When delving into the intricate workings of power tools, comprehending the layout of their individual components is crucial. This knowledge not only aids in effective maintenance and repair but also enhances the overall functionality of the equipment. A well-organized representation of these elements can significantly streamline the troubleshooting process.

Effective management of tool components ensures optimal performance and longevity. Each part plays a vital role, contributing to the efficiency and reliability of the device. Understanding the specific arrangement of these elements allows users to identify potential issues and address them promptly, minimizing downtime and enhancing productivity.

Furthermore, familiarity with the configuration of components empowers users to make informed decisions regarding upgrades or replacements. By recognizing the interconnections and functions of each part, one can better assess the tool’s capabilities and limitations, ultimately leading to a more satisfying and successful experience in various projects.

This section aims to provide a comprehensive overview of a specific power tool, focusing on its essential components and their functionalities. By exploring the inner workings, users can better appreciate how the tool operates and maintain it effectively.

Understanding the various elements of the device allows for informed usage and troubleshooting. Here are the key aspects to consider:

- Core Features: Identify the primary functionalities that enhance performance.

- Component Roles: Each part contributes to the overall operation, playing a vital role in efficiency.

- Maintenance Tips: Regular upkeep is crucial for longevity, ensuring optimal performance over time.

Furthermore, familiarity with the structure aids in recognizing potential issues, leading to quicker resolutions. Here’s a breakdown of notable components:

- Power Source: Understand the type of energy that drives the tool.

- Motor: The heart of the device that powers all operations.

- Attachment Mechanism: Explore how different accessories can enhance functionality.

By grasping these fundamental aspects, users can maximize their experience and ensure that their equipment remains in top-notch condition.

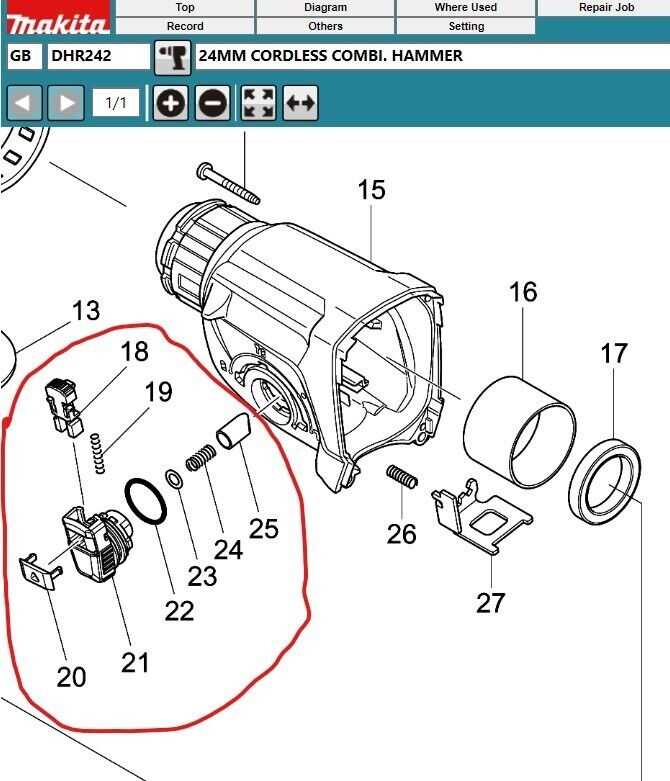

Key Features of DHR242 Model

This tool stands out due to its exceptional performance and versatility, catering to a variety of applications. Designed for both professionals and DIY enthusiasts, it boasts advanced capabilities that enhance efficiency and effectiveness during use.

Power and Performance

- Equipped with a robust motor that delivers high-speed operation.

- Features multiple speed settings for different tasks, allowing for optimal control.

- Engineered for minimal vibration, promoting user comfort during extended use.

Durability and Design

- Constructed with high-quality materials for long-lasting durability.

- Ergonomically designed handle that ensures a secure grip, reducing fatigue.

- Compact and lightweight structure, making it easy to maneuver in tight spaces.

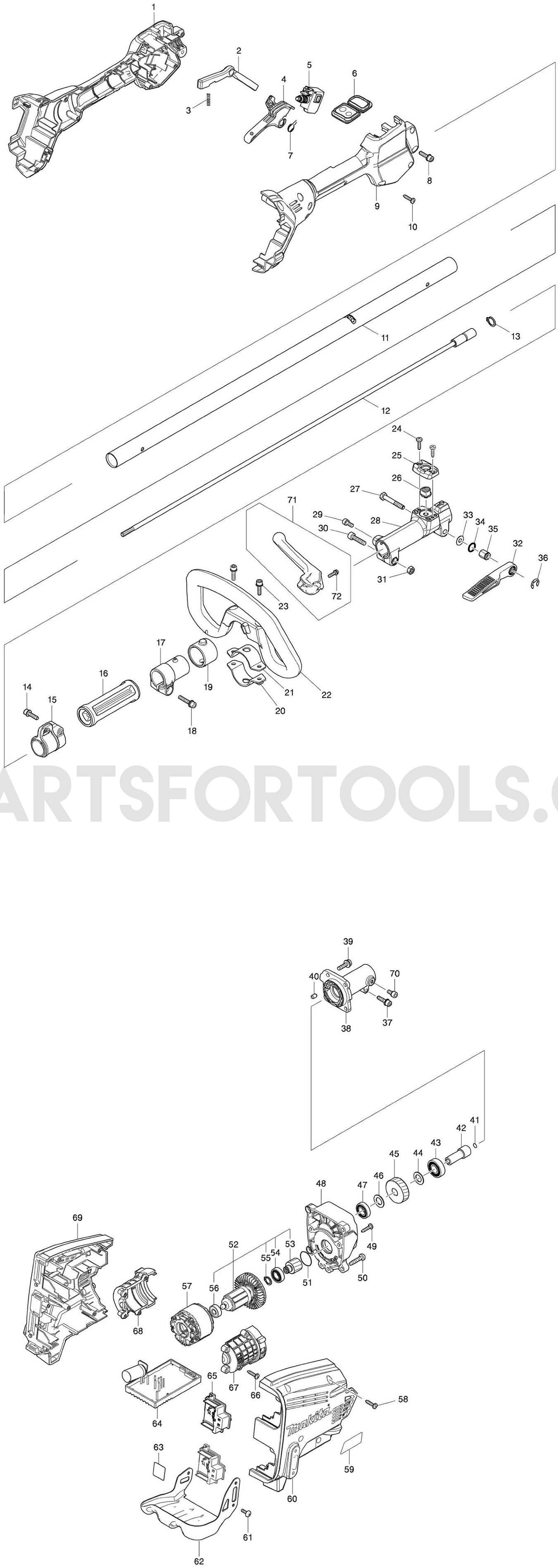

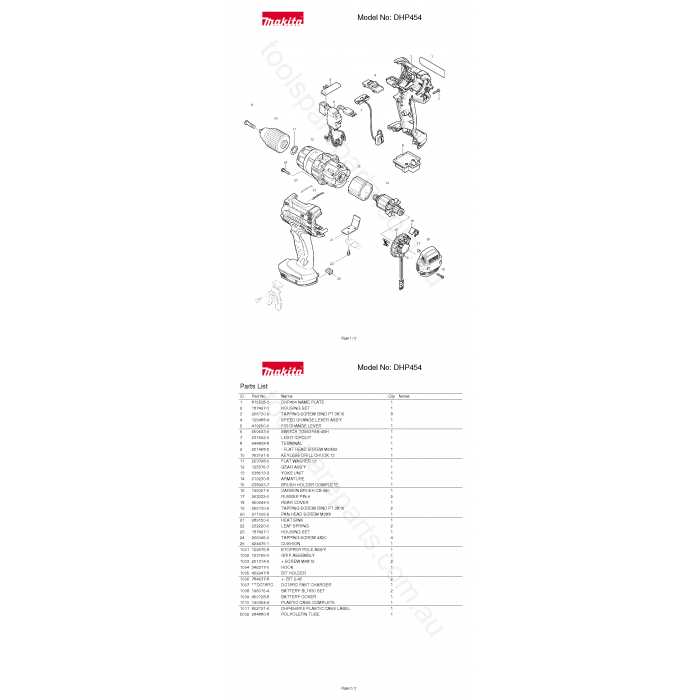

Importance of Parts Diagrams

Understanding the components of a tool and how they fit together is crucial for effective maintenance and repair. Visual representations of these elements provide valuable insights into their arrangement and functionality, facilitating smoother servicing processes.

Utilizing such illustrations offers several advantages:

- Enhanced Clarity: Visual guides break down complex machinery into understandable sections, making it easier to identify each component.

- Efficient Troubleshooting: When issues arise, these references allow users to pinpoint the source of a problem quickly.

- Accurate Reassembly: After disassembly for repairs, clear visuals ensure that all parts are reinstalled correctly, preventing future malfunctions.

- Streamlined Ordering: Knowing the exact names and numbers of each element aids in procuring replacements without confusion.

Overall, having access to these resources significantly improves the user’s ability to maintain their equipment in optimal condition, extending the lifespan of the tools.

Main Components of the DHR242

The effectiveness of this power tool relies on several key elements, each playing a crucial role in its overall functionality. Understanding these essential components helps users appreciate how they work together to deliver optimal performance during operation.

Core Elements

The primary components are designed for durability and efficiency. They ensure that the tool can handle various tasks with ease while maintaining a user-friendly experience.

| Component | Description |

|---|---|

| Motor | The powerhouse that drives the tool, providing the necessary energy for various applications. |

| Gearbox | Facilitates the transfer of power from the motor to the drill bit, allowing for speed and torque adjustments. |

| Chisel | Designed for demolition tasks, it allows for precise material removal and surface preparation. |

| Handle | Provides grip and control, enhancing user comfort and reducing fatigue during prolonged use. |

| Trigger | Enables the user to start and stop the operation easily, ensuring safety and precision. |

Additional Features

Moreover, this tool may include various attachments and accessories that enhance its versatility. These components are designed to accommodate different tasks, making the tool suitable for a wide range of applications, from light home improvement projects to more demanding construction tasks.

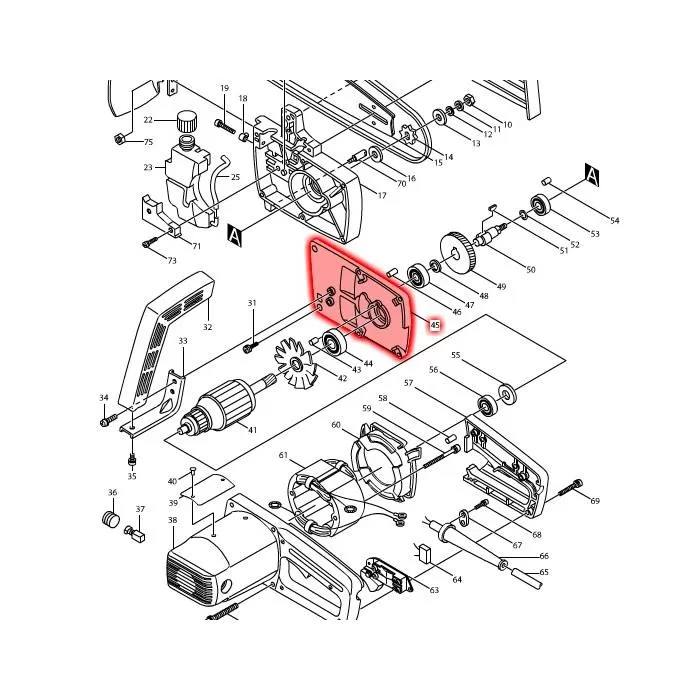

How to Read a Parts Diagram

Understanding a visual representation of components is essential for efficient assembly and maintenance. These illustrations serve as guides to identify various elements and their arrangements, ensuring proper functionality and repairs.

To effectively interpret such a visual guide, consider the following steps:

- Familiarize Yourself with the Layout: Each section of the illustration is typically organized to show different groups of components. Take a moment to recognize how the parts are categorized.

- Identify Labels and Codes: Most visual representations include identifiers next to each component. These may be numbers or letters that correspond to a list of items, making it easier to find replacements.

- Follow Assembly Instructions: If the illustration includes sequential steps, pay close attention to the order of assembly. This will guide you in reassembling or troubleshooting the device correctly.

- Note Connections and Interactions: Observe how different elements connect or interact with one another. Understanding these relationships can help you identify potential issues and solutions.

By mastering these techniques, you will enhance your ability to work with such visual references, leading to more successful repairs and efficient maintenance tasks.

Common Replacement Parts Explained

Understanding the various components that may require replacement is crucial for maintaining the longevity and efficiency of your tool. Regular wear and tear can affect performance, making it essential to know which elements are most likely to need attention over time.

1. Drill Chuck

The drill chuck is a vital part of any drilling device, responsible for securing the bit in place. A malfunctioning chuck can lead to inaccurate drilling and may need to be replaced if it becomes loose or damaged. Ensuring a snug fit is important for optimal performance.

2. Battery Pack

A reliable battery pack is essential for cordless operations. Over time, batteries can lose their ability to hold a charge due to cycles of use. Replacing an old battery with a new one can significantly improve the functionality and convenience of your equipment.

Regular maintenance and timely replacement of these crucial components can enhance the overall performance and lifespan of your tool.

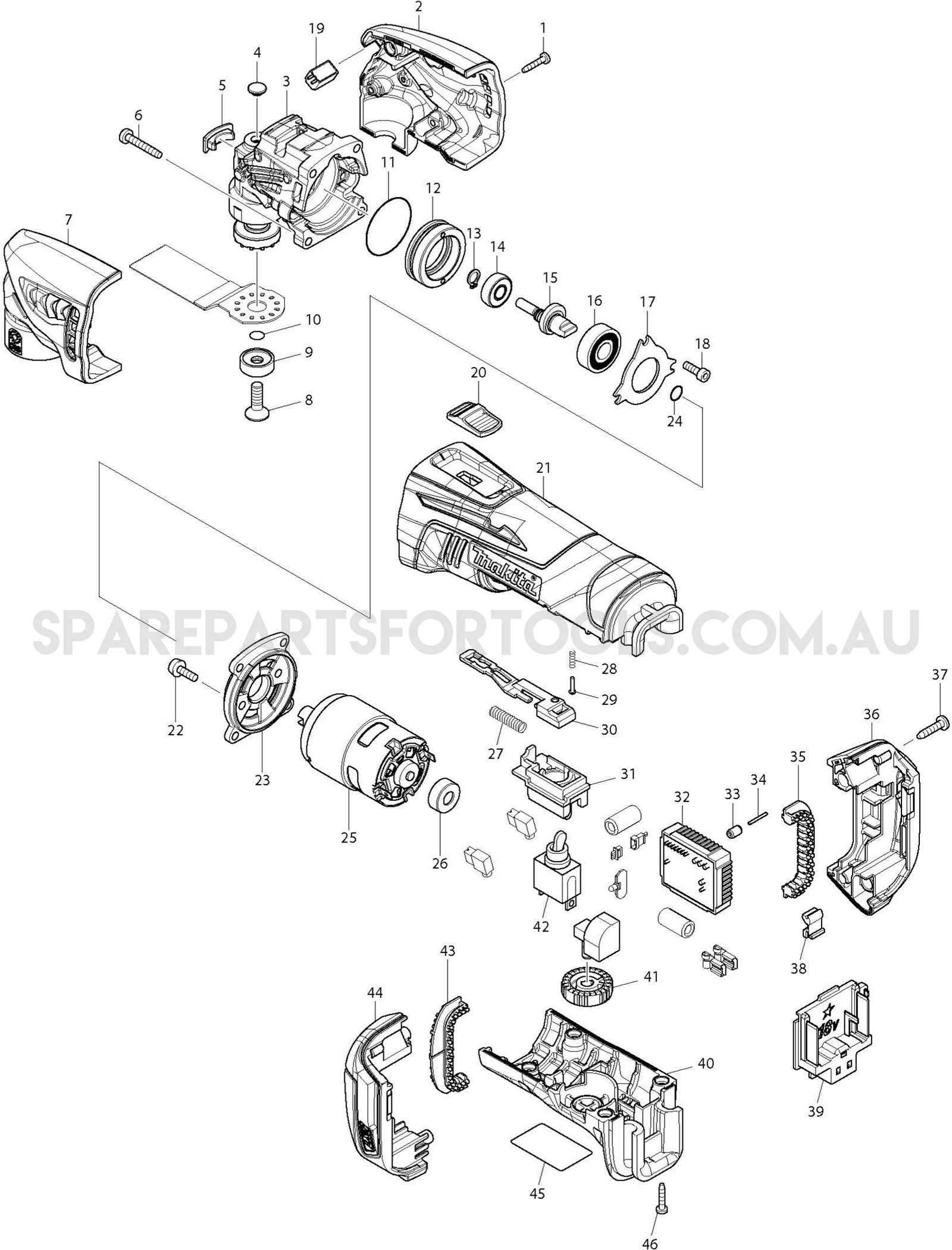

Assembly and Disassembly Guide

This section provides a comprehensive overview of the procedures for assembling and disassembling the tool, ensuring efficient maintenance and repair. Understanding the correct methods for handling components is crucial for maintaining optimal performance and longevity.

Before starting the assembly or disassembly process, gather the necessary tools and materials:

- Screwdrivers (Phillips and flathead)

- Wrenches

- Pliers

- Replacement parts

- Cleaning cloth

Follow these steps for successful assembly:

- Ensure that all components are clean and free from debris.

- Align the main body and housing parts, making sure the fittings match properly.

- Insert screws or fasteners in their designated holes, tightening them securely but avoiding over-tightening.

- Attach any additional components, such as handles or guards, as required.

- Perform a final inspection to confirm that everything is correctly in place.

For disassembly, adhere to the following steps:

- Disconnect the power source to ensure safety during the process.

- Carefully remove any external covers or guards.

- Unscrew and detach components systematically, noting their positions for reassembly.

- Keep small parts organized to prevent loss during the process.

- Clean each part as it is removed, preparing for future assembly.

By following these guidelines, you can efficiently manage the assembly and disassembly of your tool, facilitating effective maintenance and repair work.

Maintaining Your Makita DHR242

Proper upkeep of your power tool ensures optimal performance and longevity. Regular maintenance not only enhances efficiency but also minimizes the risk of unexpected breakdowns, allowing you to complete your tasks without interruptions.

Here are some essential maintenance tips:

- Regular Cleaning: After each use, wipe down the tool to remove dust and debris. Pay special attention to vents and moving parts to prevent clogs and overheating.

- Lubrication: Apply appropriate lubricants to the moving components to reduce friction and wear. Check the user manual for specific lubrication points.

- Inspect Cables: Examine the power cord for any signs of wear or damage. Replace any frayed or broken cables immediately to ensure safety.

- Check Battery Health: Monitor the battery condition regularly. Store it in a cool, dry place and avoid leaving it discharged for extended periods.

By following these simple guidelines, you can prolong the life of your tool and maintain its peak performance for all your projects.

Identifying Faulty Components

Recognizing defective elements in power tools is crucial for maintaining their performance and longevity. Various signs may indicate that certain components are not functioning correctly, leading to decreased efficiency or complete failure. Understanding these indicators can help users troubleshoot issues effectively.

Common Signs of Malfunction

One of the most noticeable symptoms of a malfunctioning tool is unusual noise during operation. Grinding, rattling, or excessive vibrations often signal that internal components are worn or damaged. Additionally, a decrease in power output or an inability to perform tasks that were previously manageable can indicate issues with motor function or power delivery mechanisms.

Visual Inspection Techniques

Performing a visual inspection is an essential step in identifying faulty parts. Users should check for any signs of wear, such as cracks, discoloration, or loose connections. Inspecting wiring for fraying or breaks can also provide clues about underlying problems. Regular maintenance and careful observation can help in detecting these issues early, preventing further damage and costly repairs.

Where to Find Parts Diagrams

Locating detailed illustrations that show the components of your equipment can greatly enhance your understanding of its assembly and maintenance. These resources provide valuable insights into each part’s function and placement, making repairs and replacements easier.

- Official Manufacturer’s Website: Start by visiting the manufacturer’s official site. They often provide comprehensive resources, including exploded views and detailed parts lists.

- Online Retailers: Websites that specialize in tools and equipment frequently have sections dedicated to providing visual aids for various models, helping you identify the exact pieces you need.

- Technical Support Forums: Online communities and forums can be treasure troves of information. Members often share links to helpful resources, including illustrations and guides.

- User Manuals: Always check the user manual that came with your tool. Many manuals include sections that illustrate the equipment’s assembly and parts, along with maintenance tips.

- Video Tutorials: Platforms like YouTube feature numerous tutorials where enthusiasts and experts demonstrate repairs, often showing the components involved. These videos can be useful for visual learners.

Original vs. Aftermarket Parts

The choice between genuine and alternative components can significantly impact performance, longevity, and overall satisfaction. While authentic items are typically designed specifically for a given tool, aftermarket options may offer a more economical solution, appealing to budget-conscious users. Understanding the differences between these two categories can help individuals make informed decisions when it comes to repairs and maintenance.

Benefits of Authentic Components

Genuine components are manufactured by the original company and are tailored to meet the precise specifications of their tools. This ensures optimal compatibility and performance, often leading to a longer lifespan and fewer issues during operation. Users can also benefit from warranties and customer support that come with authentic items, providing peace of mind.

Advantages of Alternative Options

On the other hand, alternative components can be more affordable, making them an attractive choice for those looking to save money. Many aftermarket options are designed to function similarly to genuine parts, and some may even exceed the performance of the originals. However, it is essential to research and choose reputable manufacturers to ensure quality and reliability.

| Aspect | Original Components | Aftermarket Options |

|---|---|---|

| Quality | High, with strict standards | Varies, may require research |

| Price | Generally higher | Typically more affordable |

| Warranty | Often included | Varies by manufacturer |

| Compatibility | Perfect fit | May not be guaranteed |

Tips for Efficient Repairs

When tackling maintenance tasks, having a clear approach can significantly enhance the outcome. Efficient repairs not only save time but also ensure that equipment functions optimally. Here are some strategies to streamline the process and achieve better results.

| Tip | Description |

|---|---|

| Organize Your Workspace | A tidy area helps to locate tools and components quickly, minimizing distractions and enhancing focus. |

| Use Quality Tools | Employing the right instruments for the job can prevent damage and facilitate smoother repairs. |

| Follow Instructions Carefully | Refer to manuals or guides for specific procedures to avoid common pitfalls and ensure accuracy. |

| Keep Spare Parts Handy | Having essential components readily available can reduce downtime and expedite the repair process. |

| Take Safety Precautions | Always wear appropriate safety gear and follow safety protocols to protect yourself while working. |

Frequently Asked Questions

This section addresses common inquiries related to the assembly and components of the tool, helping users gain a better understanding of its functionality and maintenance.

- What should I do if a part is damaged?

In the event of damage, it’s essential to replace the affected component to ensure safe and efficient operation. Consult the manual for specific replacement instructions.

- Where can I find replacement components?

Replacement parts can be found at authorized dealers or online retailers specializing in power tools. Ensure you verify compatibility before purchasing.

- How often should I perform maintenance?

Regular maintenance is recommended every few months, or more frequently if the tool is used heavily. This includes cleaning and checking for wear on essential components.

- What are the signs of wear on key components?

Look for any unusual noises, reduced performance, or visible wear on parts such as drill bits and housing. Addressing these signs early can prevent further issues.

- Can I perform repairs myself?

Many repairs can be conducted by the user if they have the right tools and knowledge. However, for complex issues, it’s advisable to consult a professional technician.