Understanding the core elements and structure of any mechanical system is crucial for maintaining its optimal performance. By exploring the various components and their interactions, it becomes easier to identify potential issues, streamline repairs, and ensure the longevity of the machine. This guide provides a detailed look into the essential elements, helping to break down the assembly for easy reference.

Key mechanical elements play a vital role in the overall functionality of off-road vehicles. Each component, no matter how small, contributes to the system’s efficiency, ensuring a smooth and powerful operation. Whether it’s for routine maintenance or a more complex repair, knowing the proper alignment and positioning of these parts is crucial.

In this breakdown, we’ll explore the specific sections of the assembly, highlighting the importance of each individual part. This information will serve as a valuable resource for both beginners and experienced enthusiasts looking to deepen their understanding of the machine’s architecture. From core engine components to auxiliary systems, every piece is covered in detail to support effective upkeep.

Understanding the Honda Rincon 650 Parts Layout

The internal structure of this powerful off-road vehicle is a complex system where every component works together to ensure optimal performance. By familiarizing yourself with how the various sections are arranged, you can gain a better understanding of its functionality, helping with both maintenance and upgrades. A clear view of the arrangement enables smoother identification of key elements and their relationship to one another, making troubleshooting and repairs more efficient.

Key Structural Components

At the heart of the vehicle’s system are several core areas, including the engine assembly, suspension, and drivetrain. Each of these segments plays a critical role in ensuring both power delivery and ride stability. For example, the drivetrain is responsible for transferring power from the engine to the wheels, while the suspension ensures a smooth ride across uneven terrain. Understanding the positioning and function of these components is crucial for proper upkeep.

Linking Systems and Subsystems

Beyond the major elements, many smaller parts work in tandem to keep the vehicle running smoothly. This includes the electrical systems, fuel delivery, and braking mechanisms. Each subsystem depends on precise placement and integration with the main components. For anyone looking to maintain or

Key Components of the Honda Rincon 650

The vehicle’s design is built around a selection of vital elements that ensure its functionality, durability, and overall performance. Understanding these essential systems provides insight into how the machine operates efficiently across different terrains and conditions. Below is an overview of the primary components that contribute to the reliable operation and user experience.

-

Engine Block: The heart of the machine, responsible for converting fuel into mechanical power. It ensures smooth acceleration and torque distribution, making it capable of handling tough environments.

-

Transmission System: This component governs how power is delivered from the motor to the wheels, offering seamless shifting and consistent speed adjustments to match various riding conditions.

-

Suspension System: Essential for absorbing shocks and providing a comfortable ride, especially when navigating rough terrain. This system plays a crucial role in maintaining stability and rider comfort.

-

Brake Assembly: Comprising both front and rear braking systems, this setup allows for precise control and stopping power, critical for safety and maneuverability.

Exploring the Engine Structure of the Rincon 650

The internal mechanisms of this ATV’s power unit reflect a blend of precision engineering and durability. Its layout is designed to maximize both performance and reliability across various terrains. This section delves into the core components of the engine, offering a detailed examination of how they interact to provide a smooth, consistent ride. Understanding these elements is key to appreciating the overall capabilities and maintenance requirements of this machine.

Cylinder and Piston: At the heart of the system lies the cylinder, which houses the piston responsible for generating the force needed to propel the vehicle. The efficient movement within the cylinder ensures optimal compression and energy transfer.

Crankshaft and Connecting Rod: The crankshaft converts the linear motion of the piston into rotational energy, which powers the drivetrain. The connecting rod plays a vital role in transferring the force from the piston to the crankshaft, ensuring smooth transitions between strokes.

Valve Train: The valve train regulates the intake of fuel and air, as well as the expulsion of exhaust gases. It includes the camshaft, valves, and lifters, each precisely timed to maintain proper engine function.

Cooling System: Engine temperature management is crucial for maintaining performance and preventing overheating. This system uses a combination of liquid

How the Transmission System Operates

The transmission system plays a crucial role in converting the engine’s power into usable motion for the vehicle. It efficiently manages the power generated by the engine, ensuring that it is delivered to the wheels at the appropriate speed and torque. This mechanism allows smooth operation and optimal performance, adjusting to various driving conditions and user demands.

Understanding the basic process of how the system works involves exploring the interaction of multiple components that together control the distribution of power. Below is a breakdown of how the system functions:

- Power Input: The engine produces mechanical energy, which is transferred to the transmission as rotational force.

- Gear Selection: Depending on speed and load requirements, the system selects appropriate gear ratios to optimize the power output.

- Torque Conversion: The system uses a torque converter or clutch to smoothly transfer power, adjusting the force applied to the wheels based on the driving conditions.

- Power Output: Once processed, the system delivers the adjusted power to the drive shaft, which then transfers it to the wheels for motion.

The

Suspension and Steering Parts Overview

The functionality of any vehicle’s suspension and steering systems is crucial for ensuring stability, control, and comfort during operation. These components work together to absorb shocks from uneven surfaces and provide smooth handling, enabling the operator to navigate various terrains with precision. Understanding the key elements within these systems allows for better maintenance and optimization of performance.

Suspension Components: This system is designed to support the vehicle’s weight, minimize road vibrations, and improve traction. Key elements include shock absorbers, springs, and linkages. Shock absorbers dampen the force from bumps, while springs help distribute weight evenly. The suspension linkages, such as control arms and bushings, connect the frame to the wheels, ensuring stability.

Steering Mechanism: A precise steering setup is essential for maneuverability. This mechanism typically includes a steering column, tie rods, and steering knuckles. The steering column translates the operator’s input into wheel movement, while tie rods transmit this motion to the wheels. Steering knuckles allow the wheels to pivot, enabling smooth directional changes.

Regular inspection and maintenance of both suspension and steering systems help prolong the vehicle’s operational lifespan and ensure a safe and comfortable driving experience.

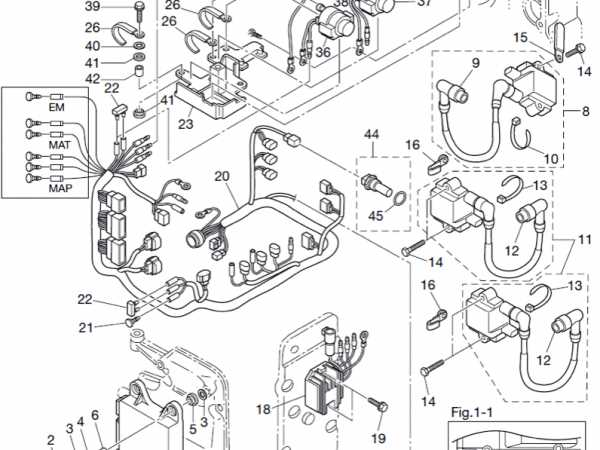

Honda Rincon 650 Electrical System Breakdown

The electrical system of an all-terrain vehicle plays a crucial role in ensuring the efficient functioning of various components. Understanding its intricacies allows for better maintenance and troubleshooting. This section will explore the key elements that make up the electrical framework, highlighting their interconnections and functionalities.

Key Components

The primary elements of the electrical network include the battery, starter motor, ignition system, and various sensors. The battery serves as the energy source, providing power to the starter motor for ignition. Once the engine is running, the alternator generates electricity to recharge the battery and power other electrical components, such as lights and gauges.

Wiring and Connectors

Proper wiring and connectors are essential for maintaining a reliable electrical system. High-quality wiring ensures minimal resistance and heat generation, while robust connectors facilitate secure connections between components. Regular inspection for wear, corrosion, or damage can prevent electrical failures and enhance overall performance.

Frame and Bodywork Parts Explained

The structural components and exterior coverings of a vehicle play a crucial role in its overall functionality and aesthetic appeal. Understanding these elements is essential for maintenance and modifications. Each piece is designed to contribute not only to the strength and stability of the machine but also to enhance its visual character and user experience.

Frame serves as the foundation of the vehicle, providing support and housing for various mechanical systems. It is typically constructed from robust materials to withstand stress and impacts while ensuring durability. A well-engineered frame is vital for the vehicle’s handling and stability, directly influencing performance on different terrains.

Bodywork, on the other hand, encompasses the outer panels and coverings that define the vehicle’s shape and appearance. This section is not only important for aesthetics but also contributes to aerodynamics, protecting internal components from environmental elements. Materials used in bodywork may vary from plastic to metal, each selected for its specific properties such as weight, strength, and resistance to corrosion.

Knowing the intricacies of the frame and bodywork elements allows enthusiasts and technicians to make informed decisions when undertaking repairs or upgrades. Proper maintenance of these components ensures longevity and optimal performance, making them a key focus for any vehicle owner.

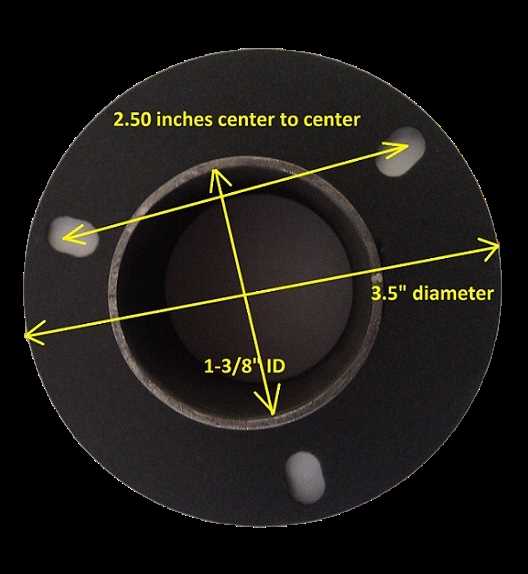

Fuel System and Carburetor Assembly Guide

The fuel delivery mechanism is a critical component of any engine, ensuring optimal performance and efficiency. This section provides a comprehensive overview of the assembly process for the fuel system and carburetor, highlighting essential steps and considerations for successful installation and maintenance.

Understanding the Components

Before diving into assembly, it’s vital to familiarize yourself with the key elements involved. The fuel system typically comprises the fuel tank, lines, filters, and the carburetor itself. Each part plays a significant role in delivering a consistent fuel flow to the engine, influencing overall functionality.

Carburetor Assembly Steps

1. Preparation: Begin by ensuring all necessary tools and components are on hand. Clean the workspace to prevent contamination during assembly.

2. Installation of the Carburetor: Secure the carburetor to the intake manifold, ensuring all gaskets are in place to prevent leaks. Tighten bolts in a crisscross pattern to achieve even pressure.

3. Connecting Fuel Lines: Attach the fuel lines to the carburetor and tank. Ensure that the connections are tight and free from kinks that could impede fuel flow.

4. Adjustments: Once assembled, make necessary adjustments to the carburetor settings, including idle speed and air-fuel mixture. This step is crucial for achieving optimal engine performance.

Maintenance Tips

Regular maintenance of the fuel system and carburetor is essential for longevity. Clean filters, inspect fuel lines for wear, and periodically check the carburetor for clogs or leaks. Implementing these practices will help maintain efficiency and performance.

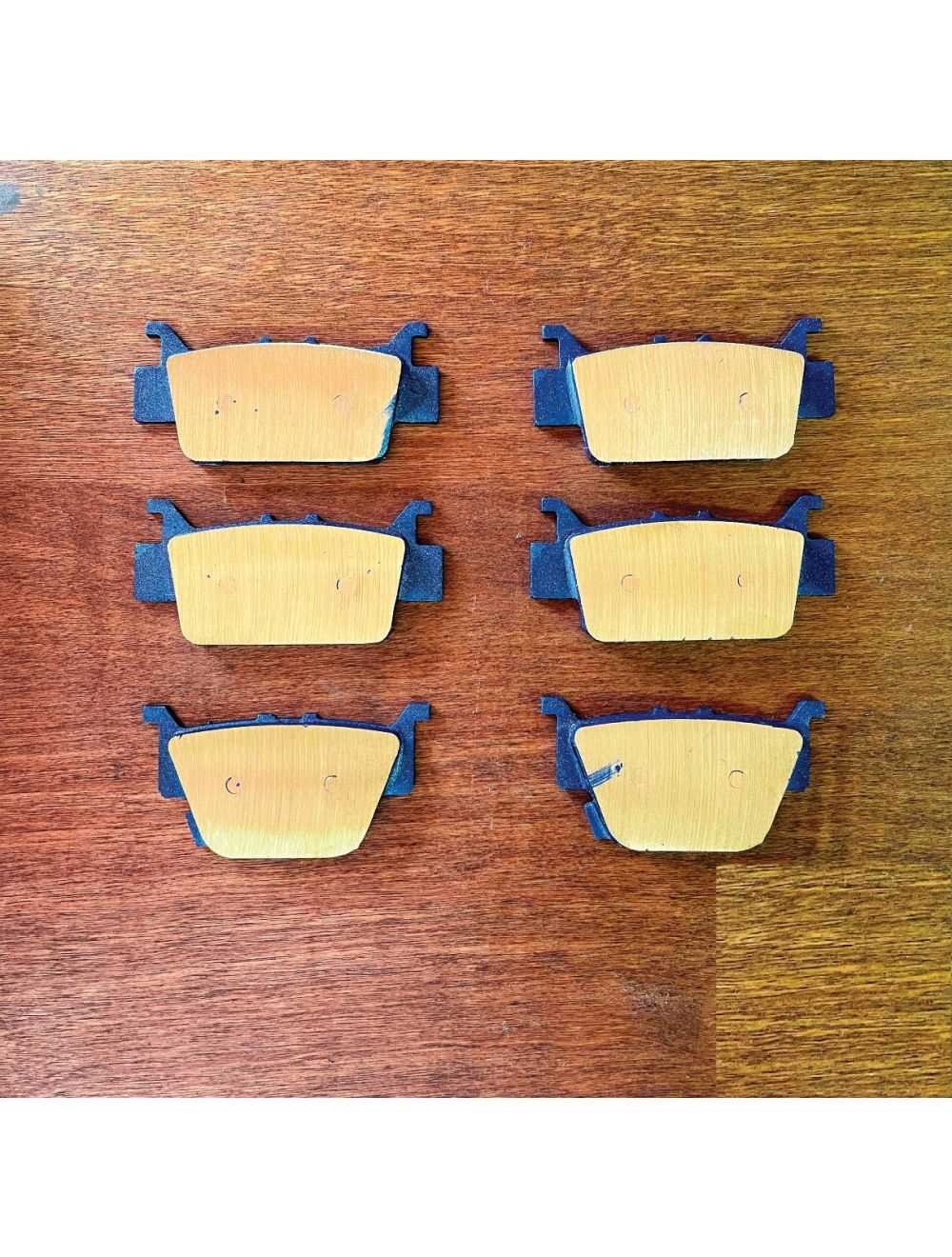

Braking Mechanism and Key Elements

The braking system is a crucial component of any vehicle, ensuring safety and control during operation. It consists of various elements working in harmony to provide reliable stopping power. Understanding the functionality and interconnection of these parts is essential for effective maintenance and performance enhancement.

Components of the Braking System

At the heart of the braking mechanism are the brake pads and rotors, which are designed to create friction and slow down the vehicle. When the brake pedal is engaged, hydraulic pressure is applied, causing the pads to clamp onto the rotors. This action generates the necessary force to reduce speed. Additionally, the calipers play a vital role by housing the brake pads and facilitating their movement.

Maintenance Considerations

Regular inspection of the braking components is critical for ensuring optimal performance. Worn-out pads can lead to decreased efficiency and may cause damage to the rotors. It’s advisable to check the fluid levels and ensure there are no leaks in the hydraulic lines. Furthermore, replacing components at the first sign of wear can prevent costly repairs and enhance overall safety.

Understanding the Exhaust System Layout

The exhaust system is a critical component of any engine, responsible for channeling combustion gases away from the power unit and reducing harmful emissions. Understanding its configuration is essential for effective maintenance and optimization of performance. This section delves into the various parts that comprise the exhaust arrangement and their respective functions.

Typically, the exhaust system includes several key elements:

- Exhaust Manifold: Collects gases from the engine’s cylinders and directs them into the exhaust piping.

- Catalytic Converter: Converts harmful pollutants into less harmful emissions through a chemical reaction.

- Muffler: Reduces noise produced by the escaping gases while allowing for an efficient flow.

- Exhaust Pipes: Channels the gases from the manifold to the tailpipe, ensuring smooth exit from the vehicle.

- Tailpipe: The final section of the system, releasing gases into the atmosphere.

Each component plays a vital role in maintaining the engine’s efficiency and ensuring compliance with environmental regulations. A well-maintained exhaust layout enhances performance, improves fuel efficiency, and minimizes noise levels.

Regular inspection of the exhaust configuration is advisable to identify signs of wear or damage, which can lead to increased emissions or engine performance issues. Proper understanding of each part’s location and function can significantly aid in troubleshooting and repair processes.

Troubleshooting Common Parts and Issues

When dealing with mechanical vehicles, understanding how to identify and resolve common issues can significantly enhance performance and longevity. This section focuses on typical components that often require attention and provides insights into effective troubleshooting methods.

Identifying Common Problems

Regular maintenance and keen observation can help spot potential issues before they escalate. Here are some prevalent concerns to look out for:

- Engine performance fluctuations

- Unusual noises during operation

- Difficulty starting the engine

- Overheating

- Fluid leaks

Effective Troubleshooting Steps

Addressing issues requires a systematic approach. Follow these steps to diagnose problems effectively:

- Inspect the owner’s manual for specific guidelines related to your vehicle model.

- Perform a visual check for signs of wear or damage in key components.

- Listen for abnormal sounds that could indicate underlying mechanical problems.

- Check fluid levels and inspect for leaks around hoses and connections.

- Conduct regular performance tests to identify any discrepancies in function.

By systematically addressing these common issues, you can maintain optimal functionality and enjoy a smoother ride.