Efficient soil cultivation is vital for successful farming, and the tools used play a significant role in achieving this. One of the fundamental implements in agriculture is designed to turn and aerate the soil, ensuring optimal conditions for planting and growth. Knowing how different elements work together within this essential tool helps in maintaining and optimizing its performance.

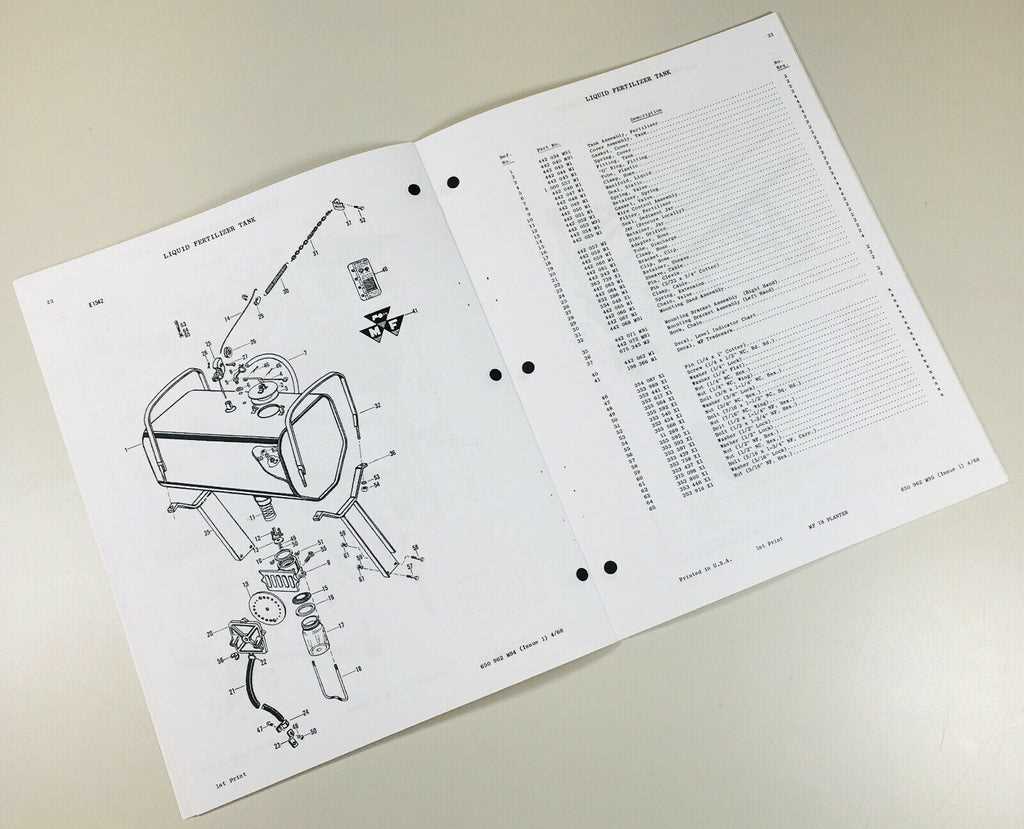

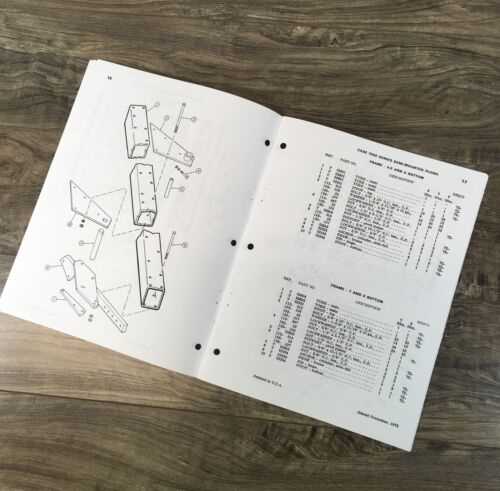

The structural layout of this equipment includes several interconnected elements that perform distinct tasks. Each piece is responsible for either cutting, lifting, or turning the soil, contributing to the overall effectiveness of the machine. Understanding the role of each section not only enhances operational efficiency but also helps in troubleshooting and repairs.

In this guide, we will explore the various components of this agricultural tool and how they come together to perform the crucial task of preparing the land. By recognizing the purpose of each element, users can ensure their equipment operates smoothly and remains in good condition for the long term.

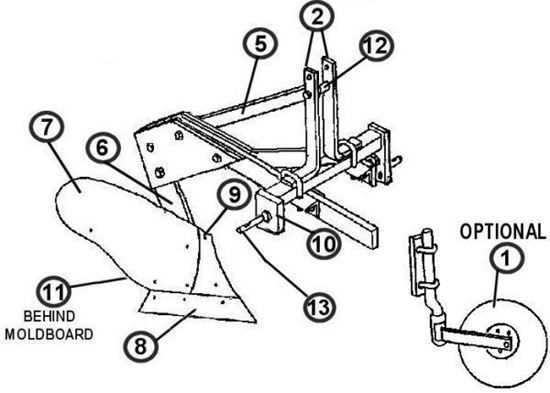

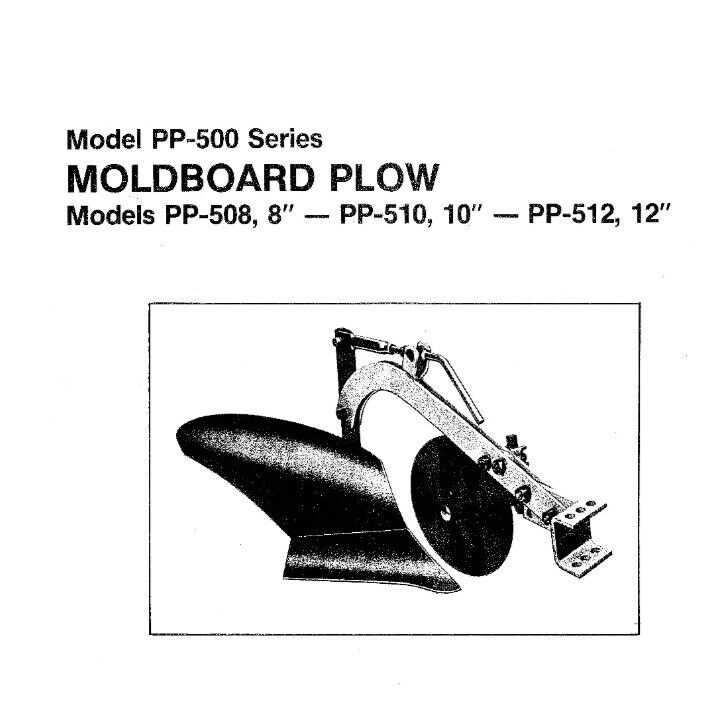

Understanding the Structure of a Moldboard Plow

The functionality of this traditional agricultural tool relies on a combination of various elements, each designed to perform a specific role during soil cultivation. Its design is structured to facilitate effective ground engagement, helping to turn over the soil and prepare the land for planting.

Key components can be categorized based on their function and position within the overall assembly. Below is a breakdown of these components:

- Main Frame: This serves as the backbone, providing the necessary support for other parts and maintaining structural integrity during operation.

- Cutting Edge: Positioned to slice through the soil, enabling deeper penetration and smooth soil displacement.

- Soil Turning Mechanism: Responsible for flipping the soil layer to bring nutrients to the surface and bury crop residues underneath.

- Adjustable Elements: These parts allow customization of the tool’s depth and angle, adapting it to varying field conditions.

Understanding the arrangement and purpose of these sections ensures proper usage, maintenance, and optimization of the equipment during field operations.

Main Components of a Plow System

Understanding the fundamental elements of a soil-turning mechanism is essential for efficient land preparation. These systems consist of various interconnected pieces that work in unison to achieve optimal soil penetration and movement. Each segment plays a specific role in ensuring the tool performs its task effectively, whether it’s cutting into the earth or managing debris.

The Cutting Edge is one of the critical elements responsible for slicing through the ground. It ensures that the surface is properly broken, allowing for further processing. Its sharpness and durability significantly affect the overall efficiency.

The Frame Structure serves as the backbone, holding all other components together. Its strength and design dictate how well the system can handle different soil conditions, ensuring stability and resilience under pressure.

The Soil Turning Mechanism plays a pivotal role in flipping and displacing earth, helping to aerate and prepare the ground for future planting. Its design ensures minimal resistance and smooth operation, promoting productivity in the field.

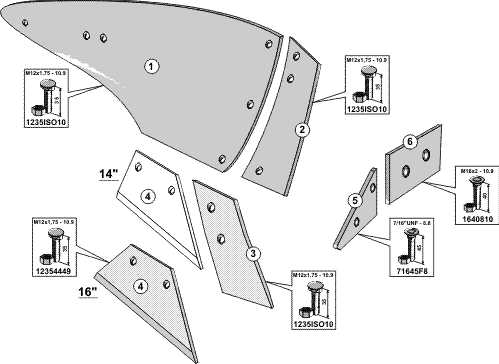

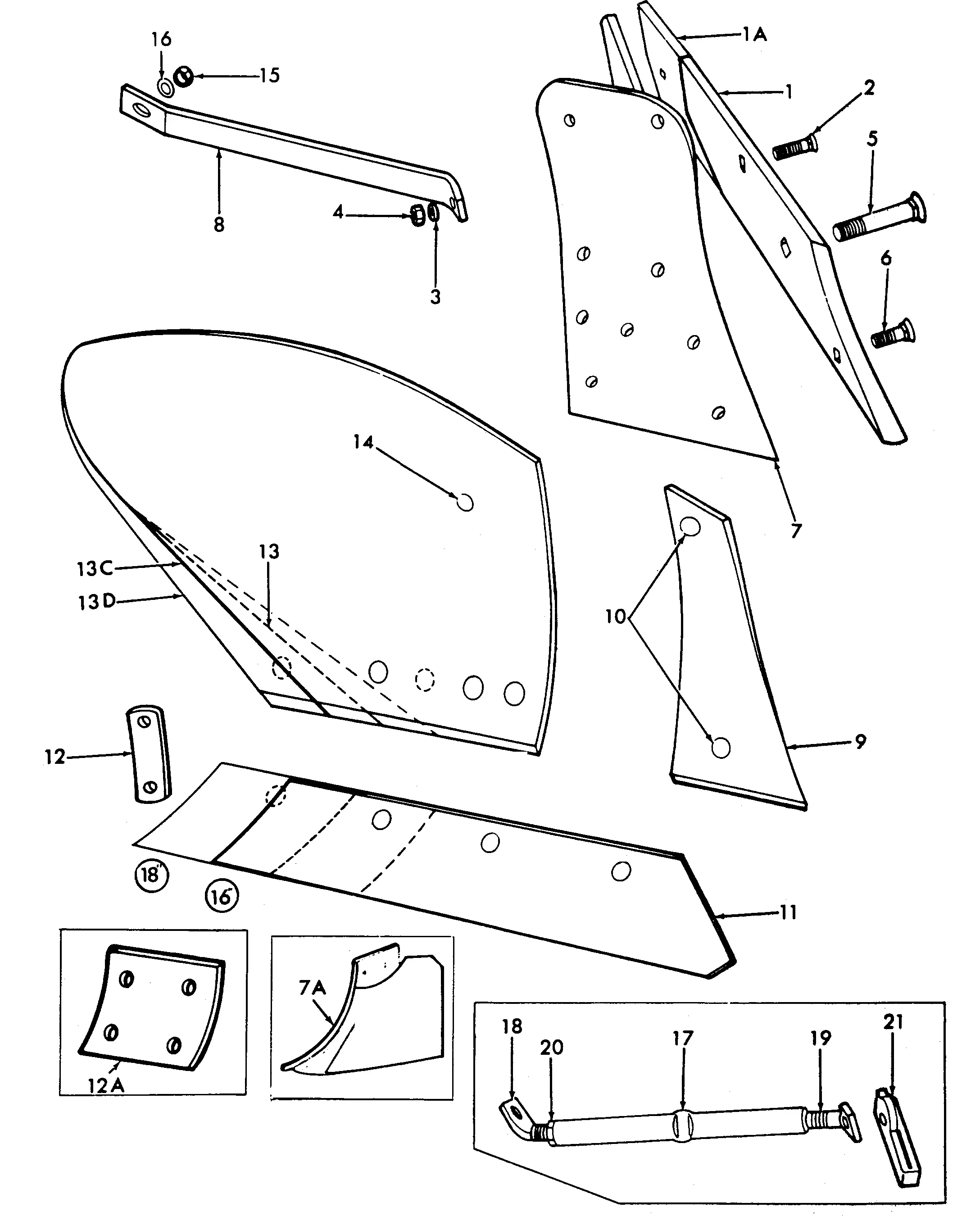

Blade Design and Its Functions

The configuration and structure of the blade play a crucial role in the overall performance of agricultural equipment. Each element of the cutting edge is meticulously designed to ensure effective soil penetration and optimal movement through various types of terrain.

Shape and Curvature: The specific curvature of the blade is engineered to facilitate smoother ground entry and efficient material displacement. By reducing resistance, it enhances operational efficiency, allowing for faster work with less effort.

Material and Durability: Blades are typically constructed from high-strength metals, chosen for their ability to withstand harsh conditions and abrasive environments. This ensures long-term reliability, even in challenging soil conditions.

Impact on Performance: The overall design directly affects the equipment’s ability to cut through the ground and manage soil distribution. A well-engineered blade improves both precision and effectiveness, contributing to enhanced productivity in the field.

Role of the Moldboard in Soil Turning

The component responsible for effectively transforming and shifting the earth plays a crucial role in preparing fields for planting. By reshaping the surface and breaking apart layers, this tool helps create an ideal environment for growing crops. Its design ensures proper movement and rearrangement of the land, making it more suitable for future agricultural activities.

- Assists in breaking up compact layers, improving soil aeration.

- Creates uniform patterns, promoting even moisture distribution.

- Helps incorporate organic matter into the ground for better fertility.

The efficient turning of soil helps in reducing weeds and providing a fresh, loose base for new plantings, contributing to enhanced crop growth and productivity.

Shear Bolt and Its Safety Function

The shear bolt plays a crucial role in ensuring the durability and safety of heavy equipment during operation. This component is designed to act as a safeguard, preventing damage by breaking under excessive load. When pressure exceeds the intended limit, the bolt sacrifices itself to protect more critical elements from harm, thereby minimizing potential breakdowns and costly repairs.

How it Works: The shear bolt is engineered to withstand a specific amount of force. However, when an obstacle or overstrain occurs, the bolt fractures, disengaging the affected mechanism. This action helps absorb the shock and reduce the risk of structural damage.

Advantages of Using Shear Bolts: By incorporating this safety feature, machinery operators can benefit from extended operational life and reduced downtime. Replacing a broken bolt is far more efficient than repairing or replacing larger, more integral components.

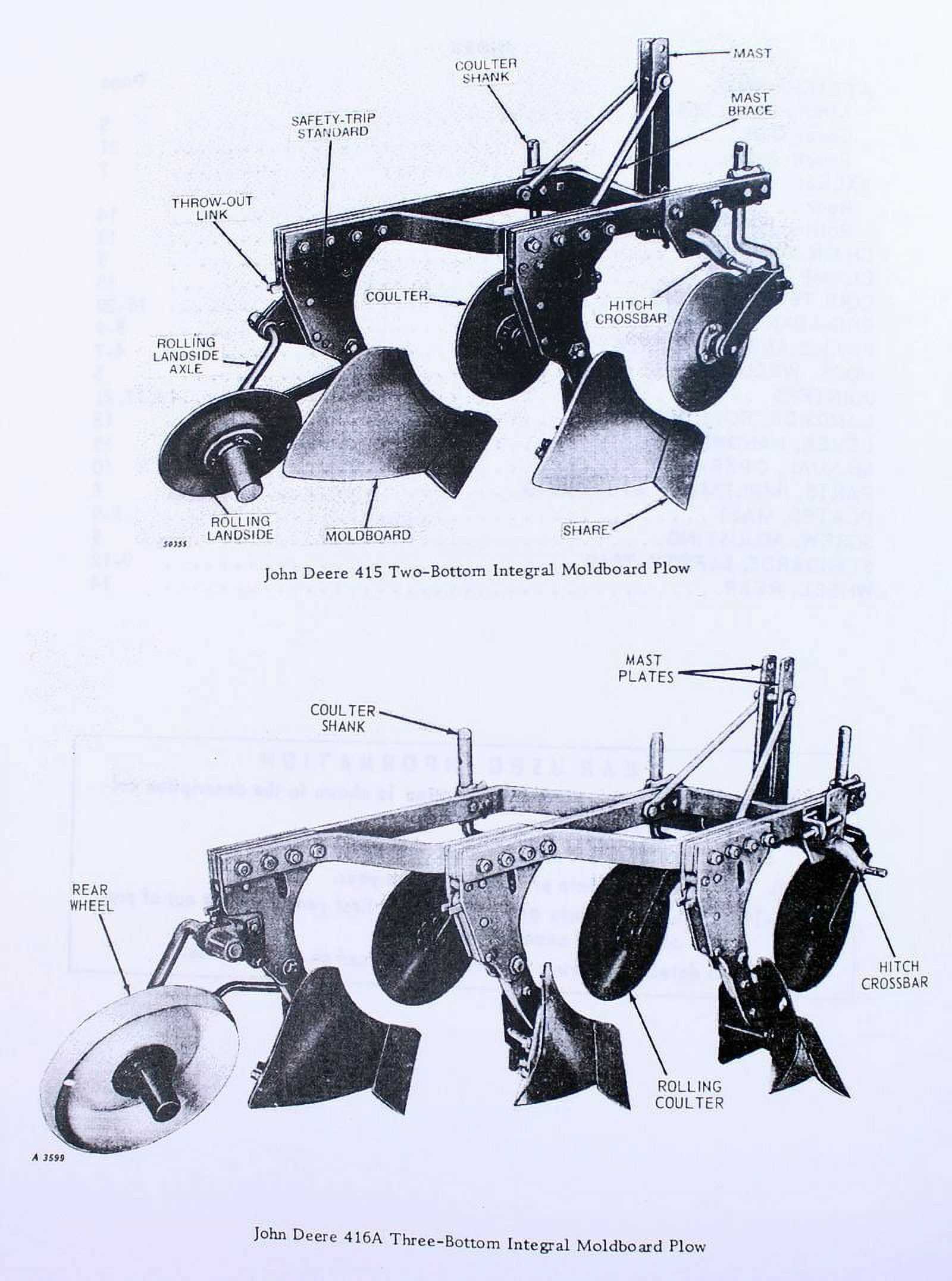

Exploring the Landside and Its Purpose

The landside plays a crucial role in soil cultivation equipment, serving as a key component in enhancing the efficiency of soil turnover. Its design and functionality are essential for achieving optimal results during the tilling process.

This element works in conjunction with other components to ensure effective operation. Its primary responsibilities include:

- Guiding the implement through the soil to maintain direction.

- Reducing friction and wear on the equipment.

- Enhancing the overall stability during operation.

- Facilitating a clean cut through the soil for improved aeration.

Understanding the significance of this component is vital for farmers and agricultural professionals. Proper maintenance and adjustment can lead to increased efficiency and longevity of the equipment. Regular checks can help in identifying wear and tear, ensuring optimal performance during critical farming periods.

The Importance of the Frog in Stability

The frog plays a crucial role in ensuring balance and support within agricultural equipment designed for soil cultivation. Its unique design contributes to the overall functionality and effectiveness of the tool, enabling efficient operation during various farming tasks. Understanding the significance of this component is essential for maximizing performance and durability.

Functionality and Benefits

This element not only provides structural integrity but also aids in maintaining the alignment of the implement during use. By distributing weight evenly, it minimizes the risk of tipping or uneven wear, which can lead to decreased efficiency and increased maintenance costs. Recognizing its contribution to the operational stability of the machinery is vital for any farming professional.

Key Characteristics

Several features make this component indispensable for optimal performance. The following table highlights its essential characteristics and their effects on the overall functionality of the equipment:

| Characteristic | Effect |

|---|---|

| Design Shape | Enhances soil penetration and control |

| Material Strength | Provides durability and resistance to wear |

| Weight Distribution | Improves balance and minimizes tipping |

How the Share Cuts Through Soil

The cutting element plays a crucial role in the process of soil preparation, enabling effective cultivation. By penetrating the earth’s surface, it initiates the disruption of compacted layers, facilitating aeration and nutrient accessibility. The design and shape of this component significantly influence its performance and efficiency.

When the cutting tool engages with the ground, it utilizes a sharp edge that slices through the soil, creating a clean cut. This action reduces resistance and allows for smoother movement through various types of terrain. As it advances, the design of the cutting element helps to lift and turn the earth, enhancing the overall tilling process.

Furthermore, the angle and position of the cutting edge are meticulously crafted to optimize its interaction with the soil. A well-engineered cutting tool can efficiently manage varying soil conditions, whether loose, compact, or sticky. This adaptability ensures that the cultivation process is both effective and uniform, promoting healthy crop growth in the following planting season.

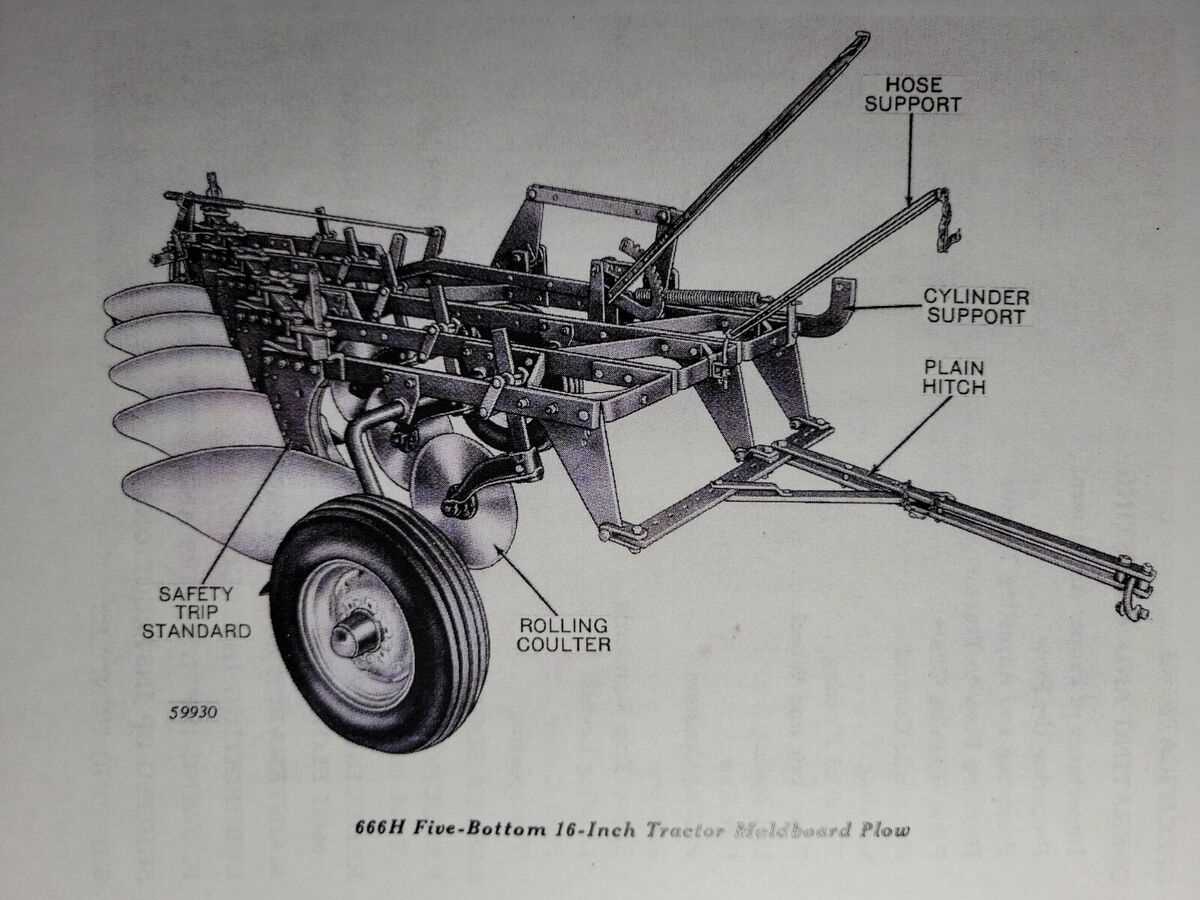

Adjusting the Coulter for Better Cutting

Proper adjustment of the cutting tool is crucial for achieving optimal performance during tillage operations. By fine-tuning the settings, one can enhance the efficiency of the tool, ensuring it penetrates the soil effectively and provides a clean cut. This section discusses the key considerations and steps for adjusting the cutting tool for improved results.

Key Considerations

- Soil Type: Different soil conditions require varying depths and angles of the cutting tool to perform effectively.

- Moisture Levels: Wet soil may necessitate a shallower cut, while dry conditions can allow for deeper penetration.

- Crop Residue: The presence of debris may impact the necessary adjustment for optimal cutting.

Steps for Adjustment

- Assess the Current Setting: Begin by examining the current depth and angle of the tool.

- Make Initial Adjustments: Use the adjustment mechanisms to change the depth and angle based on the identified soil conditions.

- Test the Performance: Conduct a test run to evaluate the effectiveness of the adjustments made.

- Fine-tune as Needed: After testing, make any necessary refinements to ensure the cutting is efficient and consistent.

Plow Beam: Foundation of the Structure

The beam serves as the essential backbone of the agricultural implement, providing stability and support during operation. Its robust design allows it to withstand the forces exerted while working the soil, ensuring efficient performance. This component plays a crucial role in maintaining the overall integrity and functionality of the machine.

Key Functions of the Beam

- Support: It holds various attachments in place, ensuring they operate effectively.

- Durability: Constructed from high-strength materials, it is designed to resist wear and tear.

- Alignment: The beam helps maintain the correct positioning of the implement for optimal results.

Maintenance Tips

- Regularly inspect for signs of wear or damage.

- Clean debris that may accumulate on or around the component.

- Ensure all connections are secure to maintain stability during operation.

Types of Plow Handles and Their Usability

Understanding the various types of handles used in agricultural implements is essential for enhancing operational efficiency. Each handle design serves distinct functionalities, impacting ease of use, comfort, and control. An informed choice can significantly influence the overall performance of the tool in various soil conditions.

Different configurations are available, catering to the needs of diverse farming practices. The following table outlines the primary types of handles, their characteristics, and their respective usability advantages:

| Handle Type | Characteristics | Usability Advantages |

|---|---|---|

| Straight Handle | Linear design, often made of metal or strong composite materials. | Offers direct control and is easy to maneuver; ideal for precise operations. |

| Curved Handle | Ergonomically shaped to fit the hand comfortably. | Reduces hand fatigue and improves grip, especially in extended use. |

| Telescoping Handle | Adjustable length to accommodate different user heights. | Versatile for various tasks and enhances comfort for multiple users. |

| Loop Handle | Formed as a circular grip for easy handling. | Provides a secure grip, allowing for increased leverage and control. |

Choosing the right handle type is crucial for optimizing performance and reducing physical strain during agricultural activities. Each design offers unique benefits, catering to specific operational needs.

The Hitch: Connecting to the Tractor

Establishing a secure connection between agricultural machinery and the vehicle is crucial for effective operation. This component serves as the essential link, allowing for the transfer of power and movement. Understanding its configuration and functionality is key to ensuring that the equipment performs optimally during various field tasks.

Types of Hitches

There are several configurations available for attaching equipment to tractors. The most common types include the three-point hitch, which allows for flexibility and ease of use, and the drawbar, which is more straightforward and robust. Each type has its own advantages, catering to different operational needs and preferences.

Installation and Adjustments

Proper installation of the hitch is vital for safety and performance. It is important to align the attachment accurately and make necessary adjustments to ensure stability. Regular inspections and maintenance are recommended to prevent wear and tear, keeping the connection secure throughout its usage.

Plow Frame and Its Durability Factors

The structure designed to support the essential components of tilling equipment plays a vital role in agricultural efficiency. Its integrity is crucial for ensuring optimal performance under various working conditions. Several factors influence the longevity and robustness of this framework, which can significantly impact overall functionality and operational costs.

Key aspects that determine the durability of the frame include material selection, design precision, and exposure to environmental elements. The choice of materials can enhance resistance to wear, while precise engineering contributes to stability during usage. Additionally, prolonged exposure to moisture, soil, and debris can affect the structural integrity over time.

| Factor | Description |

|---|---|

| Material Quality | High-grade materials resist wear and corrosion, extending lifespan. |

| Design | Efficient engineering ensures balance and reduces stress on components. |

| Maintenance | Regular inspections and timely repairs prevent deterioration. |

| Environmental Impact | Exposure to harsh conditions can lead to accelerated wear and tear. |

Understanding these factors allows users to make informed decisions regarding maintenance and upgrades, ultimately enhancing the performance and lifespan of tilling equipment.