For enthusiasts and professionals alike, a comprehensive understanding of marine engine components is essential for optimal performance and maintenance. An intricate system of various elements works in harmony to ensure the smooth operation of watercraft. Familiarity with these elements not only aids in troubleshooting but also enhances the overall boating experience.

The layout and functionality of these components can vary significantly depending on the manufacturer and model. A detailed exploration of these configurations reveals how each component interacts with others, contributing to the engine’s efficiency. Understanding these relationships is crucial for anyone involved in the upkeep or enhancement of marine vessels.

Whether you are replacing a worn-out element or looking to upgrade your engine, knowing the specific arrangement and roles of each piece is vital. Having access to clear visual representations can significantly simplify the process, ensuring that each installation or replacement is done correctly. This knowledge empowers users to make informed decisions, leading to improved performance and longevity of their watercraft.

Understanding the essential elements of marine propulsion systems is crucial for maintaining performance and ensuring safety on the water. This section will explore the various components that comprise these systems, providing insights into their functions and interconnections. Knowledge of these elements can significantly aid in troubleshooting and optimizing engine efficiency.

Essential Components Overview

- Engine Assembly

- Cooling System

- Fuel Delivery Mechanism

- Electrical System

- Gearbox and Drive Shaft

- Steering Mechanism

- Control Cables

- Exhaust System

- Propeller and Shaft

- Fuel Tank

- Mounting Bracket

- Safety Features

Functionality of Each Element

- Engine Assembly: The powerhouse that generates thrust.

- Cooling System: Prevents overheating by circulating water.

- Fuel Delivery Mechanism: Ensures the proper mixture of air and fuel.

- Electrical System: Powers ignition and electrical components.

- Gearbox and Drive Shaft: Transmits power to the propeller.

- Steering Mechanism: Controls the direction of the vessel.

- Control Cables: Connects controls to the engine.

- Exhaust System: Manages the release of exhaust gases.

- Propeller and Shaft: Generates thrust to propel the vessel.

- Fuel Tank: Stores fuel for the engine.

- Mounting Bracket: Secures the engine to the transom.

- Safety Features: Ensures operator safety during use.

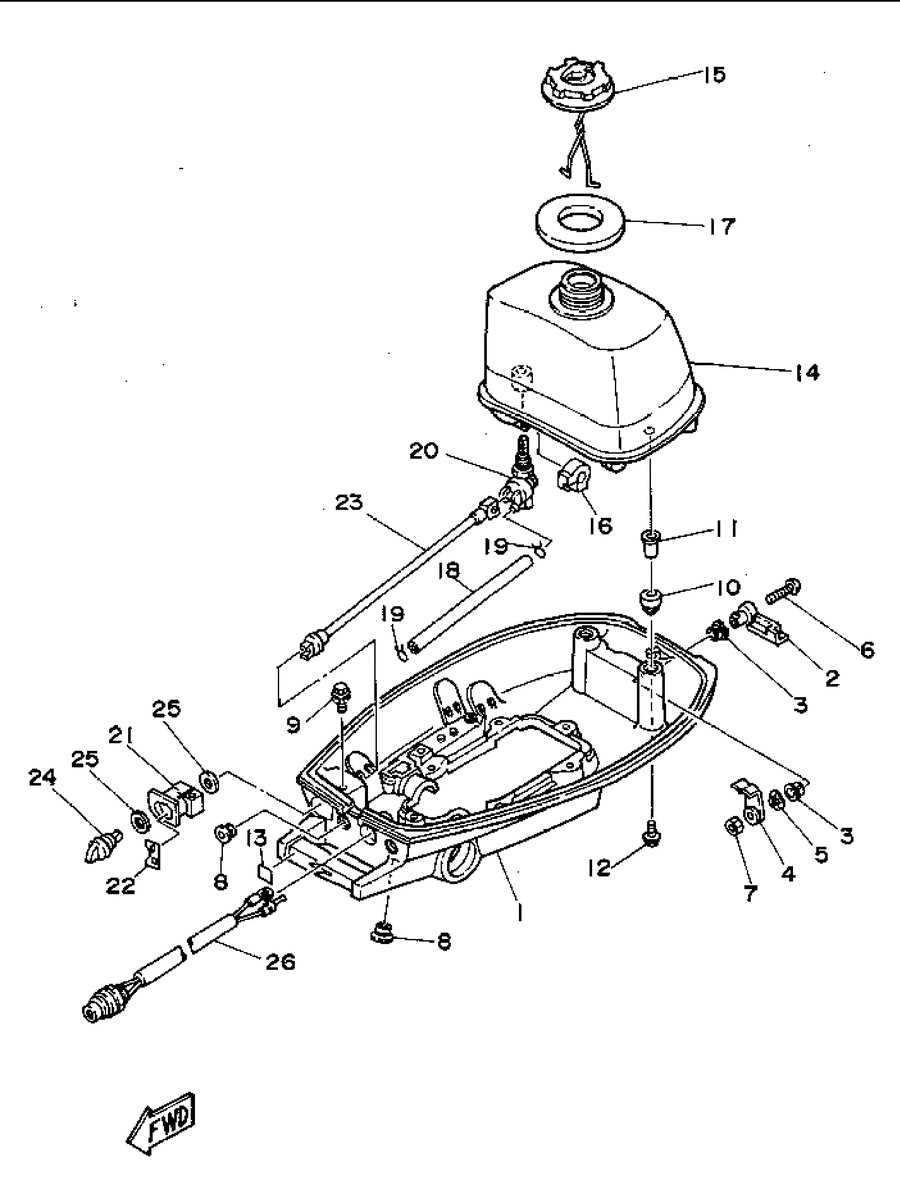

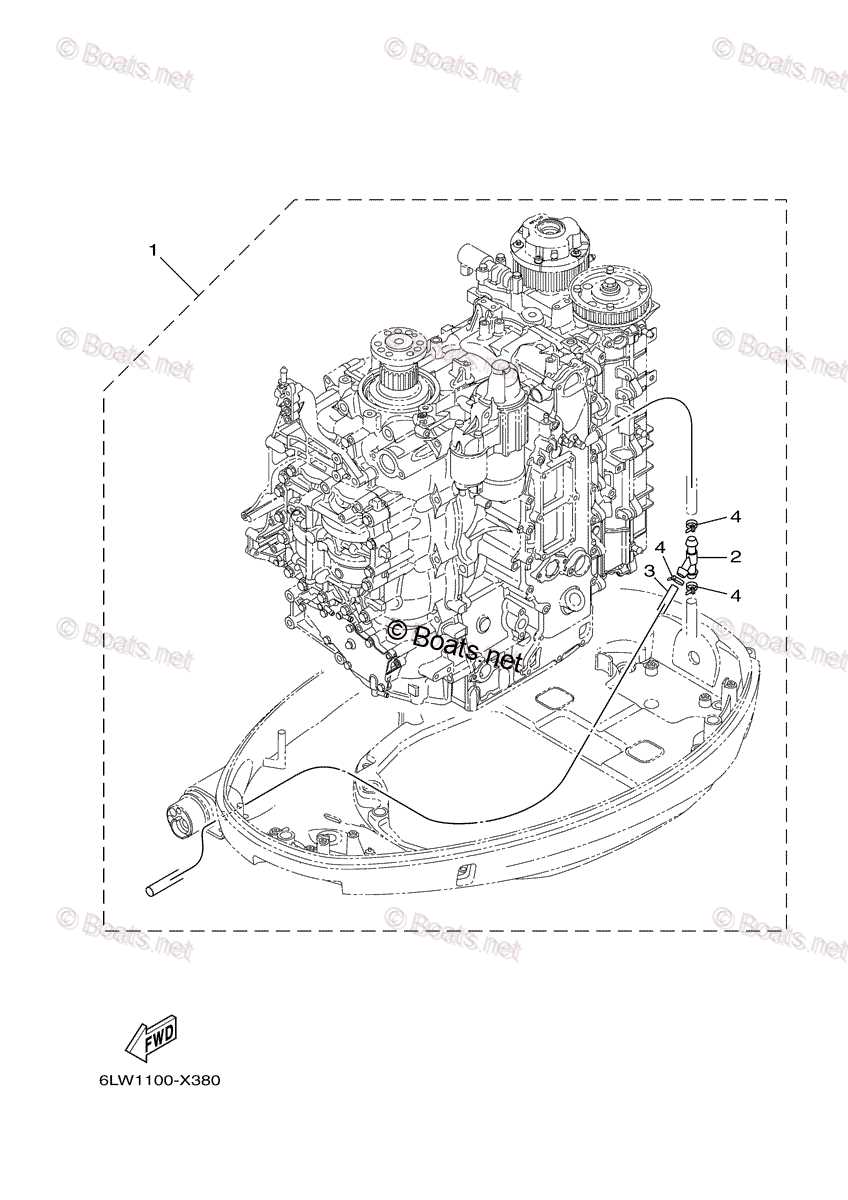

Importance of Parts Diagrams

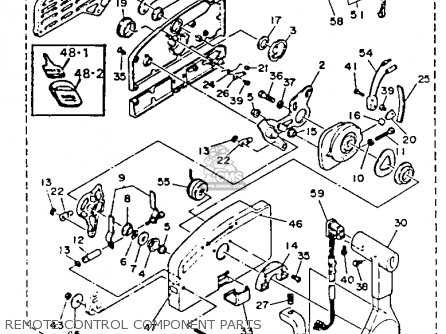

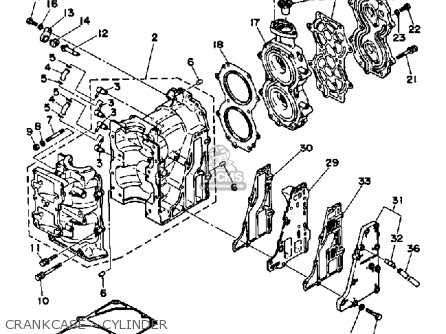

Understanding the layout and organization of components within a mechanical assembly is essential for effective maintenance and repair. Visual representations play a crucial role in simplifying complex structures, allowing users to identify individual elements and their functions. This clarity enhances troubleshooting processes and ensures a comprehensive understanding of the system.

These visual aids are particularly beneficial for various reasons:

- Enhanced Clarity: Illustrations provide a clear depiction of components, reducing confusion during repairs.

- Streamlined Identification: Users can quickly locate specific elements, facilitating faster assembly and disassembly.

- Improved Efficiency: With a visual reference, maintenance tasks can be performed more effectively, minimizing downtime.

- Comprehensive Understanding: Diagrams offer insights into how components interact, promoting better decision-making during repairs.

In summary, these visual resources are invaluable tools for anyone involved in the maintenance and repair of mechanical systems, enabling improved understanding and efficiency in their work.

Key Elements of Yamaha Outboards

The performance and reliability of marine propulsion systems rely heavily on several crucial components. Understanding these fundamental elements enhances the overall experience on the water and ensures optimal functionality. Each section plays a vital role in the seamless operation of these engines, making it essential for users and technicians to familiarize themselves with their significance.

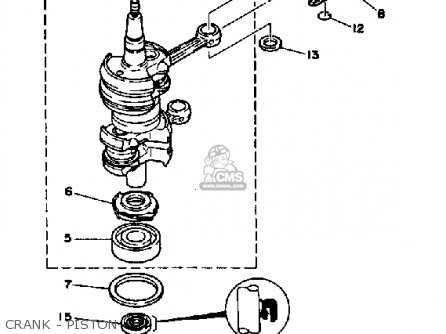

Power Units

At the heart of any marine engine lies the power unit, responsible for generating thrust. This component translates fuel into mechanical energy, enabling the vessel to navigate through water. Variations in power units can affect acceleration and speed, making it essential to select the appropriate model for specific boating needs.

Control Mechanisms

Effective navigation relies on intuitive control mechanisms that allow the operator to manage speed and direction effortlessly. These systems encompass throttle controls and steering components, ensuring precise maneuverability. Proper maintenance of these mechanisms is crucial for safe and enjoyable boating experiences.

Reading Diagrams Effectively

Understanding technical illustrations is crucial for anyone involved in maintenance and repair. These visual aids provide essential information that helps in identifying components and their interconnections, facilitating a smoother workflow and reducing errors.

To maximize the effectiveness of these illustrations, consider the following strategies:

- Familiarize Yourself with Symbols: Each visual representation uses specific icons and symbols. Understanding these can significantly enhance comprehension.

- Follow a Systematic Approach: Begin by identifying the primary components, then progressively work through the connections and functionalities.

- Use Color Codes: Many illustrations utilize color coding to differentiate between various types of elements. Pay attention to these details for clarity.

- Refer to Accompanying Documentation: Often, technical visuals are paired with manuals or guides that provide additional context and explanations.

By adopting these techniques, individuals can effectively interpret complex illustrations, leading to improved efficiency and accuracy in their tasks.

Common Parts in Outboard Motors

The functionality and performance of marine engines greatly depend on their individual components. Understanding these essential elements can enhance maintenance and operational efficiency, ensuring a smooth experience on the water.

Powerhead: This is the core of the engine, housing the combustion chamber and associated mechanisms. It generates the necessary thrust for propulsion.

Gearcase: The gearcase plays a crucial role in transmitting power from the engine to the propeller. It contains the gears that facilitate smooth movement and direction control.

Propeller: This rotating device is vital for movement, converting the engine’s power into thrust. The design and size of the propeller significantly impact performance and efficiency.

Fuel System: This assembly manages the delivery of fuel to the combustion chamber. It often includes components like fuel pumps and filters, ensuring optimal engine operation.

Electrical System: This encompasses the ignition and charging systems, providing power for starting the engine and operating essential electronics. Proper functionality is critical for reliable performance.

Cooling System: This system prevents overheating by circulating coolant, ensuring the engine maintains a safe operating temperature. It includes components such as water pumps and thermostats.

Familiarity with these components is essential for anyone looking to enhance their understanding of marine engines and ensure they operate at peak efficiency.

How to Identify Components

Identifying various elements of a marine propulsion system can be crucial for effective maintenance and repair. Understanding the layout and function of each component helps ensure that your vessel operates smoothly and efficiently.

To effectively recognize different elements, follow these steps:

- Refer to the Manufacturer’s Manual: Start by consulting the official documentation provided by the manufacturer. This resource typically includes detailed descriptions and illustrations of each component.

- Use Online Resources: Explore reputable websites that offer information and visuals related to marine systems. Online forums and communities can also be valuable for gaining insights from experienced users.

- Visual Inspection: Conduct a thorough examination of the components. Familiarize yourself with their shapes, sizes, and connections to distinguish between similar elements.

- Consult a Specialist: If you encounter difficulties identifying certain elements, seek advice from a qualified technician or expert in marine technology.

By employing these strategies, you can enhance your understanding of the various components and ensure proper functioning of your vessel.

Maintenance Tips for Longevity

To ensure the enduring performance of your marine engine, regular upkeep is essential. Implementing effective maintenance practices can significantly enhance the lifespan of the equipment while optimizing its functionality. Following a structured maintenance schedule will help identify potential issues before they escalate into costly repairs.

Regular Inspection

Consistent examination of key components is vital for early detection of wear and tear. Look for signs of corrosion, leaks, or abnormal wear. Regularly checking the following parts can prevent unexpected breakdowns:

| Component | Recommended Frequency |

|---|---|

| Fuel System | Every 100 hours or annually |

| Cooling System | Every 50 hours or bi-annually |

| Electrical Connections | Monthly |

| Propeller | Every 200 hours or annually |

Proper Storage

When not in use, proper storage is crucial for prolonging the life of your equipment. Ensure that the environment is dry and protected from extreme temperatures. Utilize protective covers to safeguard against dust and moisture, which can lead to deterioration over time.

Locating Replacement Parts

Finding suitable components for marine engines can be a daunting task. Understanding where to search and how to navigate various resources will streamline the process, ensuring that your vessel remains in optimal condition. Whether you are seeking original or compatible alternatives, the right approach is essential for effective repairs.

Online Resources

The internet is a treasure trove of information and options. Many specialized websites offer detailed catalogs and allow users to filter by model and specifications. Utilizing these platforms can save time and effort, providing instant access to a wide array of components.

Local Dealers and Service Centers

Visiting authorized dealers or local service centers can be advantageous. Experts at these locations can provide personalized assistance, often having in-depth knowledge of specific models. Moreover, they can help identify compatible alternatives that may not be readily available online.

Visual Guide to Yamaha Models

This section aims to provide an insightful overview of various marine craft models, highlighting their unique features and specifications. By understanding the distinctions among these vessels, enthusiasts can make informed decisions regarding maintenance and upgrades.

Here are some popular models that stand out in the marine industry:

- Model A

- Type: High-performance vessel

- Key Features: Agile handling, efficient fuel consumption

- Model B

- Type: Family-friendly boat

- Key Features: Spacious interior, comfortable seating

- Model C

- Type: Fishing craft

- Key Features: Ample storage, durable construction

Each model offers distinct advantages, making them suitable for various activities on the water. Whether you are cruising, fishing, or simply enjoying time with family, selecting the right craft enhances the experience.

Compatibility Across Different Models

Understanding the interchangeability of components is crucial for effective maintenance and repair. Various models exhibit similarities in design and functionality, allowing certain elements to be utilized across different units. This aspect not only enhances the versatility of replacements but also aids in optimizing performance and efficiency.

Key Factors to Consider:

- Model Year: Changes in design often occur over the years, impacting compatibility.

- Engine Type: Similar engine configurations can facilitate the use of specific elements between different models.

- Manufacturer Updates: Regular updates from the manufacturer may improve or restrict compatibility among various units.

When selecting components for replacement or repair, it is essential to verify their suitability for the specific model in question. This careful consideration ensures optimal functionality and longevity, preventing potential issues that may arise from mismatched elements.

DIY Repairs Using Diagrams

Engaging in do-it-yourself repairs can be a rewarding experience, especially when guided by clear visual aids. These illustrations serve as invaluable resources, simplifying complex tasks and providing a roadmap for maintenance. By carefully studying these visuals, individuals can enhance their understanding of their equipment, making it easier to identify components and troubleshoot issues.

When embarking on repair projects, having a detailed visual reference allows for a systematic approach. This method not only improves efficiency but also minimizes the likelihood of errors. Moreover, it empowers enthusiasts to take control of their maintenance, fostering a sense of accomplishment and confidence in their skills. Whether addressing minor adjustments or significant repairs, utilizing these resources ensures a more streamlined and successful process.

Resources for Parts Information

Accessing reliable resources for obtaining information about components is essential for efficient maintenance and repair. Various platforms and materials can assist in identifying the necessary elements for effective servicing. Here are some recommended avenues to explore:

- Manufacturer Websites: Official websites often provide detailed catalogs and specifications, ensuring the authenticity of information.

- Service Manuals: Comprehensive manuals offer insights into assembly, disassembly, and troubleshooting, enhancing understanding of the machinery.

- Online Forums: Engaging with communities can yield valuable experiences and advice from fellow enthusiasts and professionals.

- Specialty Retailers: Authorized dealers can supply specific components and provide expert guidance on selections and compatibility.

- Video Tutorials: Visual aids available on platforms like YouTube can demonstrate installation processes and maintenance techniques.

Utilizing these resources can significantly enhance knowledge and confidence when addressing component-related tasks.

Frequently Asked Questions

This section addresses common inquiries related to the assembly and maintenance of marine engines. Here, you will find useful information to assist you in understanding various components and their functionalities.

General Questions

- What resources are available for troubleshooting engine issues?

- How can I identify the correct components for my vessel?

- Where can I find installation instructions for different elements?

Maintenance and Care

- What routine maintenance should I perform on my engine?

- How often should I inspect essential components?

- Are there any recommended cleaning procedures for keeping parts in good condition?