In the world of outdoor machinery, comprehending the various components that make up these tools is essential for effective maintenance and repair. Knowing the structure and function of each element allows users to ensure optimal performance and longevity. A well-organized overview can provide valuable insights into how these pieces interact within the whole system.

Exploring the configuration of an equipment assembly can illuminate common issues and enhance the troubleshooting process. By delving into the specifics, users can identify parts that may require attention or replacement, thereby minimizing downtime and improving overall efficiency. Having a clear reference can serve as a significant advantage when it comes to managing maintenance tasks.

Furthermore, understanding the relationships between the various elements can foster a deeper appreciation for the engineering that underpins these machines. This knowledge empowers users to take informed steps in their upkeep, ensuring that their tools remain reliable and effective over time.

Key Features of Husqvarna 575xp

This model stands out in the market for its impressive functionality and robust design. It is engineered to cater to the needs of both professional users and enthusiastic hobbyists. The combination of power and efficiency makes it an exceptional choice for various tasks, from forestry to landscaping.

- Powerful Engine: Equipped with a high-performance engine, it delivers excellent cutting capabilities.

- Lightweight Design: The thoughtful construction ensures easy maneuverability without sacrificing strength.

- Enhanced Safety Features: Safety mechanisms are integrated to protect the operator during use.

- Ergonomic Handle: The comfortable grip reduces fatigue, allowing for extended operation periods.

- Durability: Made with high-quality materials, it withstands rigorous use in demanding environments.

These elements work together to create a reliable tool that excels in performance and user satisfaction.

Importance of Parts Diagrams

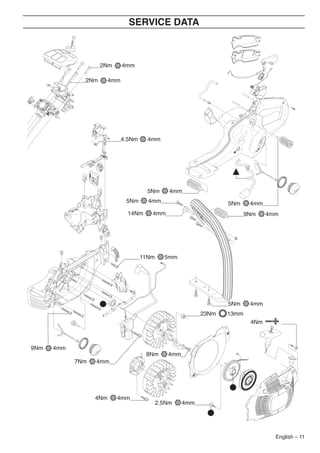

Understanding the arrangement and functionality of components in a machine is crucial for effective maintenance and repair. Visual representations serve as valuable tools, enabling users to grasp the structure and interrelationships between various elements. These illustrations aid in identifying specific components and comprehending their roles within the overall system.

Enhancing Maintenance Efficiency

Utilizing visual aids simplifies the repair process by providing clear guidance on disassembly and reassembly. This clarity reduces the likelihood of errors, ensuring that every piece is correctly positioned, which ultimately extends the life of the equipment. A well-structured representation allows technicians to quickly locate parts and streamline their workflow.

Facilitating Replacement and Upgrades

Visual references also play a significant role when it comes to replacing or upgrading components. By clearly displaying the necessary elements, these guides help users make informed decisions about compatible upgrades. This not only enhances the performance of the machine but also fosters a better understanding of how different components interact.

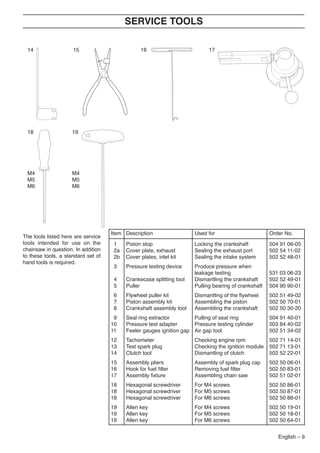

Common Replacement Parts Overview

When maintaining outdoor power equipment, understanding frequently replaced components is essential for optimal performance. Regular wear and tear can affect functionality, so familiarizing yourself with essential elements can help ensure a smoother operation.

Typical Components for Maintenance

Among the most commonly exchanged items are filters and spark plugs. These components play crucial roles in the efficiency of the machine, impacting fuel consumption and overall performance. Ensuring they are in good condition can prevent potential issues and extend the life of the equipment.

Additional Parts to Consider

Other vital elements that may require attention include chains, bars, and carburetors. Regular inspection and timely replacement of these parts can enhance productivity and minimize downtime. Keeping spare components on hand can help address any sudden failures, allowing for quick repairs and continuous use.

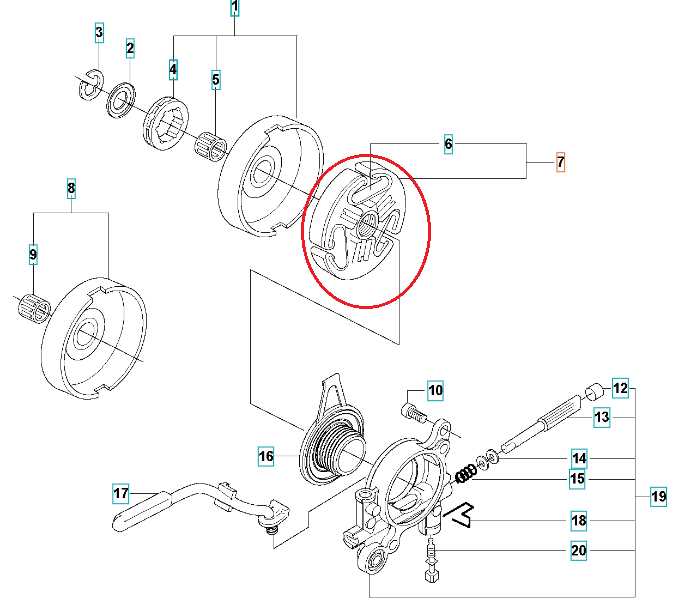

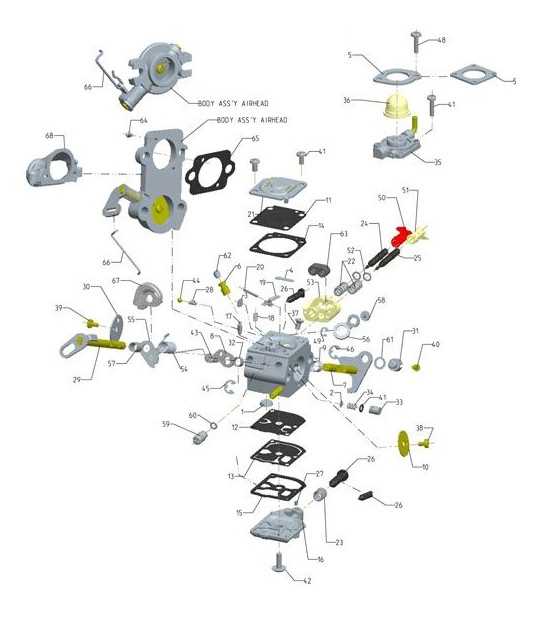

How to Interpret Parts Diagrams

Understanding visual representations of components can greatly enhance your ability to identify and locate each element within a machine. These illustrations serve as valuable guides, allowing users to see the arrangement and relationships between various sections. By familiarizing yourself with the layout, you can effectively navigate through complex assemblies.

When examining these visuals, focus on the labels and numbers assigned to each item. These identifiers correlate to a list or catalog, which provides further details about each element, including specifications and potential replacement options. This connection is crucial for accurately sourcing the required components when repairs or replacements are necessary.

Additionally, pay attention to the overall structure shown in the illustration. Recognizing how different parts fit together and understanding their functions will facilitate smoother assembly and disassembly processes. A comprehensive grasp of the assembly’s architecture leads to improved maintenance practices and can significantly prolong the lifespan of your equipment.

Maintenance Tips for 575xp

Proper upkeep is essential for ensuring the longevity and optimal performance of your equipment. Regular maintenance not only enhances efficiency but also prevents costly repairs in the future. Following a structured routine can help you avoid common issues and keep your machine running smoothly.

Regular Inspection

Conducting periodic checks is vital for identifying potential problems before they escalate. Look for signs of wear and tear, ensuring that all components are functioning correctly. Addressing minor issues promptly can save time and resources.

Cleaning and Lubrication

Keeping your device clean is crucial for maintaining its efficiency. Remove any debris and buildup from the exterior and internal components. Additionally, ensure that all moving parts are properly lubricated to reduce friction and prevent premature wear.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Check air filter | Every 10 hours | Replace if dirty or damaged |

| Inspect spark plug | Every 25 hours | Clean or replace as needed |

| Sharpen chain | As needed | Maintain sharpness for efficiency |

| Change oil | Every 50 hours | Use recommended oil type |

Finding Genuine Replacement Parts

When it comes to maintaining outdoor machinery, sourcing authentic components is crucial for optimal performance and longevity. Ensuring that you obtain the correct items can make a significant difference in the functionality and efficiency of your equipment.

Importance of Authentic Components

Utilizing genuine components guarantees compatibility and reliability. Imitation alternatives may seem cost-effective initially, but they often lead to further issues, including decreased efficiency and potential damage to the machinery. Investing in quality ensures peace of mind and extends the lifespan of your equipment.

Where to Look for Authentic Items

There are several reliable sources for acquiring authentic components. Official retailers and authorized dealers typically offer a wide range of items and provide assurance of their authenticity. Additionally, reputable online platforms can also be a great resource, but it’s essential to verify the seller’s credibility before making a purchase.

Assembly and Disassembly Guidance

This section provides essential instructions for the effective assembly and disassembly of your equipment. Understanding the proper techniques will ensure optimal performance and longevity. Following these guidelines will help you safely manage the components involved, making the process straightforward and efficient.

Before starting, gather all necessary tools and components. Ensure that you work in a well-lit area to minimize errors. Read through the steps carefully to familiarize yourself with the entire procedure.

| Step | Action | Notes |

|---|---|---|

| 1 | Remove any protective covers | Ensure the equipment is turned off before starting. |

| 2 | Loosen the screws | Use the appropriate screwdriver for the screws. |

| 3 | Carefully detach the components | Keep track of the order for reassembly. |

| 4 | Clean any residue from surfaces | Use a cloth or brush suitable for the material. |

| 5 | Reattach components in reverse order | Ensure all screws are tightened properly. |

Following these steps will help you navigate the assembly and disassembly processes effectively. Always prioritize safety and take your time to avoid mistakes.

Identifying Wear and Tear Issues

Recognizing signs of deterioration in machinery is crucial for maintaining optimal performance and longevity. Regular inspection helps detect problems before they escalate, ensuring that equipment operates efficiently. By being aware of common indicators, operators can prevent costly repairs and downtime.

Common symptoms of wear may include unusual noises, reduced efficiency, or visible damage to components. Frequent maintenance and careful observation of these signs can significantly enhance the lifespan of the equipment. Addressing these issues promptly not only ensures safety but also maximizes productivity.

Upgrades and Modifications Options

Enhancing and customizing your equipment can significantly improve its performance and efficiency. By exploring various upgrade possibilities, users can tailor their machines to better suit their specific needs and preferences. This section highlights some of the most effective options for modifications that can elevate the overall functionality and usability of your unit.

| Upgrade Type | Description | Benefits |

|---|---|---|

| Fuel System Upgrade | Replacing the stock fuel system with a high-performance variant. | Improved fuel efficiency and increased power output. |

| Air Filter Modification | Installing a high-flow air filter to enhance air intake. | Better airflow leads to enhanced engine performance. |

| Exhaust System Upgrade | Upgrading to a performance exhaust for better exhaust flow. | Reduces back pressure and increases horsepower. |

| Bar and Chain Adjustments | Using longer bars or specialized chains for specific tasks. | Increased cutting efficiency and versatility. |

| Anti-Vibration Handles | Installing ergonomic grips to reduce user fatigue. | Enhances comfort during extended use. |

Frequently Asked Questions

This section addresses common inquiries regarding the components and assembly of a particular outdoor power equipment model. Here, you will find valuable insights that assist in understanding various aspects related to maintenance and functionality.

What should I do if a component breaks?

If you encounter a malfunction, it’s advisable to consult a repair manual or a professional service to ensure correct replacement and functionality of the unit.

How can I identify the correct replacement part?

Identifying the appropriate replacement can be achieved by referencing the user manual or consulting online resources that provide detailed specifications for your model.

Where can I purchase replacement components?

Replacement components can typically be found at authorized dealers, online marketplaces, or specialty stores that focus on outdoor machinery supplies.

Is it difficult to install new components myself?

The installation process can vary in complexity depending on the part. It’s essential to follow guidelines carefully, and if uncertain, seeking professional assistance is recommended.