When delving into the intricate world of heating and cooling systems, having a clear understanding of individual elements and their relationships is crucial for efficient maintenance and repair. This knowledge enables technicians and homeowners alike to troubleshoot issues effectively and optimize system performance. A comprehensive overview of these components can significantly enhance one’s ability to manage climate control solutions.

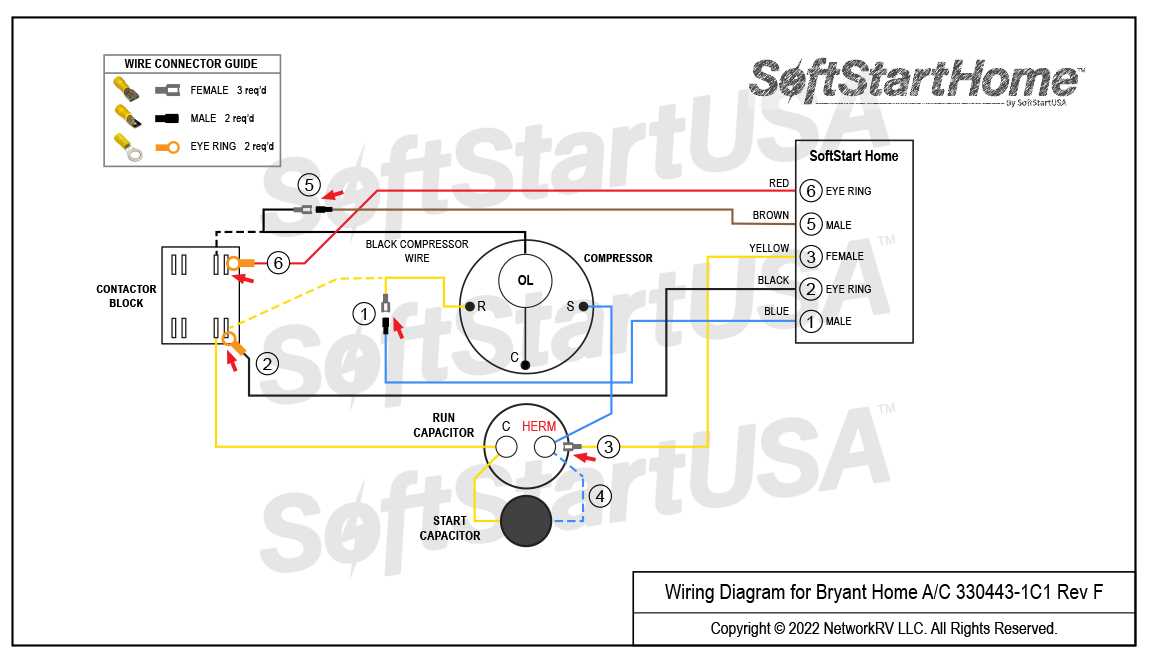

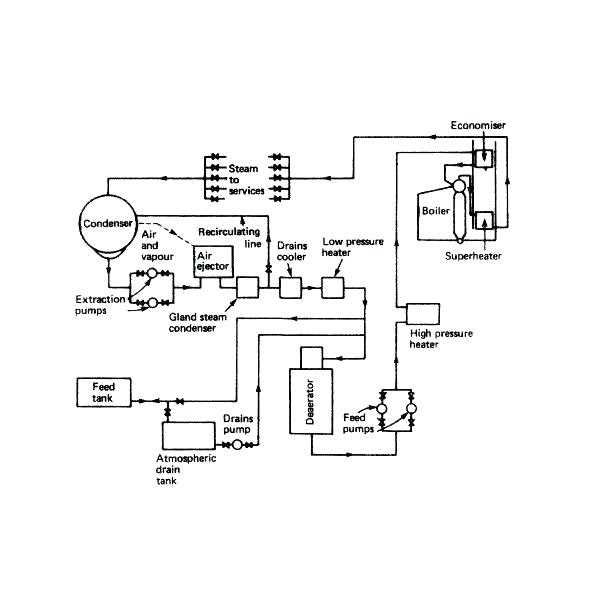

Detailed visual representations serve as invaluable tools for both novices and experienced professionals in the field. They offer insights into how various elements interact within a system, highlighting their functions and interdependencies. Such illustrations not only simplify complex assemblies but also facilitate a more profound grasp of operational principles.

By familiarizing oneself with these visual guides, users can identify specific components, understand their roles, and recognize potential points of failure. This foundational knowledge ultimately leads to better decision-making regarding repairs, upgrades, or replacements, ensuring a more reliable and efficient climate management experience.

Understanding Bryant 340AAV Components

Grasping the intricacies of essential components in heating and cooling systems is vital for efficient operation and maintenance. Each element plays a crucial role in the overall functionality, contributing to optimal performance and energy efficiency.

Key Elements of the System

- Compressor: The powerhouse responsible for circulating refrigerant.

- Evaporator Coil: Facilitates heat absorption, cooling the air effectively.

- Condenser Coil: Releases heat, allowing the refrigerant to return to liquid form.

- Expansion Valve: Regulates refrigerant flow, ensuring proper pressure balance.

Maintenance Considerations

- Regularly inspect components for wear and tear.

- Clean coils to enhance heat exchange efficiency.

- Monitor refrigerant levels to prevent system strain.

- Schedule professional servicing to ensure longevity.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the structure and functionality of complex systems. They serve as invaluable tools for technicians and engineers, facilitating the identification of each element and its specific role within the assembly. By utilizing these illustrations, one can efficiently locate issues, perform maintenance, and ensure proper reassembly after repairs.

Enhanced Understanding

Having a clear visual reference aids in grasping the relationships between different components. It simplifies the learning process for new users and helps seasoned professionals quickly recall specific details. This clarity not only boosts confidence but also enhances overall efficiency in troubleshooting and repair tasks.

Streamlined Maintenance Processes

When facing repairs or upgrades, having an accurate visual reference can significantly expedite the process. It allows technicians to plan their approach, gather necessary tools, and minimize errors during disassembly and reassembly. This systematic approach ultimately leads to reduced downtime and increased reliability of the system.

Key Features of Bryant 340AAV

This section explores the standout characteristics of a specific heating and cooling unit designed for efficiency and reliability. The advanced engineering behind this model ensures optimal performance while meeting the diverse needs of modern environments.

Efficiency and Performance

One of the most notable aspects is its exceptional energy efficiency, which translates to lower utility bills. The innovative technology employed allows for enhanced heat exchange, making it an ultimate choice for energy-conscious users.

Durability and Design

Built with high-quality materials, this unit offers long-lasting durability. Its compact design facilitates easy installation and maintenance, ensuring that it blends seamlessly into various settings while providing reliable service.

Common Issues with Bryant Units

Heating and cooling systems are vital for maintaining comfort in any environment. However, like any mechanical system, they can encounter various challenges over time. Understanding these common problems can help in early detection and resolution, ensuring efficiency and longevity of the unit.

Typical Problems Encountered

- Thermostat Malfunctions: Incorrect temperature readings can lead to inefficient operation.

- Noisy Operation: Unusual sounds may indicate loose components or wear.

- Airflow Issues: Restricted airflow can result from clogged filters or ductwork obstructions.

- Inconsistent Heating/Cooling: Fluctuations in temperature may point to refrigerant leaks or compressor problems.

- System Overheating: Continuous running without cooling may cause components to fail.

Preventative Measures

- Regular maintenance checks to identify wear and tear early.

- Cleaning or replacing filters every few months to ensure optimal airflow.

- Monitoring system performance and addressing any unusual behavior promptly.

- Ensuring proper installation and insulation of ducts to prevent energy loss.

Step-by-Step Repair Guide

This section provides a comprehensive approach to troubleshooting and fixing common issues that may arise with your heating system. By following these detailed instructions, you can effectively restore functionality and enhance performance.

- Gather Necessary Tools:

- Screwdriver set

- Multimeter

- Wrenches

- Cleaning supplies

- Ensure Safety:

- Turn off the power supply.

- Wear protective gear.

- Inspect Components:

- Check for visible wear and tear.

- Listen for unusual noises.

- Test Electrical Connections:

- Use a multimeter to check voltage.

- Look for loose wires and connections.

- Clean the Unit:

- Remove dust and debris.

- Ensure air vents are unobstructed.

- Replace Faulty Parts:

- Identify defective elements.

- Follow the manufacturer’s instructions for replacement.

- Conduct a Final Test:

- Restore power and monitor the system.

- Check for normal operation.

By following these steps, you can successfully address common problems and ensure your system operates at its ultimate efficiency.

Identifying Replacement Parts

Understanding how to locate the necessary components for your heating and cooling system is crucial for maintaining optimal performance. Proper identification ensures that you select the correct items to enhance efficiency and longevity.

Key Steps for Identification

- Consult the user manual for specific model details.

- Examine the existing components for manufacturer numbers and specifications.

- Research online databases or forums dedicated to HVAC systems.

Common Sources for Components

- Local hardware and HVAC supply stores

- Authorized distributors and retailers

- Online marketplaces specializing in heating and cooling equipment

Tools Required for Maintenance

Proper upkeep of your system is essential for optimal performance and longevity. Having the right tools at your disposal not only simplifies the maintenance process but also ensures that tasks are completed efficiently and safely. Below is a list of essential instruments and equipment needed for regular service and repairs.

Essential Tools

- Wrenches: A set of adjustable and fixed wrenches for various fasteners.

- Screwdrivers: A variety of flathead and Phillips screwdrivers for different screw types.

- Pliers: Needle-nose and standard pliers for gripping and manipulating components.

- Torque Wrench: For applying precise torque to fasteners, ensuring proper tightness.

- Multimeter: For testing electrical connections and diagnosing issues.

- Vacuum Cleaner: To remove dust and debris from internal components.

Safety Equipment

- Safety Goggles: Protect your eyes from debris and chemicals.

- Gloves: Ensure a secure grip and protect hands from sharp edges.

- Face Mask: Prevent inhalation of dust and harmful particles.

- First Aid Kit: Be prepared for minor injuries that may occur during maintenance.

Equipping yourself with the right tools and safety gear can greatly enhance the effectiveness of maintenance tasks, helping to maintain the functionality of your equipment over time.

Safety Precautions During Repairs

When engaging in maintenance activities, it is crucial to prioritize safety to prevent accidents and injuries. Understanding potential hazards and employing protective measures can ensure a secure working environment. Always be prepared and vigilant to create a safe repair process.

Essential Safety Measures

- Wear appropriate personal protective equipment (PPE), such as gloves and safety goggles.

- Ensure the power source is disconnected before starting any work.

- Keep the workspace clean and organized to minimize trip hazards.

- Use tools that are in good condition and suitable for the task.

Emergency Preparedness

- Familiarize yourself with the location of first aid kits and emergency exits.

- Have a plan for reporting accidents or emergencies.

- Regularly review safety protocols with all team members.

Where to Buy Bryant Parts

Finding components for your heating and cooling systems can be a straightforward process if you know where to look. Numerous retailers, both online and brick-and-mortar, offer a variety of options for replacement items. Understanding the best places to source these essentials can save time and ensure you acquire the right elements for optimal performance.

Local HVAC Suppliers: Visiting nearby suppliers can provide immediate access to necessary items, along with expert advice. Many of these shops carry a comprehensive selection and can help identify the exact components you need.

Online Marketplaces: Websites like Amazon and eBay feature a vast inventory, allowing you to compare prices and read reviews. This option offers the convenience of shopping from home while also exploring numerous alternatives.

Manufacturer Websites: Directly visiting the official site often leads to reliable sources for specific items. They may also provide warranties and guarantees, ensuring quality and performance.

With these options at your disposal, you can confidently navigate your search for essential components, ensuring your systems run smoothly and efficiently.

Understanding HVAC Terminology

Grasping the essential vocabulary related to heating, ventilation, and air conditioning systems is crucial for both professionals and homeowners. A clear comprehension of these terms enables effective communication, troubleshooting, and maintenance of equipment. This section aims to illuminate key concepts and phrases that are foundational in the HVAC industry.

One fundamental term is “tonnage,” which refers to the cooling capacity of a system. Understanding how this measurement impacts efficiency and performance is vital for selecting appropriate units. Another important concept is “SEER,” or Seasonal Energy Efficiency Ratio, which indicates the energy efficiency of air conditioning systems. Familiarity with these metrics allows for informed decisions when purchasing or upgrading units.

Comparing Bryant Models and Features

In the realm of heating and cooling systems, various models offer distinct characteristics and capabilities that cater to diverse needs. Understanding the differences between these options can greatly influence the decision-making process for consumers seeking efficiency and reliability.

Efficiency Ratings are a crucial factor to consider. Some models excel in energy conservation, boasting higher Seasonal Energy Efficiency Ratios (SEER) and Annual Fuel Utilization Efficiency (AFUE) ratings. This not only translates to lower utility bills but also contributes positively to environmental sustainability.

Durability is another essential aspect. Many units are built with advanced materials designed to withstand harsh conditions, ensuring longevity. Features like enhanced corrosion resistance and robust construction can significantly impact the lifespan of the equipment.

Noise Levels are often a concern for homeowners. Some units incorporate innovative technology to minimize operational sound, providing a quieter indoor environment. This feature is particularly beneficial in residential settings where peace and comfort are prioritized.

Smart technology integration is becoming increasingly common. Certain models now offer Wi-Fi connectivity and smartphone applications that allow users to monitor and control their systems remotely, enhancing convenience and user experience.

Lastly, customization options vary among different lines. Some systems offer a range of accessories and configurations, enabling users to tailor their setup to better fit their specific requirements and preferences.

Expert Tips for Efficient Repairs

When it comes to maintaining and fixing equipment, having a structured approach can significantly enhance the effectiveness of your efforts. Understanding the components and their functions allows for quicker diagnostics and repairs, ultimately saving time and resources.

1. Familiarize Yourself with the Components

Knowing the layout of the system is crucial. Take time to study the assembly and function of various elements. This knowledge not only speeds up the repair process but also helps in identifying potential issues before they escalate.

2. Use Quality Tools and Parts

Investing in reliable tools ensures that repairs are performed safely and efficiently. Always opt for high-quality replacement items to guarantee durability and optimal performance. This proactive approach minimizes future complications and maximizes efficiency.