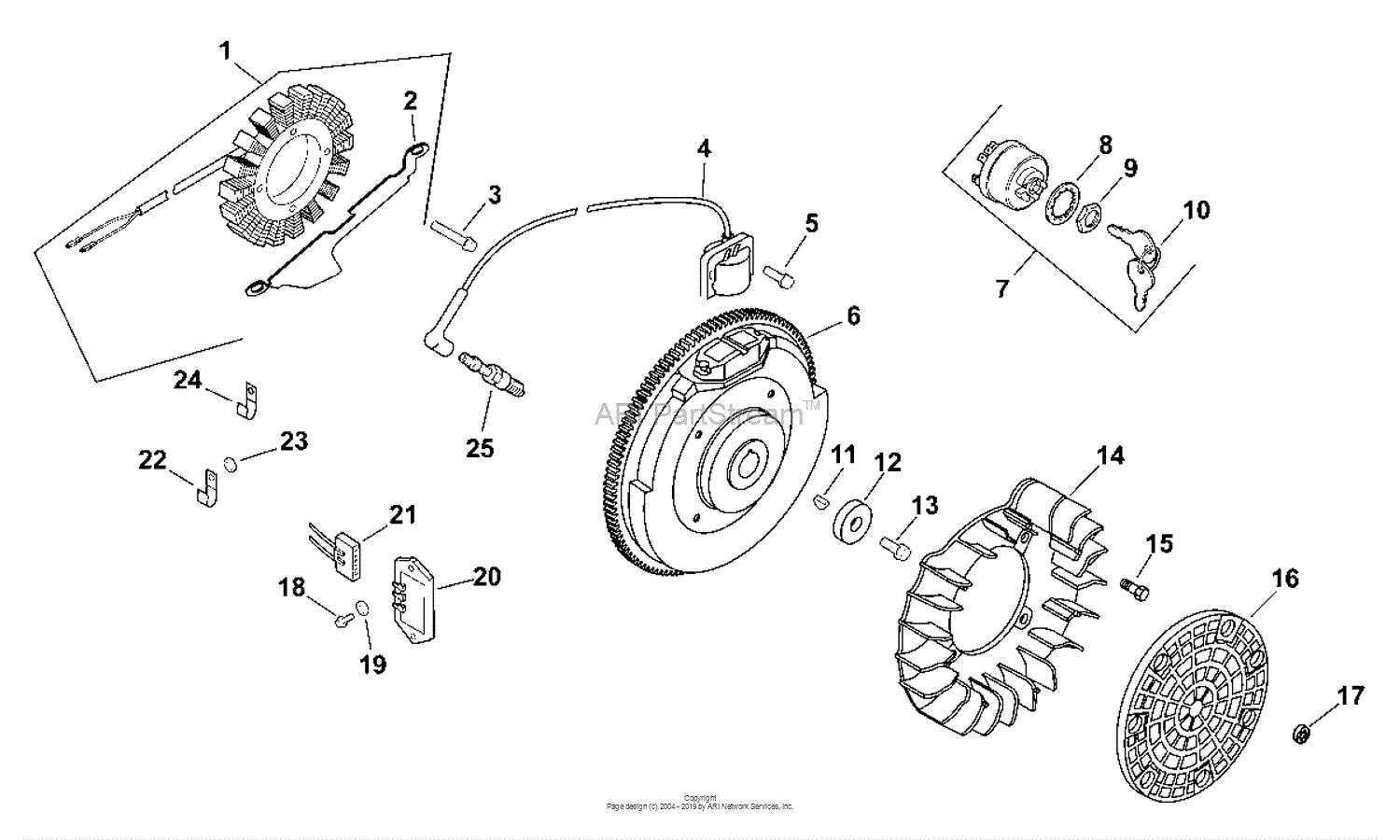

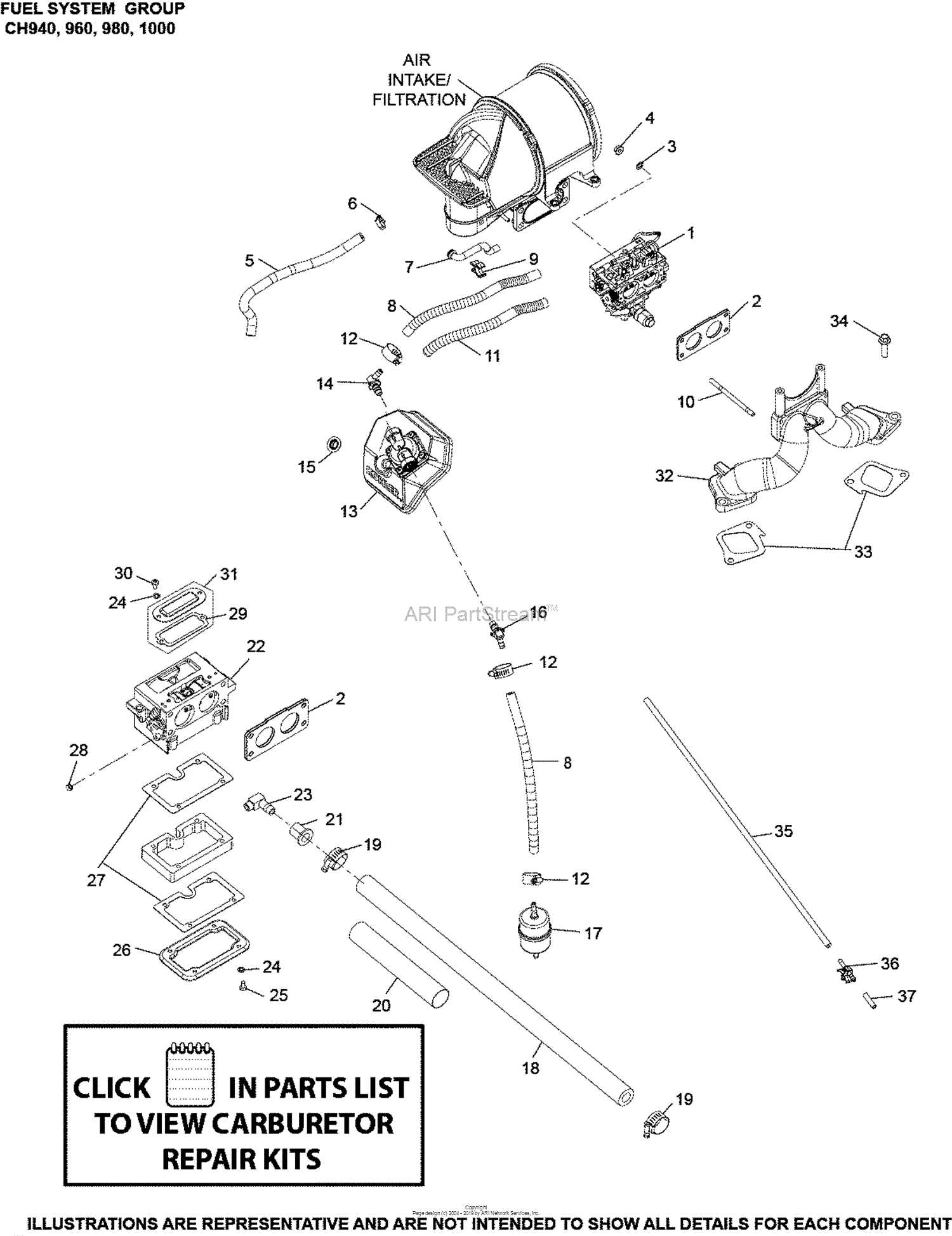

Importance of a Parts Diagram

A visual representation of components plays a crucial role in understanding machinery and equipment. It serves as an essential tool for maintenance, repair, and assembly, allowing users to identify and locate specific elements quickly. Such representations are invaluable for both novice and experienced technicians, ensuring efficient workflow and minimizing errors.

Here are several key reasons why having a visual reference is vital:

- Improved Efficiency: Quick identification of components reduces the time spent searching for parts during repairs or maintenance.

- Enhanced Communication: Clear visuals facilitate better communication among team members, ensuring everyone understands the specific elements being discussed.

- Accurate Repairs: Knowing the exact placement and connection of parts leads to more precise and reliable repairs.

- Training Resource: New technicians can use these visual aids to familiarize themselves with equipment layout and assembly, speeding up the learning process.

- Reduced Downtime: With clear guidance, maintenance tasks can be completed faster, minimizing operational interruptions.

Overall, the use of a comprehensive visual guide is indispensable in the effective management and operation of machinery, ensuring longevity and optimal performance.

Key Components of the Chipper

Understanding the essential elements of a wood chipper is crucial for effective operation and maintenance. Each part plays a specific role in ensuring the machine functions efficiently and delivers optimal performance. By familiarizing yourself with these components, you can enhance both productivity and longevity of the equipment.

Feeding System

The feeding mechanism is responsible for directing material into the chipper. It often consists of rollers that grip and pull the wood toward the blades. A well-designed feeding system minimizes jams and maximizes throughput, allowing for a smoother operation.

Cutting Mechanism

This section contains the blades or knives that shred the wood into chips. High-quality cutting tools are essential for achieving clean cuts and efficient processing. Regular maintenance of this component ensures consistent performance and reduces the need for replacements.

Safety Features are also integral to the chipper’s design, protecting the operator and ensuring safe operation during use. Understanding these critical elements is vital for anyone working with this machinery.

How to Read the Diagram

Understanding a schematic representation is essential for anyone involved in maintenance or repair tasks. These visual guides provide crucial information about the components and their relationships, enabling efficient troubleshooting and assembly. A clear grasp of how to interpret these illustrations can significantly enhance your ability to work with machinery.

Start with the Legend: Most diagrams include a legend or key that explains the symbols and notations used. Familiarizing yourself with these symbols is the first step toward accurate comprehension. Each icon typically represents a specific component, making it easier to identify parts at a glance.

Follow the Flow: Diagrams often depict the flow of processes or systems. Look for arrows or lines that indicate movement or connection between parts. Understanding this flow helps in visualizing how the system operates as a whole, which is vital for effective repairs.

Pay Attention to Numbers: Many representations include numbered components or sections. These numbers often correspond to lists or tables that provide detailed descriptions. Referencing these resources can give you further insight into specifications, dimensions, and other critical details.

Identify Groupings: Components are usually organized in groups based on their functions or locations. Recognizing these groupings can aid in isolating specific issues or understanding how different elements interact with each other. This organization is especially helpful during disassembly and reassembly tasks.

By taking the time to thoroughly analyze each element of the schematic representation, you can enhance your ability to diagnose problems and execute repairs with confidence and precision.

Common Maintenance Tips

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. By adhering to a routine maintenance schedule, you can prevent unexpected breakdowns and enhance overall performance. Here are some key practices to keep in mind.

Routine Checks

- Inspect all moving components for signs of wear and tear.

- Ensure that all bolts and fasteners are securely tightened.

- Examine hydraulic systems for leaks or damage.

- Check fluid levels regularly and replenish as needed.

Cleaning and Lubrication

- Clean all external surfaces to prevent dirt accumulation.

- Lubricate pivot points and moving parts to reduce friction.

- Replace air and oil filters as per the manufacturer’s recommendations.

- Clear debris from cooling systems to maintain optimal temperatures.

By implementing these simple yet effective maintenance practices, you can significantly extend the lifespan of your machinery and ensure it operates at peak performance.

Identifying Replacement Parts

When maintaining machinery, recognizing the essential components that require substitution is crucial for optimal performance. A thorough understanding of each element’s function can greatly aid in ensuring that the equipment operates smoothly. This section focuses on how to effectively identify and source the necessary items to keep your machinery in top condition.

To assist in the identification process, a systematic approach can be employed. Begin by familiarizing yourself with the key components, their specifications, and any common issues that may arise. This knowledge will enable you to pinpoint which elements are in need of replacement.

| Component | Function | Common Issues |

|---|---|---|

| Drive Belt | Transfers power from the engine | Wear and tear, fraying |

| Hydraulic Filter | Removes contaminants from hydraulic fluid | Clogging, reduced efficiency |

| Oil Seal | Prevents leakage of fluids | Cracking, loss of pressure |

| Air Filter | Filters air entering the engine | Dirt accumulation, decreased airflow |

By following this structured approach and consulting the relevant resources, you can confidently identify the components that need attention. Remember to always refer to the manufacturer’s guidelines for accurate information on specifications and compatibility.

Where to Source Genuine Parts

Finding authentic components for your machinery is crucial for maintaining performance and longevity. Quality replacement items ensure that your equipment operates efficiently and minimizes the risk of future issues. This section explores reliable avenues for acquiring these essential supplies.

Authorized Dealers

One of the most dependable options is to purchase from authorized dealers. These distributors are officially recognized by the manufacturer and typically stock a comprehensive range of original components. Engaging with these suppliers not only guarantees authenticity but also provides access to expert advice and support.

Online Marketplaces

Another viable avenue is to explore online marketplaces. Websites that specialize in machinery components often feature listings from trusted sellers. When using these platforms, look for items marked as “genuine” and check seller ratings to ensure you’re receiving high-quality merchandise. Reading customer reviews can also help identify reliable sources.

Tools Required for Repairs

Proper maintenance and repair of equipment necessitate a specific set of instruments to ensure efficiency and effectiveness. Having the right tools on hand not only streamlines the repair process but also enhances safety and accuracy.

Below is a list of essential tools that are commonly required for carrying out repairs:

- Wrenches: A variety of sizes for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips for different types of screws.

- Socket Set: For removing and installing fasteners in tight spaces.

- Pliers: Useful for gripping, bending, and cutting wire or other materials.

- Hammer: For driving nails or fitting parts together.

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications.

- Utility Knife: Handy for cutting materials with precision.

- Multimeter: For testing electrical systems and components.

Before beginning any repair work, it’s advisable to gather all necessary tools to avoid interruptions. Familiarity with each tool’s purpose will also contribute to a more efficient repair experience.

Safety Precautions During Repairs

When undertaking maintenance or fixing machinery, adhering to safety guidelines is crucial to ensure a secure working environment. Proper precautions not only protect the individual performing the repairs but also help prevent potential hazards that could affect others nearby.

First and foremost, it is essential to wear appropriate personal protective equipment (PPE). This includes safety goggles to shield the eyes from debris, gloves to protect the hands from sharp edges or chemicals, and sturdy footwear to prevent injuries from falling objects. Additionally, using hearing protection may be necessary if the repair process involves loud tools.

Before starting any work, it is vital to disconnect the power supply to the equipment. This minimizes the risk of accidental starts and electrical shocks. Ensuring that the workspace is well-lit and free of clutter can also significantly reduce the likelihood of accidents. A clean environment allows for better visibility and access to tools, which can enhance efficiency and safety.

Understanding the equipment’s manual and safety instructions is imperative. Familiarizing oneself with the machinery’s components and the correct procedures for disassembly and reassembly helps avoid mistakes that could lead to injuries. Moreover, utilizing the right tools for the job prevents unnecessary strain and damage.

Finally, if assistance is needed, don’t hesitate to ask for help. Having a second person available can be invaluable, especially when handling heavy parts or complex repairs. By taking these safety measures seriously, one can ensure a more secure and effective repair process.

FAQs About BC600XL Parts

This section addresses common inquiries related to components and their maintenance for the specified machinery. Understanding these elements can help ensure optimal performance and longevity of the equipment.

What are the signs that a component needs replacement?

Several indicators suggest that a specific element may require attention. Look for unusual noises, decreased efficiency, or visible wear and tear. Regular inspections can help identify issues before they escalate.

Where can I find replacement components?

Replacement elements can typically be sourced from authorized dealers or online retailers specializing in equipment accessories. Always ensure that the items are compatible and of high quality to maintain functionality.

Comparing BC600XL with Other Models

In the realm of equipment designed for efficient tree care and landscaping, different models offer unique features that cater to various operational needs. Analyzing the distinctions between a specific model and its counterparts can provide valuable insights for users aiming to select the most suitable option for their tasks.

Performance and Efficiency

When evaluating performance, it is essential to consider the power output and processing capabilities. Some models may excel in handling larger branches, while others are optimized for speed and maneuverability. Efficiency often hinges on the balance between engine strength and weight, influencing how easily the equipment can be transported and operated in various environments.

Durability and Maintenance

Another critical aspect is the construction quality and maintenance requirements. Certain designs feature robust materials that enhance longevity, whereas others may prioritize lightweight construction for ease of use. Regular maintenance schedules can differ significantly, impacting long-term operational costs and performance reliability. Users must weigh these factors when making a choice that aligns with their specific operational demands.